Machining method for forming centripetal notches in titanium alloy and glass fiber reinforced plastic composite conical part

A processing method and glass fiber reinforced plastic technology, applied in the field of machining, can solve the problems of slag loss, design index influence, poor rigidity, etc., and achieve the effect of small deformation of finished products, reasonable and reliable process method, and small deformation of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

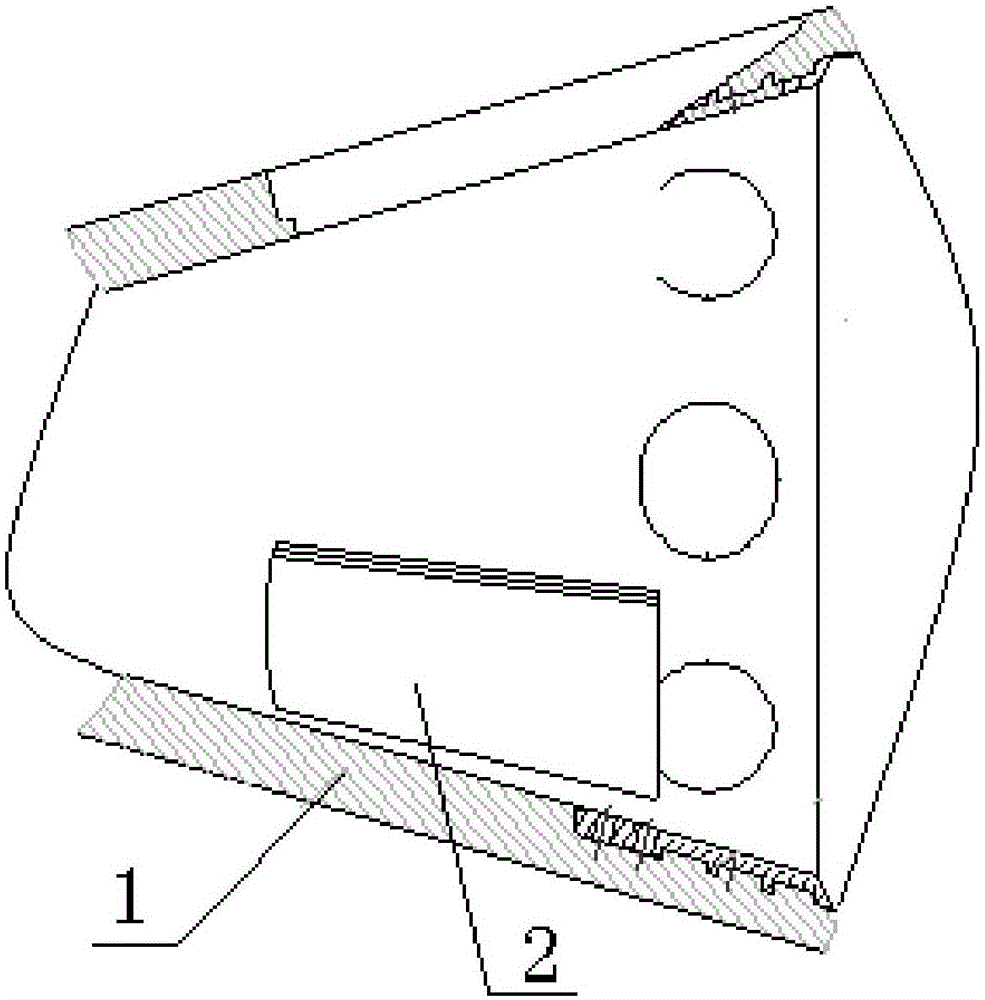

[0062] Milling process design: fillet milling, rough milling above the opening, rough milling below the opening, semi-finishing the entire opening 2, semi-finishing the slope, finishing the entire contour, and finishing the fillet; specifically include:

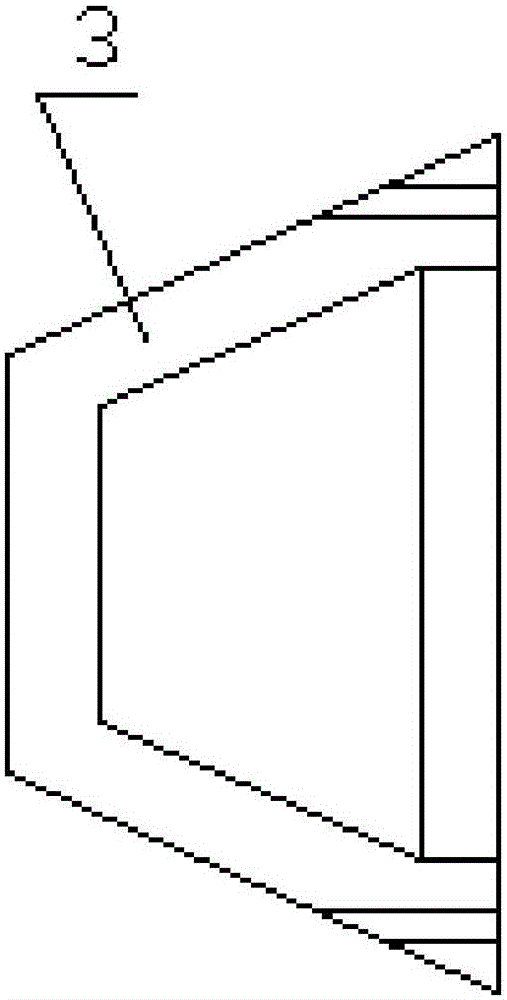

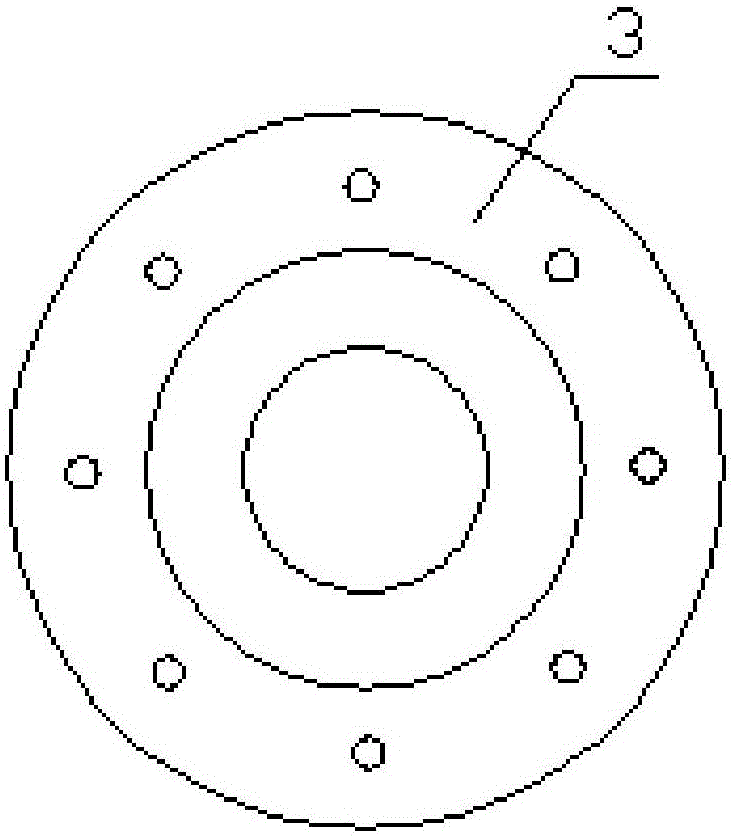

[0063] S1: Fix the milling clamp on the workbench, the conical part 1 fits the inner hole through the milling clamp, attach the flat milling clamp to the bottom surface, place the milling clamp pressure plate on the small end of the conical part 1, and align the outer circle of the large end. Within 0.1.

[0064] S2: Process the four rounded corners by milling holes. This process uses a YG8 carbide end mill with a specification of Ф10. The speed of the spindle is controlled at 600r / min, and the feed is 500mm / r.

[0065] S3: Align the quadrant line, rough mill the opening of the conical part 1; when processing the opening 2, divide the opening 2 into two parts, the upper end of the opening is made of FRP material, and mainly c...

Embodiment 2

[0071] Milling process design: fillet milling, rough milling above the opening, rough milling below the opening, semi-finishing the entire opening 2, semi-finishing the slope, finishing the entire contour, and finishing the fillet; specifically include:

[0072] S1: Fix the milling clamp on the workbench, the conical part 1 fits the inner hole through the milling clamp, attach the flat milling clamp to the bottom surface, place the milling clamp pressure plate on the small end of the conical part, and align the outer circle of the large end at 0.1 within.

[0073] S2: Process the four rounded corners by milling holes. This process uses a YG8 carbide end mill with a specification of Ф10. The spindle speed is controlled at 700r / min and the feed is 550mm / r.

[0074] S3: Align the quadrant line, rough mill the opening of the conical part 1; when processing the opening 2, divide the opening 2 into two parts, the upper end of the opening is made of FRP material, and mainly cut off t...

Embodiment 3

[0079] Milling process design: fillet milling, rough milling above the opening, rough milling below the opening, semi-finishing the entire opening 2, semi-finishing the slope, finishing the entire contour, and finishing the fillet; specifically include:

[0080] S1: Fix the milling clamp on the workbench, the conical part 1 fits the inner hole through the milling clamp, attach the flat milling clamp to the bottom surface, place the milling clamp pressure plate on the small end of the conical part, and align the outer circle of the large end at 0.1 within.

[0081] S2: Process the four rounded corners by milling holes. This process uses a YG8 carbide end mill with a specification of Ф10. The spindle speed is controlled at 800r / min and the feed is 600mm / r.

[0082] S3: Align the quadrant line, rough mill the opening 2 of the conical part 1; when processing the opening 2, divide the opening 2 into two parts, the upper end of the opening is made of FRP material, and mainly cut the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com