Multiple row sectional drive combined type domestic garbage incinerator

A domestic waste incineration and segmented drive technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of easy agglomeration, grate failure, high water content of domestic waste, etc., to prevent blockage of blowing pipes, Effect of reducing inflow to the grate and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

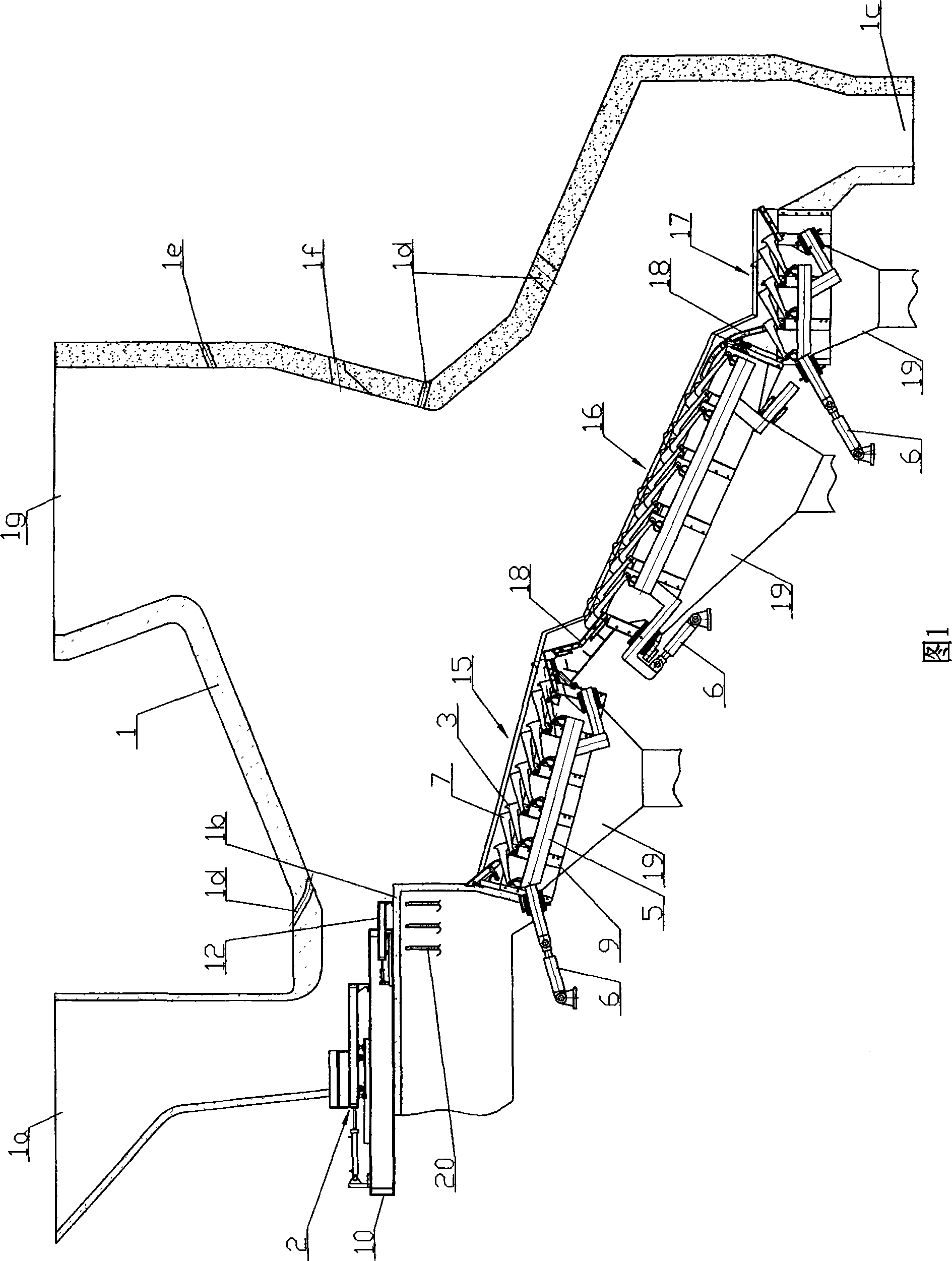

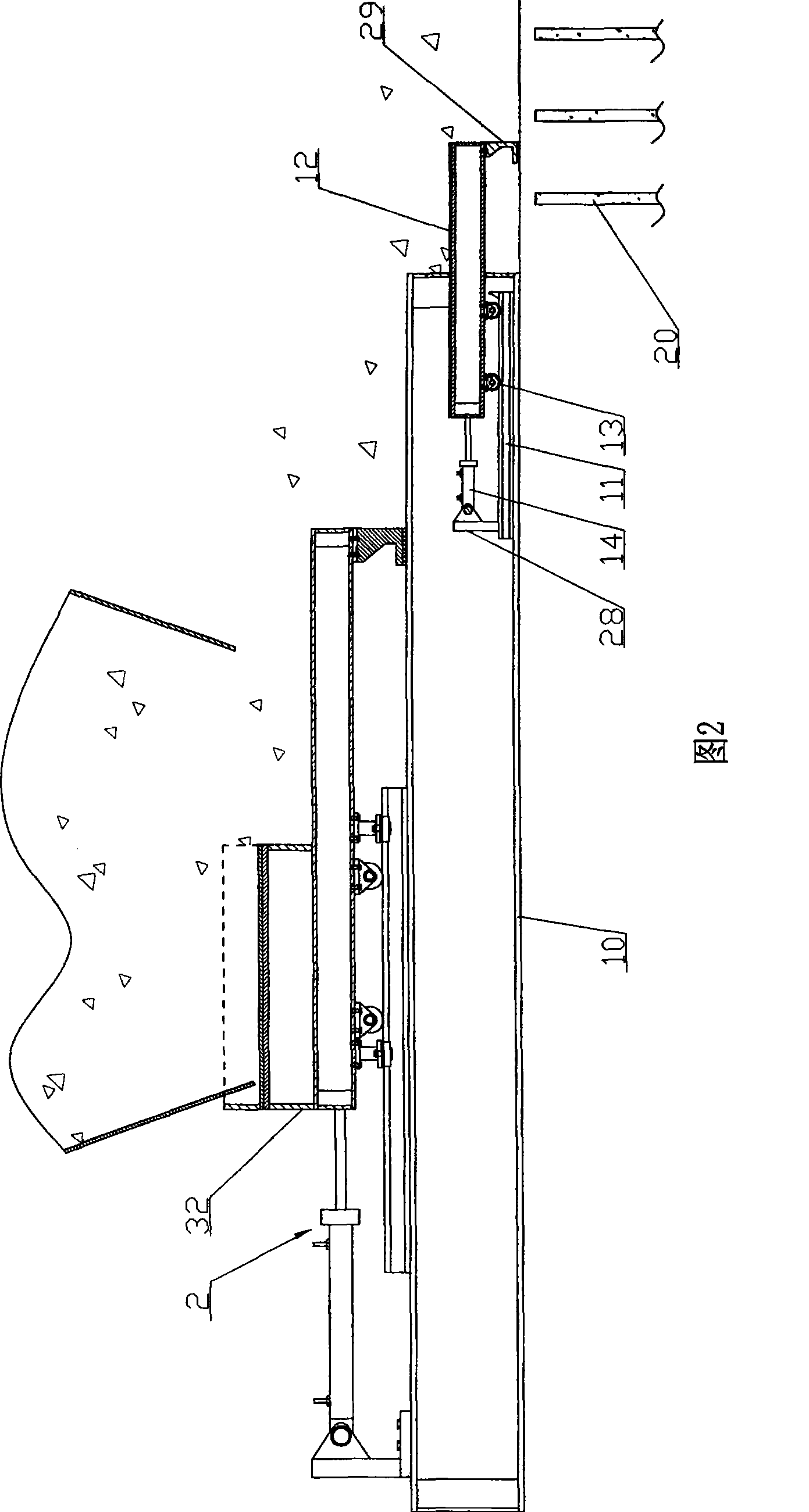

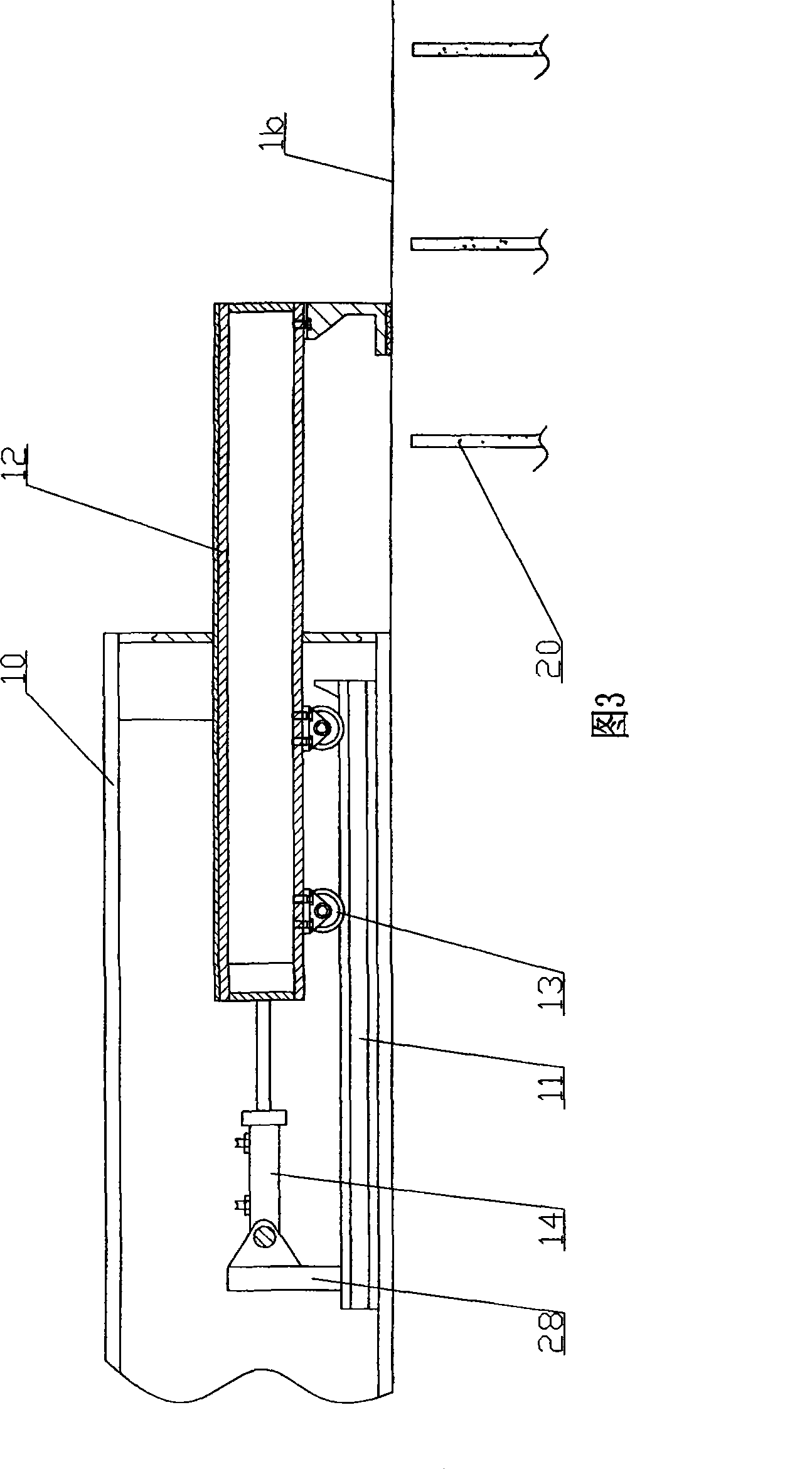

[0041] As shown in Figure 1, the front and rear ends of the top of the furnace body 1 have a feed inlet 1a and an outlet 1g, and the bottom of the rear end has a slag outlet 1c, and a flue gas hole is opened on the upper part of the rear wall of the furnace body 1 near the outlet 1g. 1e, the inner cavity of the furnace body 1 communicates with the flue gas detection device installed outside the furnace body 1 through the flue gas through hole 1e; a secondary air hole 1f is set under the flue gas through hole 1e, and is installed outside the furnace body 1 The secondary air device communicates with the inner cavity of the furnace body 1 through this hole; a preheating ventilation hole 1d is set up between the feed inlet 1a and the outlet 1g, and on the wall of the furnace body below the secondary air hole 1f, and is installed in the furnace body. The preheatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com