Preparation technology of radiation protection material and radiation protection material

A technology of radiation protection and preparation technology, which is applied in the field of radiation protection materials, can solve problems such as shrinkage cavities and air bubbles, and achieve the effect of small density difference and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The invention provides a preparation process of a radiation protection material, comprising the following steps:

[0014] (1) Provide raw materials for preparing radiation protection materials;

[0015] (2) mixing and degassing the raw materials of the radiation protection material to obtain a mixture;

[0016] (3) Pouring the mixture;

[0017] It also includes curing treatment after pouring. The curing treatment makes the mixture gradually solidify from bottom to top by making the temperature of the upper part of the poured mixture lower than the temperature of the lower part of the mixture.

[0018] Preferably, in the curing treatment, the upper part of the poured mixed material is cooled down and / or the lower part of the mixed material is heated, so that the mixed material is gradually solidified from bottom to top.

[0019] Preferably, a cooling zone is set outside the top of the pouring chamber to cool the upper part of the poured mixture. The cooling zone can be...

Embodiment 1

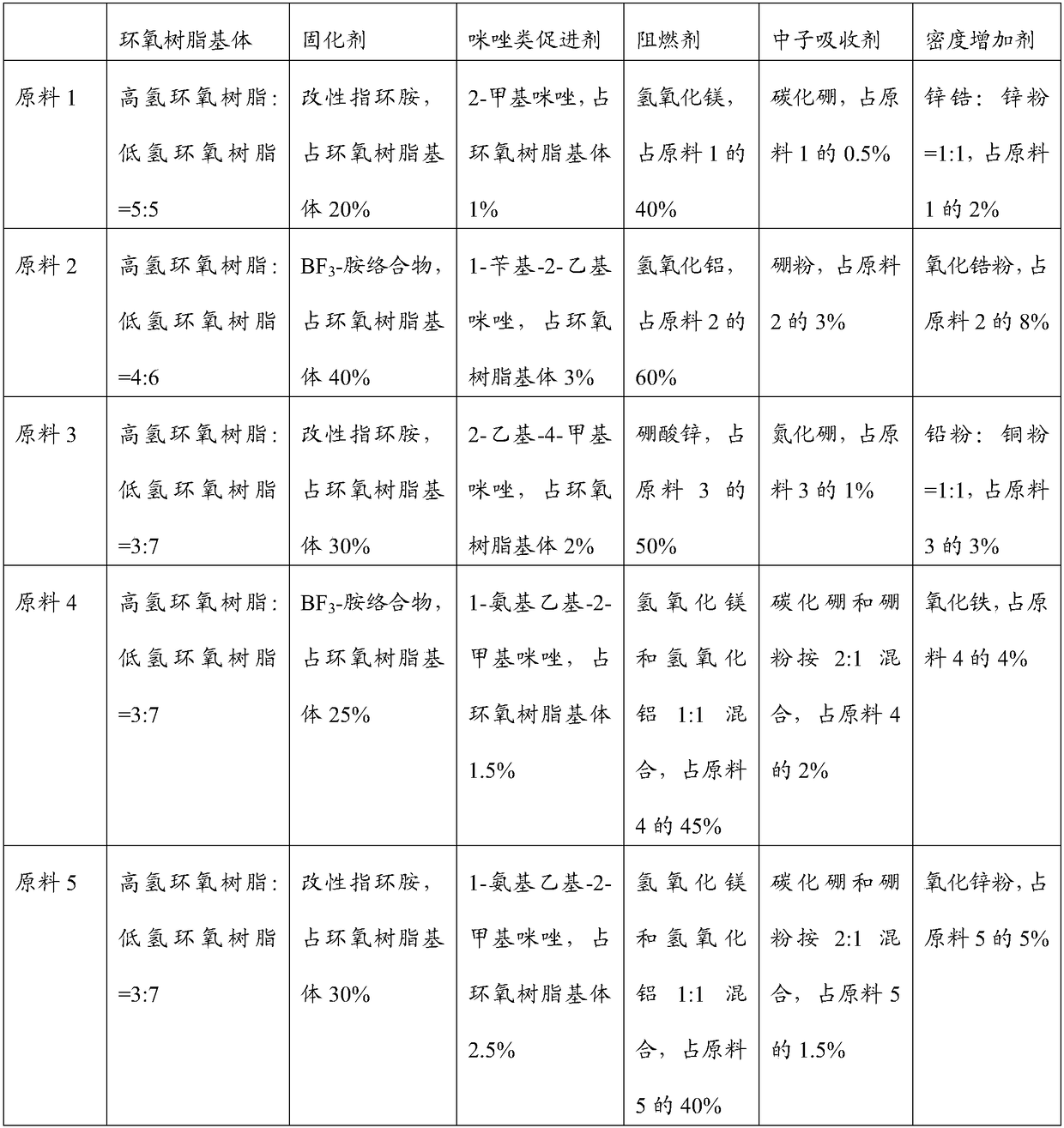

[0031] (1) Provide raw materials for preparing radiation protection materials according to raw material 1 from the table of raw material components and weight content of radiation protection materials;

[0032] (2) Mixing and degassing the raw materials of radiation protection materials:

[0033] 1. Raw material mixing

[0034] 1.1 The first mixing treatment and degassing treatment

[0035] Put the epoxy resin matrix in the first premixing tank for heating and stirring, put the curing agent and imidazole accelerator in the second premixing tank for heating and stirring, the stirring temperature for heating and stirring is 60°C, the stirring rate is 20r / min, Stirring time 1h, stirring until the epoxy resin matrix, curing agent and imidazole accelerator reach 60°C;

[0036] Divide the flame retardant, neutron absorber and metal density increaser into two parts according to the weight ratio of epoxy resin matrix / curing agent and imidazole accelerator, and add them to the first ...

Embodiment 2

[0045] (1) Provide raw materials for preparing radiation protection materials according to raw material 2 from the table of raw material components and weight content of radiation protection materials;

[0046] (2) Mixing and degassing the raw materials of radiation protection materials:

[0047] 1. Raw material mixing

[0048] 1.1 The first mixing treatment and degassing treatment

[0049] Put the epoxy resin matrix in the first premixing tank for heating and stirring, put the curing agent and imidazole accelerator in the second premixing tank for heating and stirring, the stirring temperature for heating and stirring is 80°C, the stirring rate is 30r / min, Stirring time 2h, stirring until the epoxy resin matrix, curing agent and imidazole accelerator reach 80°C;

[0050] Divide the flame retardant, neutron absorber and metal density increaser into two parts according to the weight ratio of epoxy resin matrix / curing agent and imidazole accelerator, and add them to the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com