Heat pump drying system for drying clothes by using roller and control method of heat pump drying system

A technology of heat pump drying and heat pump system, which is applied to household clothes dryers, clothes dryer equipment, applications, etc. It can solve problems such as affecting the service life of compressors, prolonging drying time, and increasing external heat dissipation, so as to improve condensation The effect of shortening the drying time and the effect of the best heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

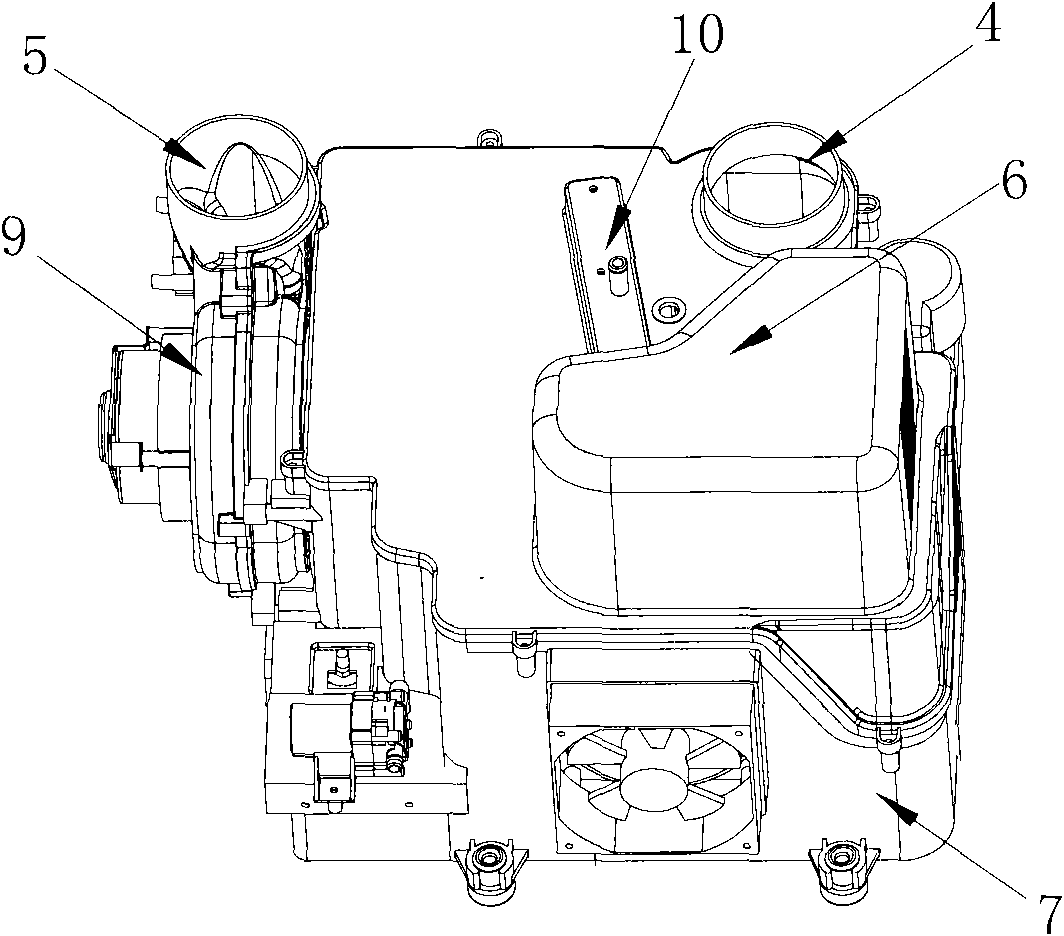

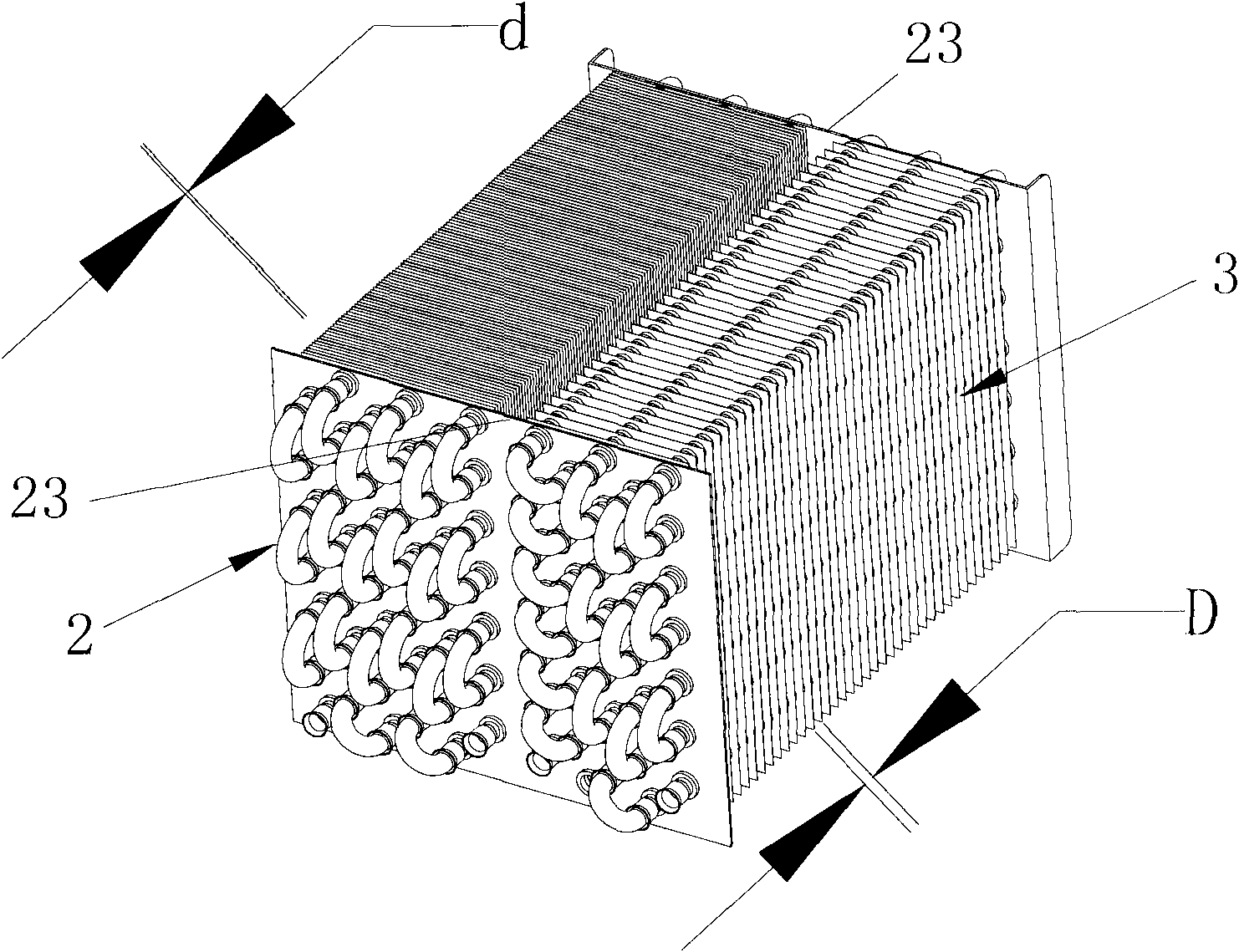

[0037] Such as Figure 1 to Figure 5As shown, a heat pump drying system for tumble drying according to the present invention is used for a tumble washer-dryer, or is used for a tumble dryer, including a heat pump system for drying clothes, respectively and The air inlet and outlet connected to the drum where the clothes are placed. The heat pump system includes a compressor 1, a condenser 2, a throttling device and an evaporator 3, and the compressor 1, condenser 2, throttling The flow device, the evaporator 3 and then the compressor 1 are connected to form a circulation system. The heat pump system is integrated with the air inlet 4 and the air outlet 5 through the upper cover plate 6 and the lower cover plate 7. The air inlet 4 and the air outlet 5 are provided with a wind deflector 8, an evaporator 3, a condenser 2 and an air blower 9 in order to form an air path, and the compressor 1 is sealed in a closed space by an upper cover plate 6 and a lower cover plate 7, so The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com