Method for preparing silicone acrylic emulsion with high solid content and high silicon content

A high-solid-content, silicone-acrylic emulsion technology, applied in coatings, etc., can solve the problems of high dosage of protective colloid and hydrolysis inhibitor, affecting the hydrophobicity of silicone monomers, increasing production and transportation costs, etc., to achieve good results Emulsifying effect, low price, good emulsion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

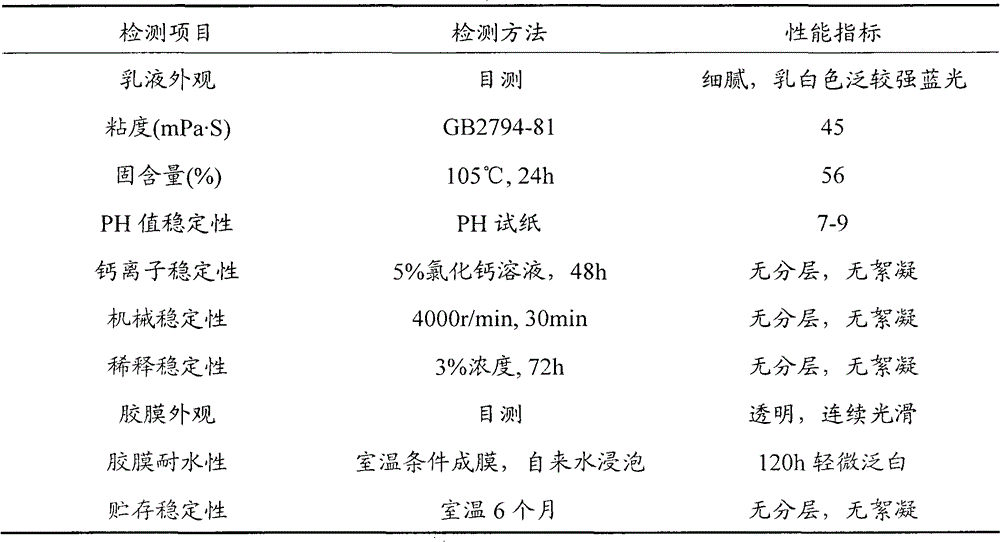

Examples

Embodiment 1

[0030] 1) Preparation of vinyl polysiloxane emulsion: first add 4g dodecylbenzenesulfonic acid, 2g sodium dodecylbenzenesulfonate, 2g NP-40, 60g deionized water into the reaction kettle, stir Fully dissolve, then raise the temperature to 80°C, then slowly add 30g of octamethylcyclotetrasiloxane and 10g of tetramethyltetravinylcyclotetrasiloxane mixed organosilicon monomers into the reaction kettle dropwise within 3 hours, and keep warm for the reaction 3h, naturally cooled to room temperature, and finally neutralized to neutral with 10% sodium carbonate aqueous solution to obtain vinyl polysiloxane emulsion.

[0031] The solid content of the obtained emulsion is greater than 35%, the molecular weight is 2000-5000, and the storage stability is greater than 3 months.

[0032] 2) Preparation of silicone acrylic copolymer emulsion:

[0033] Add 35g of vinyl polysiloxane emulsion, 42.5g of butyl acrylate, 42.5g of methyl methacrylate, 3g of acrylic acid and 20g of deionized water ...

Embodiment 2

[0036] 1) Preparation of vinyl polysiloxane emulsion: first add 4g dodecylbenzenesulfonic acid, 2g sodium dodecylbenzenesulfonate, 2g NP-40, 60g deionized water into the reaction kettle, stir Fully dissolve, then raise the temperature to 80°C, then slowly add 25g of octamethylcyclotetrasiloxane and 15g of tetramethyltetravinylcyclotetrasiloxane mixed organosilicon monomers into the reaction kettle dropwise within 3 hours, and keep warm for the reaction 3h, naturally cooled to room temperature, and finally neutralized to neutral with 10% sodium carbonate aqueous solution to obtain vinyl polysiloxane emulsion.

[0037] The solid content of the obtained emulsion is greater than 35%, the molecular weight is 2000-5000, and the storage stability is greater than 3 months.

[0038] 2) Preparation of silicone acrylic copolymer emulsion:

[0039] Add 30g of vinyl polysiloxane emulsion, 45.5g of butyl acrylate, 45.5g of methyl methacrylate, 3g of acrylic acid and 25g of deionized water ...

Embodiment 3

[0042] 1) Preparation of vinyl polysiloxane emulsion: first add 4g dodecylbenzenesulfonic acid, 2g sodium dodecylbenzenesulfonate, 2g NP-40, 60g deionized water into the reaction kettle, stir Fully dissolve, then raise the temperature to 80°C, then slowly add 35g of octamethylcyclotetrasiloxane and 5g of tetramethyltetravinylcyclotetrasiloxane mixed organosilicon monomers into the reaction kettle dropwise within 3 hours, and keep warm for the reaction 3h, naturally cooled to room temperature, and finally neutralized to neutral with 10% sodium carbonate aqueous solution to obtain vinyl polysiloxane emulsion.

[0043] The solid content of the obtained emulsion is greater than 35%, the molecular weight is 2000-5000, and the storage stability is greater than 3 months.

[0044] 2) Preparation of silicone acrylic copolymer emulsion:

[0045] Add 40g of vinyl polysiloxane emulsion, 39.5g of butyl acrylate, 39.5g of methyl methacrylate, 3g of acrylic acid and 20g of deionized water i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com