Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Increase deformation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

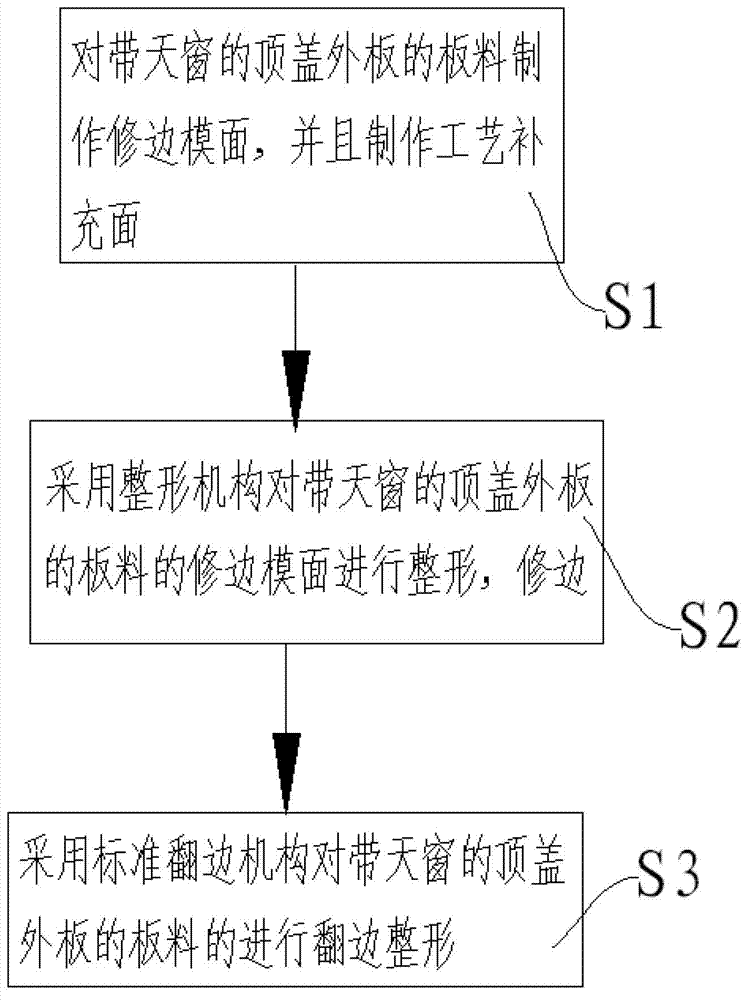

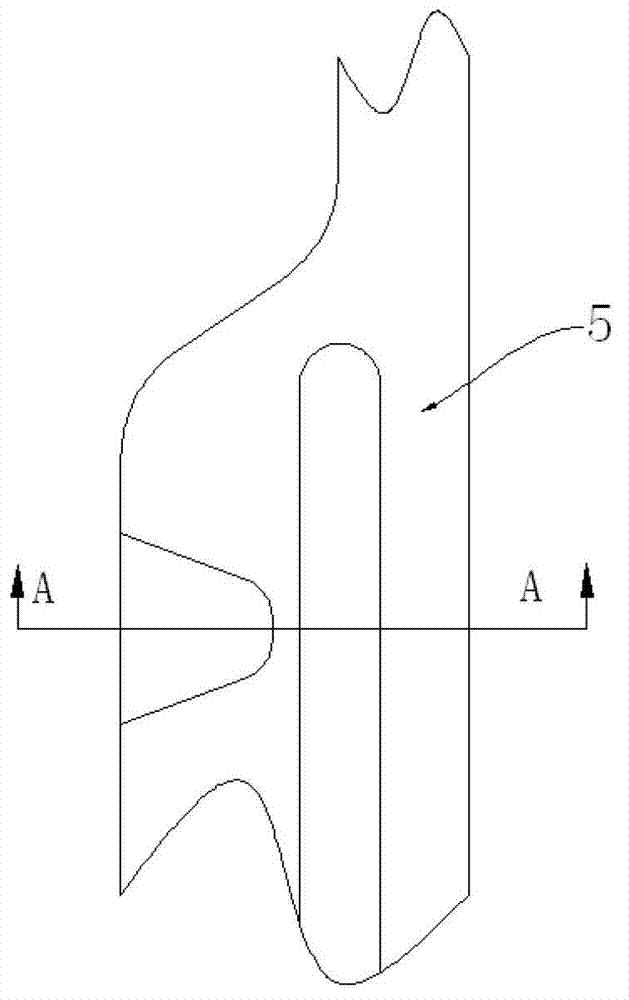

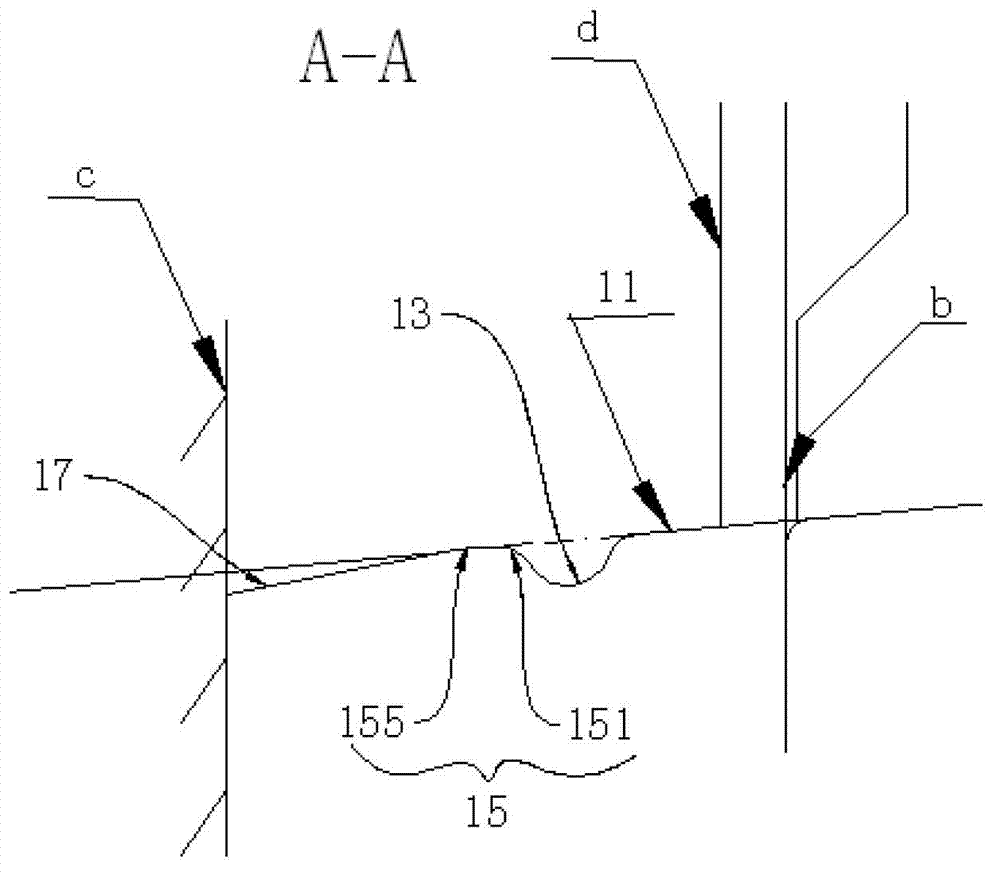

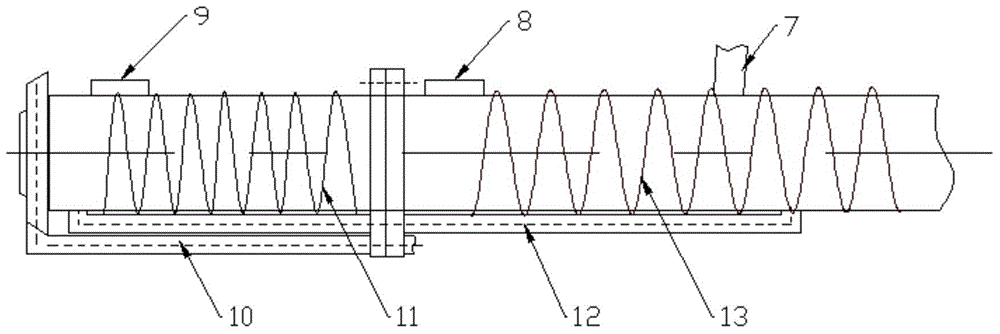

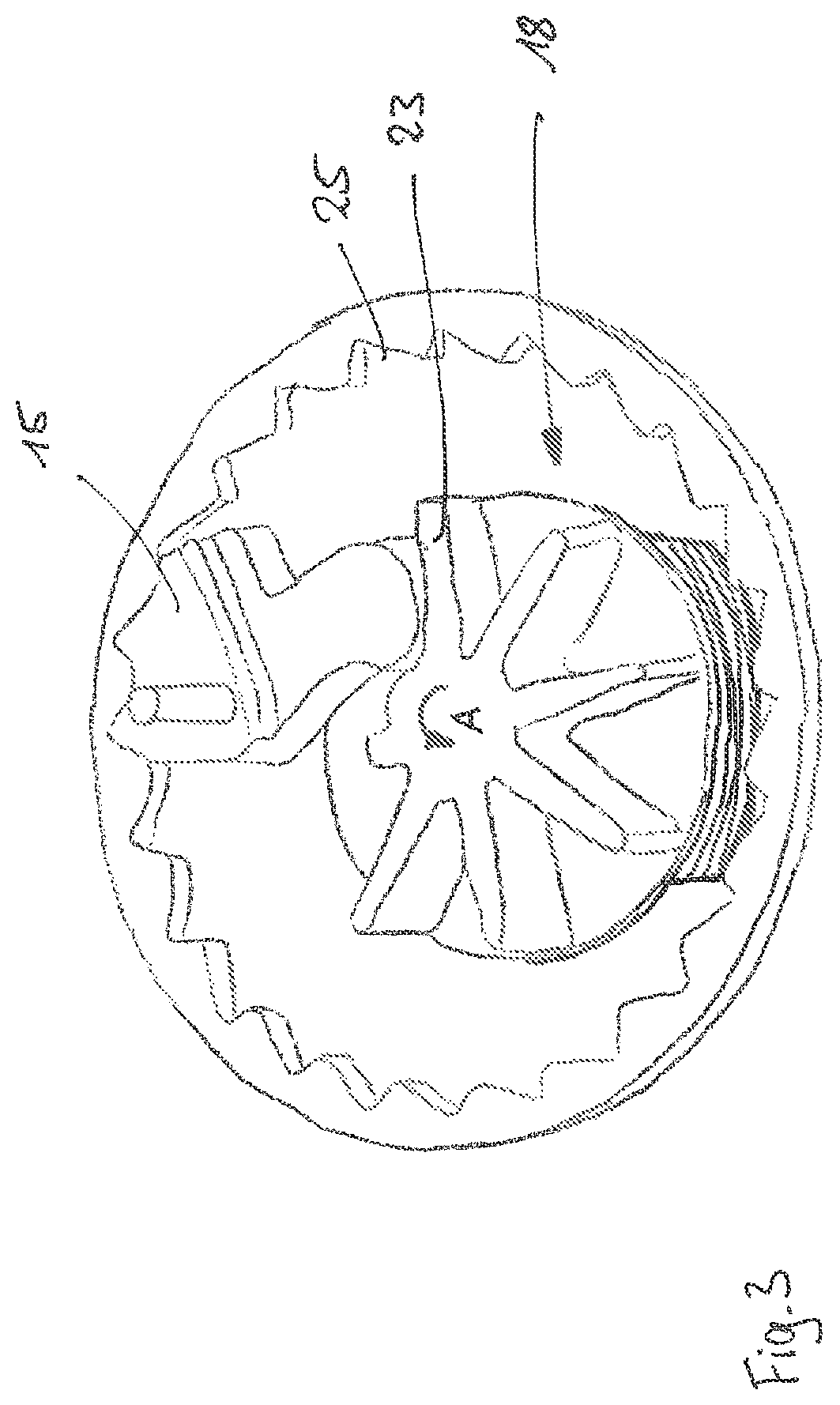

Stamping method of top cover outer plate with skylight

ActiveCN102814430AIncrease sheet metal deformation resistanceUniform flow velocity and full deformationVehicle componentsStamping processEngineering

The invention discloses a stamping method of a top cover outer plate with a skylight; and the method belongs to the field of the manufacturing of automobile white sheet metal parts. The method comprises the following steps that (1) a trimmed mould surface is manufactured on the material of the top cover outer plate with the skylight; (2) the trimmed mould surface is shaped and trimmed; (3) the material of the top cover outer plate with the skylight is flanged and shaped; in the step (1), a process supplementing surface is arranged on the mould surface outside a flanged die line; a cylindrical bar and at least one step surface comprising a wave surface which is tangibly connected with the cylindrical bar and extends are arranged on the process supplementing surface, so that the material deformation resistance of the top cover outer plate with the skylight during a stamping process is increased, the flow rate of the material of the top cover outer plate with the skylight is uniform and the deformation is full, the control on rebounding is very effective; and consequently, the part quality is ensured, significant deformation which is produced in the stamping process of the top cover outer plate with the skylight and even the collapse problem are effective prevented.

Owner:CHERY AUTOMOBILE CO LTD

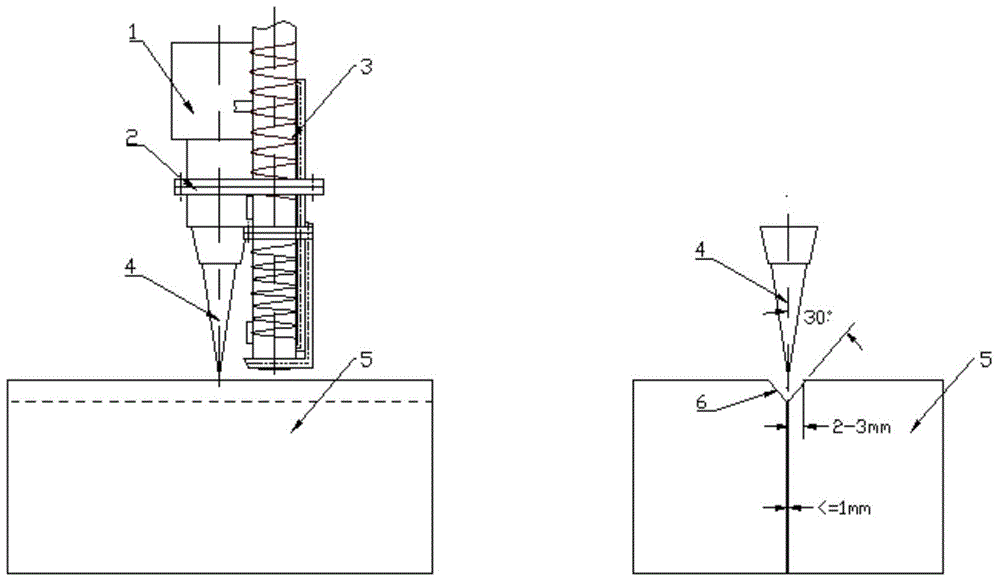

Method for restraining myriawatt-class laser welding thick plate upper surface defects

InactiveCN104625403AImprove liquidityReduce the chance of defectsMetal working apparatusWorkpiece edge portionsWeld beadInertia

The invention provides a method for restraining myriawatt-class laser welding thick plate upper surface defects. The method comprises the specific steps that 1, a welding plate (5) is machined, a metal particle conveying head (3) is installed on a laser welding head (1), and the conveying position of metal particles (16) is on the rear edge of a welding pool (27) lack of fusion; 2, the metal particles (16) are loaded into the metal particle conveying head (3), and a metal particle heating device is turned on to heat the metal particles (16) to the temperature from 900 DEG C to 1100 DEG C below the melting point; 3, the power of a laser is controlled, a laser beam (4) irradiates the welding plate (5) to form the welding pool lack of fusion, a metal particle conveying system controlled by compressed air is turned on, and the heated metal particles are pushed to the welding pool lack of fusion; 4, an inertia shielding gas annular air blow pipe (10) is turned on, and a laser welding head (1) and the metal particle conveying head (3) synchronously move to complete the welding process. According to the method, material losses generated by some splashes can be complemented, and welding bead subsidence is reduced.

Owner:HUNAN UNIV

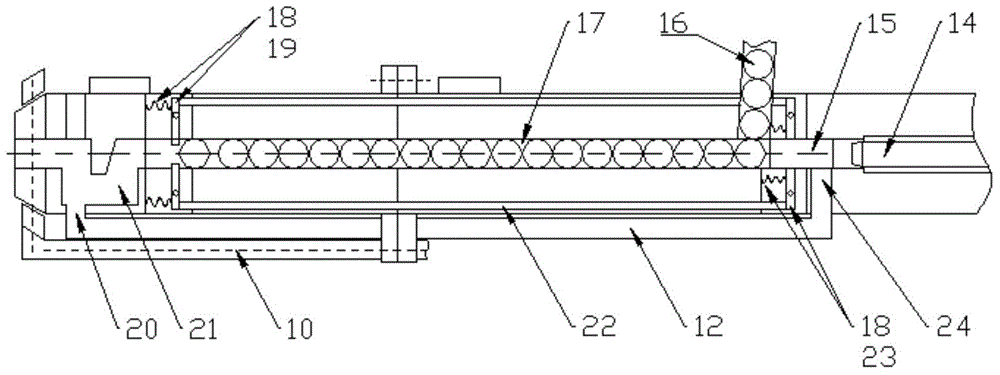

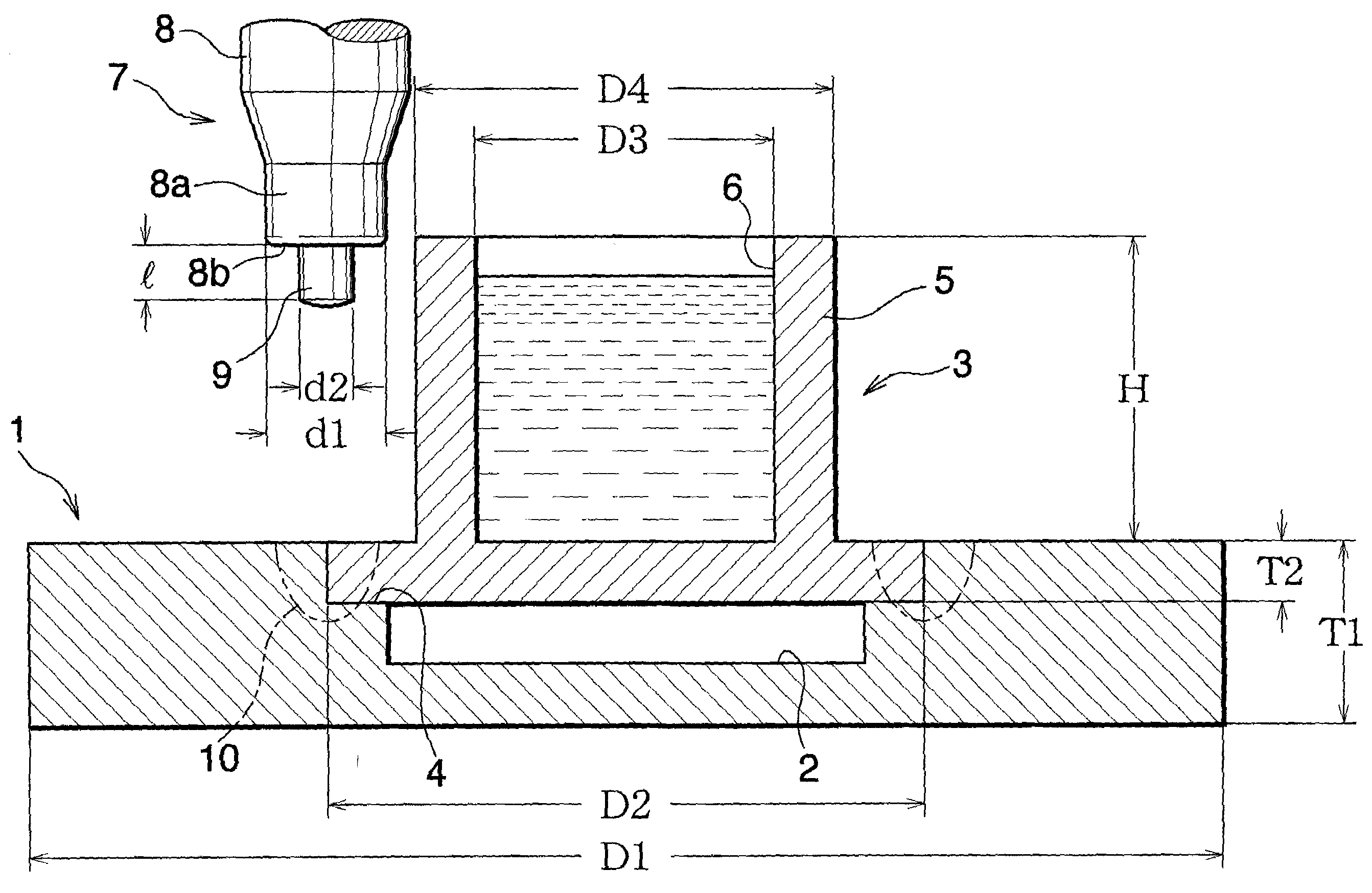

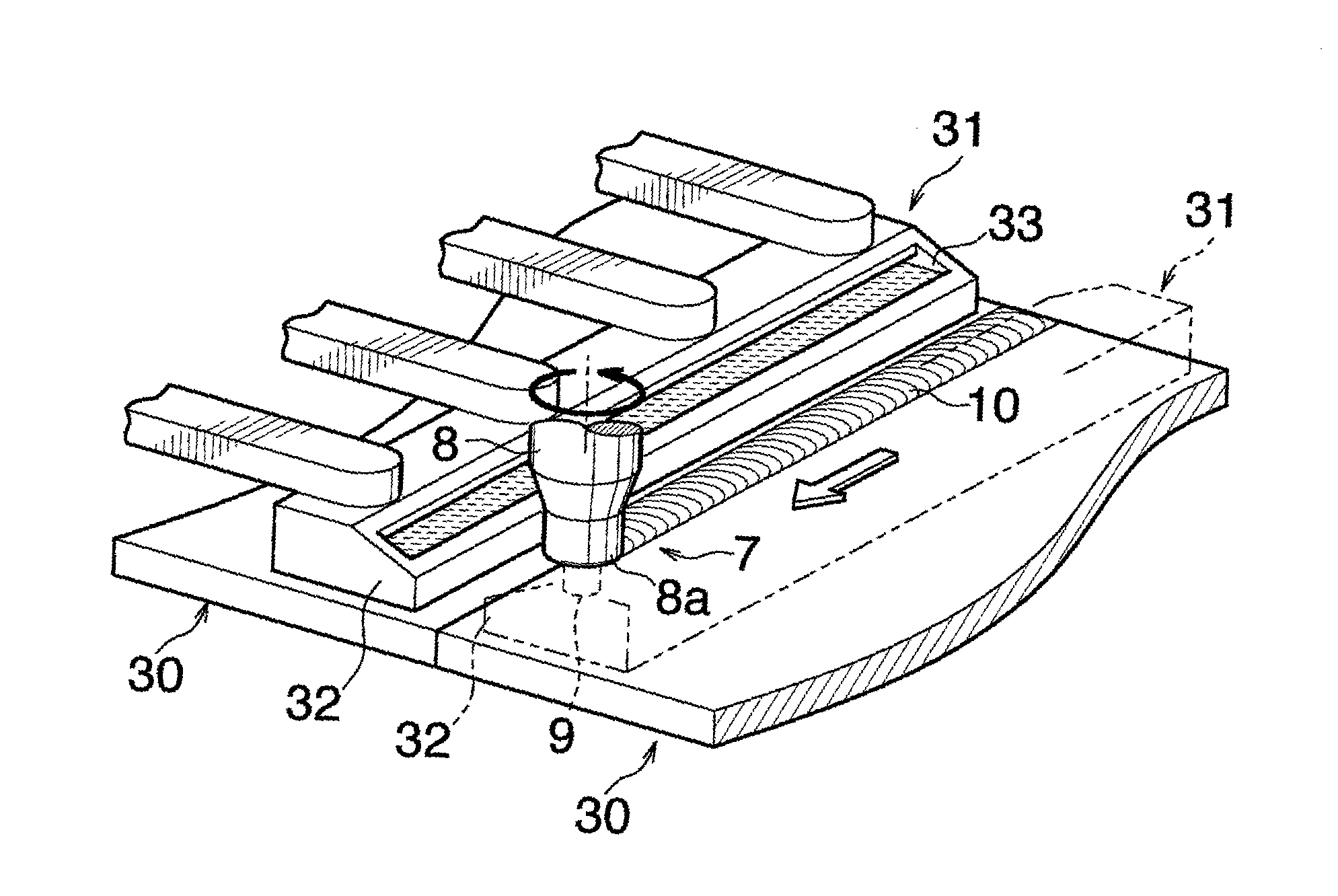

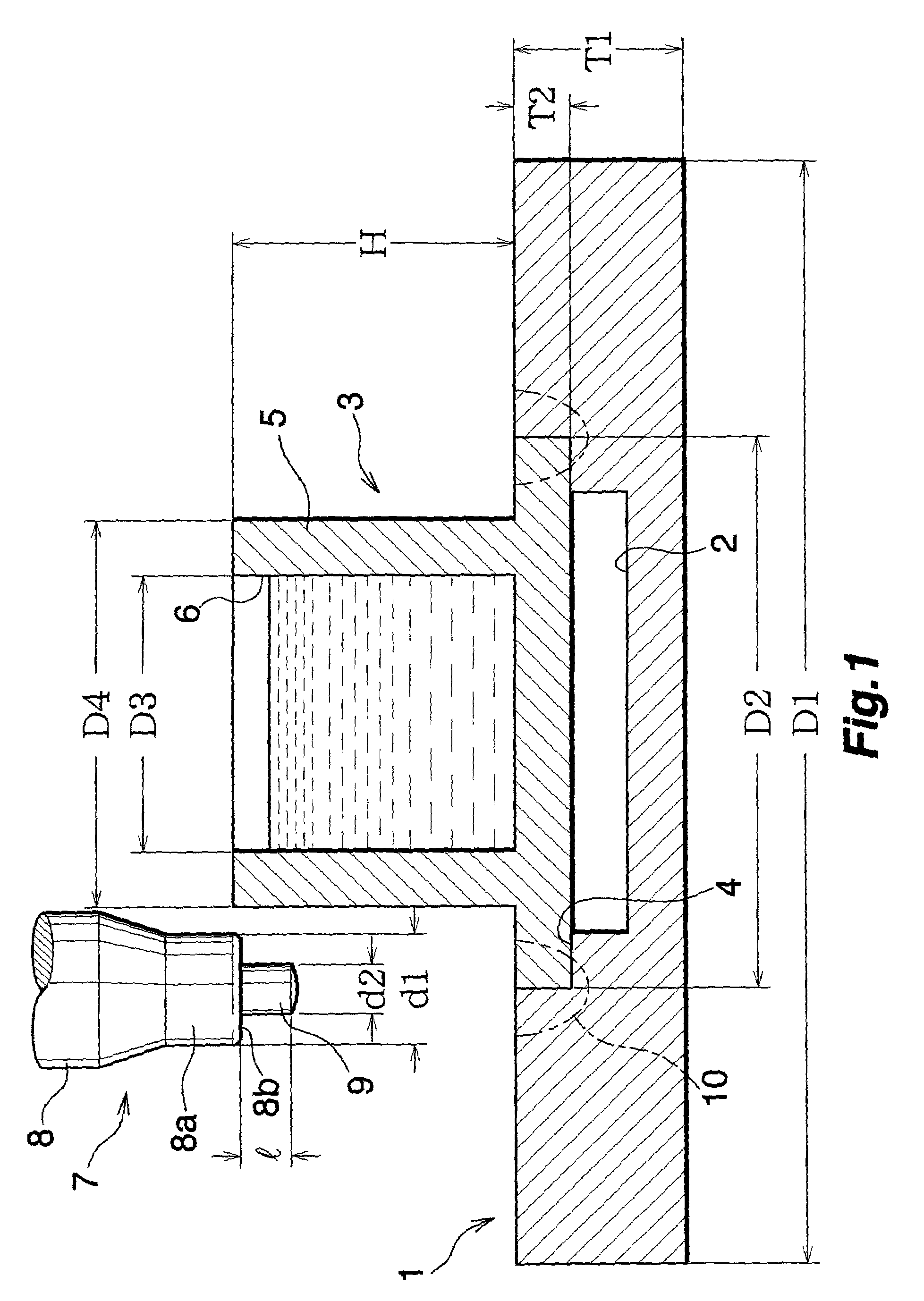

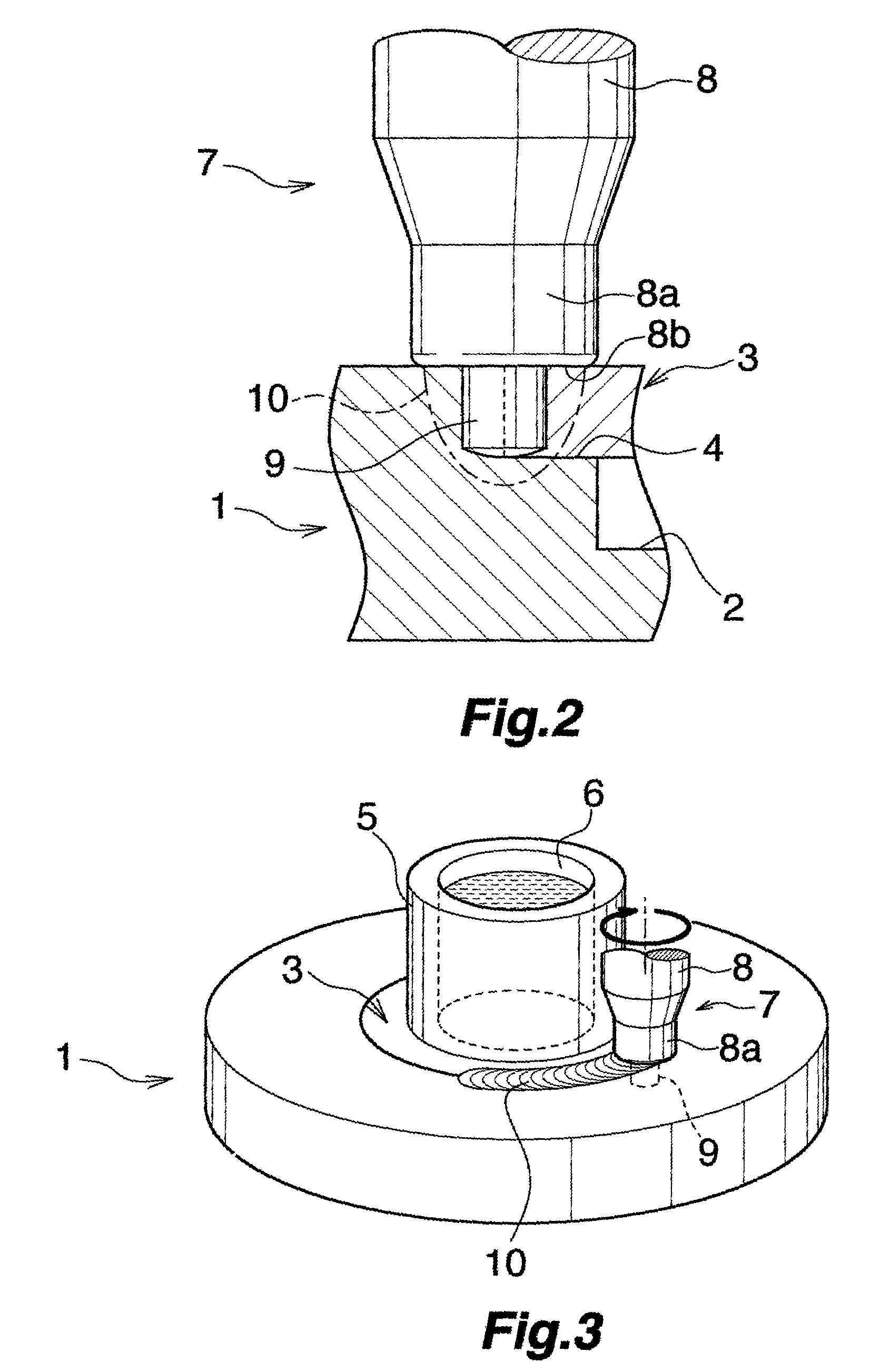

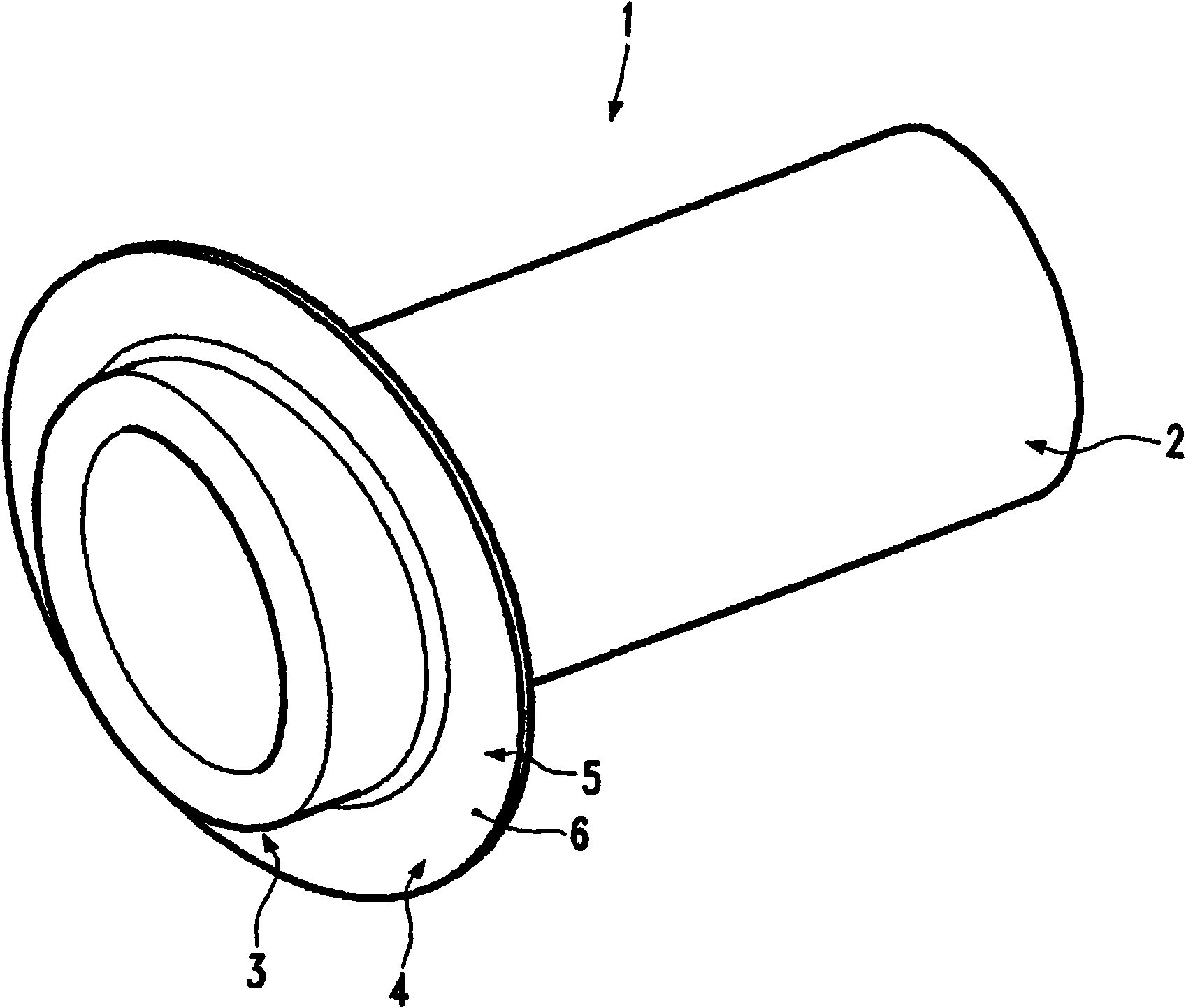

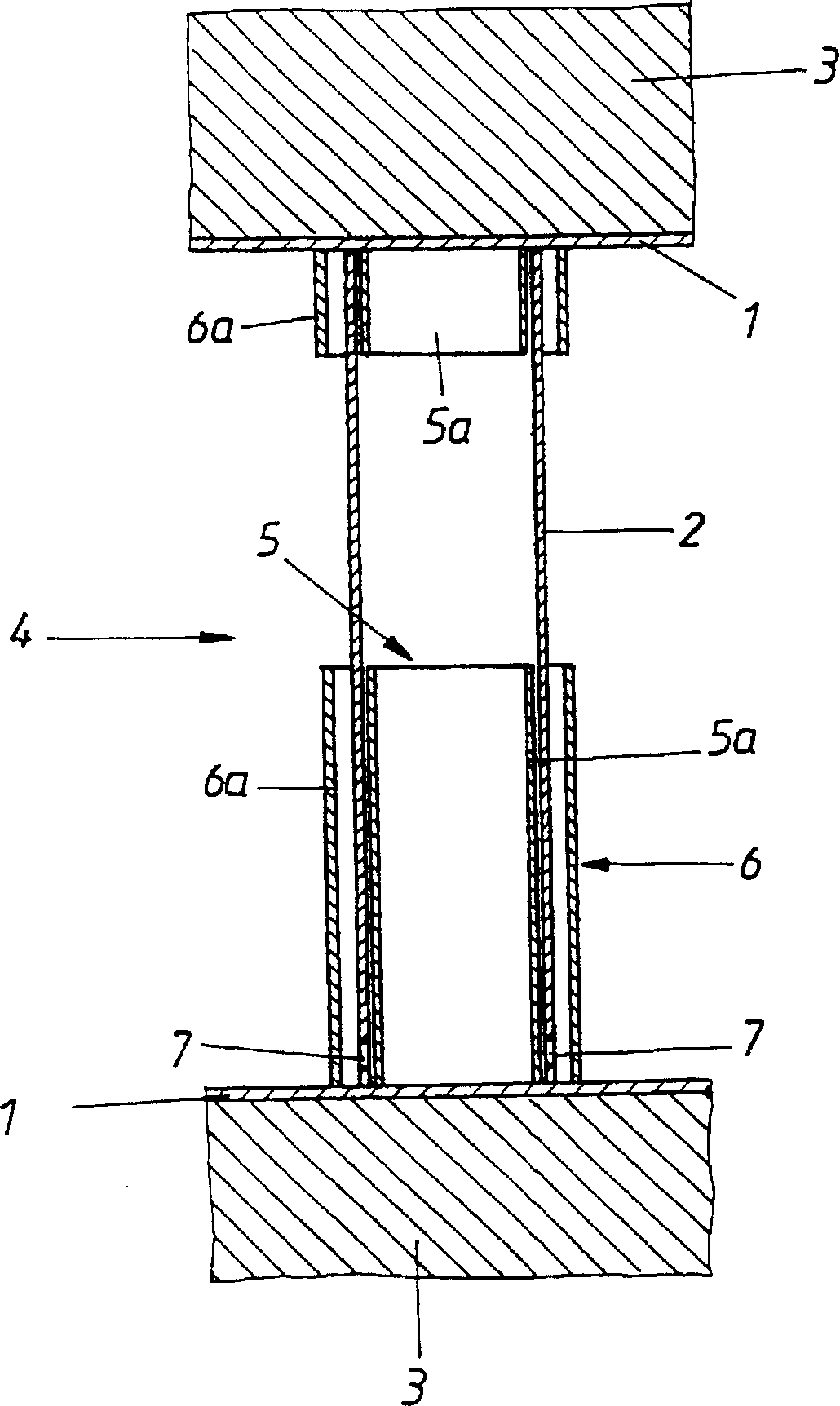

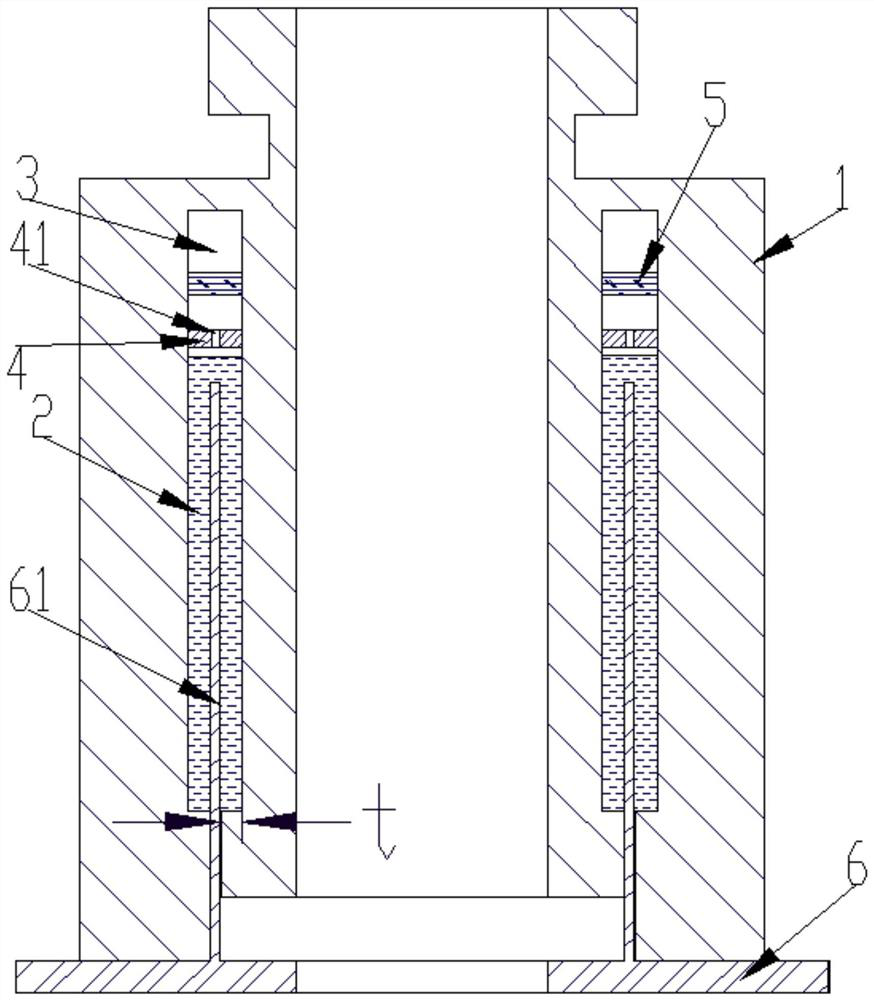

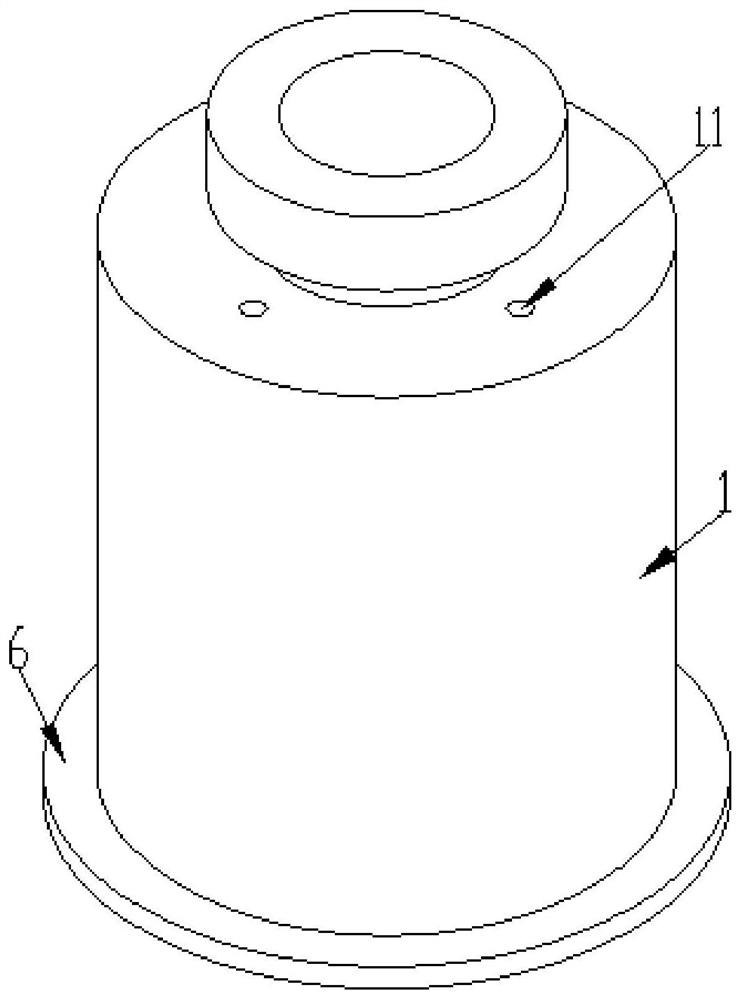

Friction stirring-joining method and method of manufaturing hollow body

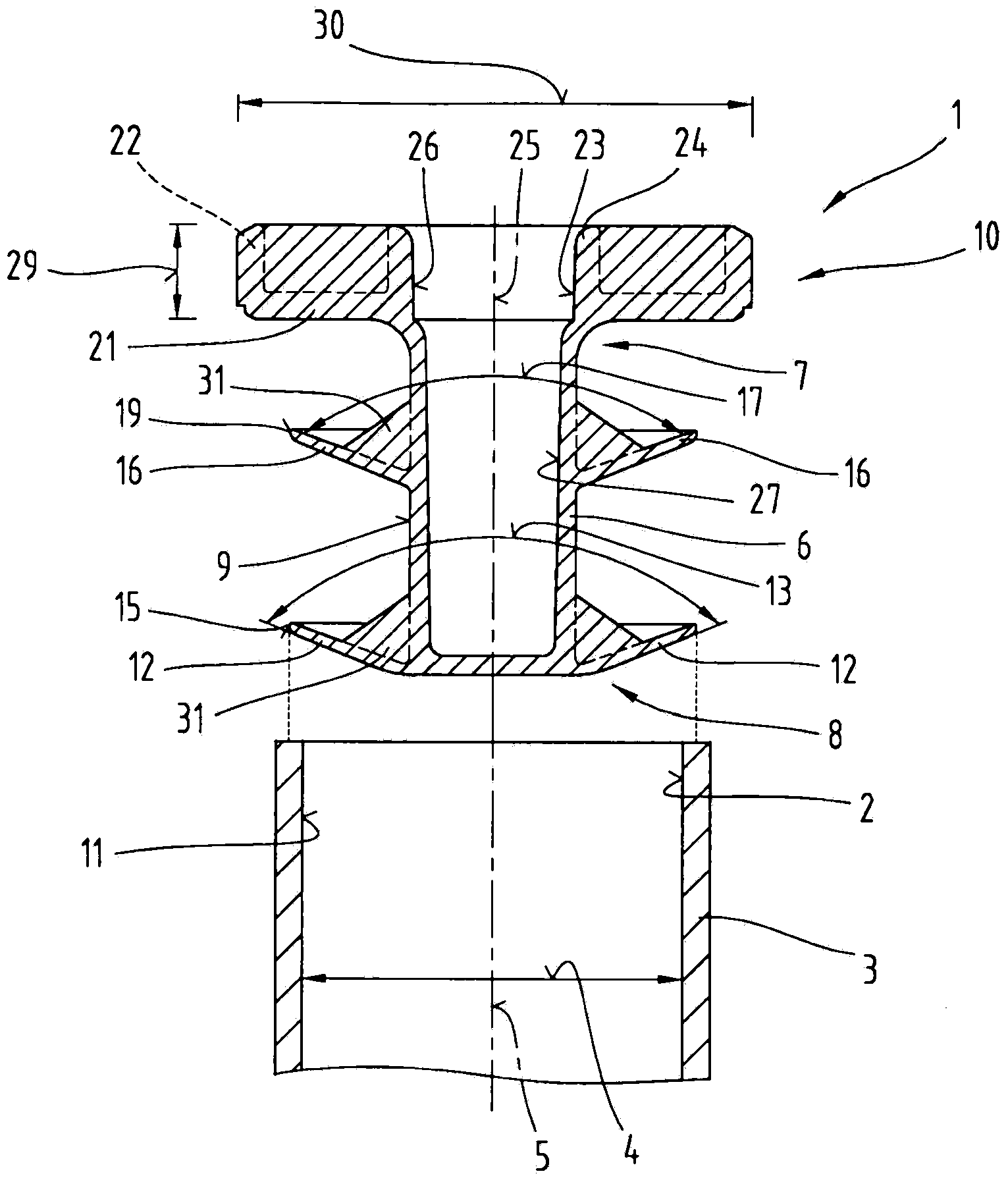

InactiveUS20090108050A1Avoid defectsIncrease resistanceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLatent heat

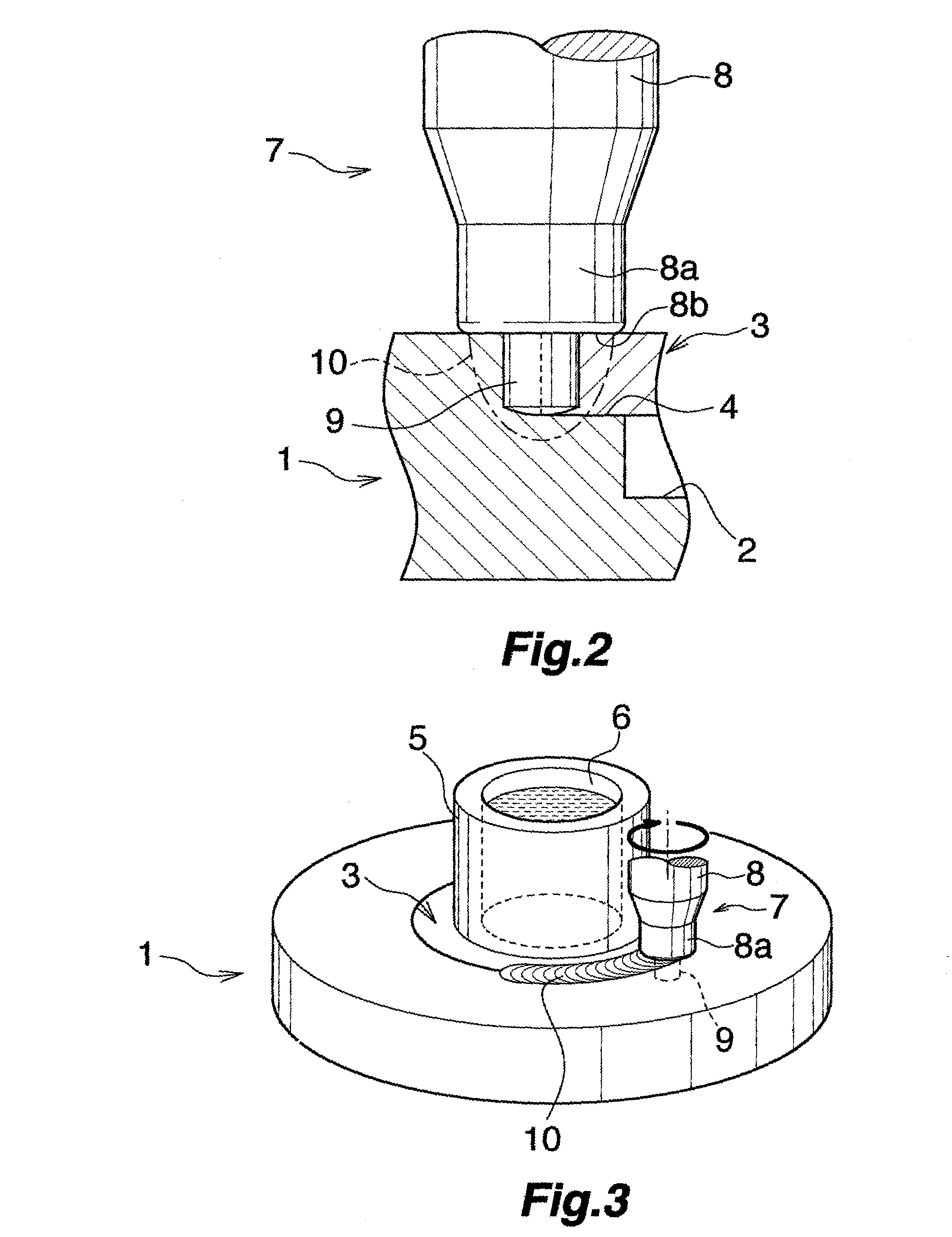

A base 1 having a recess 2, and a cover 3 to be fitted into the recess 2 and to close an opening of the recess 2 are prepared. A stepped portion 4 is formed on the inner circumferential surface of the recess 2 at an intermediate depth for allowing a peripheral portion of the cover 3 to rest thereon. A cylindrical holder portion 5 having a cooling-medium accommodation recess 6 is formed integrally with the outer surface of the cover 3. The cover 3 is fitted into the recess 2 and placed on the stepped portion 4. A cooling medium for removing latent heat is placed in the cooling-medium accommodation recess 6 of the holder portion 5 of the cover 3. A probe 9 of a friction-stir-welding tool is plunged from outside into a peripheral portion of the base 1 around an opening of the recess 2 and into a peripheral portion of the cover 3. Then, during rotation of the probe 9, the base 1 and the cover 3, and the probe 9 are caused to undergo relative movement, thereby friction-stir-welding the base 1 and the cover 3 together. This method of manufacturing a hollow body can be carried out at low cost.

Owner:SHOWA DENKO KK

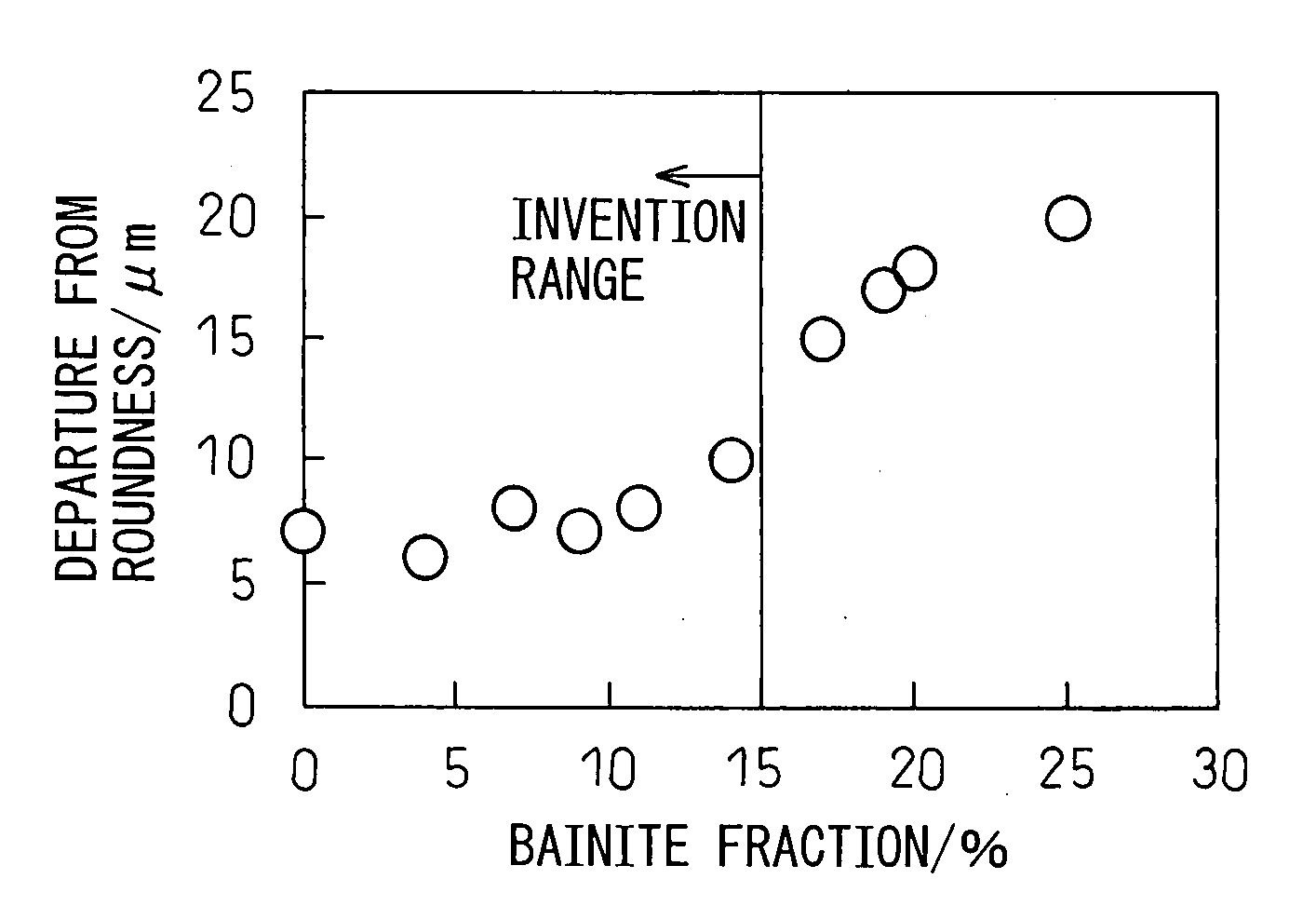

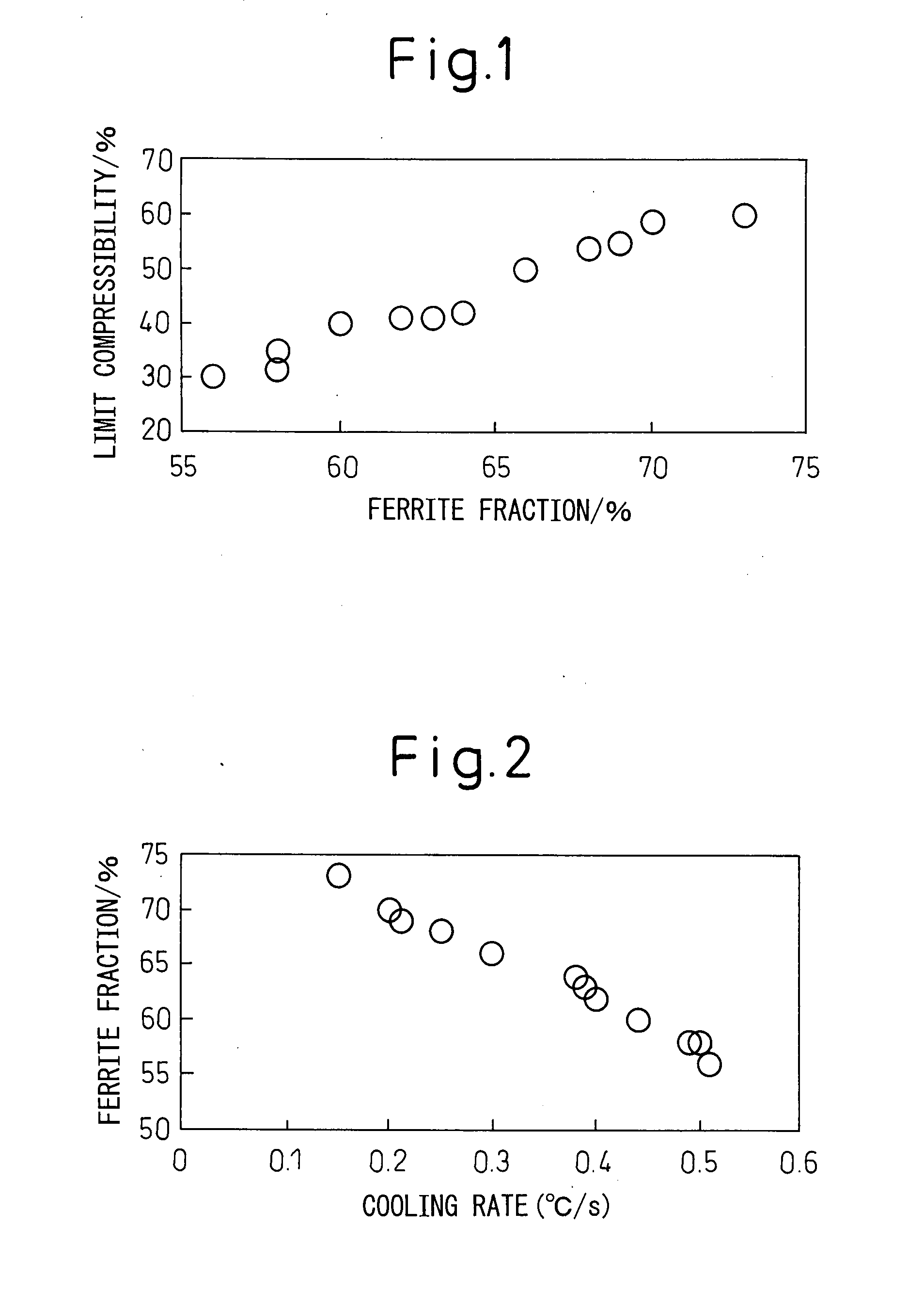

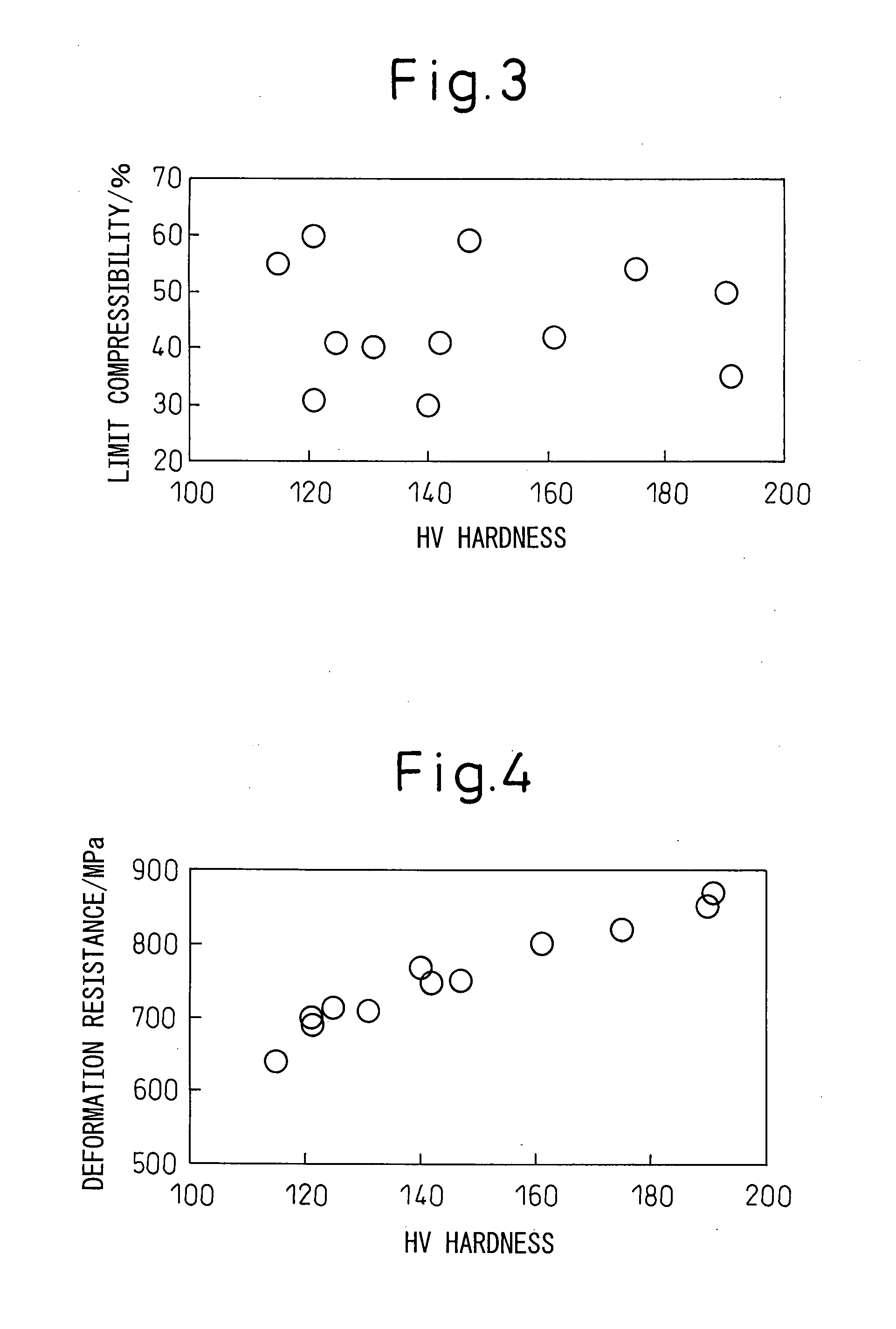

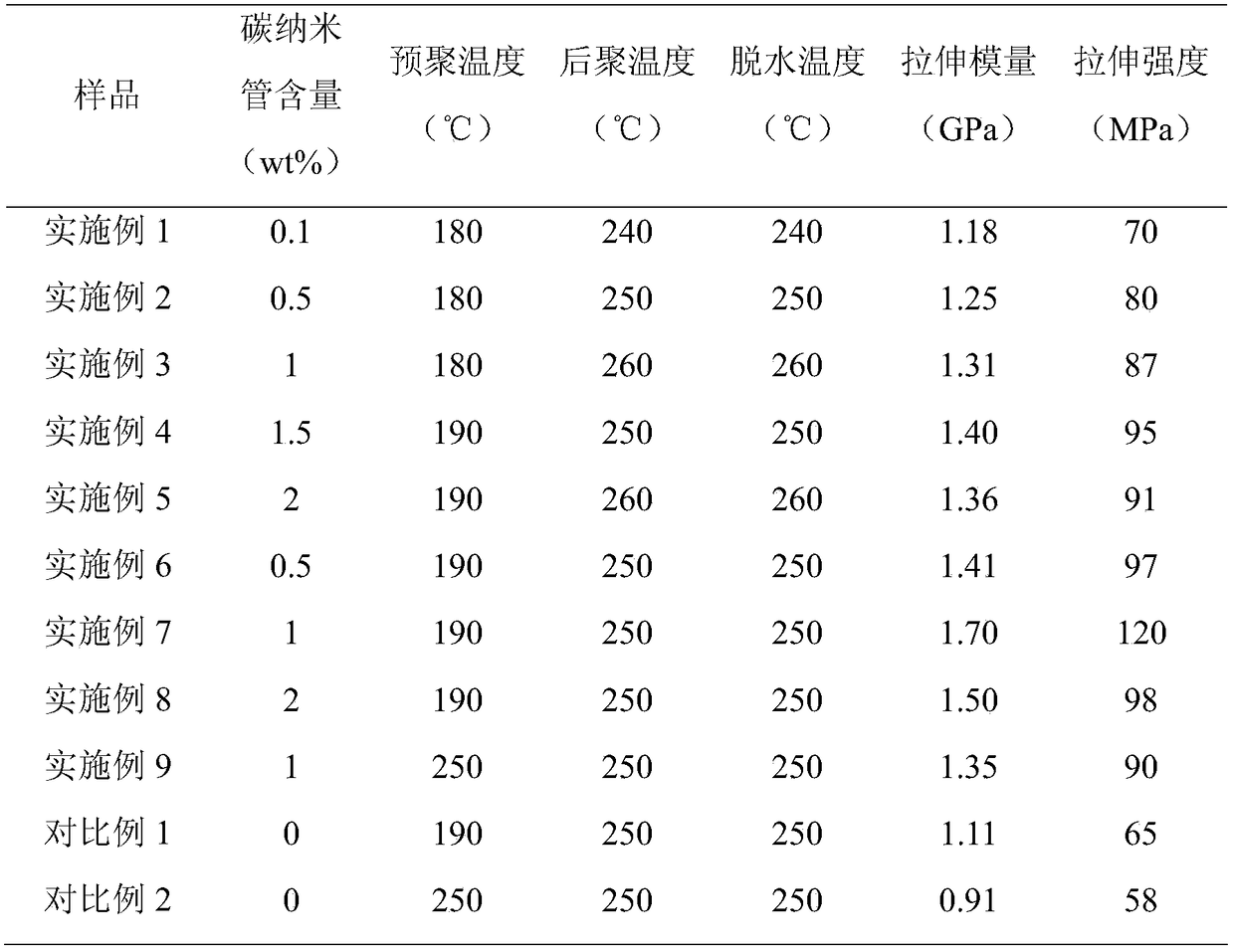

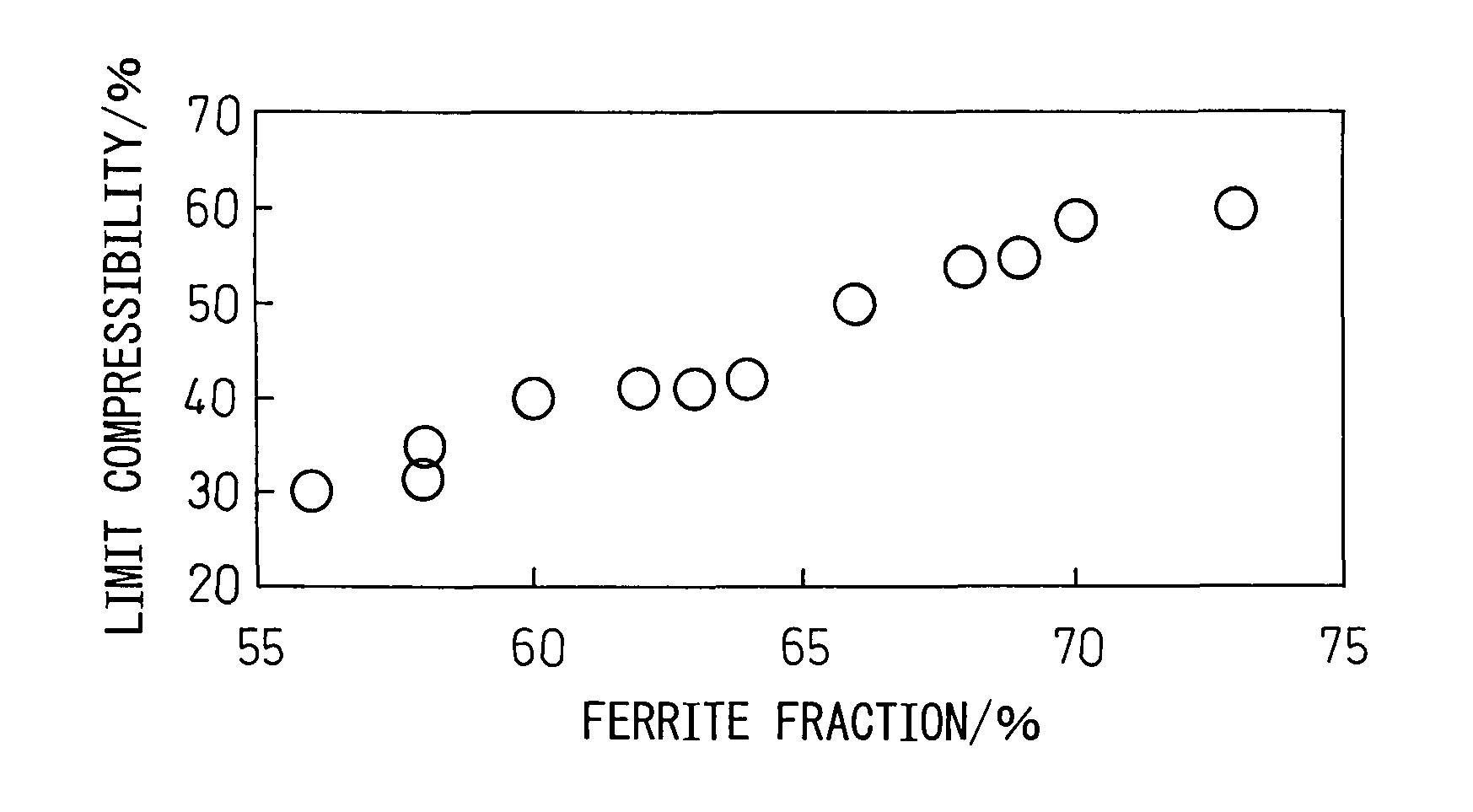

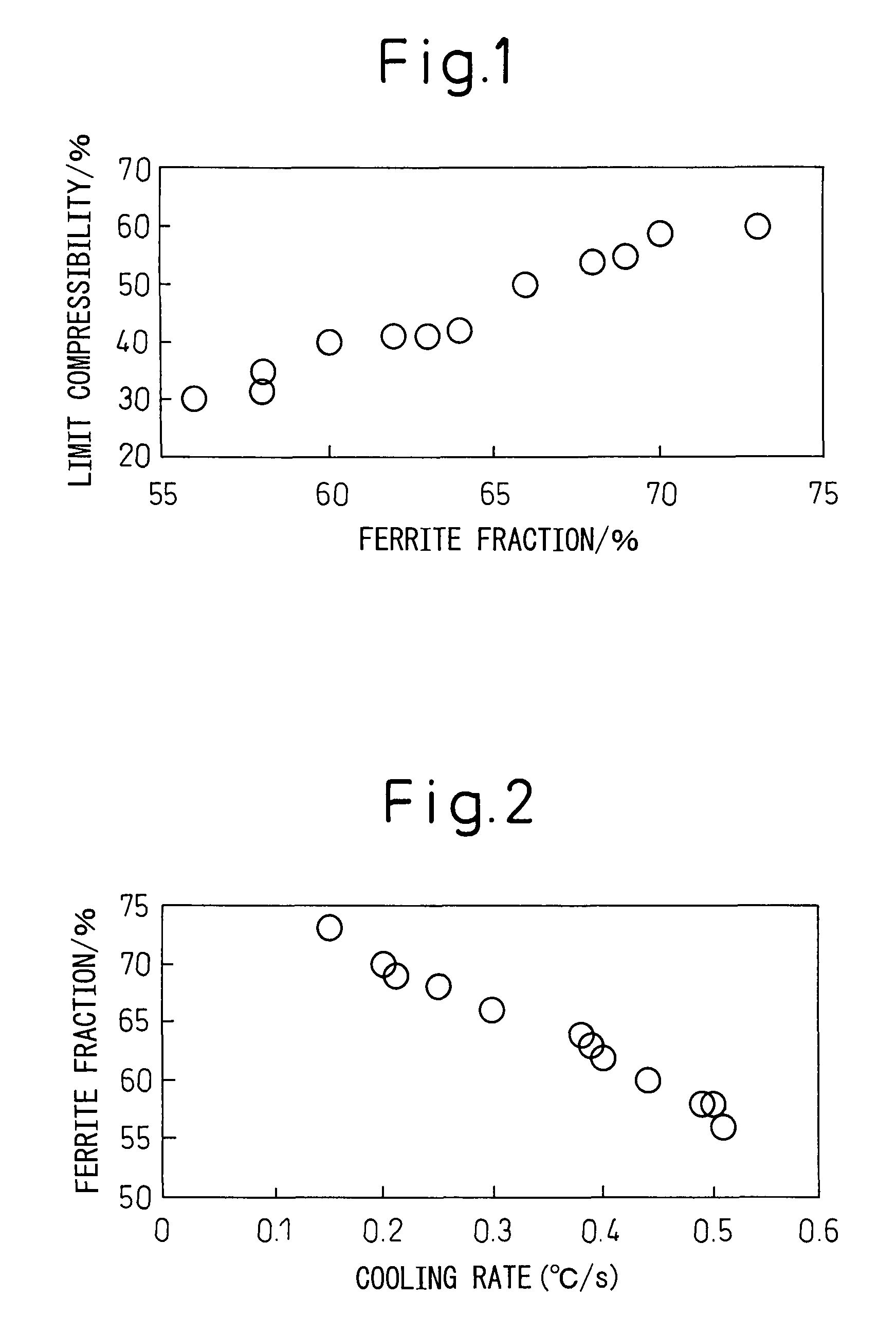

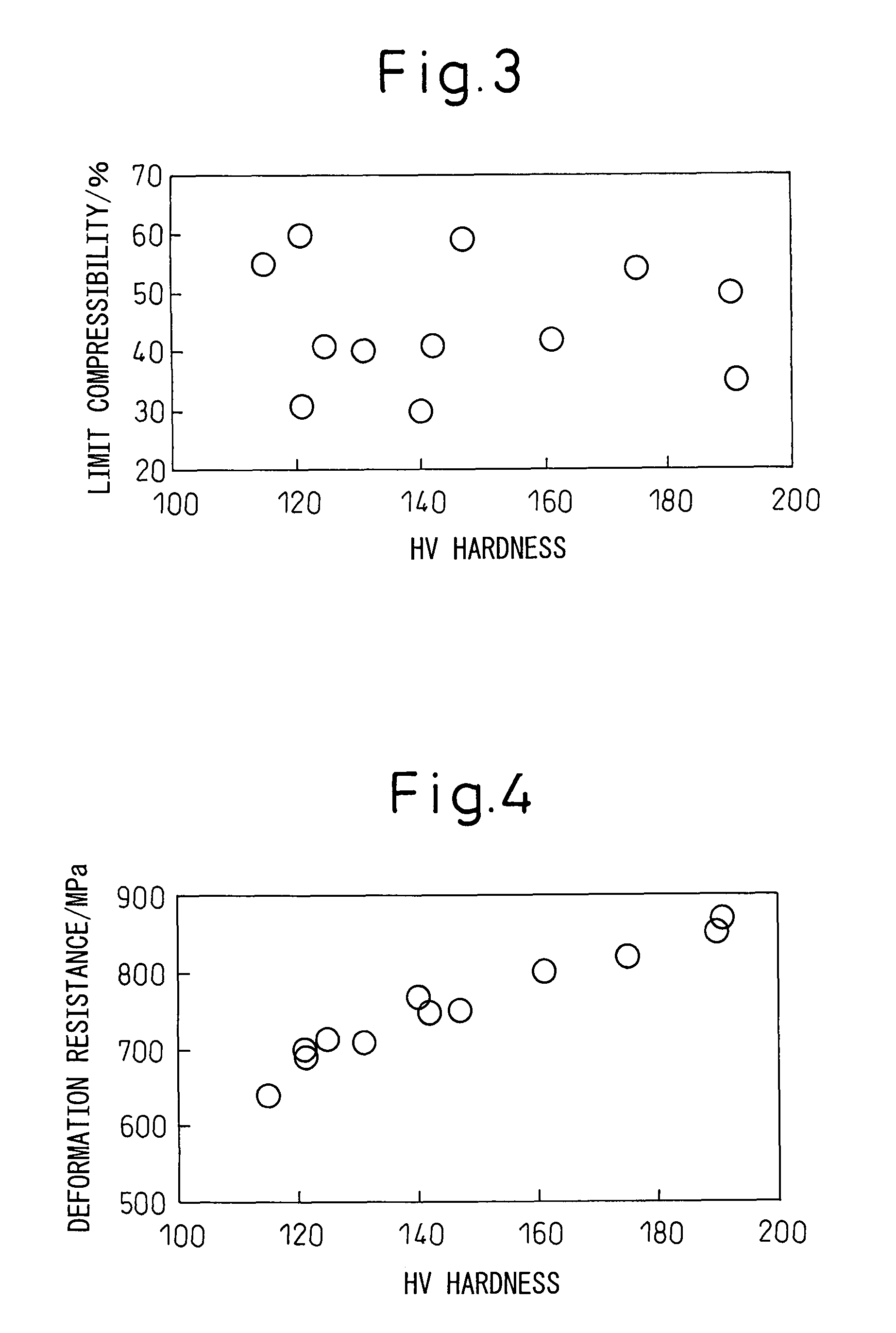

Case-hardening steel excellent in cold forgeability and low carburization distortion property

This invention provides a case-hardening steel excellent in cold forgeability and low carburization distortion property that exhibits low deformation resistance and high limit compressibility when cold, namely, a case-hardening steel excellent in cold forgeability and low carburization distortion property comprising, in mass %, C: 0.07% to 0.3%, Si: 0.01% to 0.15%, Mn: 0.1% to 0.7%, P: 0.03% or less, S: 0.002% to 0.10%, Al: 0.01% to 0.08%, Cr: 0.7% to 1.5%, Ti: 0.01% to 0.15%, B: 0.0005% to 0.005%, N: 0.008% or less, and the balance of Fe and unavoidable impurities, and having a metallographic structure comprising 65% or greater of ferrite and 15% or less of bainite.

Owner:NIPPON STEEL CORP

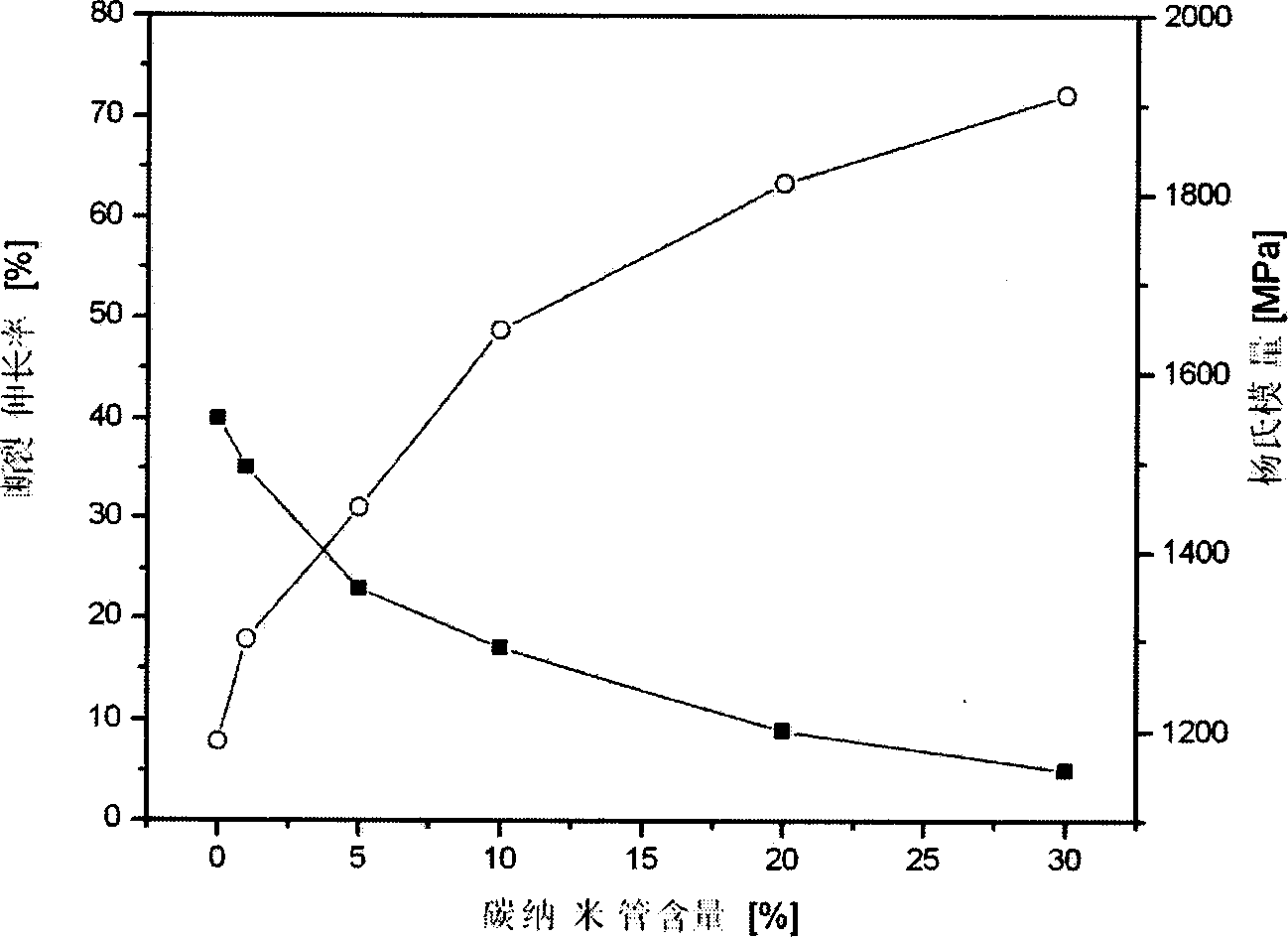

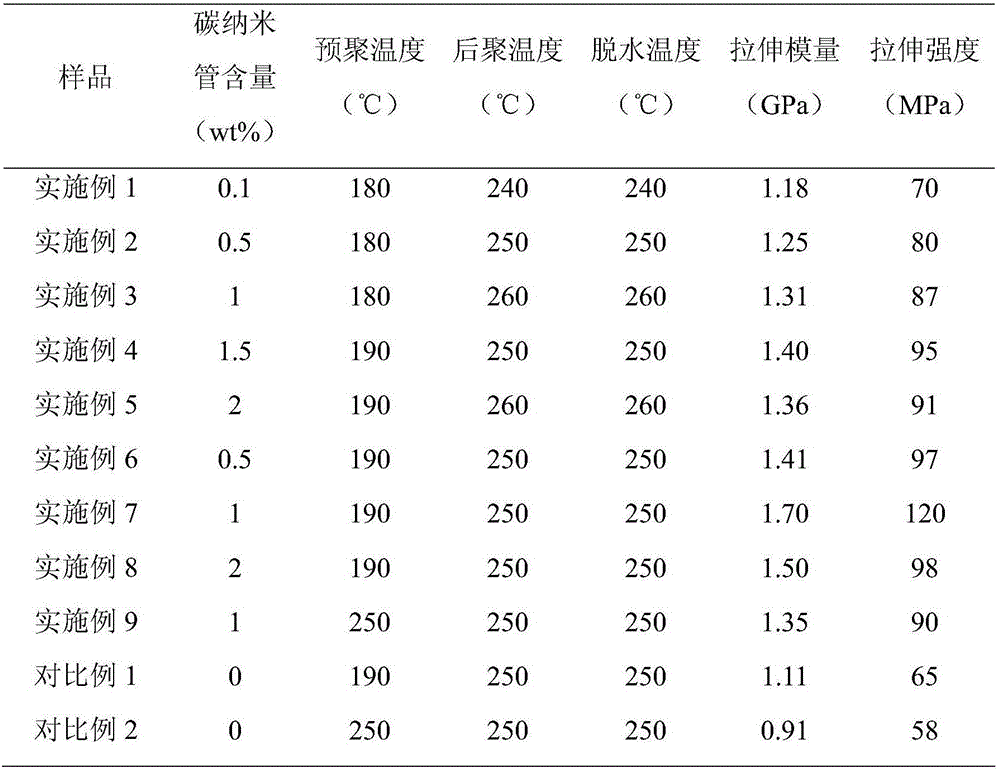

Method for preparing in-situ polycondensation enhanced carbon nanotube/nylon composite materials

InactiveCN1631978AImprove performanceImprove mechanical propertiesCarbon nanotubeMechanical property

Disclosed is a method to prepare polycondensation strengthened carbon nm pipe nylon compound material. Firstly, do acid procession to the carbon nm pipe, which is then to have polycondensation reaction with nylon monomer or salt of nylon monomer. The acidified carbon nm pipe has outstanding performance, and through the polycondensation way, compared with other nm material such as polynite or other compounding method like common mixing method, it has better mechanical property ; the polycondensation reaction can realize average distribution of carbon nm pipe as well as keeping its nm characteristics; by once synthesis to form, avoids degradation caused by heat procession and keeps stability of other performances, and its preparing method is simple.

Owner:SHANGHAI JIAO TONG UNIV

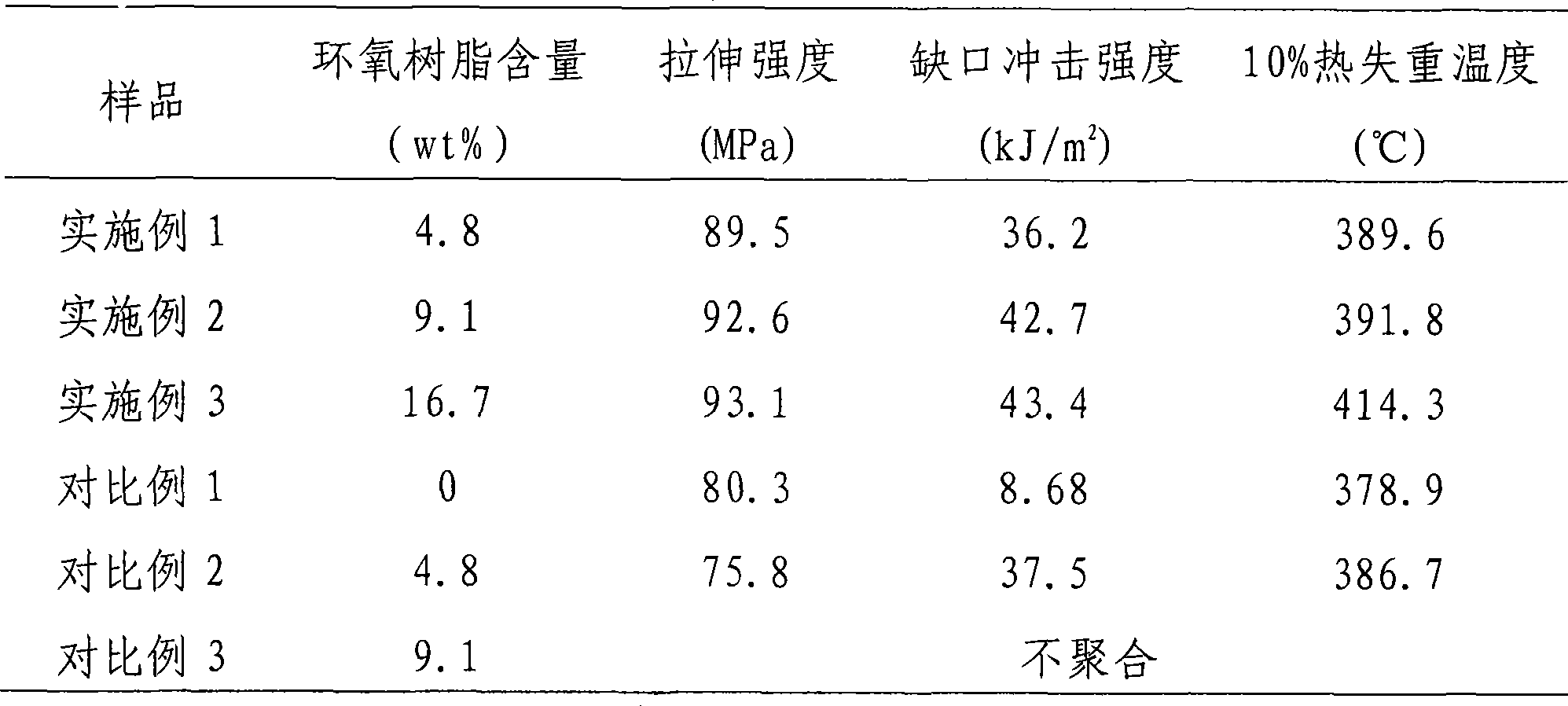

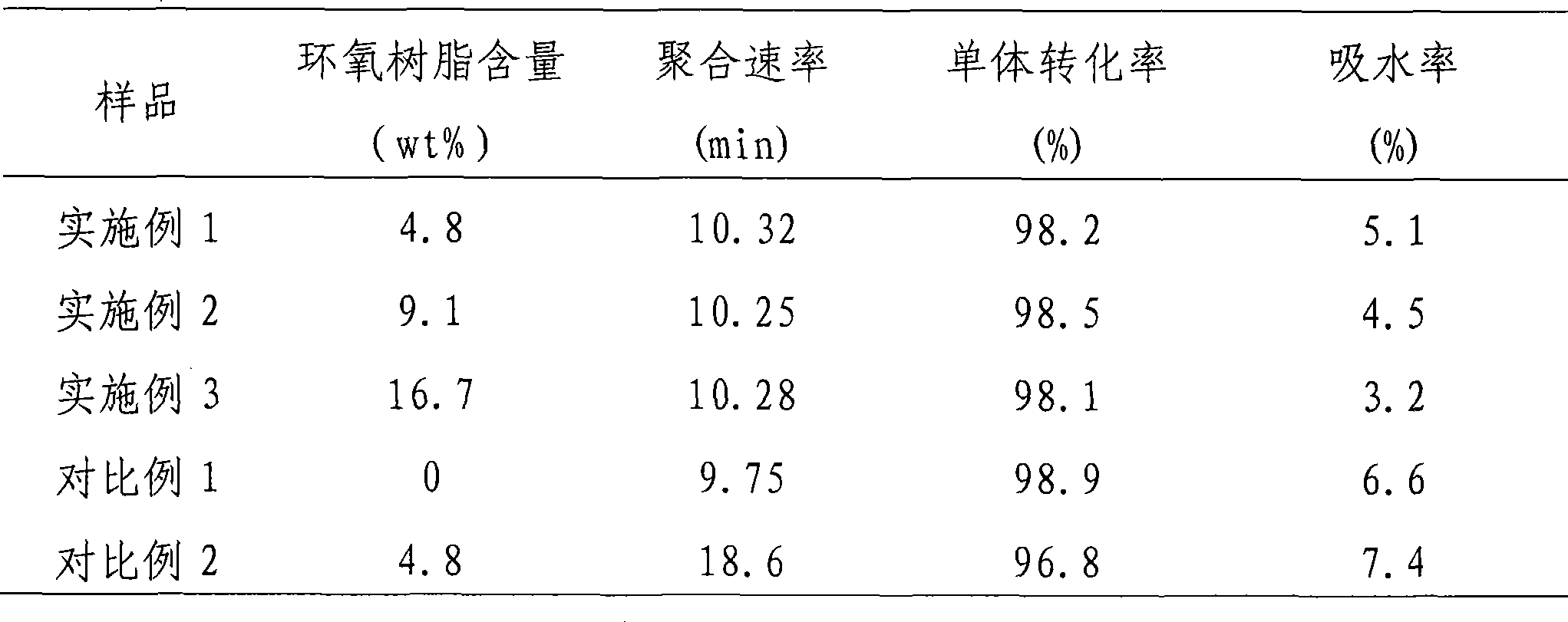

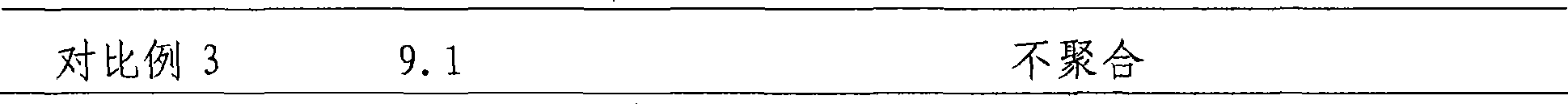

Process for producing epoxy resin//MC nylon composite material

The invention discloses a preparation method of an epoxy resin / MC nylon composite material; 100 weight portions of caprolactam is taken as the reference, and the weight portions of other components are as follows: 1 portion to 50 portions of epoxy resin, 0.005 portion to 20 portions of curing agent, 0.01 portion to 5 portions of catalyst and 0.01 portion to 5 portions of activating agent; (a) under the protection of nitrogen, the epoxy resin is added into caprolactam melt to be evenly stirred; (b) the curing agent is added to pre-cure the epoxy resin under 80 DEG C to 150 DEG C; (c) the catalyst and the activating agent are added in to initiate ring opening polymerization of caprolactam anion, to obtain the epoxy resin / MC nylon composite material. The preparation method has the advantages that: 1. the method has short gelation time, high polymerization speed, high monomer conversion rate, low water absorption and the like; 2. the method improves the deformation resistance of the MC nylon substrate, so that the tensile and impact strength of the composite material are greatly improved; 3. the heat resistant performance is greatly improved; 4. the method has low production cost and simple and convenient process, and is application to industrialized production.

Owner:XIANGTAN UNIV

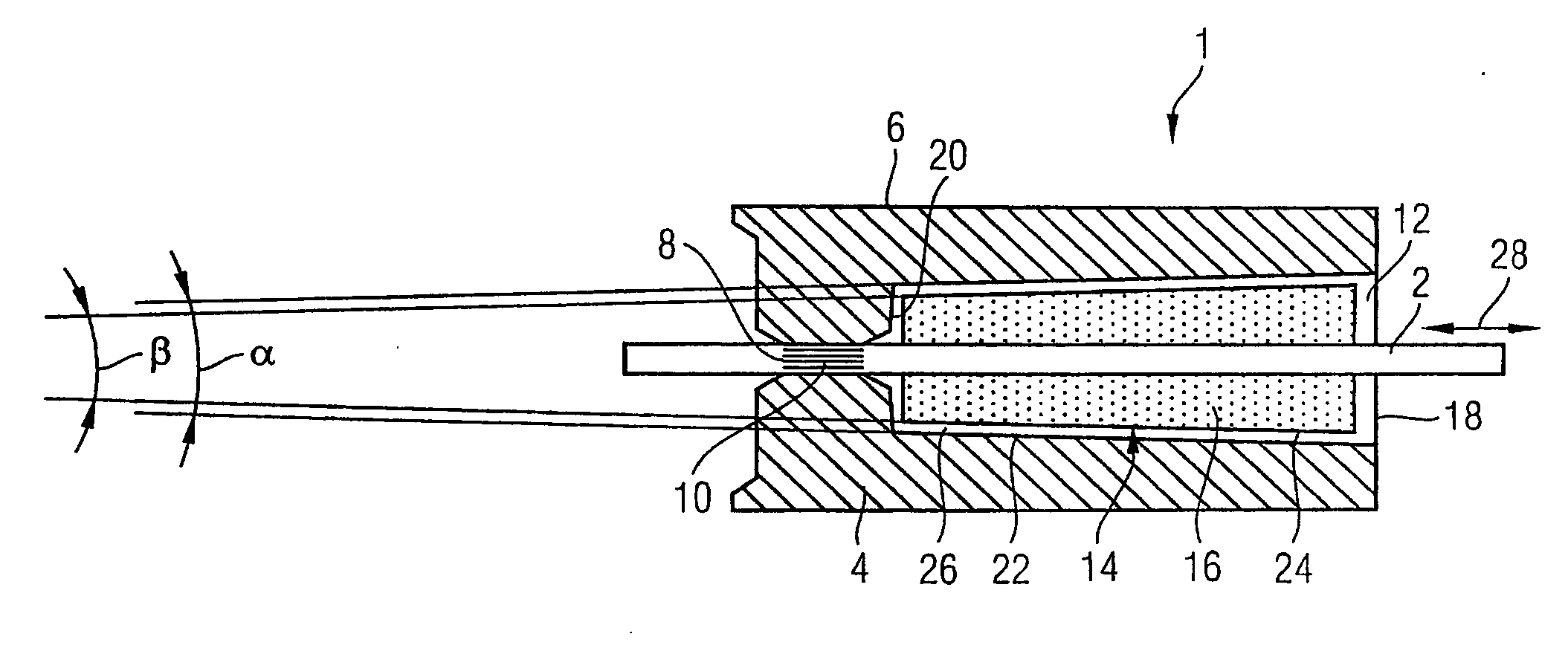

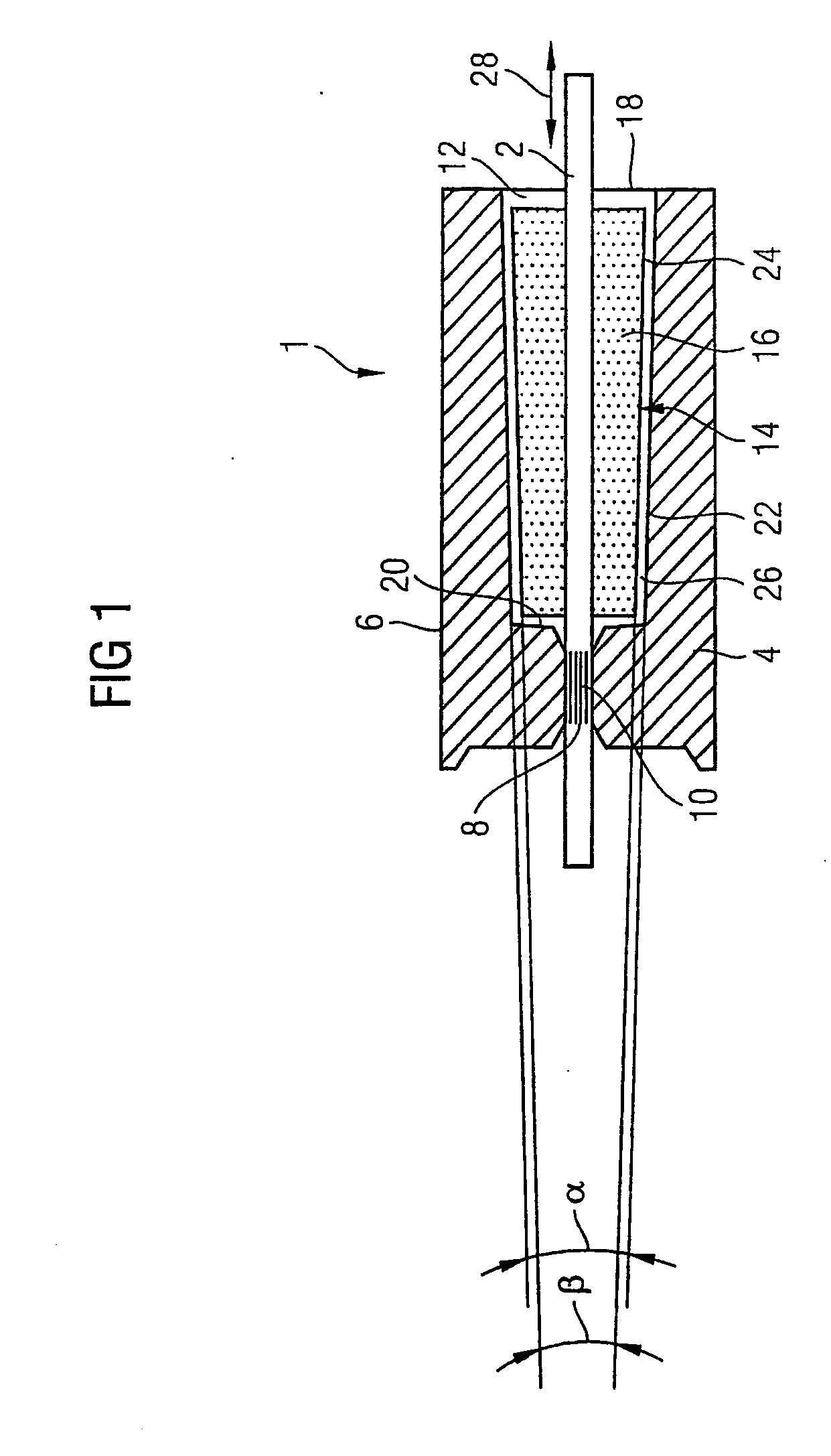

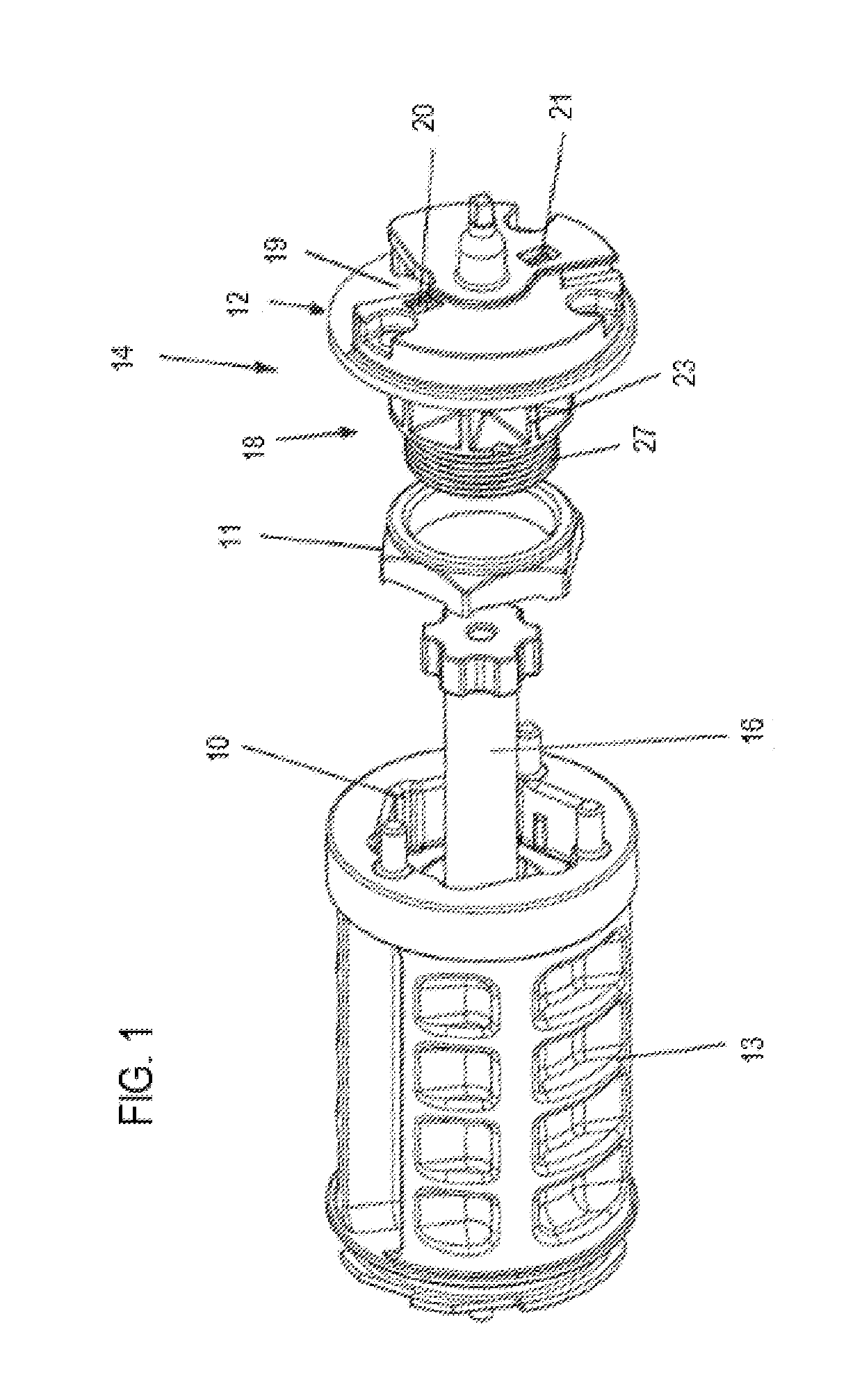

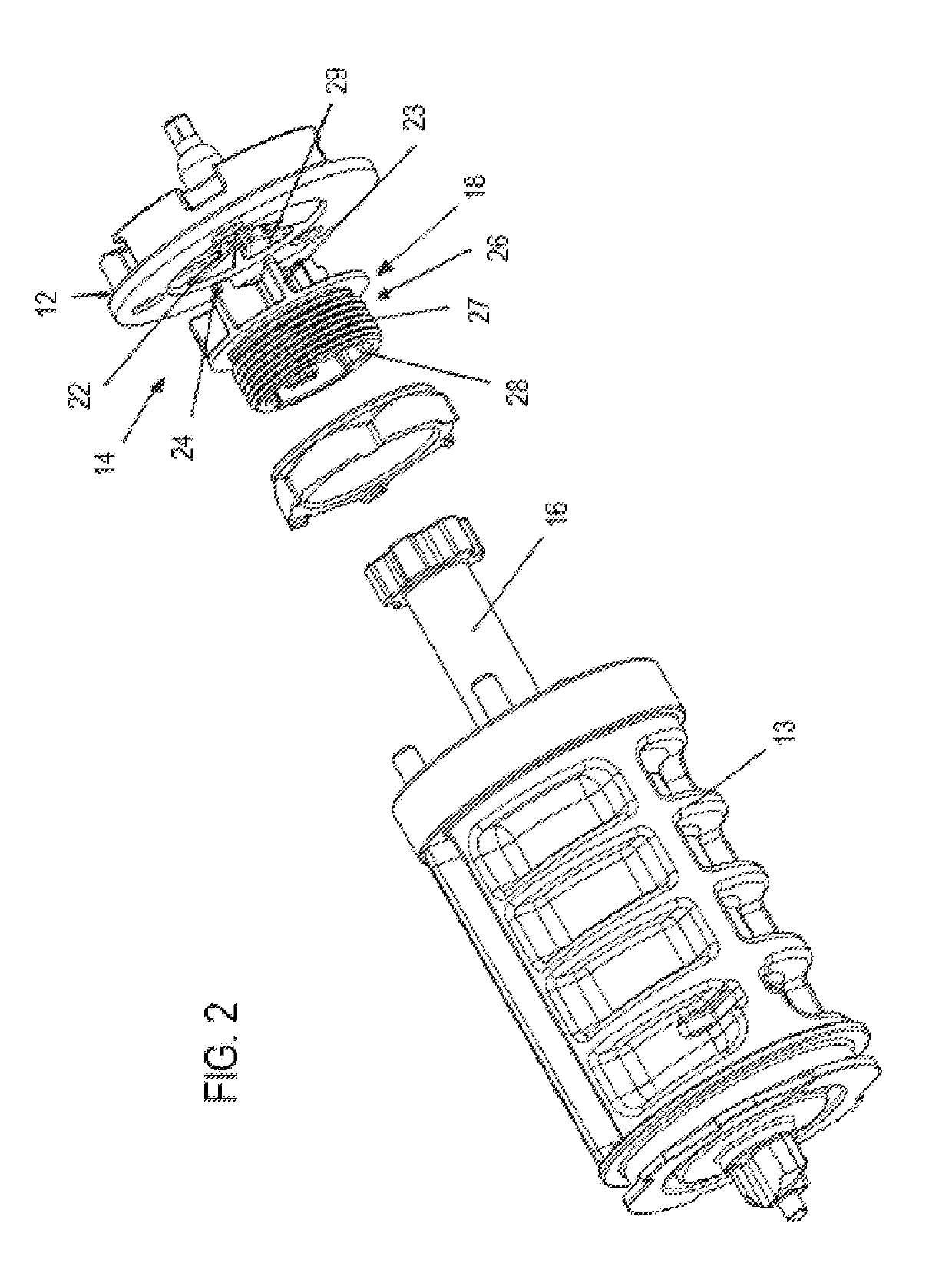

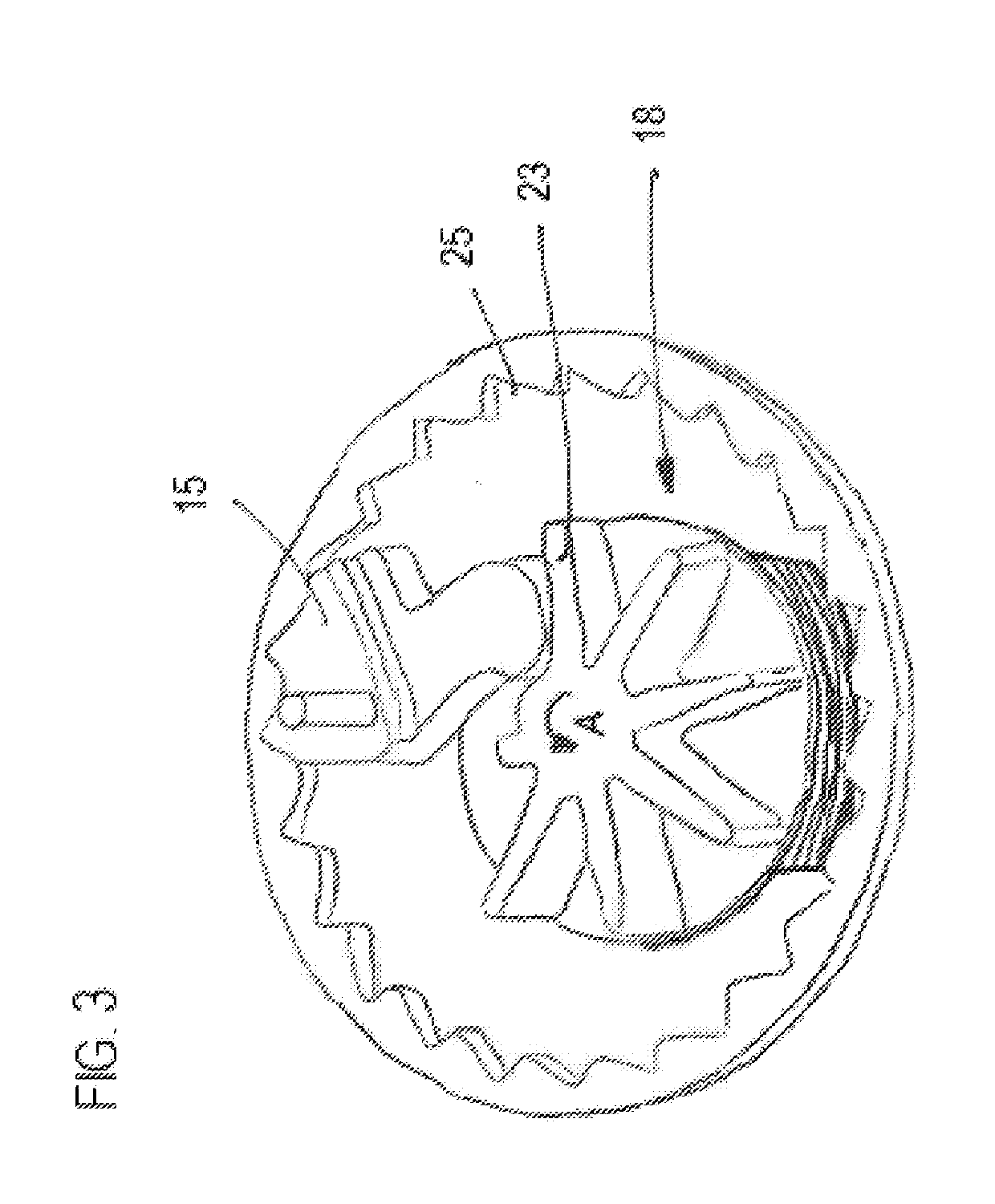

Motor for a fuel pump

InactiveUS20070108860A1Increase deformation resistanceInherent flame resistanceSynchronous generatorsWindingsElectric machineFuel pump

An electrically commutated motor for a fuel pump having a rotor connected to a shaft and having plastic-bonded ferrite, with a fuel-resistant shaped body formed by the plastic-bonded ferrite, and a magnetic return element adjustable in relation to the shaped body.

Owner:CONTINENTAL AUTOMOTIVE GMBH

Plug connector device with unlocking device

ActiveCN102195206ADiverse and variable application possibilitiesImprove legibilityCouplings bases/casesEngineeringElectrical and Electronics engineering

The present invention relates to a plug connector device (1) which is provided with a connector housing (2) that is used for accommodating at least one socket component (3,3.1), wherein, at least one socket component (3,3.1) is accommodated in the connector housing (2) through a locked mode. The plug connector device is also provided with an unlocking device (4) with an unlocking lever (5) for releasing the locked accommodation of at least one socket component (3,3.1) in the connector housing (2), wherein the unlocking lever (5) is pivotably provided on a wall (6) of the connector housing (2) so the wall (6) is at least partially deformable for releasing the locking between the socket component (3,3.1) and the connector housing (2) when the unlocking lever (5) is operated.

Owner:WAGO VERW GMBH

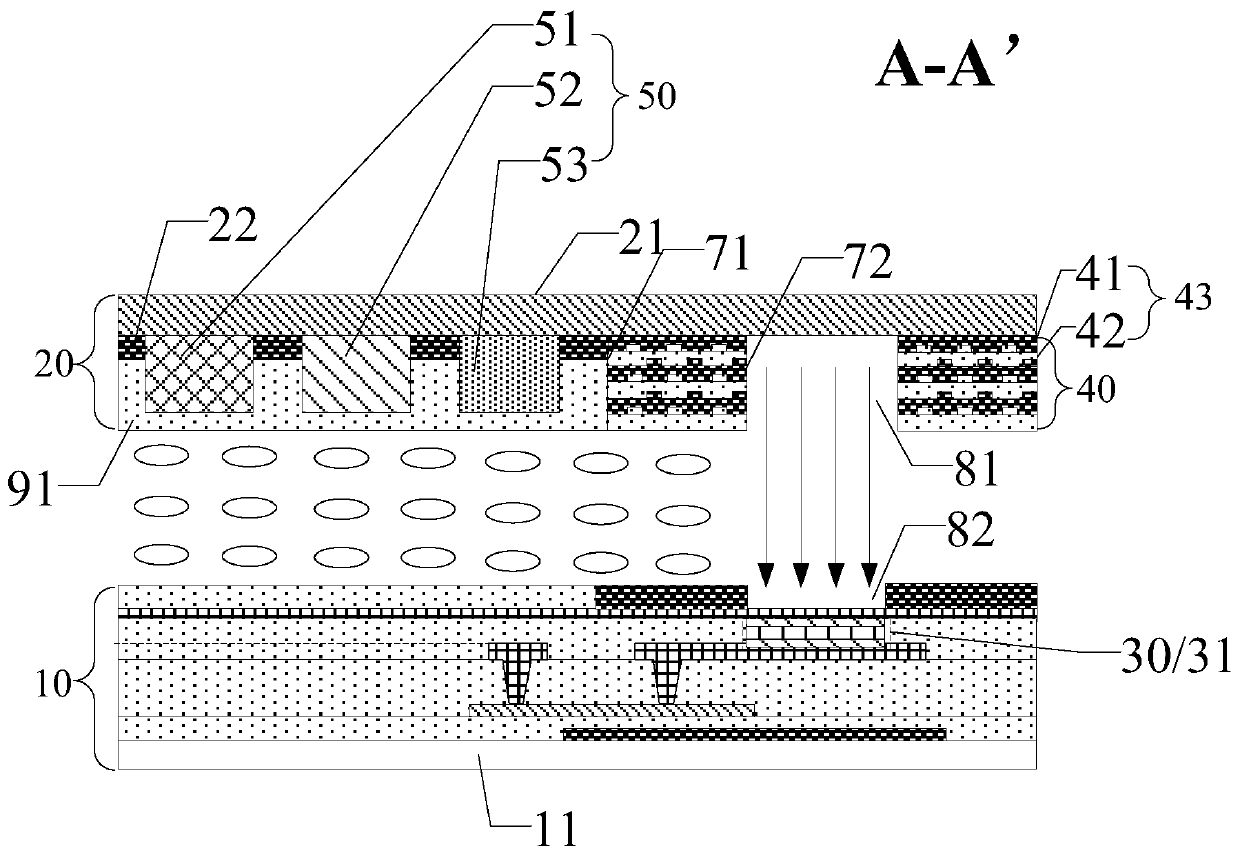

Display panel and display device

ActiveCN110928020AImprove production yieldHigh sensitivityPrint image acquisitionNon-linear opticsColor filmDisplay device

The invention discloses a display panel and a display device, and relates to the technical field of display. The display panel comprises an array substrate which comprises a first substrate; a color film substrate which comprises a second substrate, a first light-transmitting hole formed in one side, facing the array substrate, of the second substrate, and a shading part surrounding the first light-transmitting hole, the shading part comprises at least one group of sub shading parts, each sub shading part comprises a first shading layer and a first connecting layer in the direction perpendicular to the plane where the second substrate is located, the first connecting layers are located on the sides, away from the second substrate, of the first shading layers, and the surface, facing the first connecting layer, of the first shading layer and the surface, facing the first shading layer, of the first connecting layer are mutually wedged; and a fingerprint recognition unit which is locatedon one side, facing the color film substrate, of the first substrate, wherein the fingerprint identification unit comprises a plurality of photosensitive devices arranged in an array, and the orthographic projection of the photosensitive devices to the plane where the second substrate is located at least partially overlaps with the orthographic projection of the first light holes to the plane where the second substrate is located. The warping phenomenon of the film layer at the first light-transmitting hole can be improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Friction stir welding method and method of manufacturing hollow body

InactiveUS7721938B2Increase deformation resistanceVariation in joining qualityWelding/cutting auxillary devicesAuxillary welding devicesRelative motionIntermediate depth

A friction stir welding method in which a base having a recess, and a cover for fitting into and closing the opening of the recess are prepared. A stepped portion on the inner circumferential surface of the recess at an intermediate depth allows a peripheral portion of the cover to rest thereon. A cylindrical holder portion having a cooling-medium accommodation recess is formed integrally with the outer surface of the cover. The cover is fitted into the recess and placed on the stepped portion. A cooling medium is placed in the cooling-medium accommodation recess. A friction-stir-welding tool probe is plunged into a peripheral portion of the base around an opening of the recess and into a peripheral portion of the cover. During rotation of the probe, the base, and the cover, and the probe undergo relative movement, friction-stir-welding the base and the cover together.

Owner:SHOWA DENKO KK

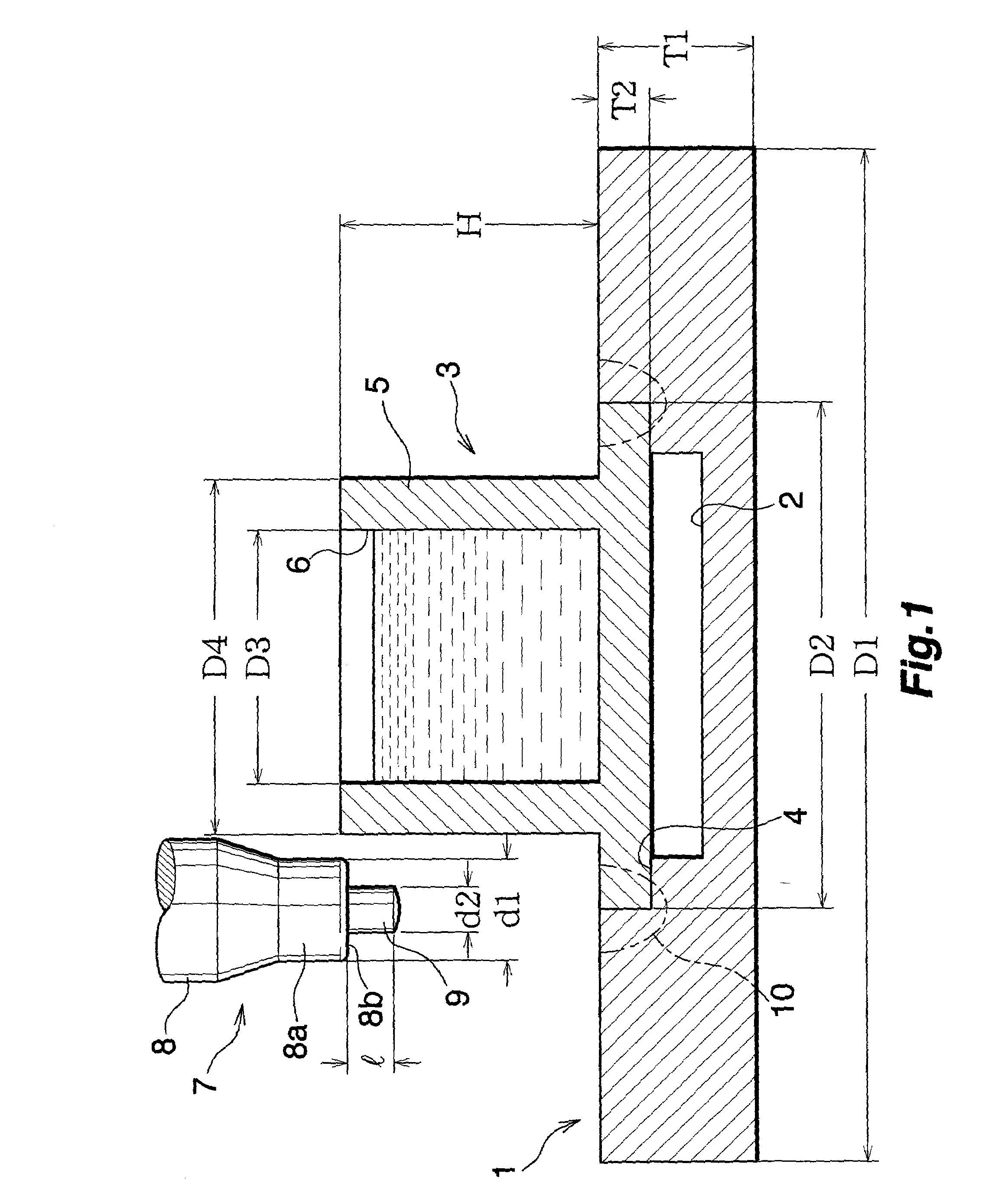

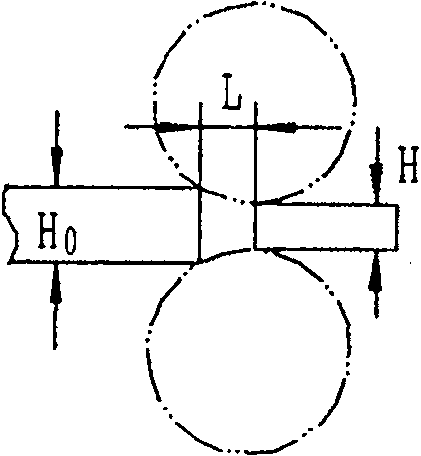

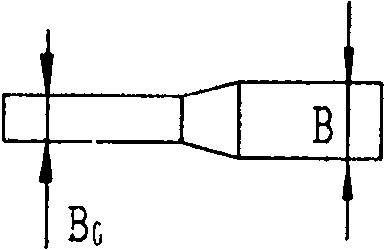

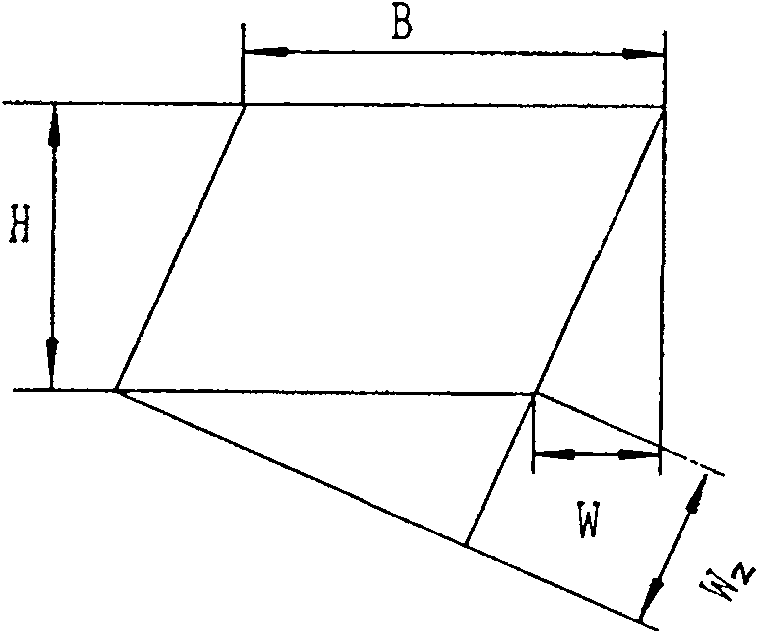

Plain-barreled roll rhomboidity rolling method

InactiveCN101176881AEasy to processEasy to manageGuiding/positioning/aligning arrangementsRoll mill control devicesSquare cross sectionDistortion

The invention relates to a plain-barreled roller skew rolling method, belonging to the steel rolling technical field, which aims to solve the molding rolling problem by adopting an unpunched plain-barreled roller rolling a workpiece. The invention uses continuous casting blank of square cross section as raw materials in two steps: a plain-barreled roller skew rolling step and a diamond-square hole rolling step. The invention adopts unpunched plain-barreled rolling in the step of the plain-barreled rolling; the skew degree of the workpiece is produced by controlling press distance and using inclined guide device through 4 to 8 pass rolling; the workpiece obtains a diamond-shaped cross section as the incremental skew degree. Then the diamond-square hole rolling step adopts diagonal square hole, diamond-shaped hole and diagonal square hole in sequence through three pass rolling, obtaining a workpiece of regular square cross section. The invention has the advantages that: the designing idea is quite the reverse of the present plain-barreled roller rolling method, skillfully utilizes the skew degree of the workpiece produced by the plain-barreled rolling and enables the workpiece to form a diamond-shaped cross section; then go to the diamond-square hole rolling step to produce the square steel. The invention resolves the difficult problem of the workpiece distortion and turnover in prior plain roller forming process.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Stable manufacturing method of aluminium-alloy medium-thickness plate

The invention discloses a stable manufacturing method of an aluminium-alloy medium-thickness plate and belongs to the technical field of aluminium alloy. The stable manufacturing method comprises thefollowing steps: (S1) preparation of aluminium-alloy molten liquid; (S2) preparation of an aluminium-alloy cast ingot; (S3) destressing treatment; (S4) sawing of the aluminium-alloy ingot; (S5) solution treatment; (S6) multidirectional forging; (S7) prestretching; (S8) ageing treatment to obtain the finished product. The stable manufacturing method disclosed by the invention has the beneficial effects that by adoption of a reasonable machining process, the comprehensive properties of ductility, strength of extension, yield strength and the like of the aluminium-alloy medium-thickness plate areimproved.

Owner:湖南恒佳新材料科技有限公司

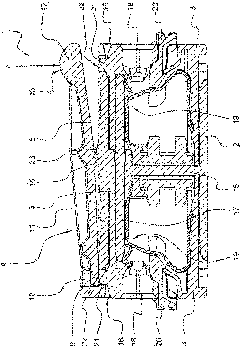

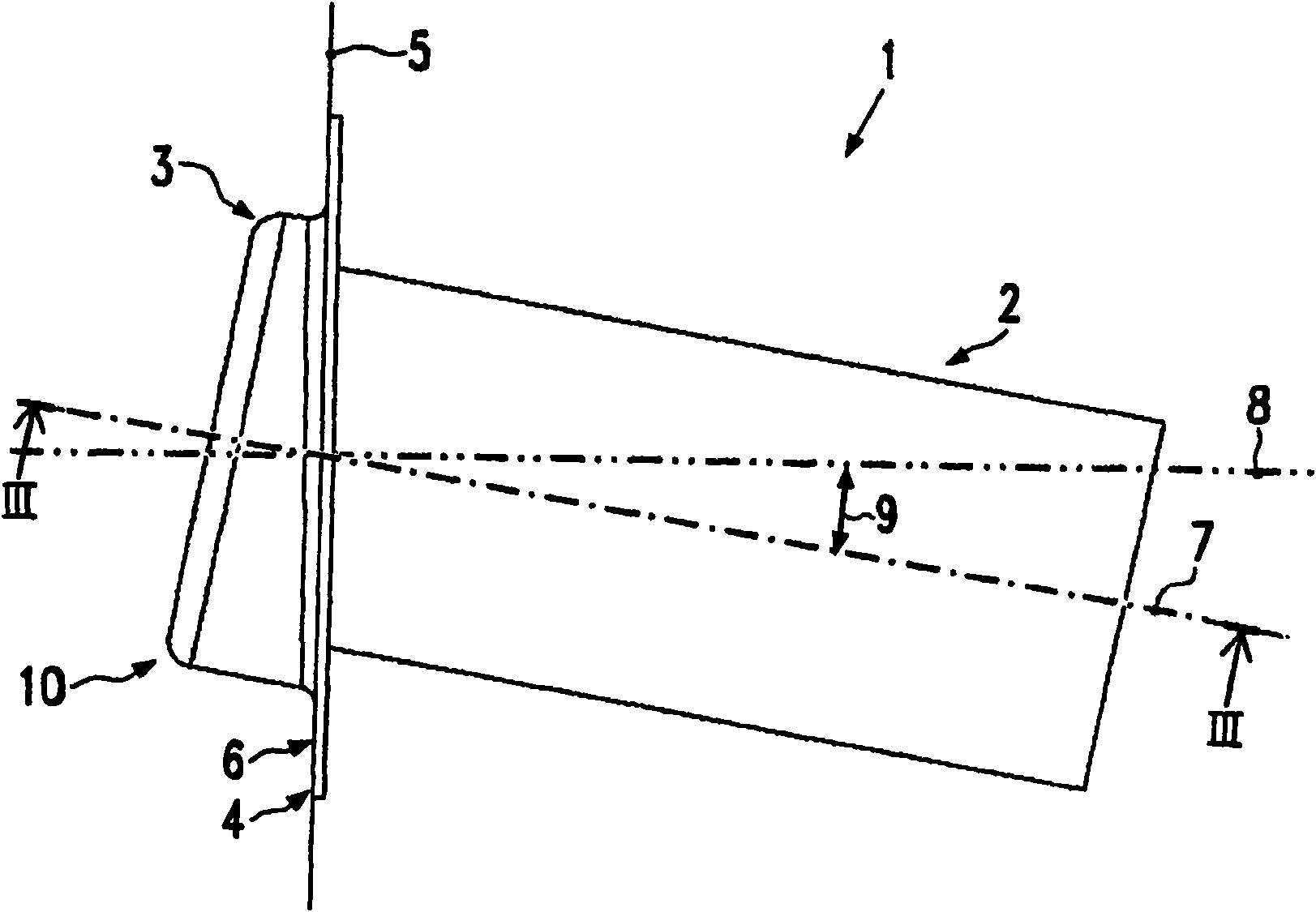

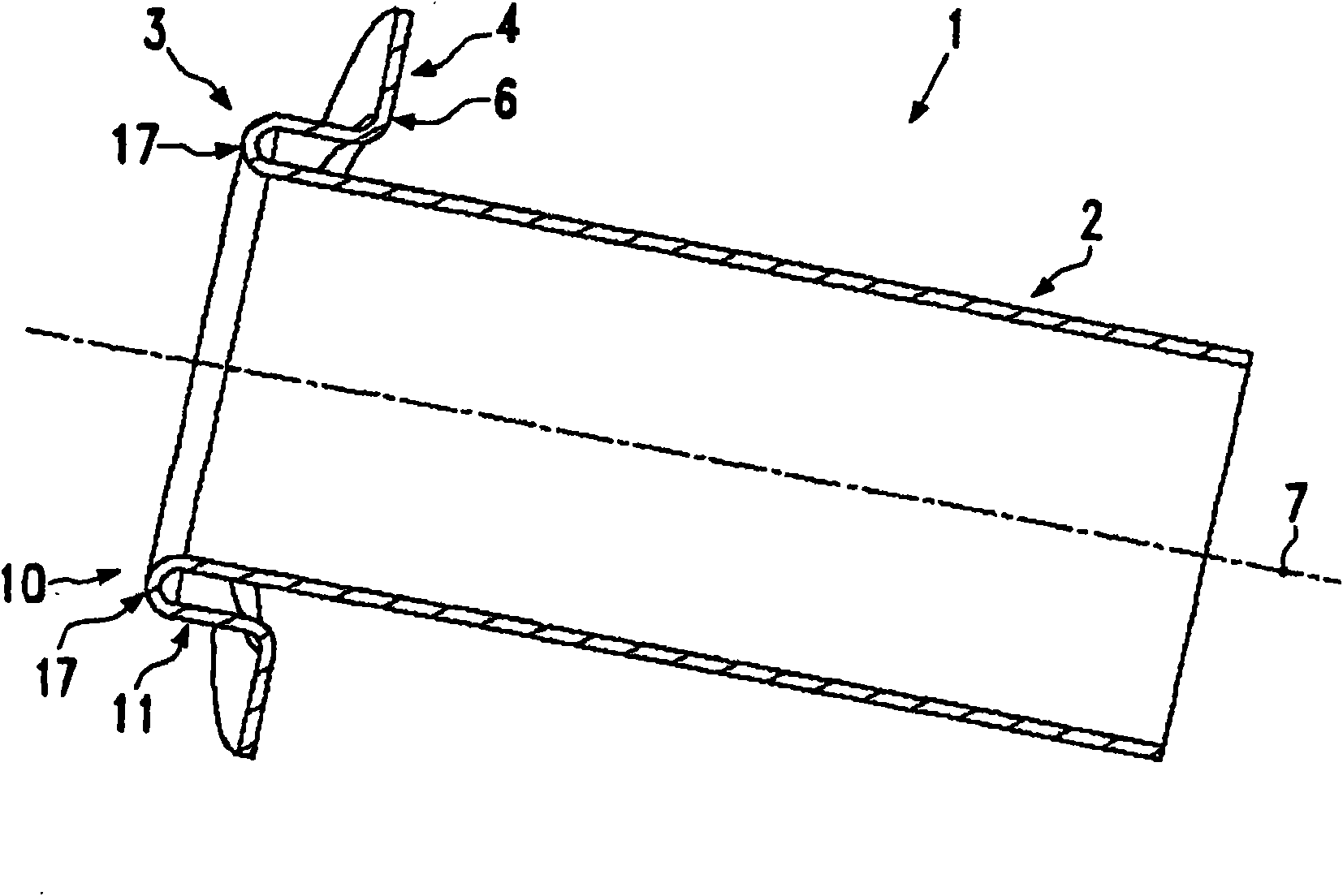

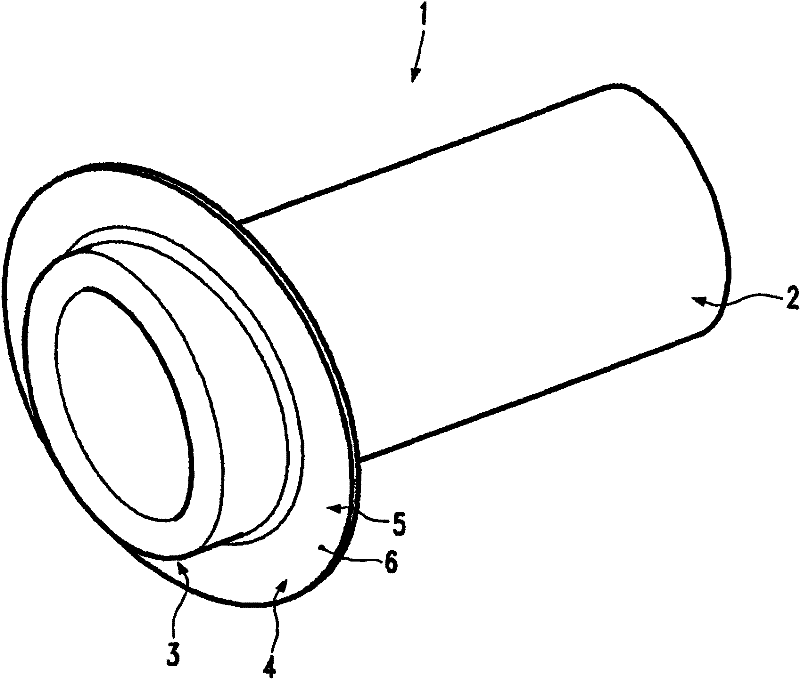

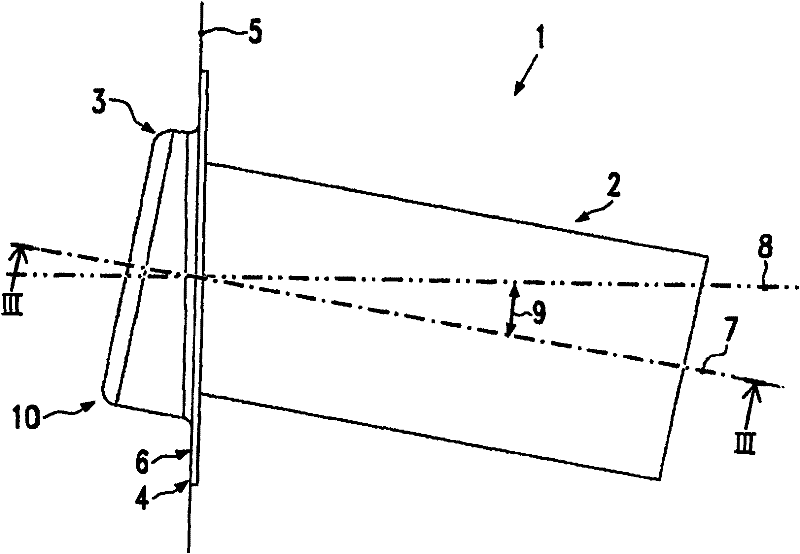

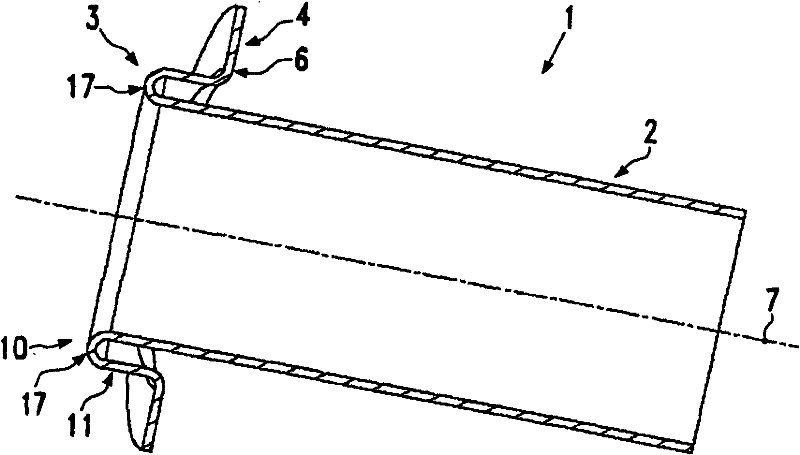

Energy absorption device

InactiveCN101610938AEasy transitionImprove stabilityElastic dampersBumpersEnergy absorptionEngineering

The present invention relates to an energy absorption device (1) for a bumper arrangement of a vehicle, with a hollow longitudinal section (2) intended for deformation, a rolled-back region (3) adjoining the hollow longitudinal section, and an extension section (4) connected to the rolled-back region. In order to improve an energy absorption device of this type to the extent that obliquely acting accident forces can be absorbed with a high degree of efficiency in as simple a manner as possible, it is proposed, in an initial state prior to energy absorption, to orient the hollow longitudinal section (2) obliquely with respect to the axial direction of the extension section (4).

Owner:COSMA ENG EURO AG

Method for preparing nylon composite modified by in-situ polymerization carbon nanotube

ActiveCN105669971AImprove mechanical propertiesImprove the lubrication effectIn situ polymerizationCarbon nanotube

The invention discloses a method for preparing a nylon composite modified by an in-situ polymerization carbon nanotube.According to the method, an MWCNTs-NH2 is prepared from the carbon nanotube, then a reaction with nylon salt is conducted, and the ammoniation multi-walled carbon nanotube composite is obtained.Compared with the prior art, the friction and wear performance, tensile strength and stability of the prepared composite are all greatly improved.

Owner:NANJING UNIV OF TECH

A kind of preparation method of in-situ polymerized carbon nanotube modified nylon composite material

ActiveCN105669971BImprove mechanical propertiesImprove the lubrication effectIn situ polymerizationCarbon nanotube

The invention discloses a method for preparing a nylon composite modified by an in-situ polymerization carbon nanotube.According to the method, an MWCNTs-NH2 is prepared from the carbon nanotube, then a reaction with nylon salt is conducted, and the ammoniation multi-walled carbon nanotube composite is obtained.Compared with the prior art, the friction and wear performance, tensile strength and stability of the prepared composite are all greatly improved.

Owner:NANJING TECH UNIV

Case-hardening steel excellent in cold forgeability and low carburization distortion property

Owner:NIPPON STEEL CORP

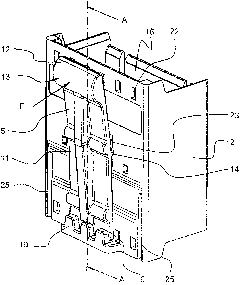

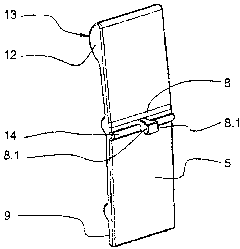

Self-locking belt retractor for a seat belt device of a motor vehicle

ActiveUS20190291687A1Serious injuryEnabling relative rotational movementBelt retractorsBelt anchoring devicesSeat beltEngineering

A self-locking belt retractor for a seat belt device of a motor vehicle with a belt shaft body and a profile head, and a blocking device with a blocking catch mounted on the profile head. When activated, the blocking device engages in a blocked position with a vehicle-affixed interlock for the purpose of blocking the belt shaft in the belt extension direction. A force-limiting device is disposed in the force transmission path from the belt shaft body to the blocking catch. The profile head is made as two parts, with a carrier component and an insert component which are affixed together. The insert component exhibits a higher resistance to deformation than the carrier component and, when the belt shaft is blocked, forms part of the force transmission path between the blocking catch and the force-limiting device.

Owner:AUTOLIV DEV AB

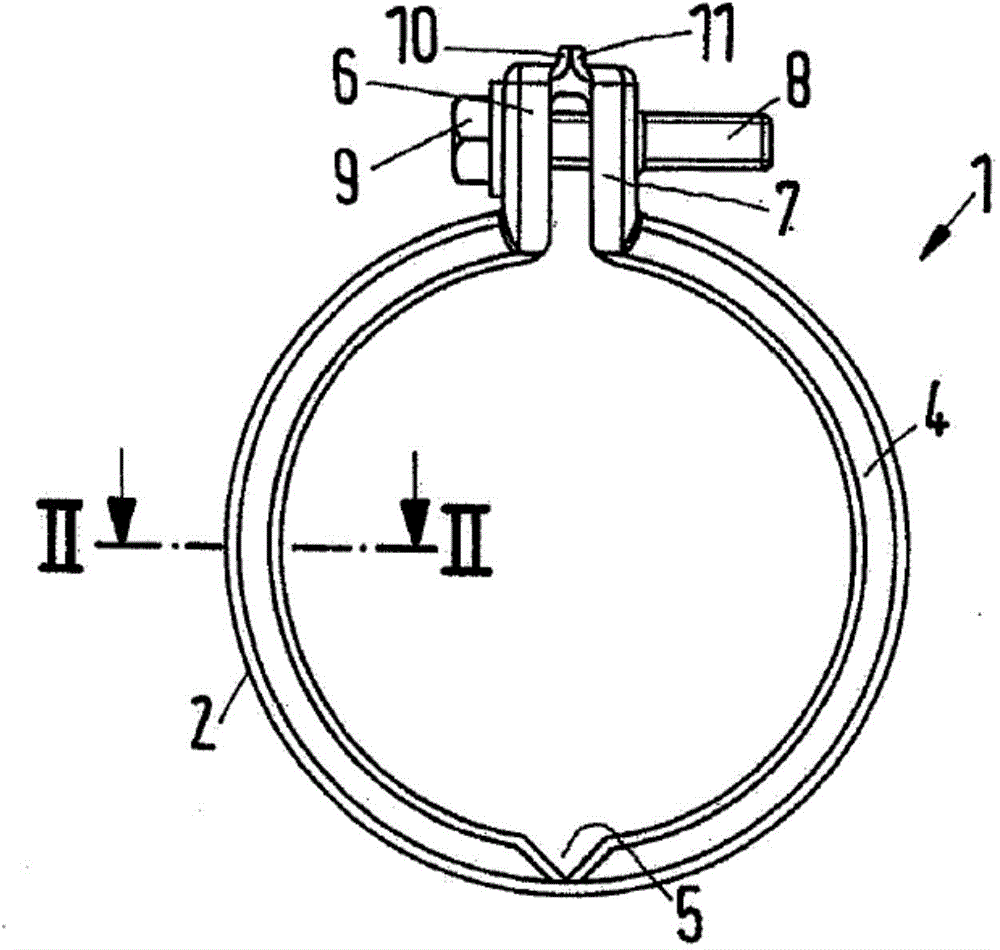

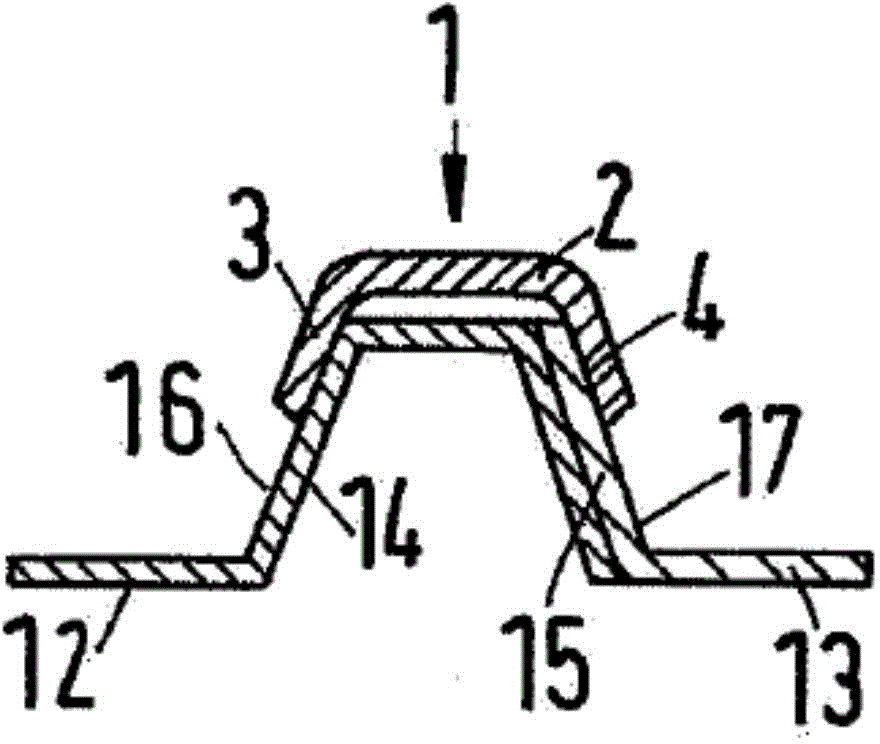

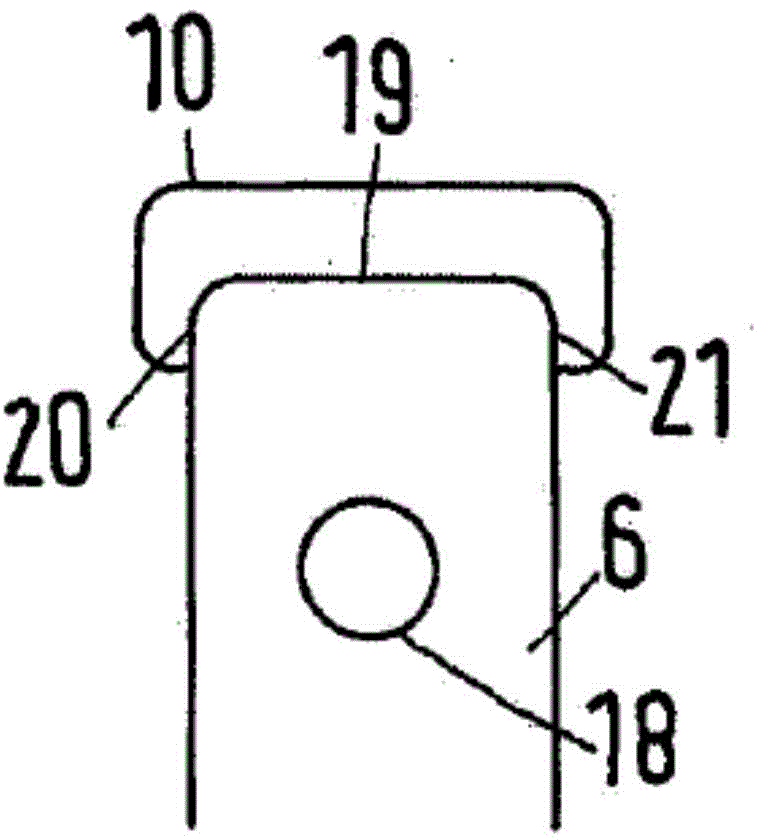

Profiled clamp

ActiveCN104930280AIncrease the lengthDifficulty bendingFlanged jointsRod connectionsMechanical engineering

Owner:NORMA GERMANY GMBH

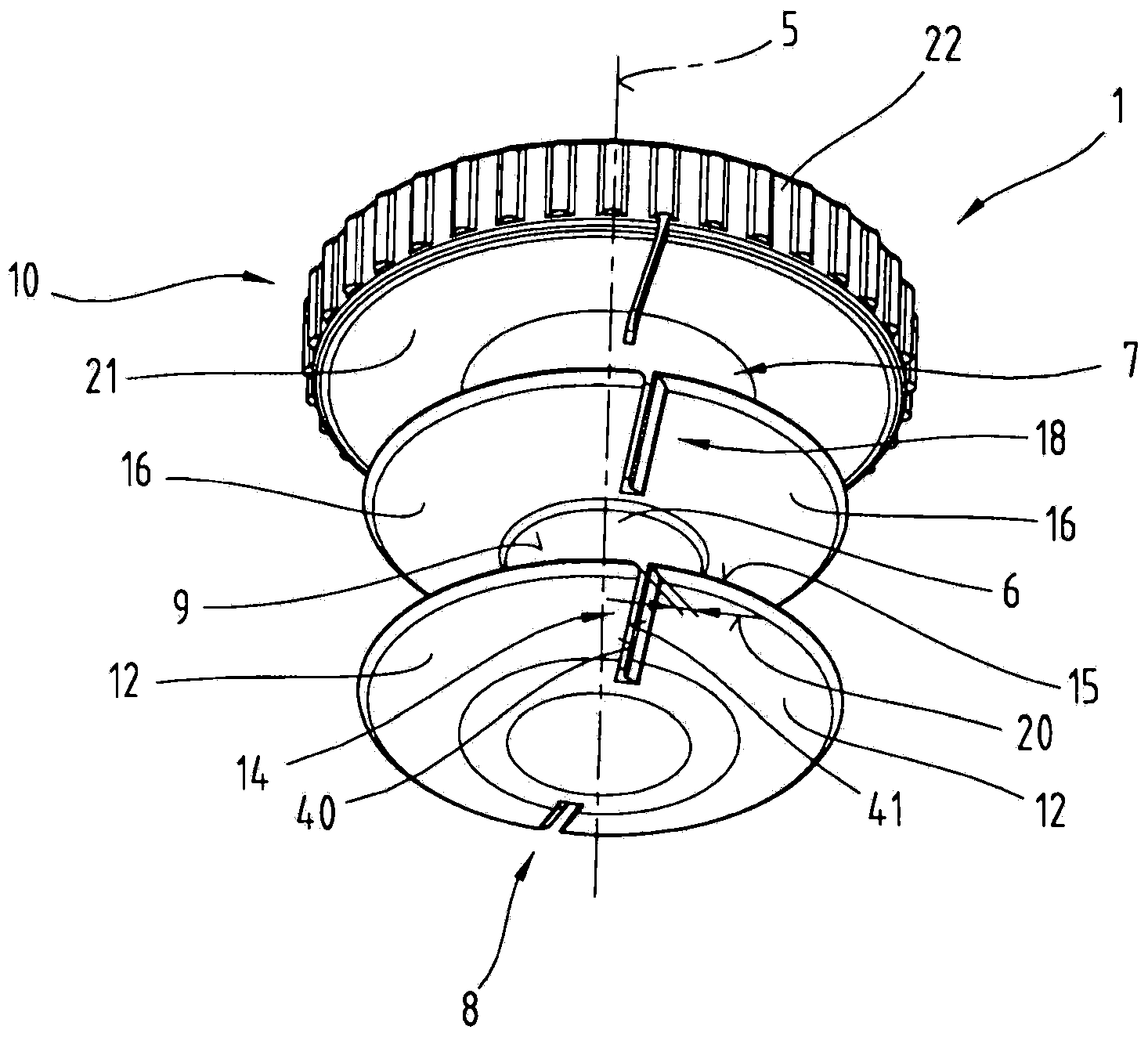

Universal closure device

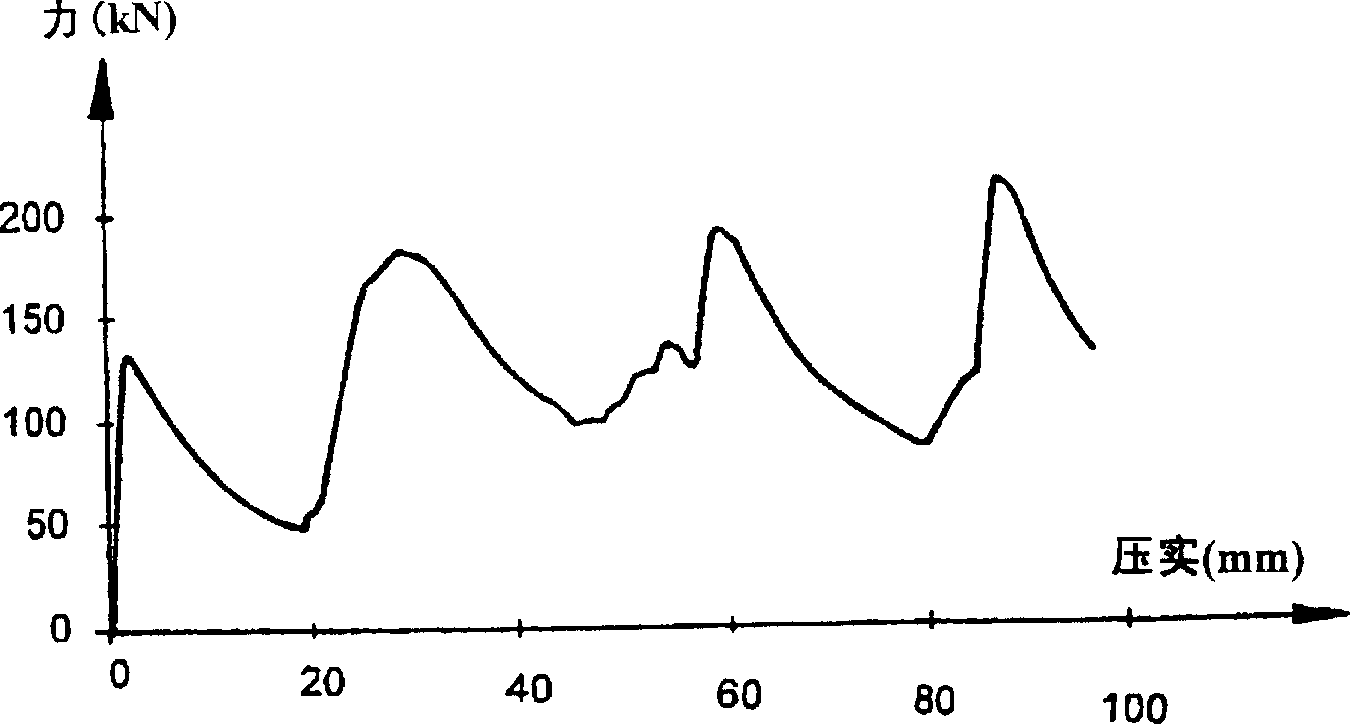

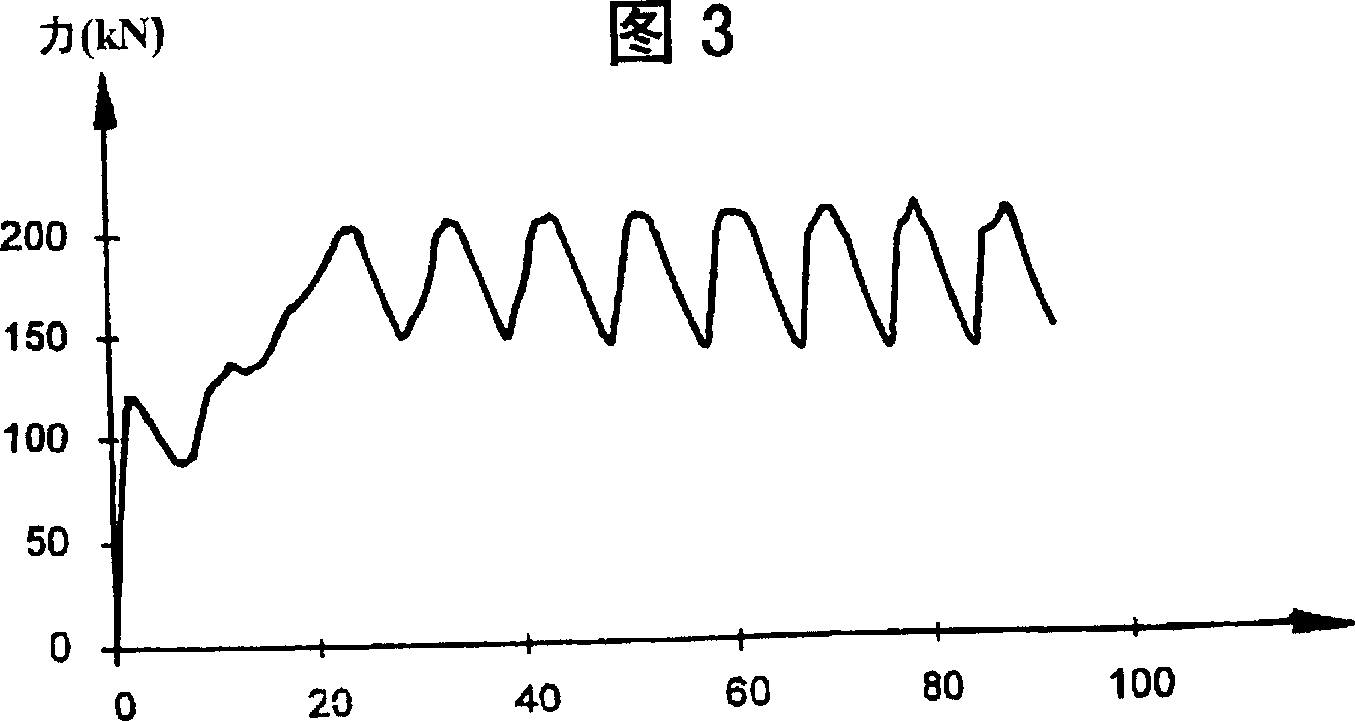

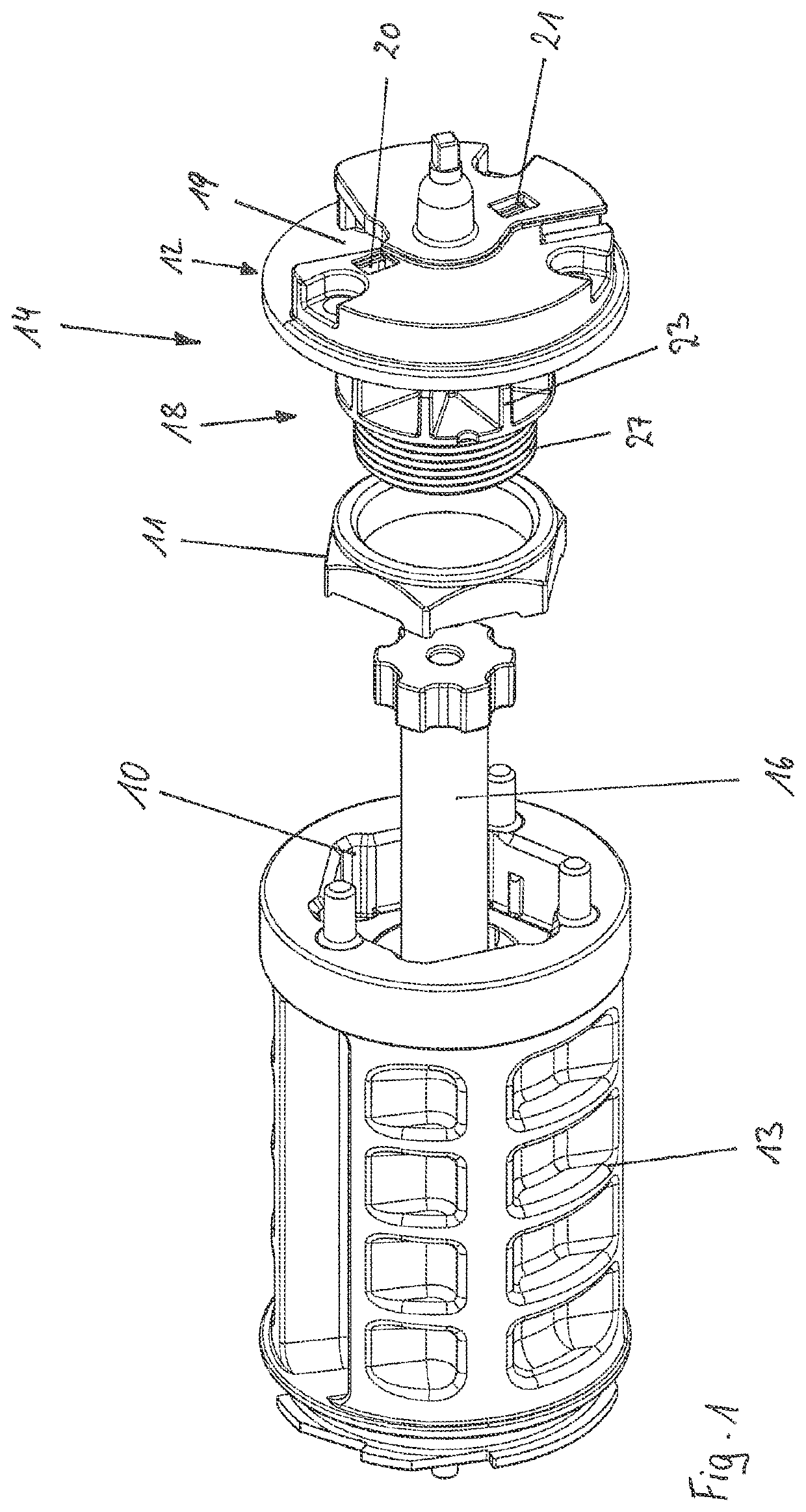

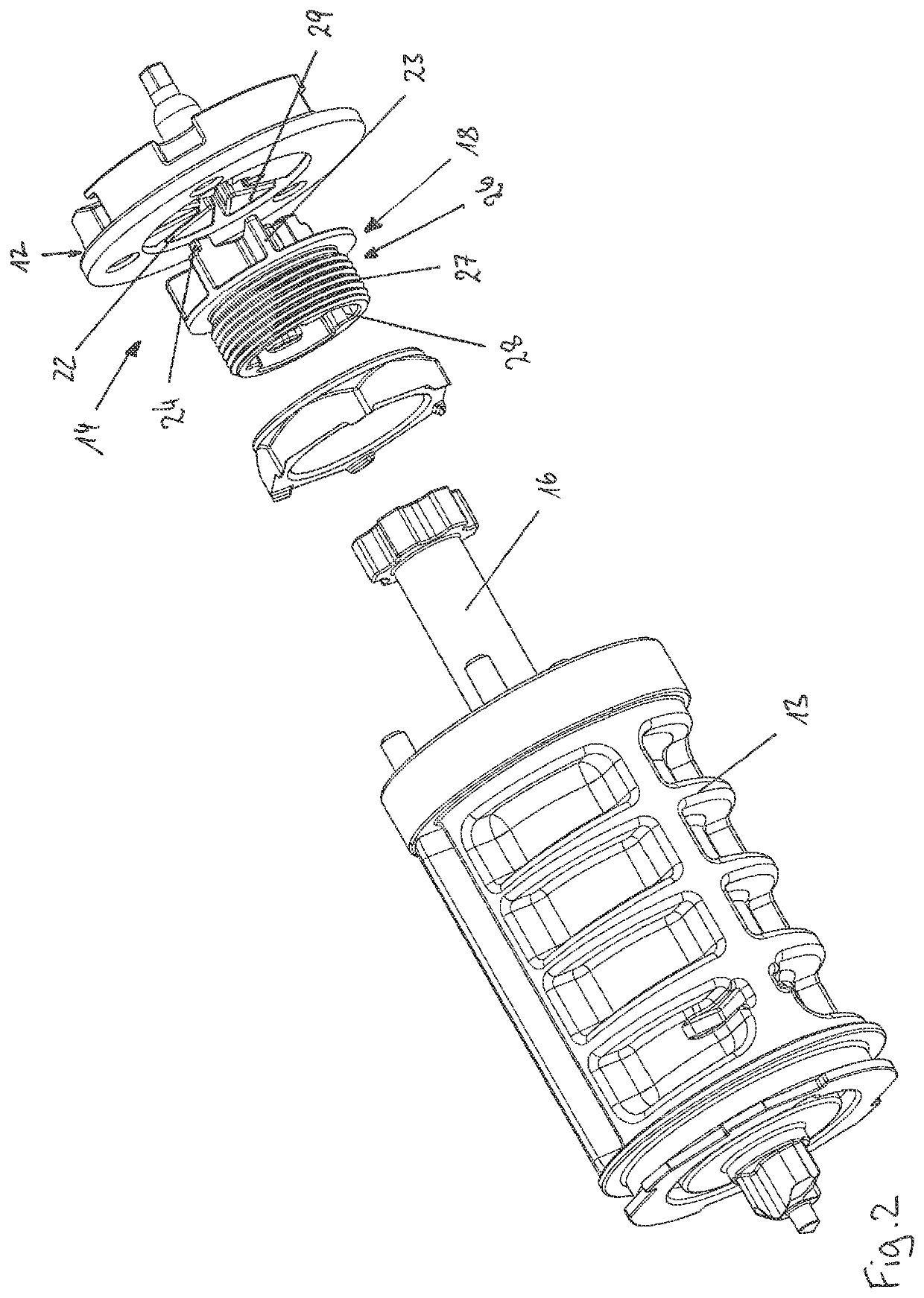

ActiveCN103415345AIncrease stiffnessPressure blockClosuresClosure using stoppersMechanical engineeringUniversal closure

Owner:STIWA HLDG

Bumper for a motor vehicle

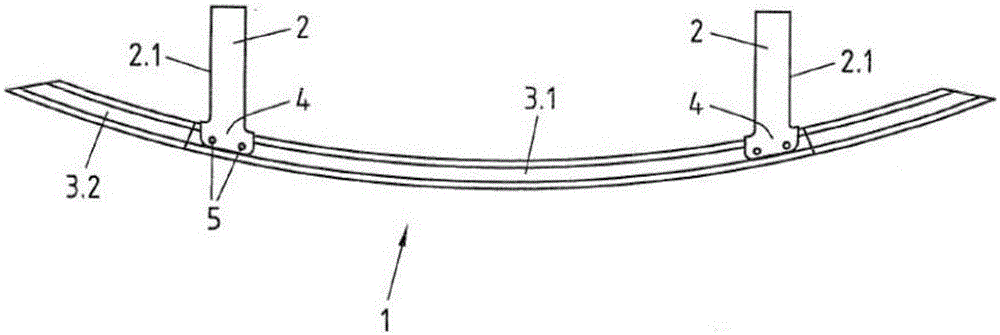

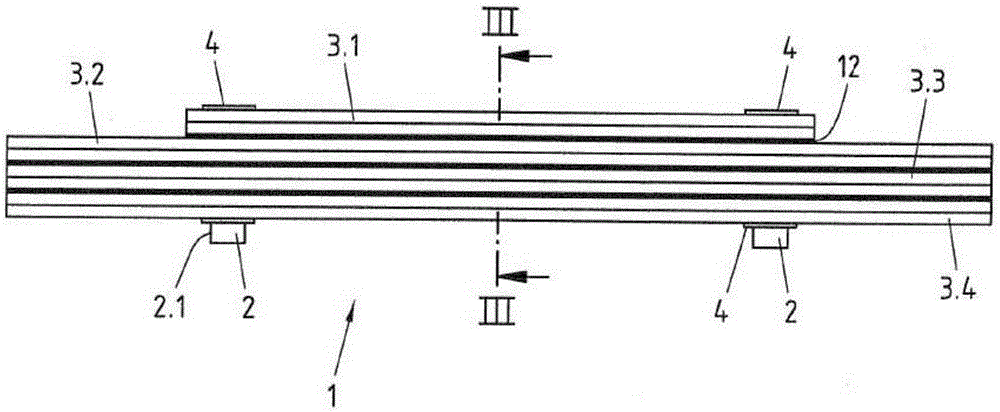

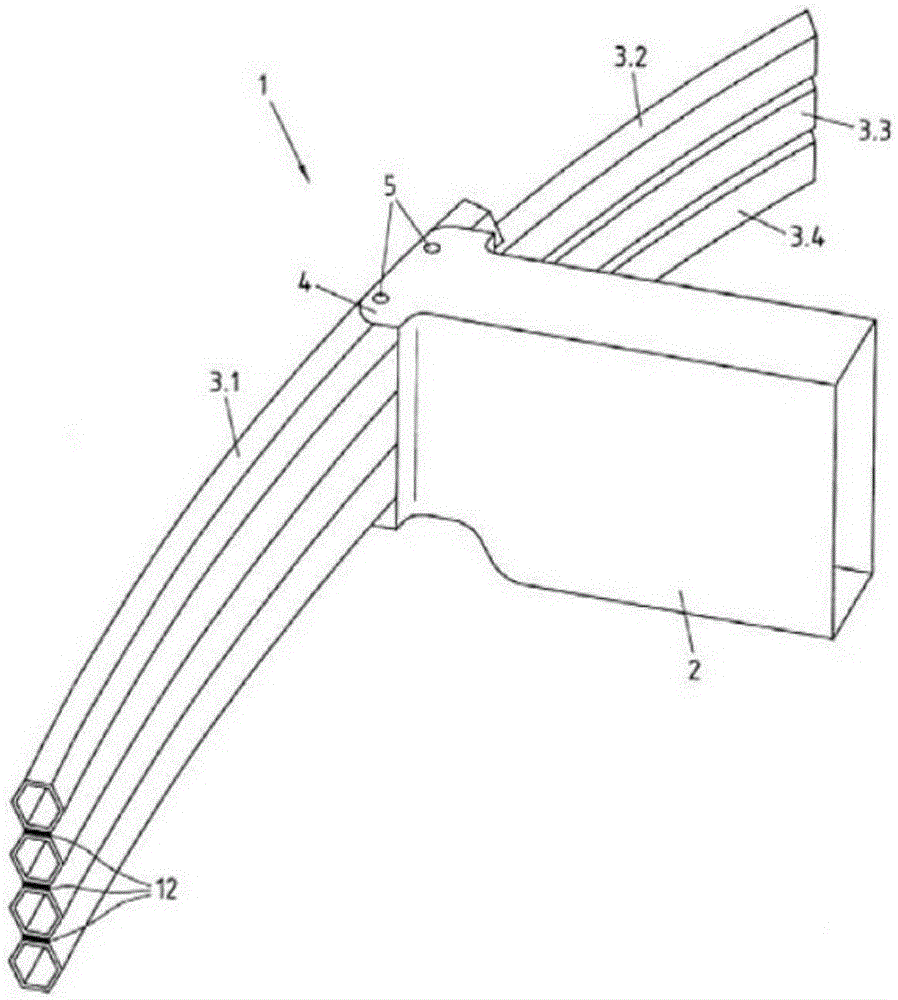

InactiveCN105142987AIncrease deformation resistanceReduce weightBumpersMotor vehicle partEngineering

The invention relates to a bumper (1) for a motor vehicle, particularly a front bumper, comprising at least two deformation elements (2) which are spaced apart from one another and whose central or longitudinal axes are aligned, when mounted, substantially parallel to the direction of travel of said motor vehicle, as well as a plurality of cross-members (3.1, 3.2, 3.3, 3.4) which have a closed profile and are arranged one above the other and connected to said deformation elements (2). In order for the bumper to provide relatively high resistance at a low weight such that in the event of a collision at speeds lower than 20 km / h, rearward displacement of the cross-member is limited in a targeted manner and movement of the bumper (1) upwards or downwards caused by the bumper of the other vehicle implicated in the collision is prohibited, said cross-members (3.1, 3.2, 3.3, 3.4) are formed from a group of at least three cross-members, each of these cross-members (3.1, 3.2, 3.3, 3.4) of the group having an at least five-cornered cross-sectional profile.

Owner:THYSSENKRUPP STEEL EURO AG

Manufacturing method of graphene composite aluminum wire-shaped materials

InactiveCN109609797ASuit one's needsGuaranteed to proceed normallyMetal rolling arrangementsIngotOxygen

The invention discloses a manufacturing method of graphene composite aluminum wire-shaped materials. The manufacturing method comprises the steps that nano-powder graphene is prepared; graphene nano powder bodies are mixed with aluminum powders, grinding and pressing into alloy ingots are carried out in an oxygen-free environment; firing and dehydrating of the alloy ingots are carried out; moltenpure aluminum is introduced into the alloy ingots, and graphene composite aluminum rods are obtained by continuous casting and rolling; and the graphene composite aluminum wire-shaped materials with different wire diameters are obtained by drawing the graphene composite aluminum rods. According to the manufacturing method of the graphene composite aluminum wire-shaped materials, the problem that graphene and aluminum are not mutually soluble is solved, the strength of a single wire is improved greatly, the repetition and magnify are easy and pollution-free.

Owner:SHANGHAI ZHONGTIAN ALUMINUM WIRE

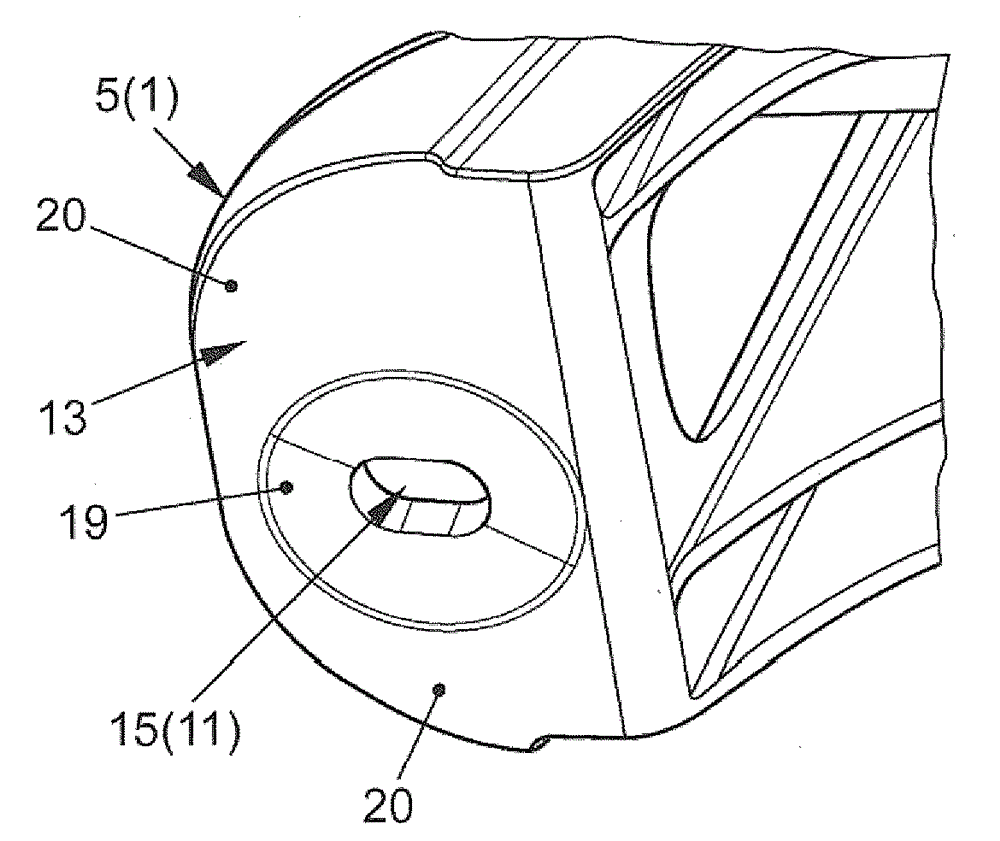

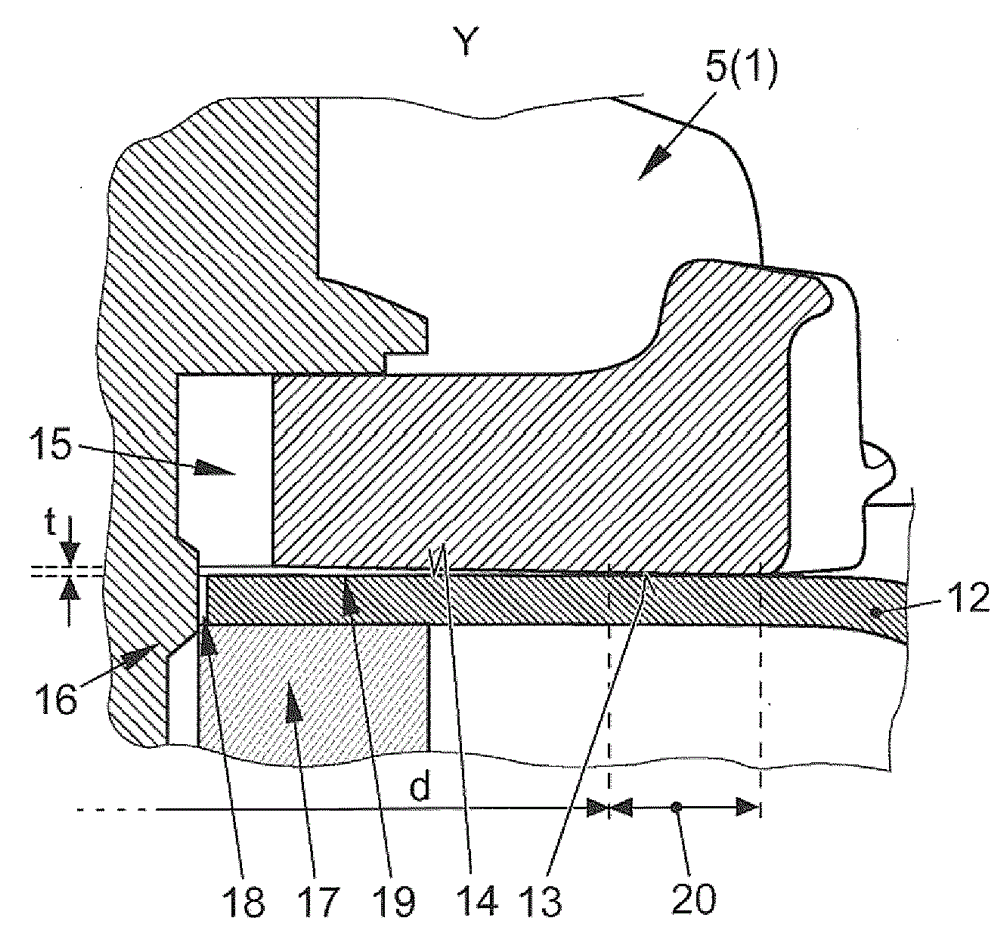

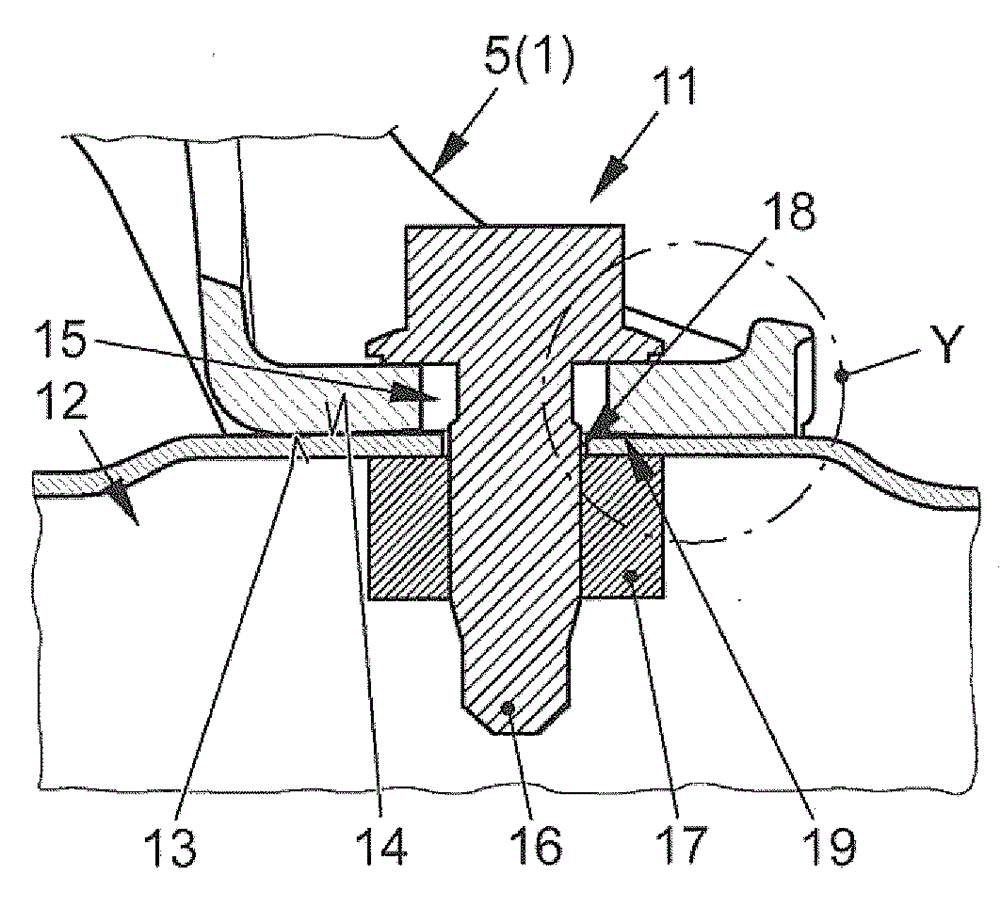

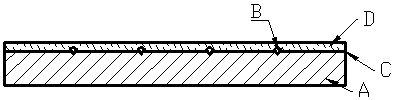

Bearing block for a handbrake lever

The invention relates to a bearing block (1) for a handbrake lever of a vehicle parking brake, comprising at least one fixing base (4, 5) or a mounting plate with a lower face that forms a screw-on surface (13), said bearing block (1) sitting on a support surface (14) of a supporting structure (12) by means of said screw-on surface. At least one fixing point (10, 11) with a through-bore (15) is provided in order to fix the bearing block (1) on the supporting structure (12), said through-bore being penetrated by a fixing screw (16), which corresponds to a nut (17) that is joined to the supporting structure (12) by a welding process, or by a threaded bolt, which is rigidly connected to the supporting structure (12) by means of a welding process. Advantageously, a concavity (19) or a recess into which the through-bore (15) is introduced is provided in the region of the at least one fixing point (10, 11) in the screw-on surface (13) of the at least one fixing base (4, 5) or of the mounting plate.

Owner:VOLKSWAGEN AG

Shock-preventive solar energy module capable of effectively preventing side frame oxide film from cracking

The invention discloses a shock-preventive solar energy module capable of effectively preventing a side frame oxide film from cracking. The shock-preventive solar energy module capable of effectively preventing the side frame oxide film from cracking comprises a side frame used for the solar energy module, wherein the side frame is manufactured from an aluminum alloy material; the aluminum alloy material comprises the following components in percentage by mass: 0.001 to 0.004% of C, 13.3 to 13.5% of Si, 0.21 to 0.23% of Fe, 0.12 to 0.14% of Cu, 0.11 to 0.13% of Zr, 0.02 to 0.04% of Ti, 0.001 to 0.002% of Ca, 0.003 to 0.005% of Hg, 0.13 to 0.15% of Pt, 0.22 to 0.24% of Pb, 0.01 to 0.03% of Cr, 0.42 to 0.46% of rare earth, 0.24 to 0.28% of assistant, and the balance Al.

Owner:RENESOLA JIANGSU LTD

Device for mutual support of two construction members

InactiveCN1093053CControl tension propertiesHigh swelling resistanceSpringsUnderground chambersClassical mechanicsStructural engineering

Owner:武尔夫·舒伯特 +1

Self-locking belt retractor for a seat belt device of a motor vehicle

ActiveUS10974691B2Enabling relative rotational movementIncrease deformation resistanceBelt retractorsBelt anchoring devicesSeat beltControl theory

A self-locking belt retractor for a seat belt device of a motor vehicle with a belt shaft body and a profile head, and a blocking device with a blocking catch mounted on the profile head. When activated, the blocking device engages in a blocked position with a vehicle-affixed interlock for the purpose of blocking the belt shaft in the belt extension direction. A force-limiting device is disposed in the force transmission path from the belt shaft body to the blocking catch. The profile head is made as two parts, with a carrier component and an insert component which are affixed together. The insert component exhibits a higher resistance to deformation than the carrier component and, when the belt shaft is blocked, forms part of the force transmission path between the blocking catch and the force-limiting device.

Owner:AUTOLIV DEV AB

Plain-barreled roll rhomboidity rolling method

InactiveCN100540164CEasy to processEasy to manageGuiding/positioning/aligning arrangementsRoll mill control devicesSquare cross sectionRoll forming

The invention relates to a flat roll off-square rolling method, which belongs to the technical field of steel rolling and is used to solve the problem of forming and rolling a rolled piece by using a non-perforated flat roll. It uses square section continuous casting slabs as raw materials, and consists of two steps: flat roll off-square rolling and diamond-square pass rolling. Measure and use the inclined guide device to make the rolled piece produce off-square amount. After 4 to 8 passes of rolling, the rolled piece forms a diamond-shaped section with the increase of off-square amount, and then enters the diamond-square pass rolling step. The pass rolling step adopts three passes of diagonal square pass, rhombus pass and diagonal square pass successively to obtain a rolled piece with regular square section. The design concept of the present invention is reversed from the existing flat roll rolling method, cleverly utilizing the off-square of the rolled piece in the flat roll rolling, so that the rolled piece forms a diamond-shaped section, and then enters the diamond-square pass to roll out square steel . The method successfully solves the problem of crooked and inverted steel in the rolled piece in the existing flat roll forming rolling technology.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

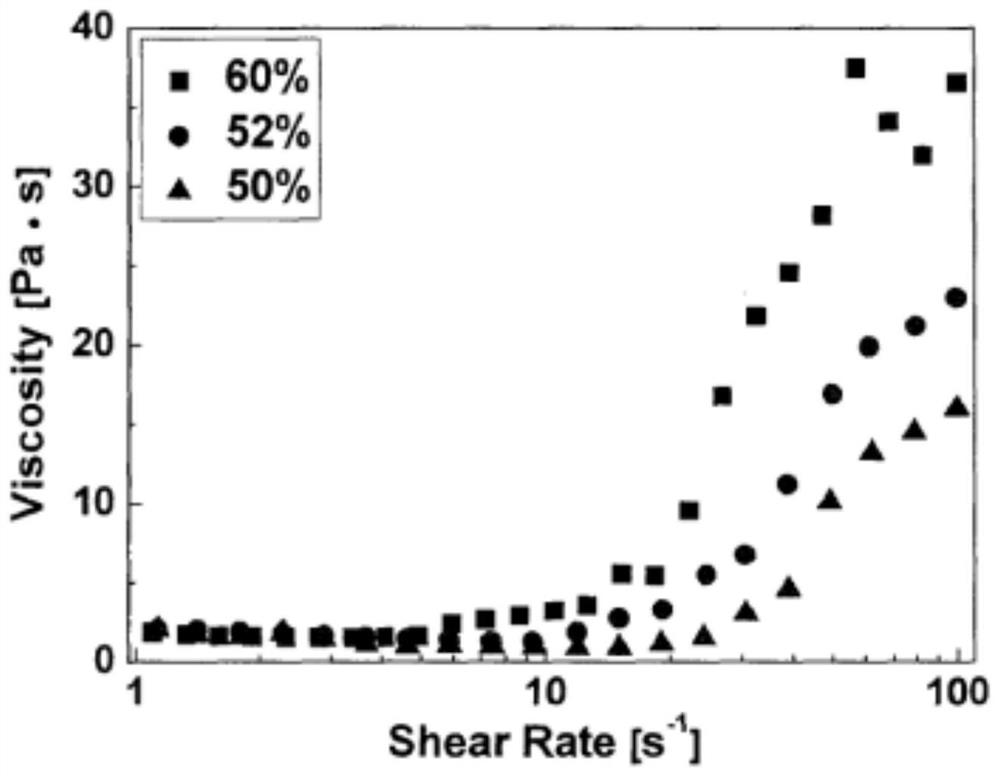

Vibration reduction foot pad, compressor and air conditioner

PendingCN113623180AImprove deformation resistanceAvoid excessive deformationPositive displacement pump componentsLighting and heating apparatusPhysicsVibration velocity

The invention provides a vibration reduction foot pad, a compressor and an air conditioner, relates to the technical field of vibration reduction parts, and aims to improve the safety of the compressor under large impact while giving consideration to the vibration reduction effect of the foot pad. The damping foot pad comprises an elastic main body, a containing cavity is formed in the elastic main body, and resistance increasing liquid is arranged in the containing cavity. When the vibration displacement of the vibration reduction foot pad exceeds a certain value, the deformation resistance of the elastic main body can be improved by extruding the resistance increasing liquid, and / or when the vibration speed of the vibration reduction foot pad exceeds a certain value, the deformation resistance of the elastic main body can be improved by increasing the viscosity of the resistance increasing liquid. According to the vibration reduction foot pad, the rigidity of the foot pad is passively controlled according to the vibration displacement and the vibration speed of the compressor under different working conditions, the vibration reduction performance of the compressor under the operation working condition is improved, and the requirements of the compressor for different performance parameters of the vibration reduction foot pad under different working scenes are met.

Owner:GREE ELECTRIC APPLIANCES INC

Energy absorption device

InactiveCN101610938BImprove stabilityIncrease deformation resistanceElastic dampersBumpersEnergy absorptionEngineering

The present invention relates to an energy absorption device (1) for a bumper arrangement of a vehicle, with a hollow longitudinal section (2) intended for deformation, a rolled-back region (3) adjoining the hollow longitudinal section, and an extension section (4) connected to the rolled-back region. In order to improve an energy absorption device of this type to the extent that obliquely actingaccident forces can be absorbed with a high degree of efficiency in as simple a manner as possible, it is proposed, in an initial state prior to energy absorption, to orient the hollow longitudinal section (2) obliquely with respect to the axial direction of the extension section (4).

Owner:COSMA ENG EURO AG

High-strength corrosion-resistant brass material and preparation method thereof

The invention discloses a high-strength corrosion-resistant brass material and a preparation method thereof. The brass material is prepared from the following components in percentage by mass: 60.9-64.2 percent of Cu, 0.85-1.3 percent of Si, 0.13-0.21 percent of Fe, 1.69-1.97 percent of Al, 0.71-1.58 percent of Ni, 0.1- 0.27 percent of Sn, 0.07-0.26 percent of Nd, 0.01-0.065 percent of Os, 0.03-0.12 percent of Ti, 1.1-2.25 percent of Mn, 0.01-0.07 percent of B and the balance of Zn and inevitable impurities. The preparation method for the high-strength corrosion-resistant brass material is simple in process, and the obtained brass material is high in strength and hardness, good in corrosion resistance and long in service life.

Owner:黄山市龙跃铜业有限公司

Preparation method of an erosion-resistant and wear-resistant iron-based composite coating

ActiveCN106591765BIncrease deformation resistancePrevent peelingMolten spray coatingArc welding apparatusWear resistantOxidation resistant

The invention discloses a preparation method of an erosive wear resistant iron-based composite coating. The method is characterized in that a non-melting argon tungsten-arc welding device and a supersonic arc spray painting device are utilized; the erosive wear resistant iron-based composite coating is prepared on the surface of a base material by first treatment of the surface of the base material, dividing of grids, preparing of a net-shaped cladding layer, secondary treatment of the surface of the base material, preparation of the composite coating, and other technological steps. The composite coating is high in capacity of combining with the base material, is high in density and oxidation resistance, and can bear high impact load, so that the base material can be protected; the composite coating can be used in severe environments such as high temperature environment or hot corrosion environment, and thus the service life of the base material can be prolonged.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com