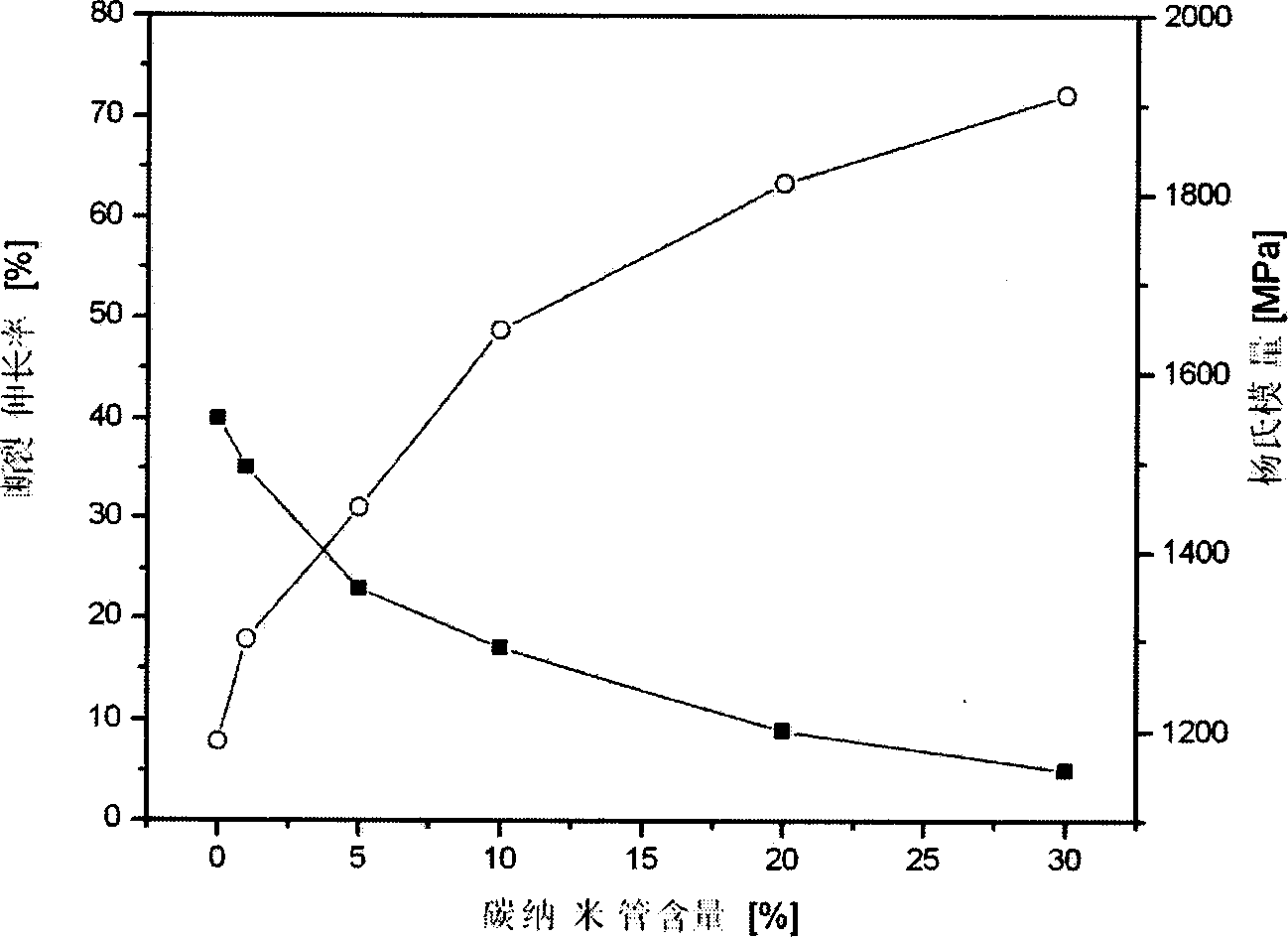

Method for preparing in-situ polycondensation enhanced carbon nanotube/nylon composite materials

A technology of nylon composite materials and carbon nanotubes, which is applied in the field of preparation of polymer composite materials, can solve problems such as poor stability and electrical properties, insufficient modulus and strength, poor rigidity and heat resistance, etc., to achieve Effects of improved tensile strength, strong mechanical properties, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Preparation of carbon nanotube / nylon 1010 composite material containing 1wt% carbon nanotube in situ polycondensation

[0022] (1) Using the single-walled carbon nanotubes prepared by catalytic pyrolysis as a raw material, add 0.7g of dry carbon nanotubes and 20ml of potassium permanganate-containing In sulfuric acid, where the concentration of sulfuric acid is 98wt%, the concentration of potassium permanganate in sulfuric acid is 5g / 100ml, heat up to 120°C after 30min with 40kHz ultrasonic treatment, stir and react under reflux for 24hr, use φ0.22μm polytetrafluoroethylene Suction filtration with a microporous membrane, repeated washing with deionized water to neutrality, and vacuum drying at 80°C for 24 hours to obtain 0.26 g of acidified carbon nanotubes;

[0023] (2) In a 100ml three-necked round bottom flask equipped with a mechanical stirrer, add 25g of nylon 1010 salt, then evacuate and fill with high-purity nitrogen. This process is repeated three tim...

Embodiment 2

[0024] Embodiment 2: Preparation of carbon nanotube / nylon 1010 composite material containing 2.5wt% carbon nanotube in situ polycondensation

[0025] (1) Using single-walled carbon nanotubes prepared by catalytic pyrolysis as raw material, add 1.75g of dry carbon nanotubes and 30mL of potassium permanganate-containing In sulfuric acid, the concentration of sulfuric acid is 98wt%, and the concentration of potassium permanganate in sulfuric acid is 4g / 100ml. After 50kHz ultrasonic treatment for 40min, heat to 120°C, stir and reflux for 48hr, and use φ0.22μm polytetrafluoroethylene Suction filtration with a microporous membrane, repeated washing with deionized water to neutrality, and vacuum drying at 80°C for 24 hours to obtain 0.64 g of acidified carbon nanotubes;

[0026] (2) In a 100ml three-necked round bottom flask equipped with a mechanical stirrer, add 25g of nylon 1010 salt, then evacuate and fill with high-purity nitrogen. This process is repeated three times to remov...

Embodiment 3

[0027] Example 3: Preparation of carbon nanotube / nylon 1010 composite material containing 5wt% carbon nanotube in situ polycondensation

[0028] (1) Using the multi-walled carbon nanotubes prepared by catalytic pyrolysis as a raw material, add 3.5g of dry carbon nanotubes and a mixed solution of 30ml of nitric acid and sulfuric acid in a 100ml single-neck round bottom flask equipped with a magnetic stirring rotor In, wherein the concentration of nitric acid is 60wt%, the concentration of sulfuric acid is 98wt%, the proportioning ratio of sulfuric acid and nitric acid is 1: 1ml / ml, heat up to 150 ℃ after 60min with 20kHz ultrasonic treatment, stir and react under reflux for 96hr, use φ0 .22 μm polytetrafluoroethylene microporous membrane filter, washed repeatedly with deionized water until neutral, vacuum dried at 80°C for 24 hours to obtain 1.4 g of acidified carbon nanotubes;

[0029] (2) In a 100ml three-necked round bottom flask equipped with a mechanical stirrer, add 25g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com