A kind of preparation method of in-situ polymerized carbon nanotube modified nylon composite material

A carbon nanotube modification and nylon composite material technology, applied in the field of modified nylon composite materials, can solve problems such as poor mechanical properties of nylon composite materials, and achieve the advantages of avoiding thermal degradation, increasing deformation resistance, and improving tensile strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] (1) Preparation of MWCNTs-COOH

[0038] Sonication with a strong oxidizing mixed acid introduced oxygen-containing groups at the ports or defect sites of MWCNTs. The specific method is: put 100mg MWCNTs in a strong oxidizing mixed acid solution, magnetically stir in a water bath at 60°C, and heat to reflux for 6h. After the reacted solution was centrifuged at 10000r / min for 10min, the supernatant was discarded, and the black solution in the lower layer was repeatedly washed with deionized water and suction filtered until the pH of the filtrate was 7-7.5; then the filter cake was vacuumed at 80°C After drying for 12 hours, the acidified multi-walled carbon nanotubes were obtained, which was recorded as: MWCNTs-COOH.

[0039] (2) MWCNTs-NH 2 preparation of

[0040]Weigh 50 mg of MWNTs-COOH, add it into 50 ml of toluene solution, and stir magnetically in an oil bath at 100 °C for 2 h. Weigh 0.2mL of EDA and toluene to make a 5mL solution, and weigh 1.5g of condensation...

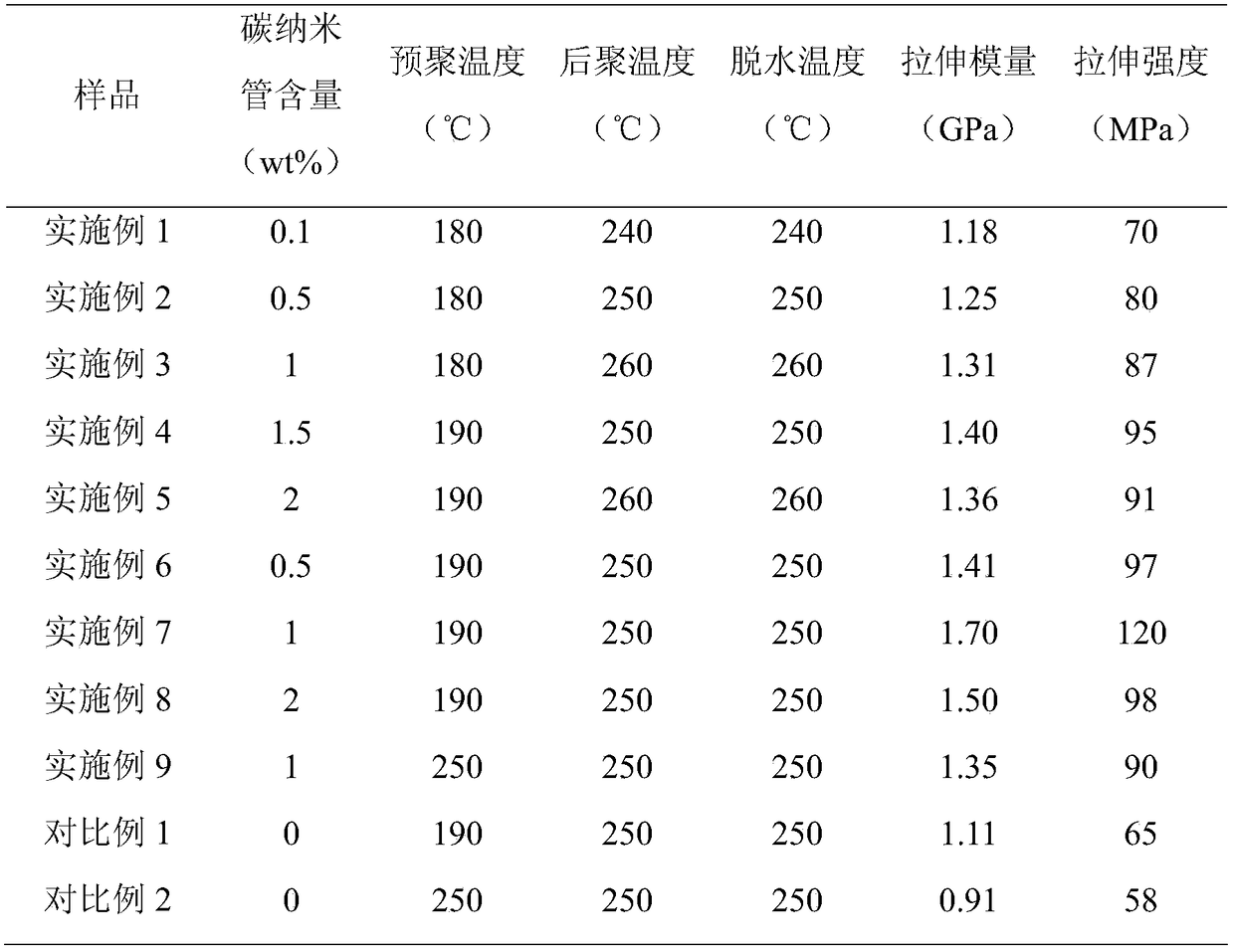

Embodiment 1

[0043] Embodiment 1: Preparation of a kind of in-situ polymerized carbon nanotube modified nylon 56 composite material containing 0.1wt%

[0044] Add 25g of nylon 56 salt into the autoclave, seal it, then vacuumize it, fill it with high-purity nitrogen, and repeat the pumping and ventilation three times to remove the moisture and air in the system, and then start heating to 180°C, that is, nylon 56 salt In a completely molten state, start the stirring device. After reacting for 1 hour, add ammoniated carbon nanotubes into the reaction system, wherein the weight of ammoniated carbon nanotubes is 25 mg; seal again, then vacuumize, fill with high-purity nitrogen, and pump Air exchange was repeated three times to remove moisture and air in the system, and the temperature was raised to 240°C for 4 hours of reaction, and then kept at 240°C for 0.5h in vacuum. In order to prevent nylon 56 from being oxidized at high temperature, antioxidants need to be added, the weight is 0.5g, and ...

Embodiment 2

[0045] Embodiment 2: Preparation of a kind of in-situ polymerized carbon nanotube modified nylon 56 composite material containing 0.5wt%

[0046] Add 25g of nylon 56 salt into the autoclave, seal it, then vacuumize it, fill it with high-purity nitrogen, and repeat the pumping and ventilation three times to remove the moisture and air in the system, and then start heating to 180°C, that is, nylon 56 salt Completely molten state, start the stirring device, react for 1 hour, then add ammoniated carbon nanotubes into the reaction system, wherein the weight of ammoniated carbon nanotubes is 0.132g; seal again, then vacuumize, and fill with high-purity nitrogen, Air pumping and ventilation were repeated three times to remove moisture and air in the system, and the temperature was raised to 250° C. for 4 hours, and then kept at 250° C. for 0.5 hours in vacuum. In order to prevent nylon 56 from being oxidized at high temperature, it is necessary to add an antioxidant with a weight of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com