Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

61results about How to "Improve Tangling Effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-resistant salt-tolerate graft polyacrylamide and preparation method thereof

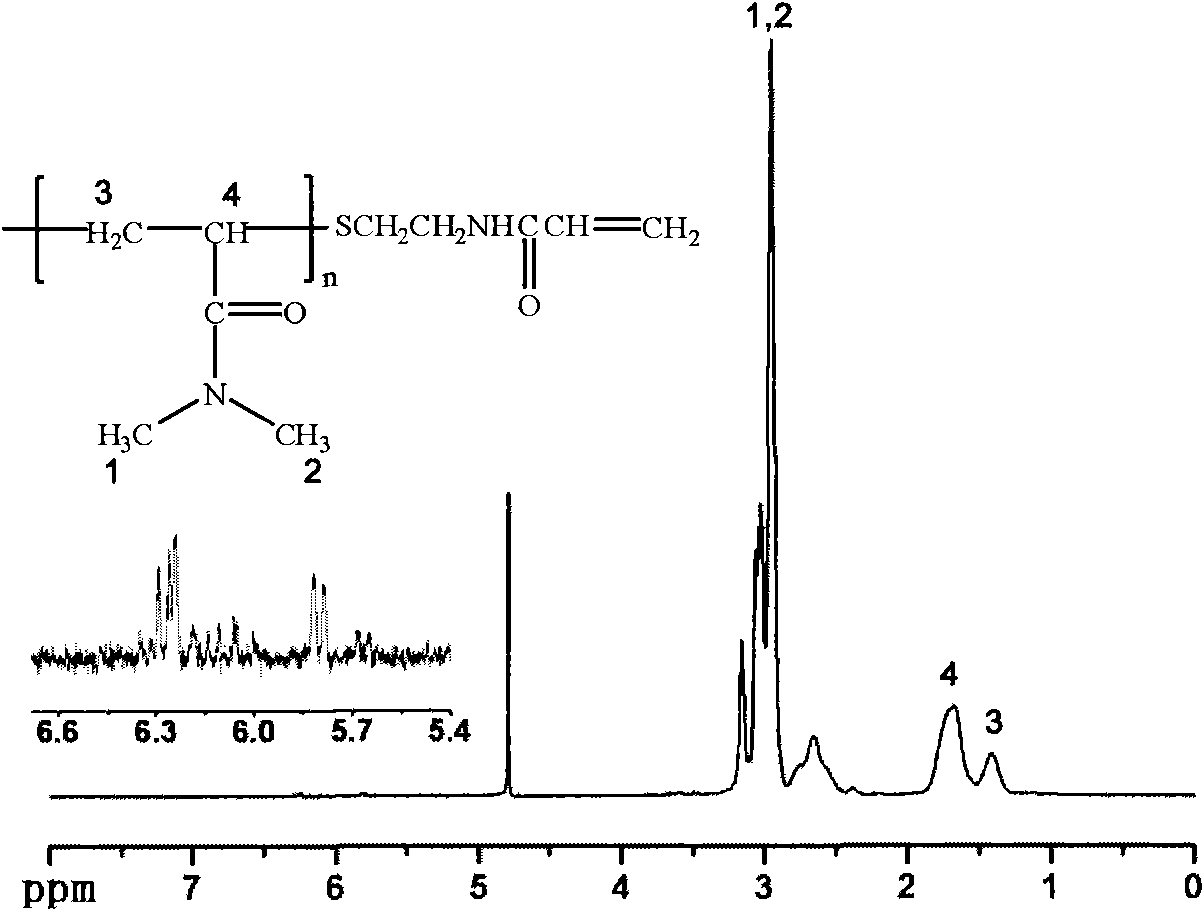

ActiveCN102050926AGood chemical stabilityReduce interfacial tensionDrilling compositionMethacrylamideSide chain

The invention belongs to the field of water-soluble flooding polymer study, particularly relates to a high-molecular-weight heat-resistant salt-tolerate graft polyacrylamide synthesized with macromolecule monomer route. The preparation method of the heat-resistant salt-tolerate graft polyacrylamide comprises obtaining poly(N-vinyl pyrrolidone)acrylamide macromolecule monomer through chain transfer free radical polymerization and terminal group replacement; and copolymerizing the macromolecule monomer with acrylamide, N-vinyl pyrrolidone, N,N-dimethylacrylamide, 2-acrylamido-2-methylpropanesulfonic acid or other heat-resistant salt-tolerate monomer in the present of an oxidation-reduction composite initiation system to obtain target product. The invention ensures the heat-resistant salt-tolerate performance of the copolymer from molecular design, and the functional long graft side chain can increase the viscoelasticity of polymer modules and reduce solution surface tension. The inventive product is used for type III oil reservoir, and provides a possible solution for increasing recovery efficiency of chemical flooding.

Owner:CHINA PETROLEUM & CHEM CORP +1

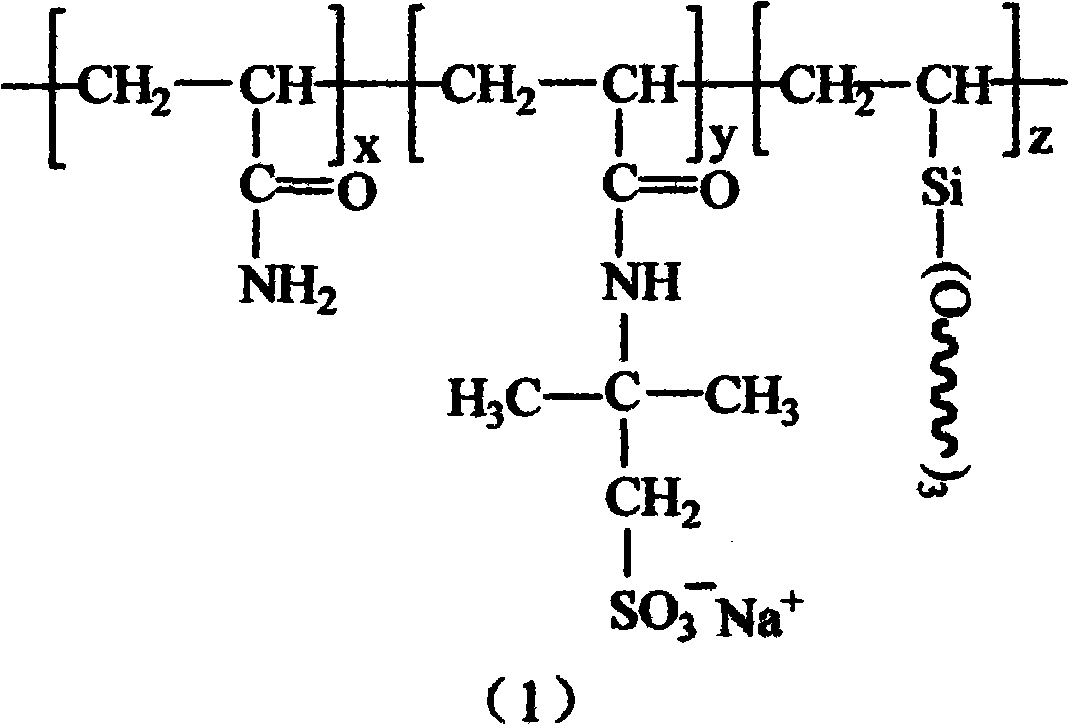

Long-branched chain polyacrylamide copolymer and preparation method thereof

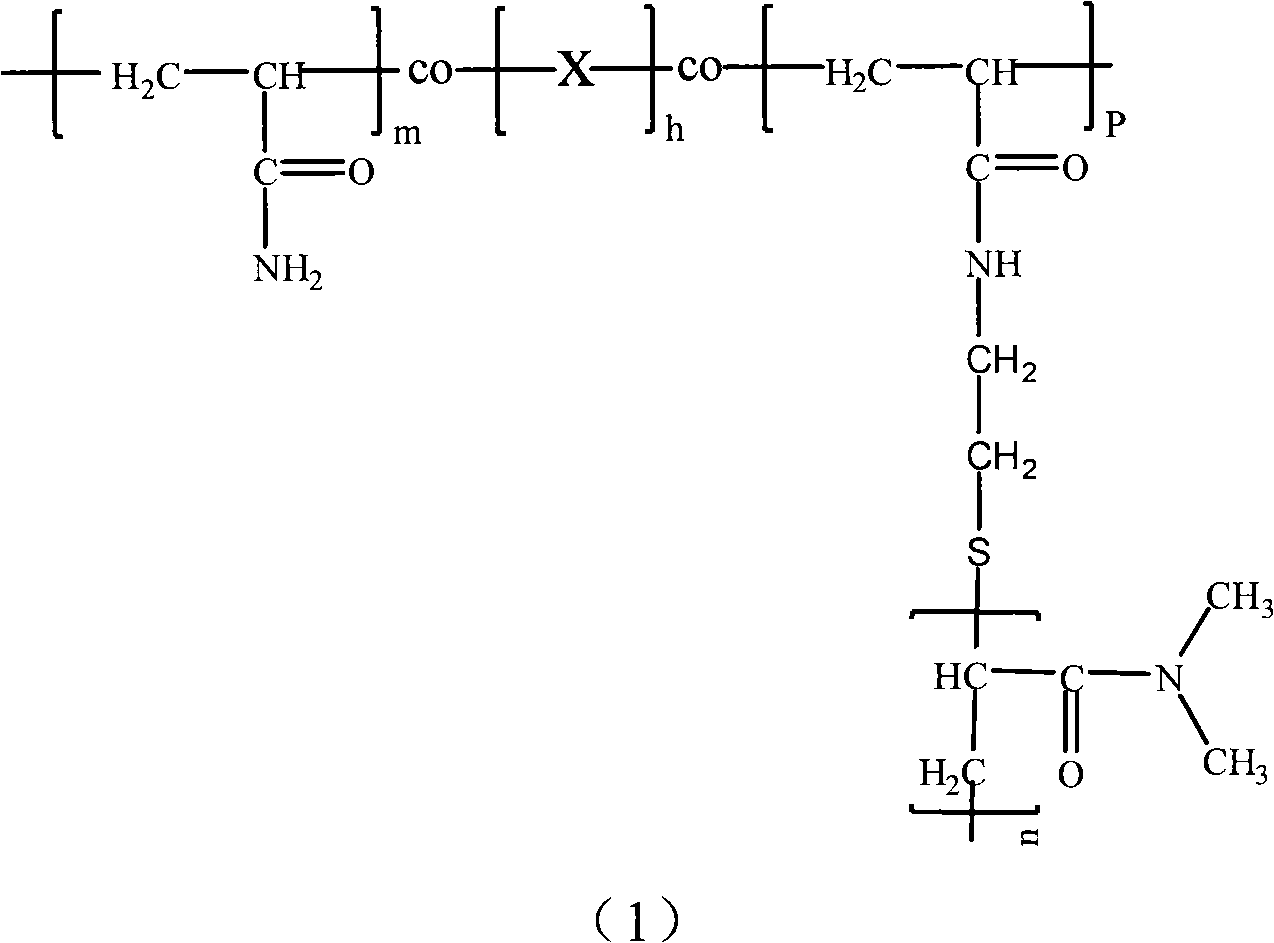

ActiveCN102382241AGood temperature and salt resistanceHigh viscoelasticityDrilling compositionSalt resistancePolymer science

The invention discloses a long-branched chain polyacrylamide copolymer. The structural formula of the long-branched chain polyacrylamide copolymer is shown as formula (1). An organic silicon monomer with temperature resistance and salt resistance is introduced into an acrylamide copolymer so as to improve the temperature resistance and salt resistance of polyacrylamide; the introduction of a long-branched chain organic silicon flexible chain greatly improves the entwisting capability of a polymer molecular chain so as to improve the viscoelasticity of the polymer for reducing the interface tension of a grafting copolymer solution and improve the affinity of displacing fluid and displaced fluid in practical use; and a copolymer main chain is formed by copolymerizing the organic silicon monomer, acrylamide and monomers with temperature resistance and salt resistance, such as 2-acrylamino-2-methy propanesulfonic acid, N-vinyl pyrrolidone, N,N-dimethyl acrylyl and the like, thereby ensuring the chemical stability of the main chain.

Owner:CHINA PETROLEUM & CHEM CORP +1

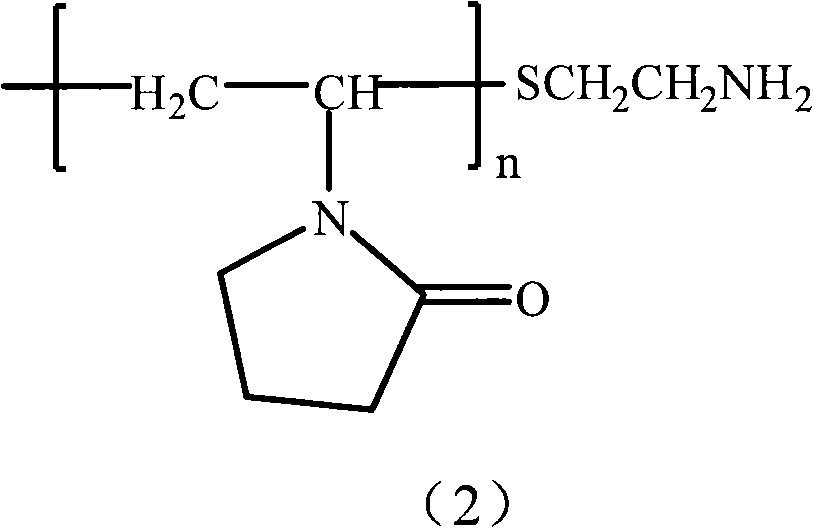

Temperature and salt resistant grafted polyacrylamide and preparation method thereof

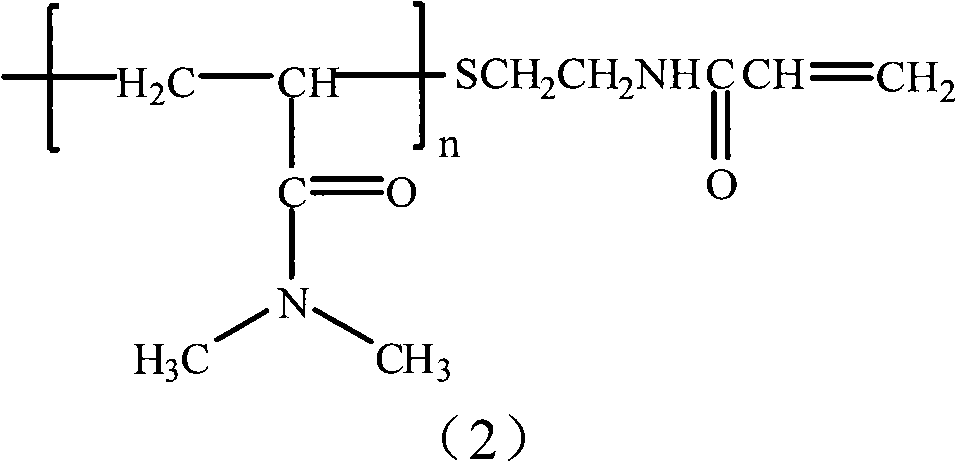

ActiveCN102050913AHigh monomer conversion rateGood temperature resistanceDrilling compositionMethacrylamideWater soluble polymers

The invention relates to a temperature and salt resistant grafted polyacrylamide synthesized by a macromonomer route, belonging to the research field of water-soluble polymer used for displacement of reservoir oil. A method of chain transfer free radical polymerization and terminal group replacement is adopted to obtain a polyacrylamide (N,N-dimethylacrylamide) type macromonomer. Under an oxidation-reduction complex initiation system, temperature and salt resistant monomers, such as the macromonomer, acrylamide, N-polyvinyl pyrrolidone, N,N-dimethylacrylamide, 2-Acryloylamino-2-methyl propanesulfonic acid and the like, are copolymerized to obtain a target product. From molecular design, a functional long-grafted side chain can increase the viscoelasticity of the polymer molecule and lower solution surface tension. The product provided by the invention can be used for three-class oil deposit and provides a possible solution for improving the recovery ratio for chemical displacement of reservoir oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for producing spunlaced composite high-performance polyphenylene sulfide fiber filtering material

InactiveCN101550634AHigh strengthHigh strength retentionFiltration separationNon-woven fabricsFiberSulfide

The invention relates to a process for producing spunlaced composite high-performance polyphenylene sulfide fiber filtering material, belongs to the fibrous raw material textile production technology field. The process uses polyphenylene sulfide fiber as raw material, has the following steps: processing raw material by checking, weighing, feeding, feeding into long certain, mixing cotton and fine loosing; layering and carding respectively by a first carding machine and a second carding machine; putting respectively into mesh placing machine for placing mesh; debatching, congruent, superposing and prewetting; spunlacing by a plurality of spunlacing machine, dewatering, drying and reeling. The advantages of the invention is that: the invention adopts polyphenylene sulfide high-performance fiber as raw material, the raw material is adapted to high efficient high speed carding production for its self physical and chemical properties, structure and adaptability to meshing and reinforcing process; improves spunlacing entanglement effect to fiber; improves the mechanical strength of spunlaced composite filtering material significantly, and ensures the end product to achieve excellent mechanical properties, filtering quality and chemical resistance property.

Owner:SHAOXING RONGLIDA TEXTILE TECH

Blend of PPC, PBAT, PCL and PLA and preparation method thereof

InactiveCN101724242ATough and strongGood flexibilityPrecipitated calcium carbonatePhysical chemistry

The invention relates to a blend of PPC, PBAT, PCL and PLA and a preparation method thereof. The blend consists of PPC, PBAT, PCL, PLA, an end-capping reagent, a lubricating agent and modified precipitated calcium carbonate. The preparation method comprises the following steps of: carrying out cold mixing on the PPC, the PBAT, the PCL, the PLA, the end-capping reagent, the lubricating agent and the modified precipitated calcium carbonate in a high-speed stirrer at the temperature not above 35 DEG C; and extruding and granulating cold mixing materials by a screw extruder, wherein the temperature of extruding and granulating is not more than 200 DEG C. With simple process method and common equipment, the invention is especially suitable for industrial production; meanwhile, the used materials are simple and easily obtained and can also be purchased in the market; the temperature of pastiness caking blocks of the blend processed by the method is greatly improved in comparison with pure PPC and the mechanical property of the blend is greatly improved in comparison with the pure PPC; and the blend widens the application range of the pure PPC and can be completely biodegraded.

Owner:INNER MONGOLIA MENG XI HIGH TECH GRP CO LTD

Production technology of high-strength and anti-wrinkle spunlace non-woven fabric

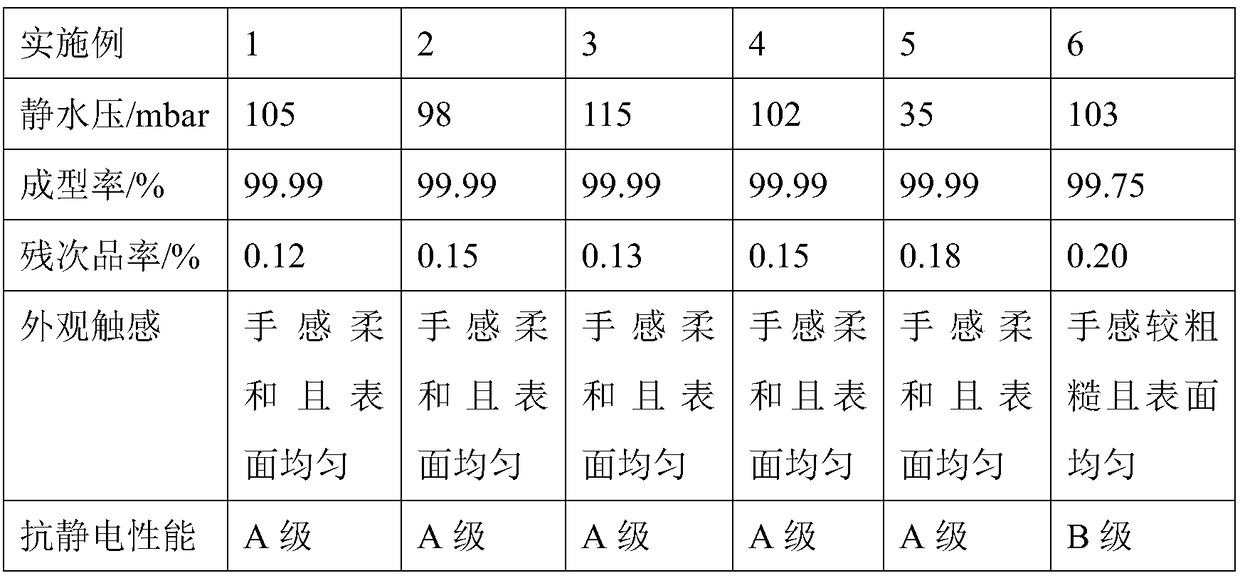

ActiveCN108950867AHigh strengthImprove molding rateLiquid/gas/vapor removalNon-woven fabricsAnti wrinklePolypropylene

The invention relates to a production technology of high-strength and anti-wrinkle spunlace non-woven fabric and relates to the technical field of non-woven fabric production. The production technology comprises the following steps of S1, preparation of fiber raw materials, wherein the fiber raw materials are prepared from, by weight, 10-15 parts of bamboo fibers, 8-12 parts of viscose, 20-30 parts of polypropylene, 15-20 parts of polyisobutene and 2-5 parts of anti-wrinkle agent, the fiber raw materials are mixed, subjected to opening and then carded into a web through a carding machine, andthe fiber web is obtained and drafted through a drafting machine; S2, spunlace, wherein the fiber web drafted in the first step is fed into a spunlace area to form non-woven fabric, and the non-wovenfabric is dried; S3, cold stacking, wherein the non-woven fabric dried in the second step is soaked in an addition agent and subjected to cold stacking; S4, washing through water, wherein the non-woven fabric subjected to cold stacking in the third step is washed through water 2-3 times, and the residual addition agent is removed; S5, drying. The production technology has the advantages that the non-woven fabric is high in strength, formation rate and production rate and does not easily wrinkle.

Owner:FUJIAN GUAN HONG IND

High-performance uniform leather base fabric

ActiveCN103192568AImprove Tangling EffectLarge vertical and horizontal strength ratioSynthetic resin layered productsNon-woven fabricsBreaking strengthPolyester

The invention discloses a high-performance uniform leather base fabric which comprises a nonwoven fabric layer and a machine-woven fabric layer, wherein the machine-woven fabric layer is composited on the nonwoven fabric layer through an acupuncture process. The nonwoven fabric layer is prepared by taking 70-100 wt % of regenerated polyester fiber and 0-30 wt % of maximized polyester short-fiber as raw materials through opening and mixing, web forming through carding, web paving, and two acupunctures; the linear density of the regenerated polyester fiber is 1.5-4D, and the fiber length is 38-76mm; and the linear density of the maximized polyester short-fiber is 1.4-3D, and the fiber length is 38-51mm. The machine-woven fabric layer is prepared by using polyester silk, the warp density is 65-85 roots / in, and the weft density is 35-50 roots / in. According to the invention, by combining a characteristic that the vertical and horizontal strength ratio of a nonwoven fabric is large and the vertical and horizontal strength ratio of a machine-woven fabric is small, the prepared leather base fabric has unique styles of the two, and performances of uniform vertical and horizontal breaking strength and elongation at break, so that the ratio of the vertical and horizontal breaking strength to the elongation at break is ensured to be within 1:1.1.

Owner:福建鑫华股份有限公司

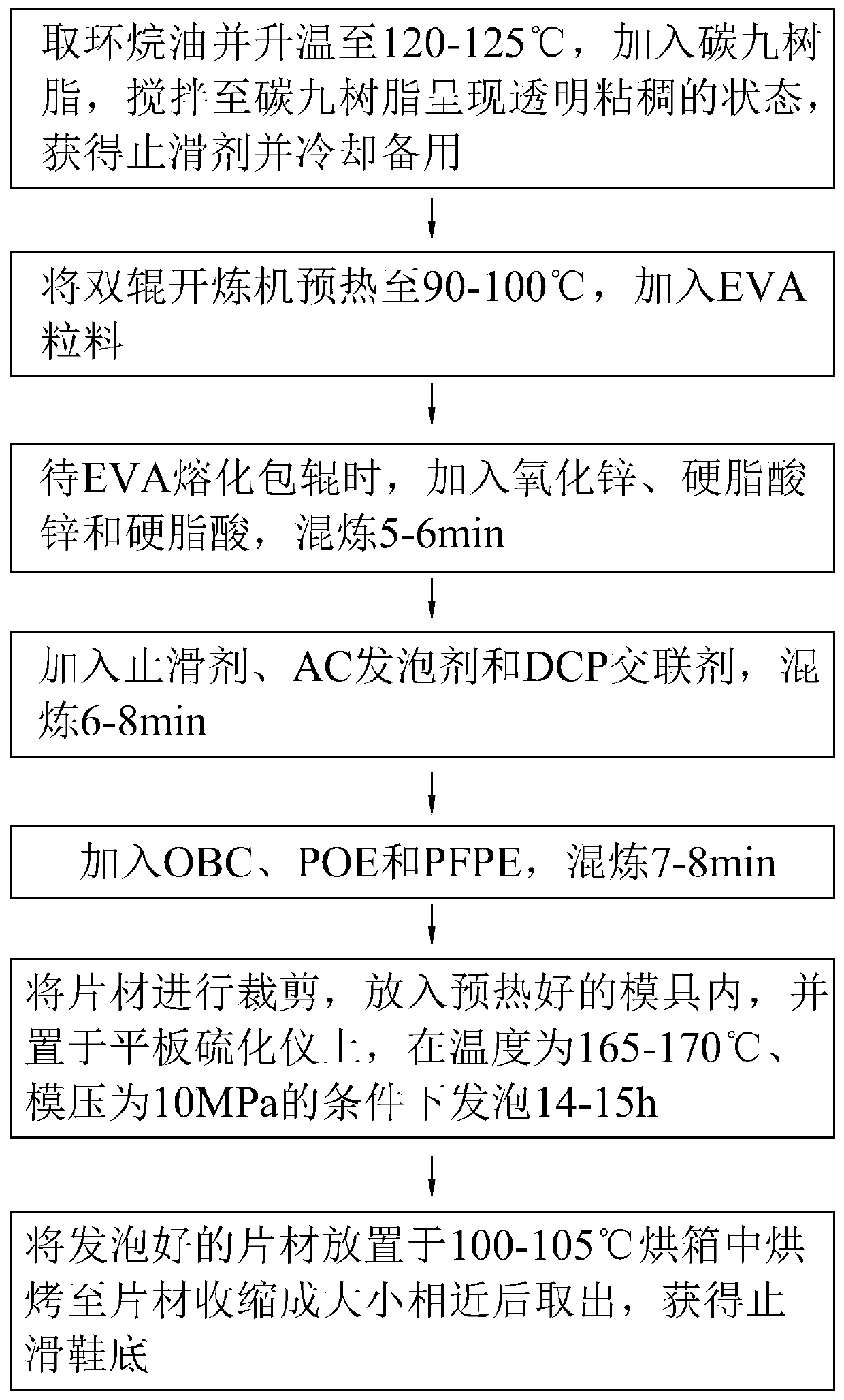

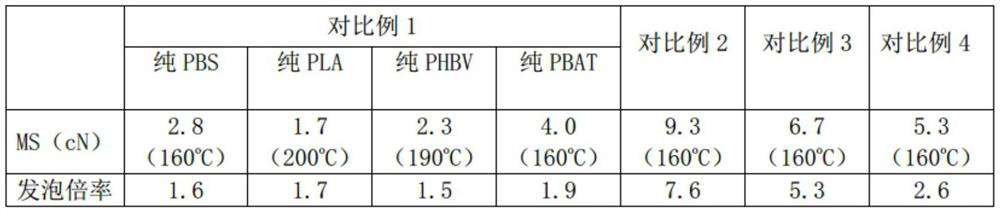

High-melt-strength biodegradable polyester material and preparation method thereof

ActiveCN112920565AStrong water absorptionEvenly dispersedBio-packagingSilane couplingPolymer chemistry

The invention discloses a high-melt-strength biodegradable polyester material which is characterized by being prepared from the following raw materials in percentage by weight: 91.00-99.88% of biodegradable polyester; 0.01-1.00% of an organic peroxide; 0.01-3.00% of a silane coupling agent; and 0.10-5.00% of silicon dioxide particles. The invention also provides a preparation method of the high-melt-strength biodegradable polyester material. The high-melt-strength biodegradable polyester material has high melt strength, is green and environment-friendly, and can completely meet the requirements of processing and forming modes related to melt stretching.

Owner:汕头市三马塑胶制品有限公司

Preparation method of polyphenylene sulfide resin for melt blowing

PendingCN107722274AImprove Tangling EffectLower melt blown temperatureMonocomponent synthetic polymer artificial filamentBenzeneDecomposition

The invention discloses a preparation method of polyphenylene sulfide resin for melt blowing. The preparation method is characterized by comprising the following steps: reacting p-dihalogenated benzene, an S<-2>-containing compound, an amide organic compound with alkali salt at a temperature 180-250 DEG C and a pressure of 0.1MPa-5.0MPa for 1-24 hours, so as to obtain a linear PPS prepolymer; andreacting the linear PPS prepolymer with dihalogenated hydrocarbon at a temperature of 230-280 DEG C and a reaction pressure of 0.1MPa-5.0MPa for 1-24 hours, so as to obtain PPS resin for melt blowing,wherein dihalogenated hydrocarbon is m-dihalogenated aromatic hydrocarbon or p-dihalogenated hydrocarbon. When being added, m-dihalogenated aromatic hydrocarbon is taken as a structural regulator, and the high-entanglement helical-structure or spring-structure PPS resin for melt blowing is obtained; and when being added, p-dihalogenated hydrocarbon is taken as a chain extender, and high-linearityand relatively-low-viscosity PPS resin for melt blowing is obtained. The preparation method is relatively low in processing temperature, so that the decomposition and carbonization of PPS can be inhibited, and the oxidation and crosslinking of PPS can be prevented.

Owner:TIANJIN POLYTECHNIC UNIV

Processing method of alginic acid fiber for non-woven medical dressing fabric

The invention discloses a processing method of alginic acid fiber for non-woven medical dressing fabric, belonging to the field of biofiber processing. The processing method comprises the steps of: weighing and mixing the following ingredients in parts by weight: 30-50 parts of tween-80 solution and 70-50 parts of water to obtain an emulsifying agent; cutting off alginic acid fiber wool tops to obtain short-cut alginic acid fiber wool tops; spraying the emulsifying agent on the short-cut alginic acid fiber wool tops, controlling the weight ratio of the emulsifying agent and the short-cut alginic acid fiber wool tops, and filling in a close container for standing after the spraying is finished, thereby obtaining emulsified alginic acid fiber; taking out the emulsified alginic acid fiber from the close container to be spread in an exposed state, and controlling the spreading time to obtain the alginic acid fiber for non-woven medical dressing fabric. The alginic acid fiber for non-woven medical dressing fabric has desirable strength and excellent toughness, can meet the carded web requirement of a carding machine in a non-woven process, can show good entanglement effect among fibers in the following needling process of a needling machine without the scattering phenomenon.

Owner:SUZHOU EMY MEDICAL SUPPLIES

Filament non-woven composite material and preparation method thereof

ActiveCN112726029AHigh breaking strengthGood hygroscopicityFilament/thread formingNon-woven fabricsPolymer scienceSpinning

The invention relates to the field of non-woven materials, and discloses a filament non-woven composite material and a preparation method thereof. The filament non-woven composite material comprises an aggregate prepared by taking filament fibers and ultra-short fibers as raw materials, wherein the filament fibers are synthetic fiber filaments; the ultra-short fibers are hydrophilic ultra-short fibers; and the hydrophilic ultra-short fibers are distributed in the synthetic fiber filaments, and the hydrophilic ultra-short fibers and the synthetic fiber filaments are intertwined and / or the hydrophilic ultra-short fibers are bonded and fixed to the synthetic fiber filaments. The filaments and the ultra-short fibers are used as raw materials, the filament non-woven composite material is produced through polymer spinning and a wet-process net forming process, and the filament non-woven composite material has the advantages of being high in breaking strength, not prone to scrap falling, soft in hand feeling and good in moisture absorption.

Owner:HANGZHOU NBOND NONWOVENS

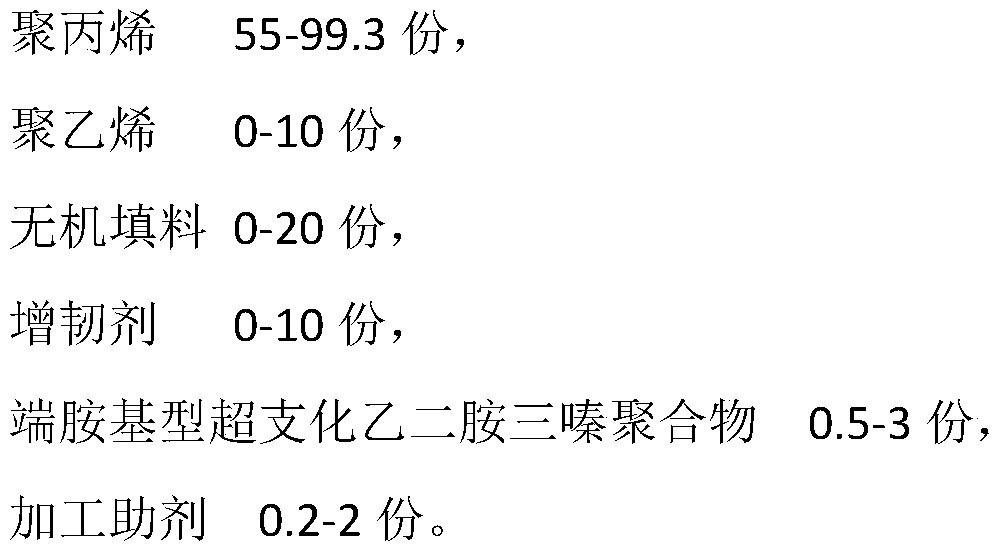

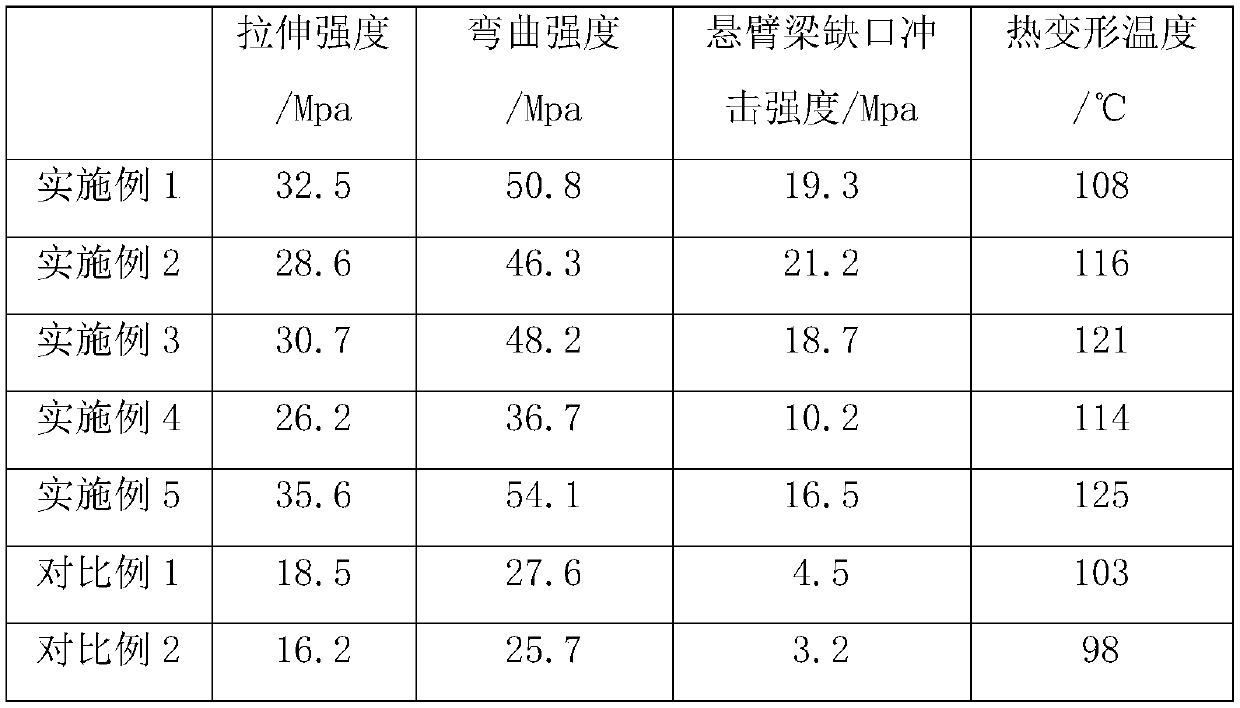

High-performance polypropylene material and preparation method thereof

The invention discloses a high-performance polypropylene material and a preparation method thereof, wherein the high-performance polypropylene material is prepared from the following components in parts by weight: polypropylene, polyethylene, an inorganic filler, a toughening agent, an amino-terminated hyperbranched ethylenediamine triazine polymer and a processing aid through mixing, extrusion and granulation. According to the invention, the amino-terminated hyperbranched ethylenediamine triazine polymer is used as a modification auxiliary agent in blending modification of polypropylene, andbased on the special structure of the amino-terminated hyperbranched ethylenediamine triazine polymer, the rigidity and the toughness of the polypropylene material can be obviously improved.

Owner:HEFEI GENIUS NEW MATERIALS

Blend of PPC, PBAT and PCL and preparation method thereof

InactiveCN101724244ASimple processSuitable for industrial productionPrecipitated calcium carbonateMass ratio

The invention relates to a blend of PPC, PBAT and PCL and a preparation method thereof. The blend consists of PPC, PBAT, PCL, an end-capping reagent, a lubricating agent and modified precipitated calcium carbonate, wherein the mass ratio of the summation of the PCL and the PBAT to the PPC is 10-100:100 and the proportion of each component of the PCL and the PBAT to the summation of the PCL and the PBAT is not less than 5 percent in the mass ratio. The preparation method comprises the following steps of: carrying out cold mixing on the PPC, the PCL, the PBAT, the end-capping reagent, the lubricating agent and the modified precipitated calcium carbonate in a high-speed stirrer at the temperature not above 35 DEG C; and extruding and granulating cold mixed materials by a screw extruder, wherein the temperature of extruding and granulating is not more than 170 DEG C. With simple process method and common equipment, the invention is especially suitable for industrial production; meanwhile, the used materials are simple and easily obtained and can also be purchased in the market; and the granule performance of the blend processed by the method is superior to that of pure PPC.

Owner:INNER MONGOLIA MENG XI HIGH TECH GRP CO LTD

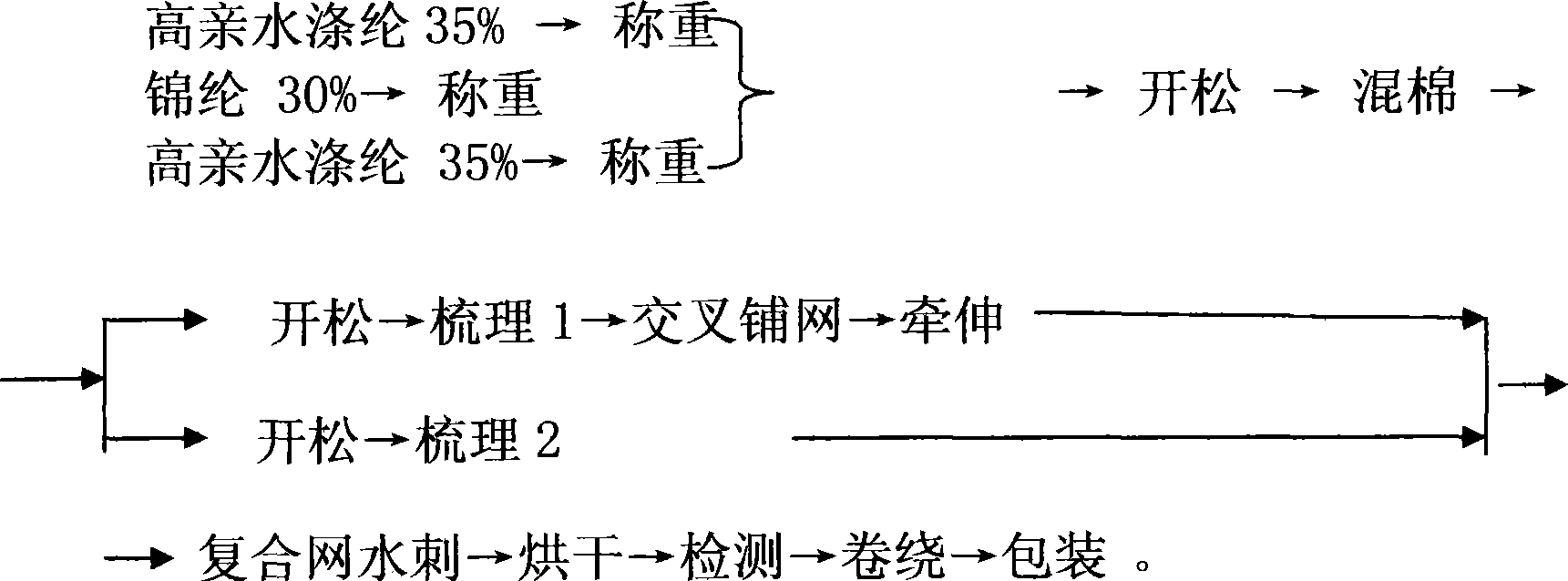

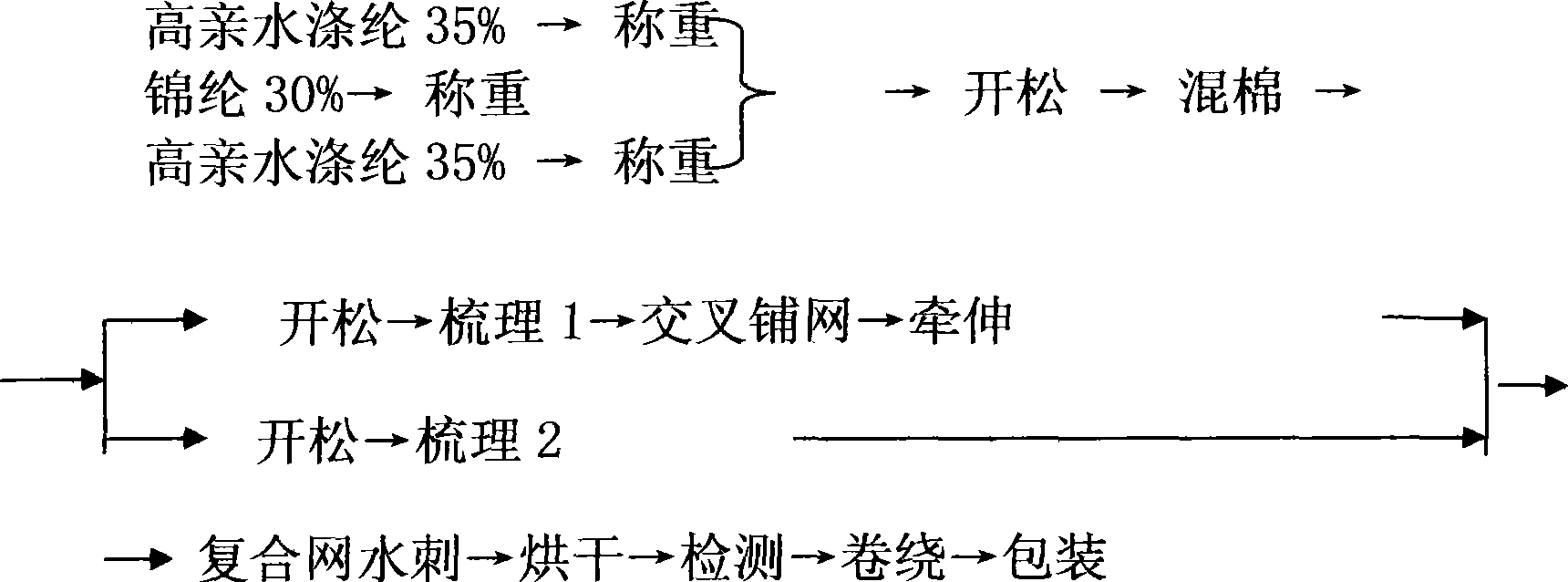

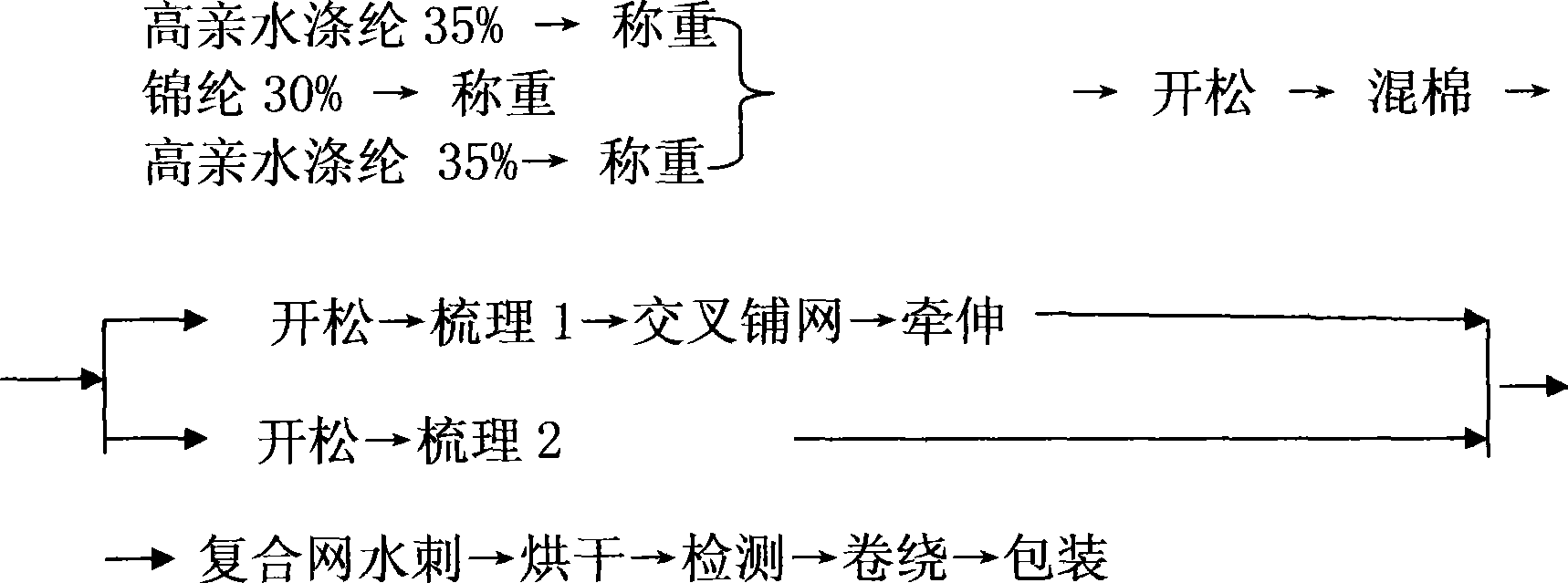

High breathable and high tearing fine denier spun-laced novel material and process for its production

InactiveCN101397722AImprove tensile strengthImprove flatnessCarding machinesNon-woven fabricsPolyesterYarn

The invention discloses a highly air permeable and highly tearing fine denier yarn spunlace novel material and a production technique thereof, which pertains to the technical field of textile materials. The novel material is produced by the following components according to weight percentage: 70 percent of highly hydrophilic polyester with the specification of 1.56dtex multiplied by 38mm and 30 percent of nylon with the specification of 1.56dtex multiplied by 38mm. The highly air permeable and highly tearing fine denier yarn spunlace novel material has good stretching strength, the ratio of MD to CD equal to 1:1, even vertical and horizontal tearing strength, good uniformity, even thickness, no fuzz, stable peeling, good winding effect, comfortable touch feeling and low formaldehyde content, and improves the simulation quality and the air permeability of a product after becoming finished leather; the product is mainly used as the base fabric of PU leather.

Owner:SHAOXING RONGLIDA TEXTILE TECH

Blend of PPC, PBAT, PLA and PBS and preparation method thereof

The invention relates to a blend of PPC, PBAT, PLA and PBS and a preparation method thereof. The blend consists of PPC, PBAT, PLA, PBS, an end-capping reagent, a lubricating agent and modified precipitated calcium carbonate. The preparation method comprises the following steps of: carrying out cold mixing on the PPC, the PBAT, the PLA, the PBS, the end-capping reagent, the lubricating agent and the modified precipitated calcium carbonate in a high-speed stirrer at the temperature not above 35 DEG C; and extruding and granulating cold mixed materials by a screw extruder, wherein the temperature of extruding and granulating is not more than 200 DEG C. With simple process method and common equipment, the invention is especially suitable for industrial production; meanwhile, the used materials are simple and easily obtained and can also be purchased in the market; the temperature of pastiness caking blocks of the blend processed by the method is greatly improved in comparison with pure PPC and the mechanical property of the blend is greatly improved in comparison with the pure PPC; and the blend widens the application range of the pure PPC and can be completely biodegraded.

Owner:INNER MONGOLIA MENG XI HIGH TECH GRP CO LTD

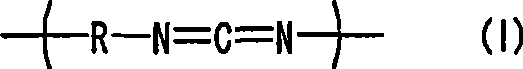

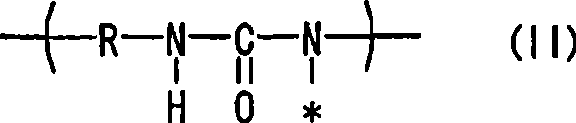

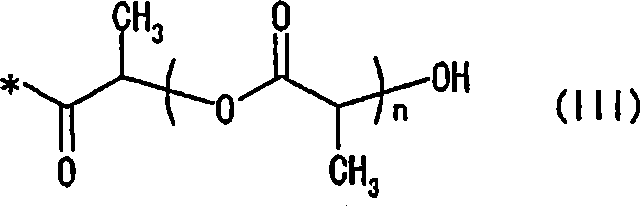

Polylactic acid-modified polycarbodiimide compound, polylactic acid resin composition containing same and molded article

InactiveCN101379117AImproved chemical affinityImprove mechanical propertiesHydrolysisPolylactic acid

Disclosed is a polylactic acid-modified polycarbodiimide compound which is blended with a polylactic acid resin for imparting hydrolysis resistance thereto while improving mechanical characteristics thereof. Also disclosed are a polylactic acid resin composition containing such a polylactic acid-modified polycarbodiimide compound, and a molded article.

Owner:NEC CORP

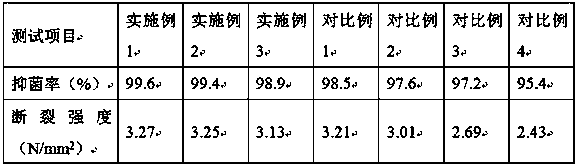

Antibacterial fabric and preparation method thereof

The invention discloses an antibacterial fabric and a preparation method thereof and belongs to the technical field of textile production. The hyperbranched polymer obtained by modifying a quaternaryammonium salt structure is used for antibacterial finishing of fabrics, on one hand, the hyperbranched polymer has high solubility, the washing resistance is improved; on the other hand, long-chain alkyl is introduced in the substitution process, the cytotoxicity is reduced, and a hydrophobic group and a hydrophilic group deeply penetrate into lipid layers and protein layers of bacterial cells respectively, so that the antibacterial performance is enhanced. After an epoxy group and a hydroxyl group of starch produce etherification action, the long-acting antibacterial property is formed, the performance of the fabric is improved, the plasticizing effect on the fiber is achieved, the antibacterial efficiency is improved, the plasticity and entanglement performance of the fiber are improved,the mechanical property and toughness of the fabric are improved, and the antibacterial efficiency is also increased. The problem is solved that an antibacterial additive in an existing antibacterialfabric is high in toxicity and has the influence on the mechanical property of the fabric itself.

Owner:常州海瑞纺织品有限公司

Environment-friendly antibacterial composite material and manufacturing method thereof

InactiveCN105177856AQuick moisture wickingPoor living environmentFibre typesNon-woven fabricsPolyesterEmulsion

The present invention discloses an environment-friendly antibacterial composite material and a manufacturing method thereof. The environment-friendly antibacterial composite material comprises regenerated polyester staple fibers of which the fineness is 2.0 D, the length is 51 mm and the content is 30-50 wt%, regenerated polyester staple fibers of which the fineness is 2.5 D, the length is 64 mm and the content is 25-40 wt%, and bamboo pulp fibers of which the fineness is 2.0 D, the length is 51 mm and the content is 25-35 wt%. A finishing liquid of the environment-friendly antibacterial composite material in a finishing process is composed of the following components of 20-30 parts by weight of a high polymer emulsion, 10-20 parts by weight of starch, 25-35 parts by weight of coarse whiting, 40-50 parts by weight of clean water, and 3-5 parts by weight of negative oxygen ion powder. Through plates commonly manufactured by the bamboo pulp fibers and negative oxygen ions, the composite material has a bacteriostatic action and also an obvious smell-removing function.

Owner:福建鑫华股份有限公司

Anti-deformation acrylic plate with heat insulation and heat preservation functions and preparation method of anti-deformation acrylic plate

PendingCN114379179AImprove deformation resistanceHigh strengthSynthetic resin layered productsLaminationCelluloseFiber

According to the preparation method of the anti-deformation acrylic plate with the heat insulation and heat preservation functions, the acrylic plate base layer is prepared in a methyl methacrylate, butyl acrylate and diallyl adipate ternary polymerization mode, the strength of the acrylic plate is greatly improved, and the mechanical property is improved; wheat straw fibers and glass fibers are mixed and woven to prepare a fiber layer, and the fiber layer is used as an anti-deformation layer to enhance the anti-deformation capability of the acrylic plate; nano-silver-loaded nanofiber crystals are prepared from nanocrystalline cellulose, glucose and a silver ammonia solution, the antibacterial property of the acrylic plate is improved, and after graphene oxide quantum dots are added, the fiber entanglement capacity is improved, the internal stress of the acrylic plate is reduced, and the thermal insulation performance of the acrylic plate is improved; the hollow glass beads are uniformly dispersed in the foamed polyurethane to prepare the heat preservation layer, the hollow glass beads and the foamed polyurethane play a synergistic role in improving the heat resistance of the acrylic plate, and the heat insulation and heat preservation performance of the acrylic plate can be greatly improved by optimizing the component proportion.

Owner:ZHEJIANG SHENMEI ARCYLIC CO LTD

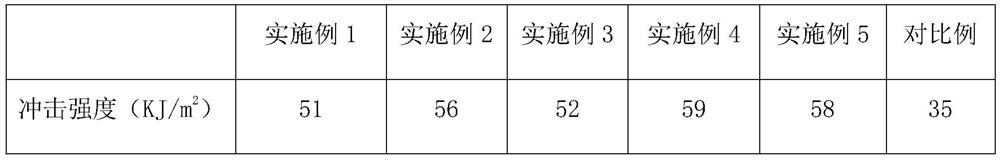

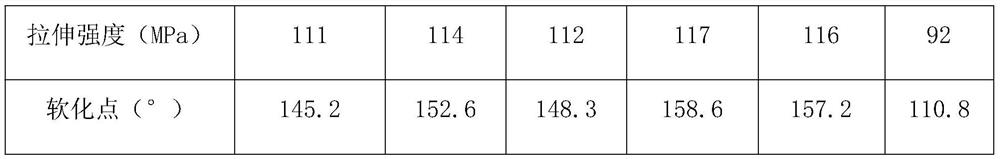

EVA sole and preparation method thereof

ActiveCN111154170AImprove heat resistanceEasy to processSolesTextile/flexible product manufacturePolymer scienceEngineering

The invention discloses an EVA shoe sole and a preparation method thereof. The EVA shoe sole is prepared from, by weight, 60-70 parts of EVA, 8-10 parts of OBC, 12-15 parts of POE, 1-2 parts of an ACfoaming agent, 1-2 parts of a cross-linking agent and 2-3 parts of an activator. The OBC has good heat resistance, high elasticity and good processability, and can provide excellent resilience for anEVA foaming system, so that the EVA sole has high elasticity and is not prone to being compacted. By adding the POE, the resilience of the EVA sole can be further improved, the surface crystallizationrate of the material can be reduced, the problem that the surface of a traditional EVA foamed shoe material is prone to wrinkling is solved, and the attractiveness of the product is improved. Besides, OBC molecules and POE molecules inevitably form entanglement in a three-dimensional space, and the entanglement can limit movement of macromolecular chain segments like chemical crosslinking, so that the EVA sole is further not prone to being compacted, the surface of the EVA sole is not prone to wrinkling, and the use performance and the attractive performance are guaranteed.

Owner:DONGGUAN CHENGGUAN SPORT PROD TECH CO LTD

Blend of PPC, PBAT, PCL, PBS and PLA and preparation method thereof

The invention relates to a blend of PPC, PBAT, PCL, PBS and PLA and a preparation method thereof. The blend consists of PPC, PBAT, PCL, PBS, PLA, an end-capping reagent, a lubricating agent and modified precipitated calcium carbonate. The preparation method comprises the following steps of: carrying out cold mixing on the PPC, the PBAT, the PCL, the PBS, the PLA, the end-capping reagent, the lubricating agent and the modified precipitated calcium carbonate in a high-speed stirrer at temperature not above 35 DEG C; and extruding and granulating cold mixed materials by a screw extruder, wherein the temperature of extruding and granulating is not more than 200 DEG C. With simple process method and common equipment, the invention is especially suitable for industrial production; meanwhile, the used materials are simple and easily obtained and can also be purchased in the market; the temperature of pastiness caking blocks of the blend processed by the method is greatly improved in comparison with pure PPC and the mechanical property of the blend is superior to that of the pure PPC; and the blend widens the application range of the pure PPC and can be completely biodegraded.

Owner:INNER MONGOLIA MENG XI HIGH TECH GRP CO LTD

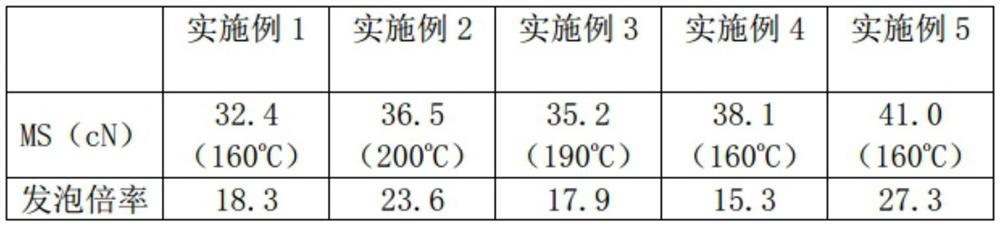

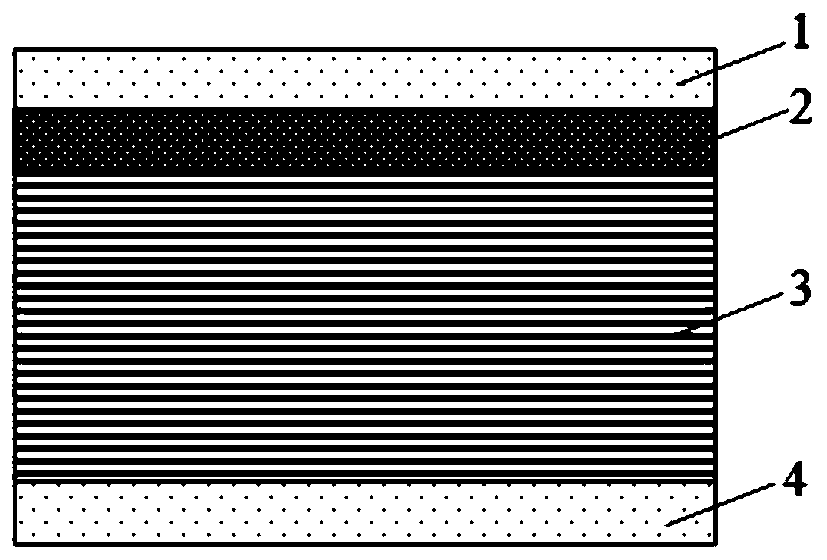

Foaming-grade biodegradable polyester material and preparation method thereof

ActiveCN112795154AStrong water absorptionImprove melt strengthPolymer scienceBiodegradable polyester

The invention discloses a foaming-grade biodegradable polyester material, and the material is characterized by being prepared from the following raw materials by weight: 88.00-99.87% of biodegradable polyester; 0.01-1.00% of an organic peroxide; 0.01-3.00% of a silane coupling agent; 0.10-5.00% of silicon dioxide particles; and 0.01-3.00% of a lubricant. The invention also provides a preparation method of the foaming-grade biodegradable polyester material. The foaming-grade biodegradable polyester material has high melt strength and excellent foamability, and can meet the process requirements of continuous extrusion foaming, kettle pressure foaming, mold pressing foaming and injection molding foaming.

Owner:SHANTOU SAMMA PLASTIC IND CO LTD

PPC (poly(propylene carbonate)), PBAT (poly(butylene adipate/terephthalate)) and PBS (poly(butylene succinate)) blend and preparation method

InactiveCN101735588ASimple processSuitable for industrial productionPropylene carbonateMixed materials

The invention relates to PPC (poly(propylene carbonate)), PBAT (poly(butylene adipate / terephthalate)) and PBS (poly(butylene succinate)) blend and a preparation method. The blend is formed by PPC, PBAT, PBS, a blocking agent, lubricant and modified light calcium carbonate, and the preparation method comprises the following steps of: cooling-mixing the PPC, the PBAT, the PBS, the blocking agent, the lubricant and the modified light calcium carbonate in a high-speed mixer under a condition with the temperature not higher than 35 DEG C, and extruding a cooling-mixed material by a screw extruder for pelleting, wherein the temperature for pelleting is not higher than 200 DEG C. The invention has the advantages that the method has simple process, common equipment, and suitability for industrialization production; meanwhile, raw materials used in the method are simple and easy to obtain and can be easily bought in a market; and the blend processed out by the method has greatly increased temperature of sticky clotting higher than that of a pure PPC and greatly improved mechanical performance of the blend larger than that of the pure PPC, broadens the application range of the pure PPC and is completely biodegraded.

Owner:INNER MONGOLIA MENG XI HIGH TECH GRP CO LTD

Thermoplastic fiber bonded palm fiber mattress core material and preparation method thereof

PendingCN111016345AWide variety of sourcesLow priceStuffed mattressesSynthetic resin layered productsPolymer sciencePalm fiber

The invention discloses a palm fiber mattress core material bonded by thermoplastic fibers. The palm fiber mattress core material sequentially comprises a non-woven fabric surface layer, a PP melt-blown non-woven fabric layer, a palm fiber layer and a non-woven fabric bottom layer, wherein the palm fiber layer has a net layer structure formed by dispersing and mixing thermoplastic fibers and palmfibers and then thermally bonding, the thermoplastic fibers are selected from PP, PET, PA, PE and ES fibers, and the palm fibers are selected from palm fibers and / or coconut fibers. According to the invention, the adopted PP and other conventional materials are wide in source and low in price, are thermoplastic materials, and can be recycled through a certain technology, so that the used materialshas cost advantage and environmental protection performance in bonding and compounding of palm fibers.

Owner:GUANGDONG VOCATIONAL & TECHNICAL COLLEGE

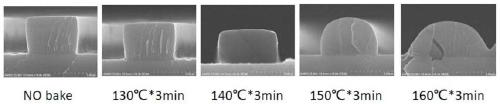

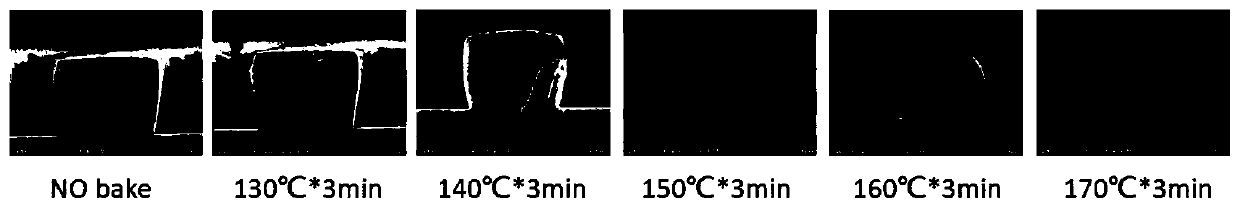

Negative photoresist composition containing carboxyl phenolic resin with high heat resistance

PendingCN111123649AHigh molecular weightMolecular weight novolaks used as film-forming resins to improve the thermal performance of photoresistsPhotosensitive materials for photomechanical apparatusPolymer scienceImage resolution

The invention discloses a negative photoresist composition containing carboxyl phenolic resin with high heat resistance. According to the high-heat-resistance carboxyl phenolic resin, the structural general formula is shown in the description, wherein x is 0-4, the ratio of m to n is 0.05-0.75: 1, R is H, phenyl or C1-C9 alkyl, and the weight-average molecular weight of the resin is 8,000-35,000g / mol. The film-forming resin is mixed with a photoacid generator, a curing agent, an additive, a solvent and other components to obtain the negative photoresist composition. Tests prove that the negative photoresist composition is high in resolution ratio, good in heat resistance and suitable for a lift-off metal stripping process under a high-temperature operation condition.

Owner:SUZHOU RUIHONG ELECTRONIC CHEM CO LTD

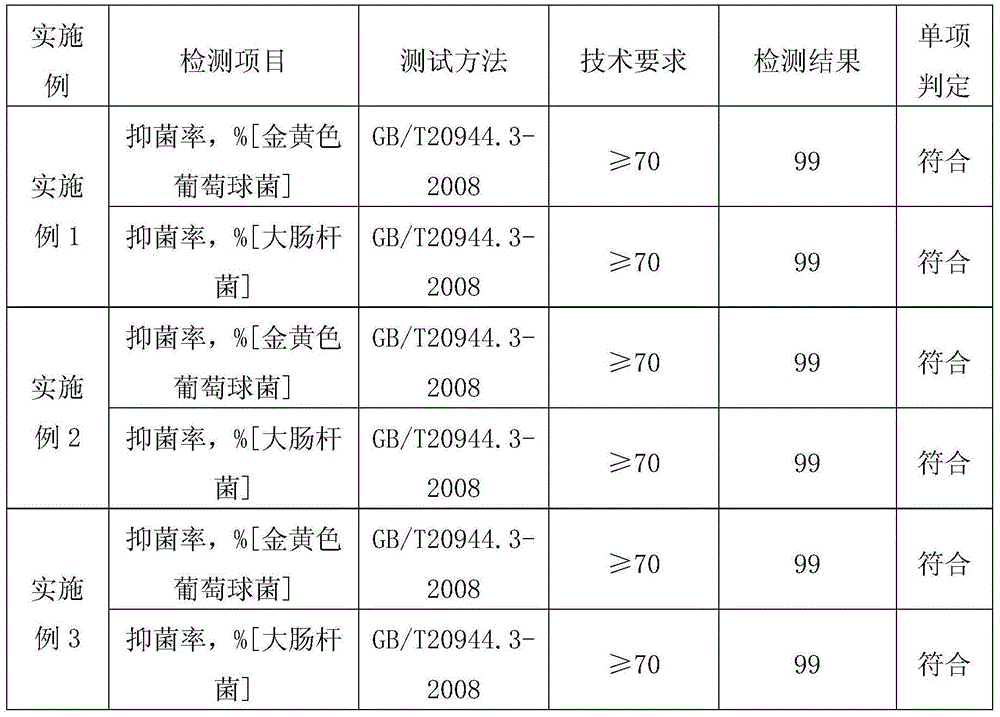

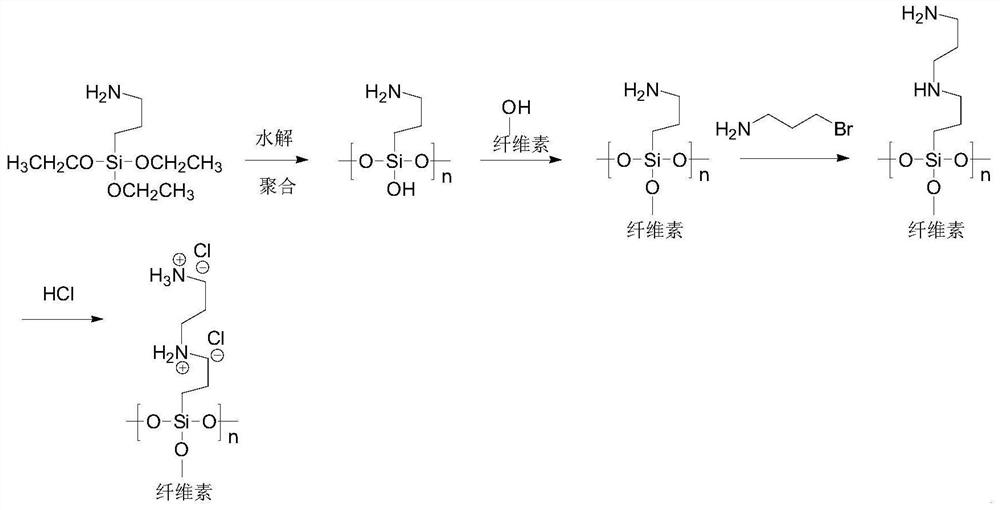

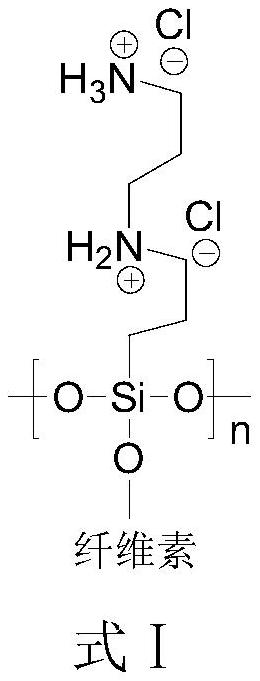

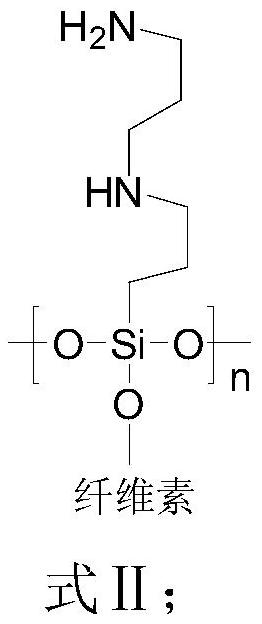

Modified cellulose spunlace non-woven fabric and preparation method thereof

ActiveCN113774562AImprove mechanical propertiesPlay a broad-spectrum antibacterial effectBiochemical fibre treatmentNon-woven fabricsPolymer scienceNonwoven fabric

The invention provides a modified cellulose spunlace non-woven fabric and a preparation method thereof, and belongs to the technical field of spunlace non-woven fabrics. The modified cellulose spunlace non-woven fabric is prepared from the following raw materials of modified cellulose, polypropylene, tetrabutyl titanate and deionized water. The modified cellulose has a structure shown in the specification, wherein n is equal to 100 to 300. The prepared modified cellulose spunlace non-woven fabric not only has good antibacterial and bacteriostatic performance, but also has certain formaldehyde purification capacity, good skin-friendly performance and good mechanical performance; after spunlace reinforcement, fibers in the non-woven fabric are displaced, interspersed, entangled and cohered to form countless flexible entanglement points, so that the non-woven fabric is reinforced, and the high-performance spunlace non-woven fabric is obtained.

Owner:深圳市鑫唯科防静电科技有限公司

Reinforced and toughened plant fiber-melamine resin composite material and preparation method thereof

ActiveCN111592734AFacilitate cross-linkingImprove Tangling EffectVegetal fibresPlant fibreMelamine formaldehyde resin

The invention discloses a reinforced and toughened plant fiber-melamine resin composite material and a preparation method thereof. The reinforced and toughened plant fiber-melamine resin composite material is prepared from the following raw materials in parts by weight: 50 to 60 parts of melamino-formaldehyde resin, 35 to 45 parts of modified plant fiber, 1 to 3 parts of mineral filler, 0.05 to 0.1 part of curing agent and 0.5 to 1 part of lubricating agent. By optimizing a plant fiber filling system, the prepared plant fiber-melamine resin composite material has excellent bending property, impact toughness and mechanical property, and the durability of a plant fiber-melamine resin product can be greatly improved.

Owner:安徽绿之态秸秆制品有限公司

Blend of PPC and PBAT and preparation method thereof

The invention relates to a blend of PPC and PBAT and a preparation method thereof. The blend consists of PPC, PBAT, an end-capping reagent, a lubricating agent and modified precipitated calcium carbonate. The preparation method comprises the following steps of: carrying out cold mixing on the PPC, the PBAT, the end-capping reagent, the lubricating agent and the modified precipitated calcium carbonate in a high-speed stirrer at the temperature not above 35 DEG C; and extruding and granulating cold mixed materials by a screw extruder, wherein the temperature of extruding and granulating is not more than 200 DEG C. With simple process method and common equipment, the invention is especially suitable for industrial production; meanwhile, the used materials are simple and easily obtained and can also be purchased in the market; the temperature of pastiness caking blocks of the blend processed by the method is greatly improved in comparison with pure PPC and the mechanical property of the blend is greatly improved in comparison with the pure PPC; and the blend widens the application range of the pure PPC and can be completely biodegraded.

Owner:INNER MONGOLIA MENG XI HIGH TECH GRP CO LTD

Blend of PPC, PBAT, PCL, PBS and PLA and preparation method thereof

The invention relates to a blend of PPC, PBAT, PCL, PBS and PLA and a preparation method thereof. The blend consists of PPC, PBAT, PCL, PBS, PLA, an end-capping reagent, a lubricating agent and modified precipitated calcium carbonate. The preparation method comprises the following steps of: carrying out cold mixing on the PPC, the PBAT, the PCL, the PBS, the PLA, the end-capping reagent, the lubricating agent and the modified precipitated calcium carbonate in a high-speed stirrer at temperature not above 35 DEG C; and extruding and granulating cold mixed materials by a screw extruder, whereinthe temperature of extruding and granulating is not more than 200 DEG C. With simple process method and common equipment, the invention is especially suitable for industrial production; meanwhile, the used materials are simple and easily obtained and can also be purchased in the market; the temperature of pastiness caking blocks of the blend processed by the method is greatly improved in comparison with pure PPC and the mechanical property of the blend is superior to that of the pure PPC; and the blend widens the application range of the pure PPC and can be completely biodegraded.

Owner:INNER MONGOLIA MENG XI HIGH TECH GRP CO LTD

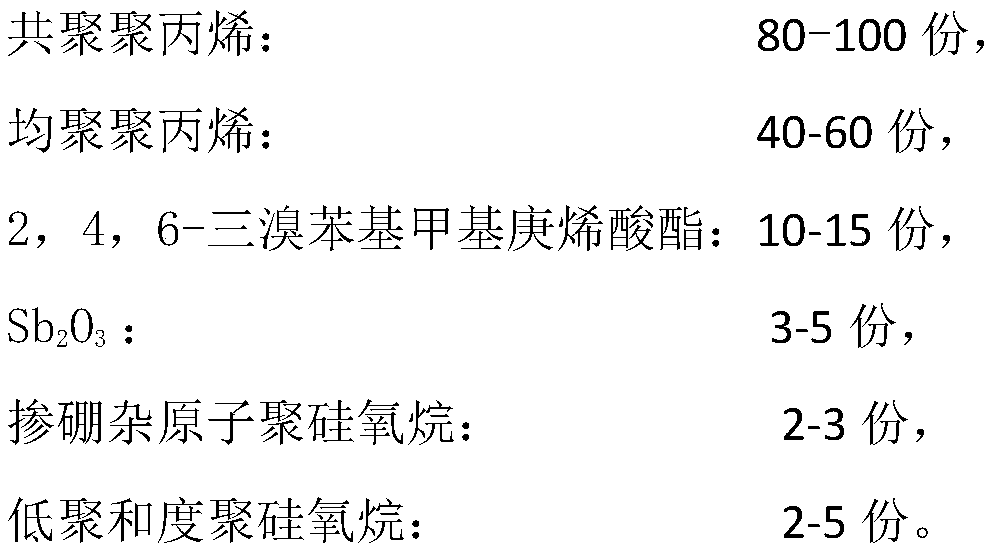

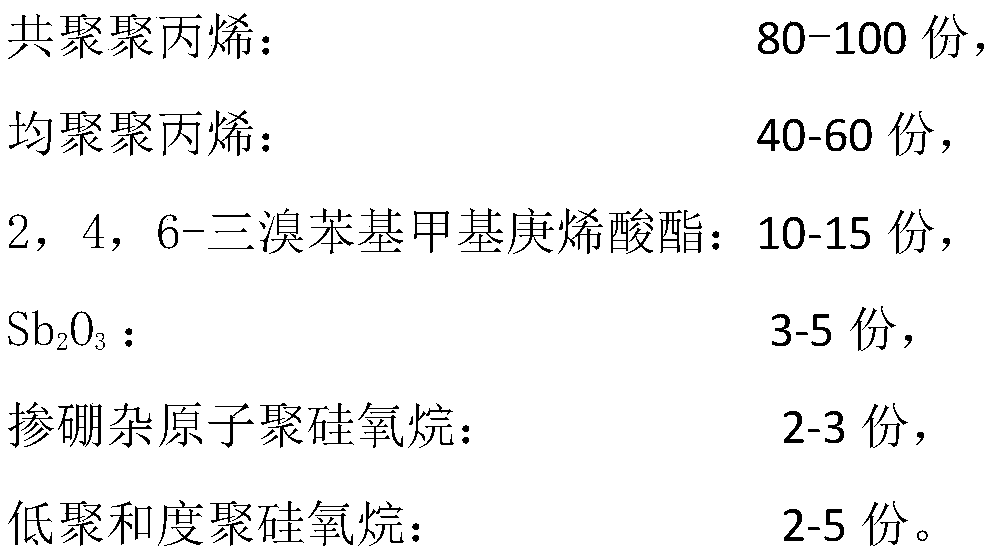

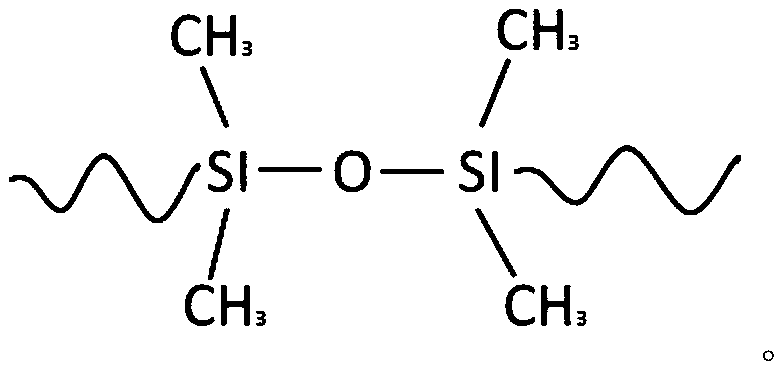

Scratch-resistant easy-to-wipe flame-retardant polypropylene composition for converter

ActiveCN110964262AImprove stabilityEnhanced wipe-cleanabilityBulk chemical productionConvertersPolymer science

The invention discloses a scratch-resistant easy-to-wipe flame-retardant polypropylene composition for a converter. The polypropylene composition comprises the following components in parts by weight:80-100 parts of co-polypropylene, 40 to 60 parts of homo-polypropylene, 10 to 15 parts of 2,4,6-tribromophenyl methyl heptenoic acid ester, 3 to 5 parts of Sb2O3, 2 to 3 parts of boron-doped heteroatom polysiloxane, and 2 to 5 parts of oligomerization degree polysiloxane. According to the invention, through selection of specific raw materials, the problem that flame retardance is influenced by high degradation rate of polysiloxane in an acid environment of a flame retardant is solved, and the problem that polypropylene material is easy to wipe and resistant to scraping of soft cleaning articles is solved.

Owner:上海日之升科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com