Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Good strength retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bioabsorbable and bioactive composite material and a method for manufacturing the composite

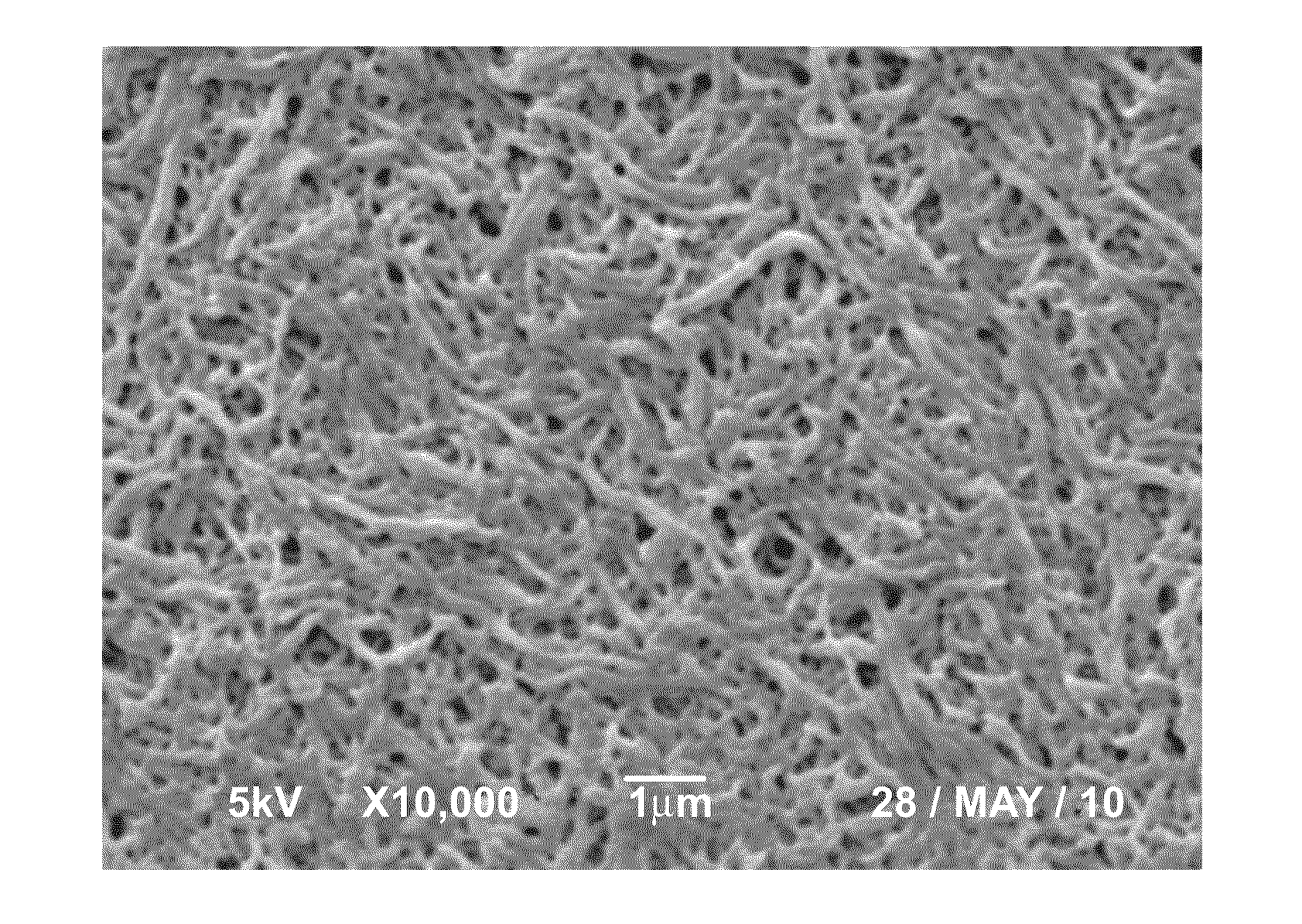

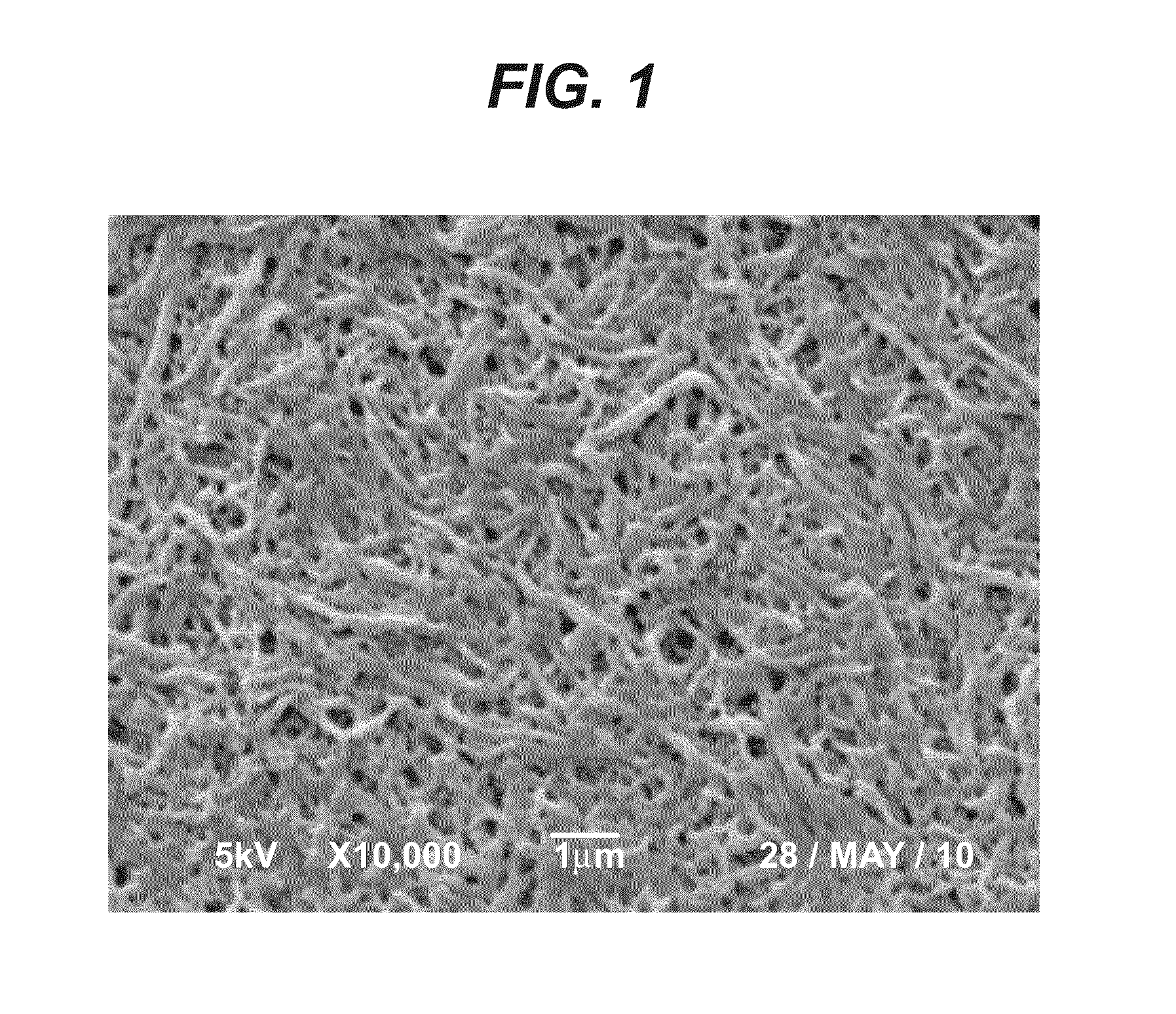

InactiveUS20100121463A1Increase strength valueIncrease toughness valueSurgeryProsthesisFiberPolymer chemistry

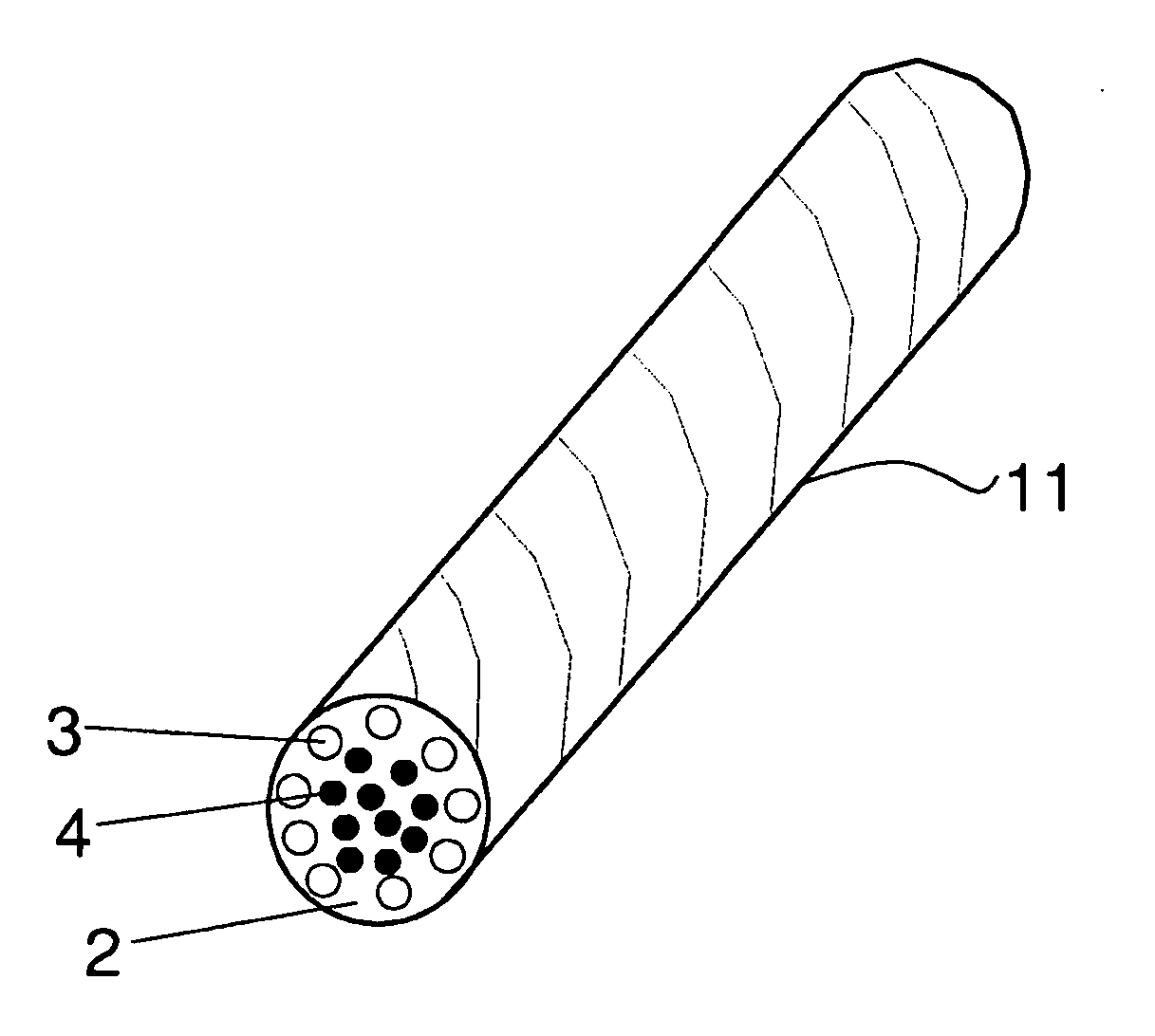

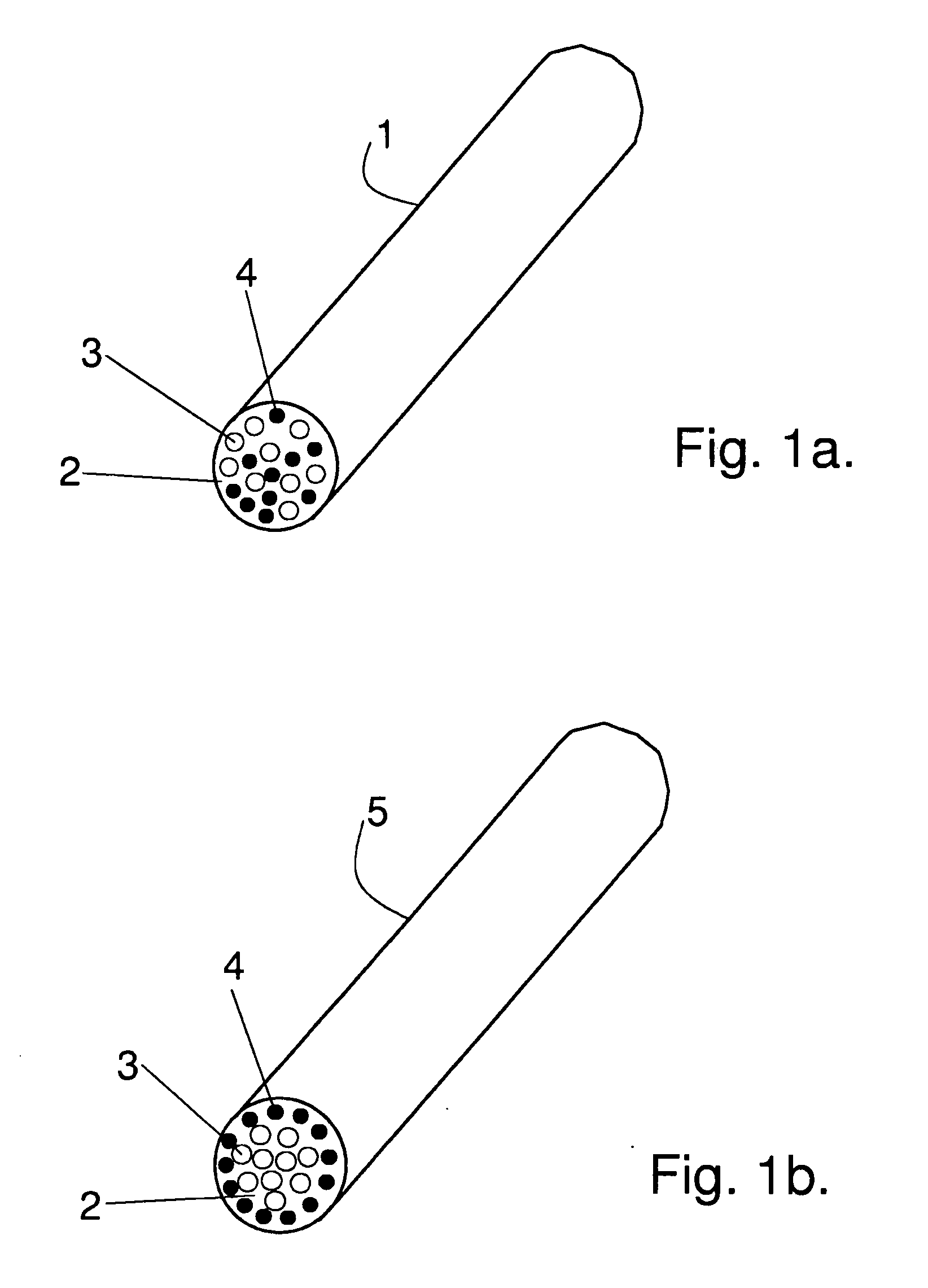

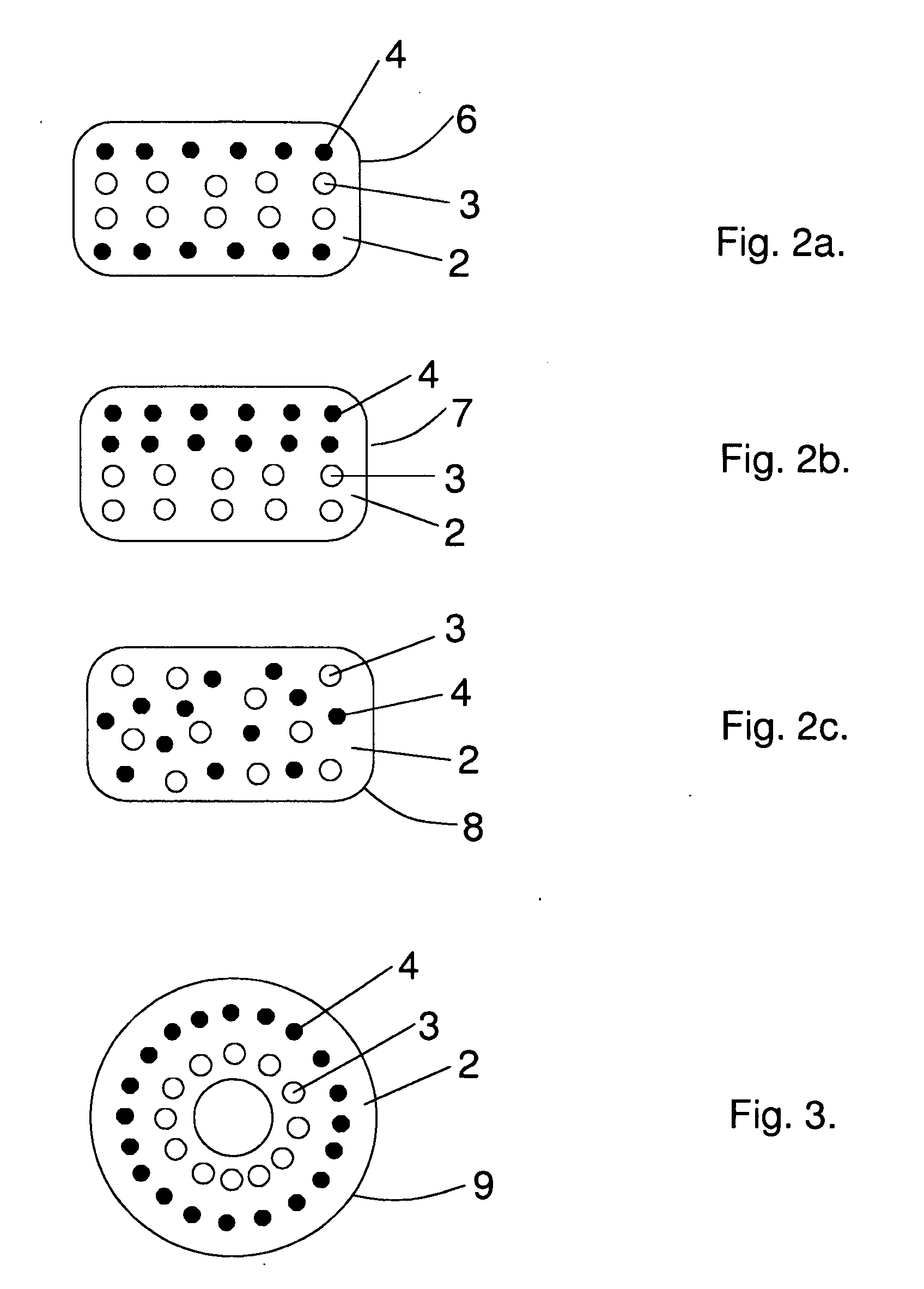

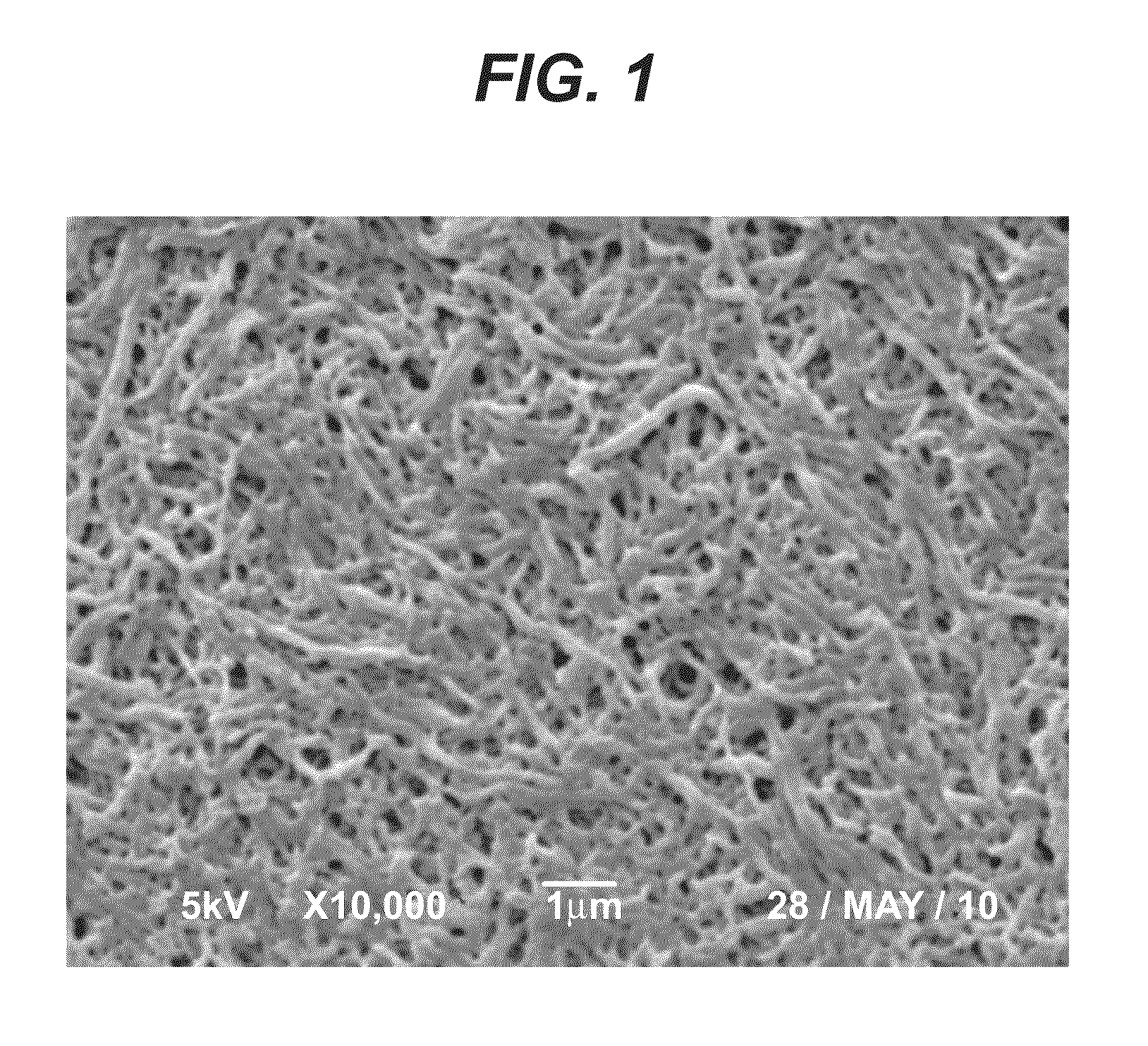

The present invention relates to a bioabsorbable and bioactive composite material for surgical musculoskeletal applications comprising a bioabsorbable polymeric matrix material which is reinforced with bioabsorbable polymeric fibers and bioabsorbable ceramic fibers. The surgical bioabsorbable polymeric matrix material is reinforced with the bioabsorbable polymeric fibers and the bioabsorbable ceramic fibers from which at least a portion is longer than 150 μm. The invention also relates to a method for manufacturing a bioabsorbable and bioactive composite material.

Owner:BIORETEC

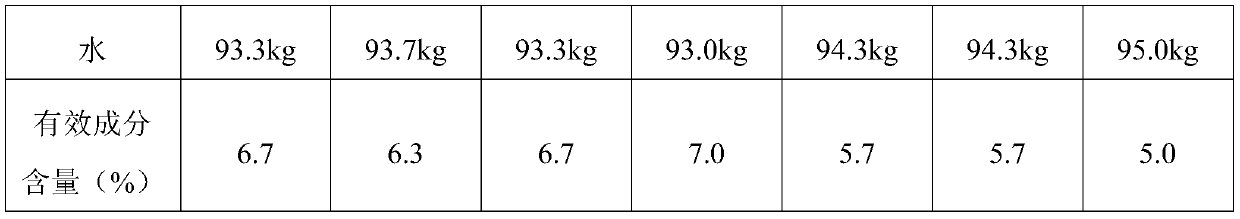

Non-efflorescing cementitious bodies

InactiveUS6923857B2Satisfactory physical propertyReduce weatheringSolid waste managementPretreated surfacesCalcium silicateHydrated alumina

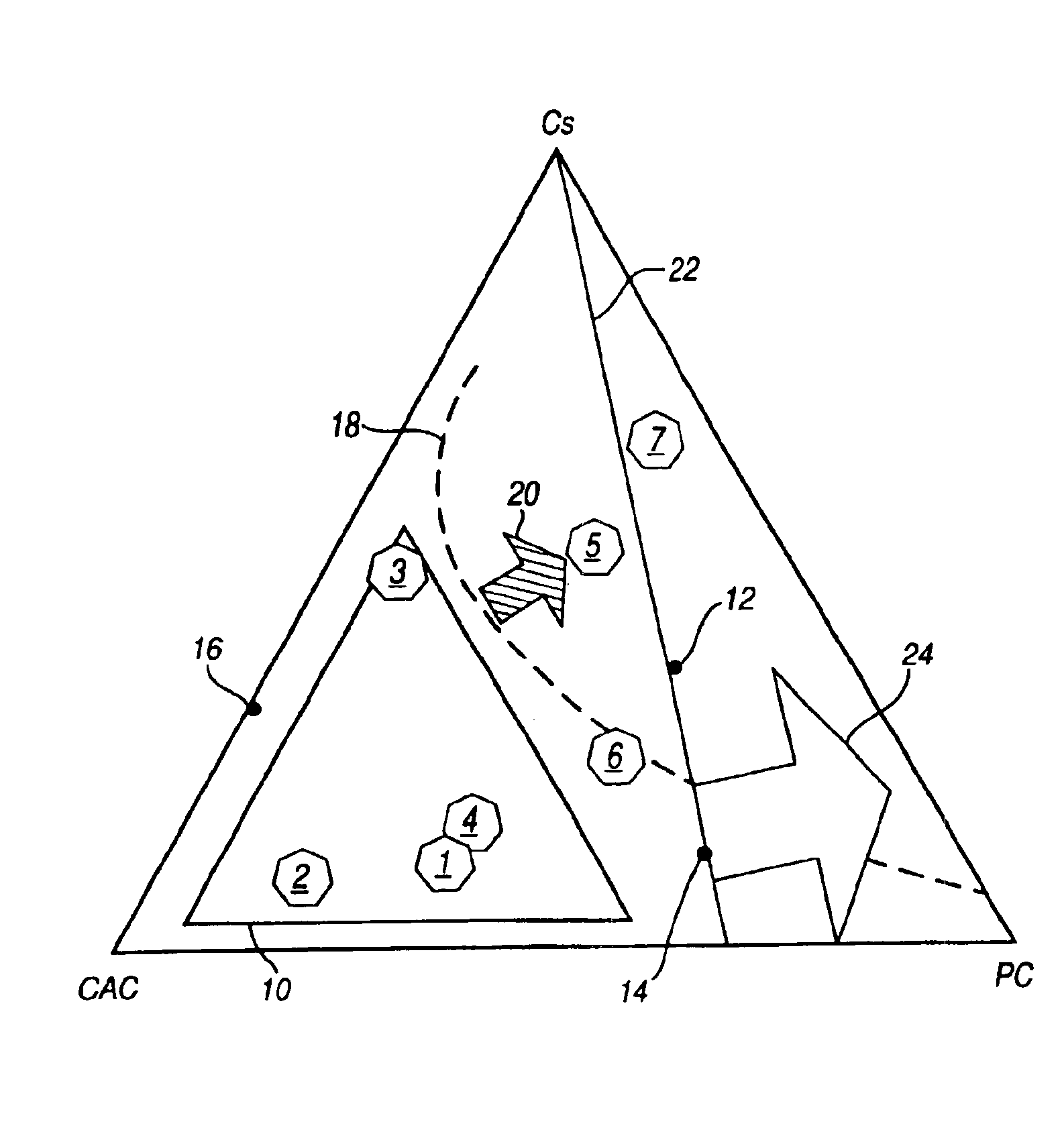

A non-efflorescing cementitious body is formed from sources of calcium aluminate, calcium silicate, calcium sulphate and reactive silica, these ingredients being present in such relative proportions that, upon hydration, both monosulphate (C3A.CŜ.12H) and hydrated alumina (AH3) are formed. Also disclosed is a hydraulic binder and a paste from which such bodies can be formed and a method for forming such bodies. In addition to exhibiting low efflorescence, these bodies retain satisfactory physical properties, especially good durability to natural weathering conditions.

Owner:LAFARGE ALUMINATES

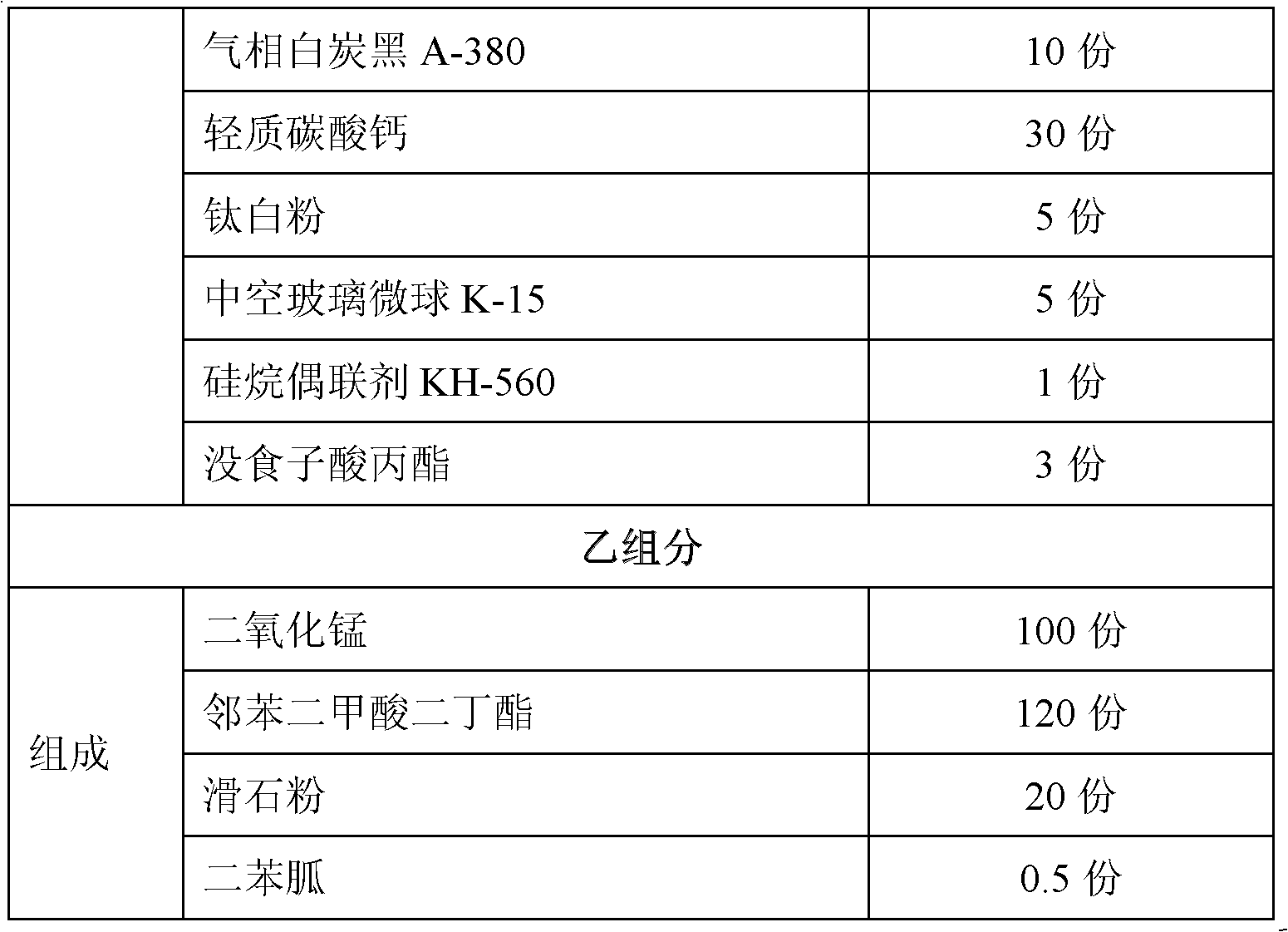

Bi-component polysulfide sealant and preparation method thereof

InactiveCN102618207AExcellent thermal degradation resistanceGood strength retentionNon-macromolecular adhesive additivesOther chemical processesThermal ageingPolymer science

Bi-component polysulfide sealant and a preparation method thereof relate to a high-polymer sealing material and a preparation method thereof and aim to solve the problems of high density and poor heatproof degradation performance of existing sealant after being sulfurized. A component includes liquid polysulfide rubber, epoxy resin, thixotropic agent, reinforcing filler, hollow glass microballs, titanium dioxide, silane coupler and antiager, B component includes manganese dioxide, plasticizer, talcum powder and melaniline. The preparation method includes: the A component is prepared by addingthe thixotropic agent, the titanium dioxide, the reinforcing filler and the antiager to grind after the liquid polysulfide rubber and the epoxy resin are pre-polymerized and then adding treated hollow glass microballs to grind; the B component is prepared by mixing and grinding the manganese dioxide, the plasticizer and the talcum powder and then adding the melaniline to grind. The bi-component polysulfide sealant with the density smaller than or equal to 1.3g / cm3 is not crispy and not viscous in flowing after thermal ageing at the temperature of 180 DEG C for 10 hours. The preparation methodis applicable to preparation of polysulfide sealant.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Process for producing spunlaced composite high-performance polyphenylene sulfide fiber filtering material

InactiveCN101550634AHigh strengthHigh strength retentionFiltration separationNon-woven fabricsFiberSulfide

The invention relates to a process for producing spunlaced composite high-performance polyphenylene sulfide fiber filtering material, belongs to the fibrous raw material textile production technology field. The process uses polyphenylene sulfide fiber as raw material, has the following steps: processing raw material by checking, weighing, feeding, feeding into long certain, mixing cotton and fine loosing; layering and carding respectively by a first carding machine and a second carding machine; putting respectively into mesh placing machine for placing mesh; debatching, congruent, superposing and prewetting; spunlacing by a plurality of spunlacing machine, dewatering, drying and reeling. The advantages of the invention is that: the invention adopts polyphenylene sulfide high-performance fiber as raw material, the raw material is adapted to high efficient high speed carding production for its self physical and chemical properties, structure and adaptability to meshing and reinforcing process; improves spunlacing entanglement effect to fiber; improves the mechanical strength of spunlaced composite filtering material significantly, and ensures the end product to achieve excellent mechanical properties, filtering quality and chemical resistance property.

Owner:SHAOXING RONGLIDA TEXTILE TECH

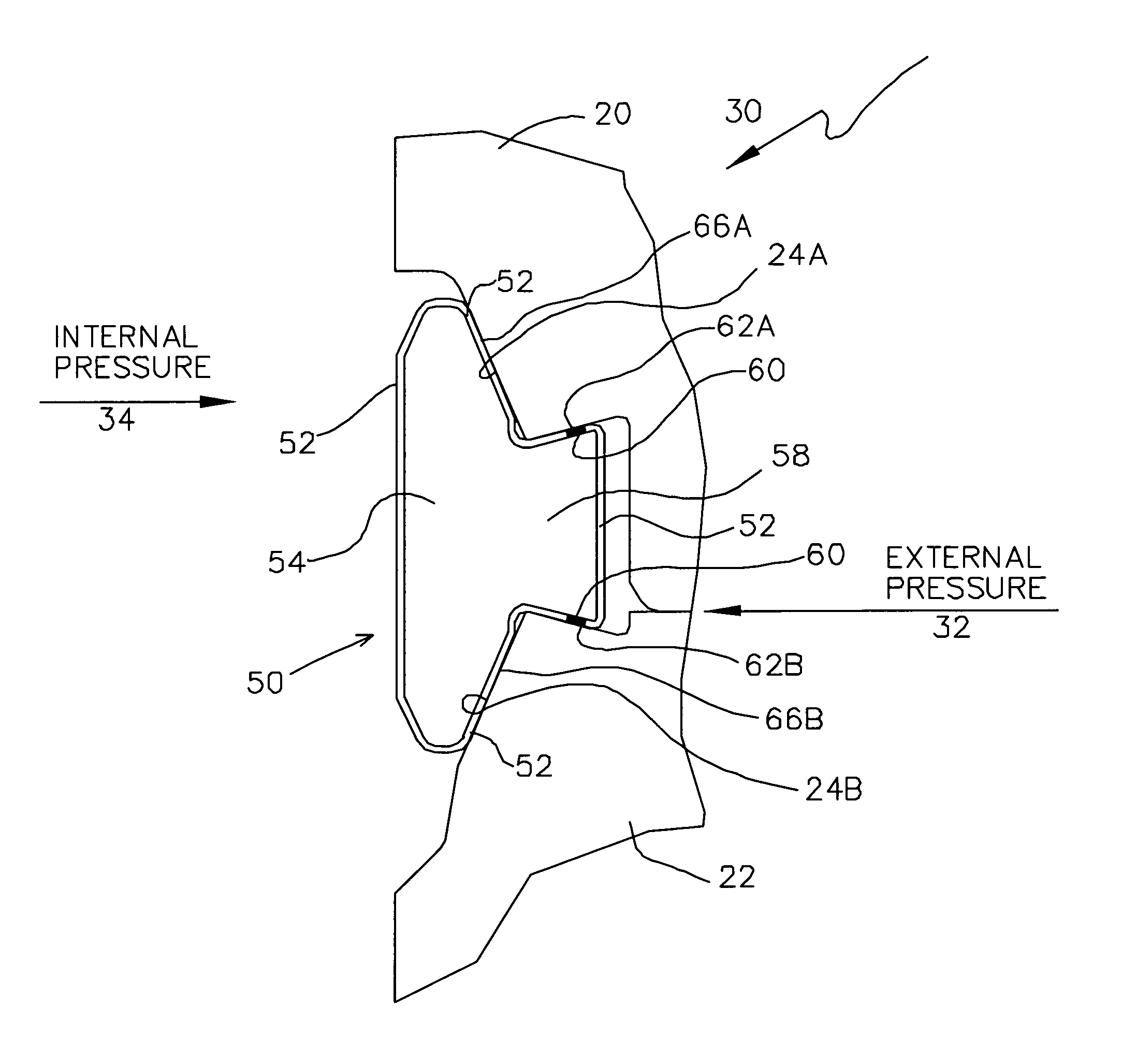

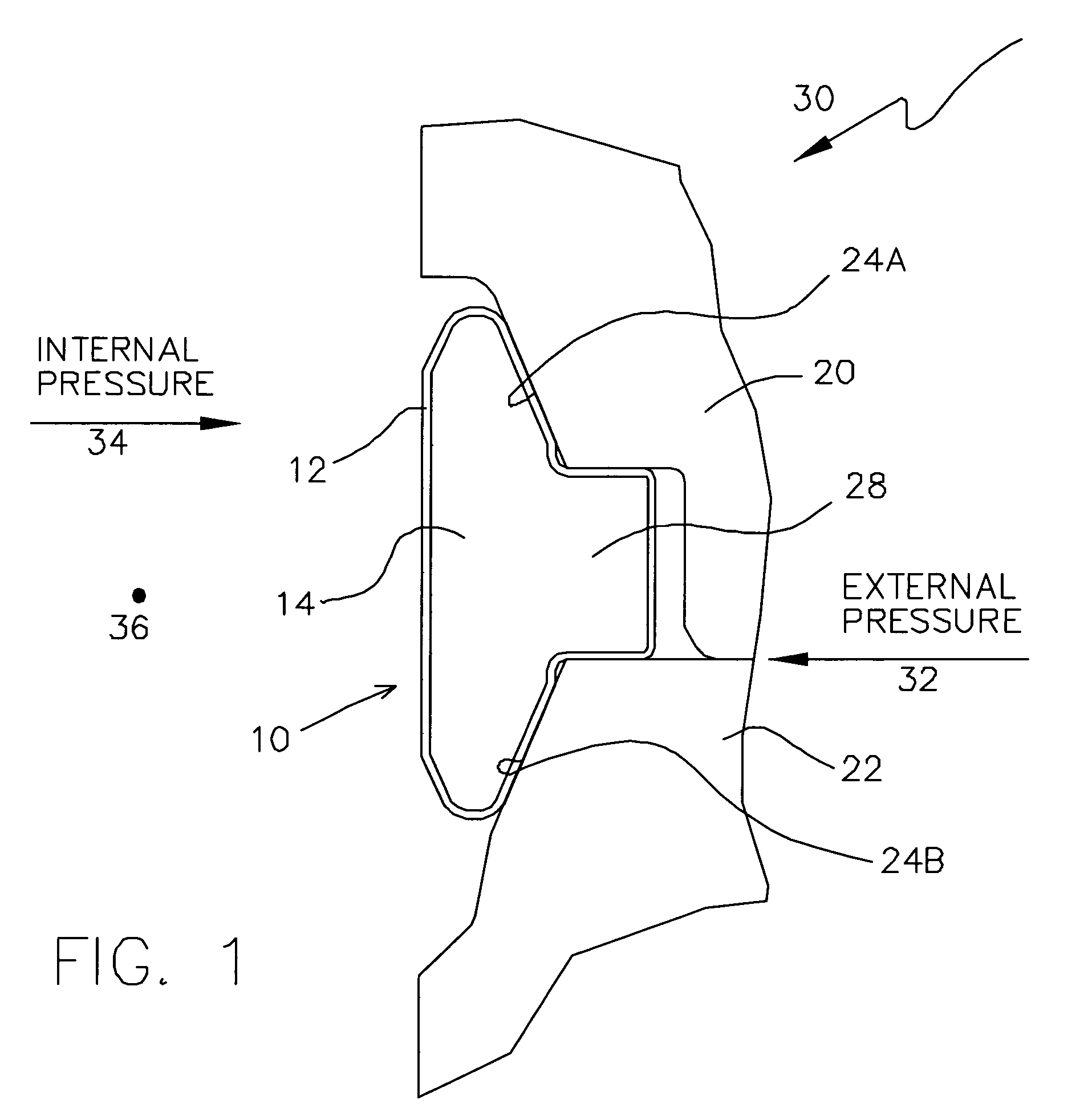

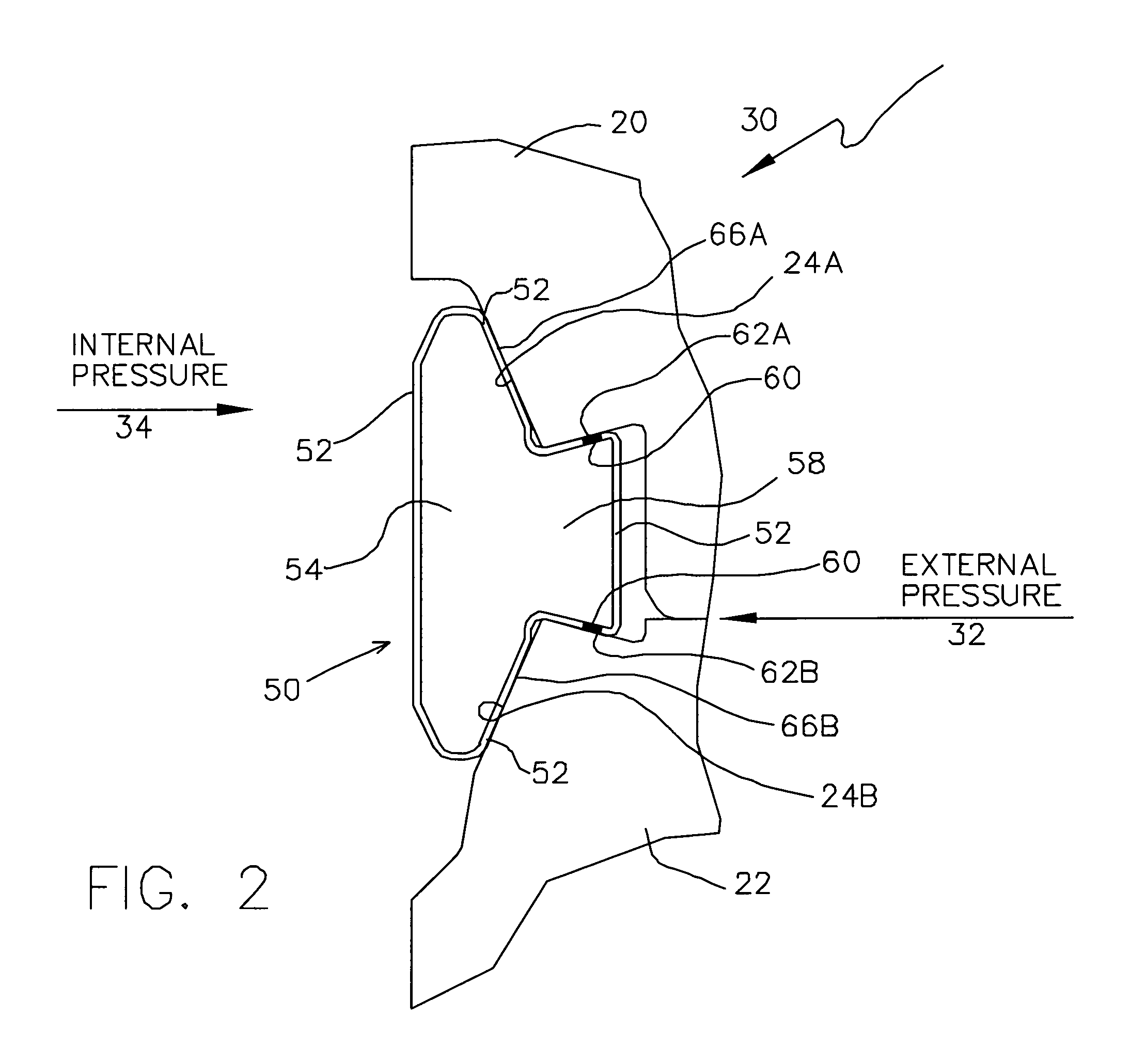

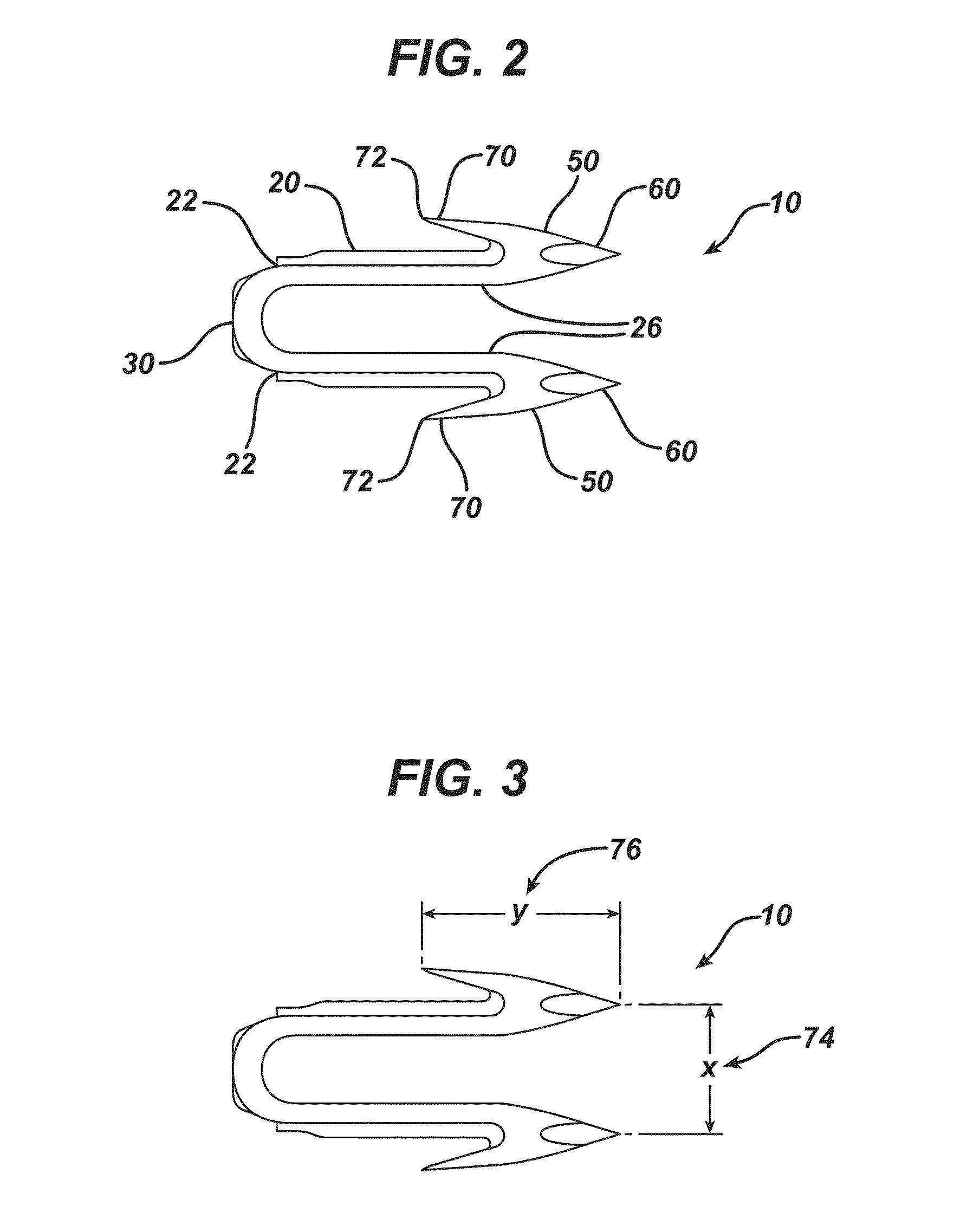

Fishtail bore seal

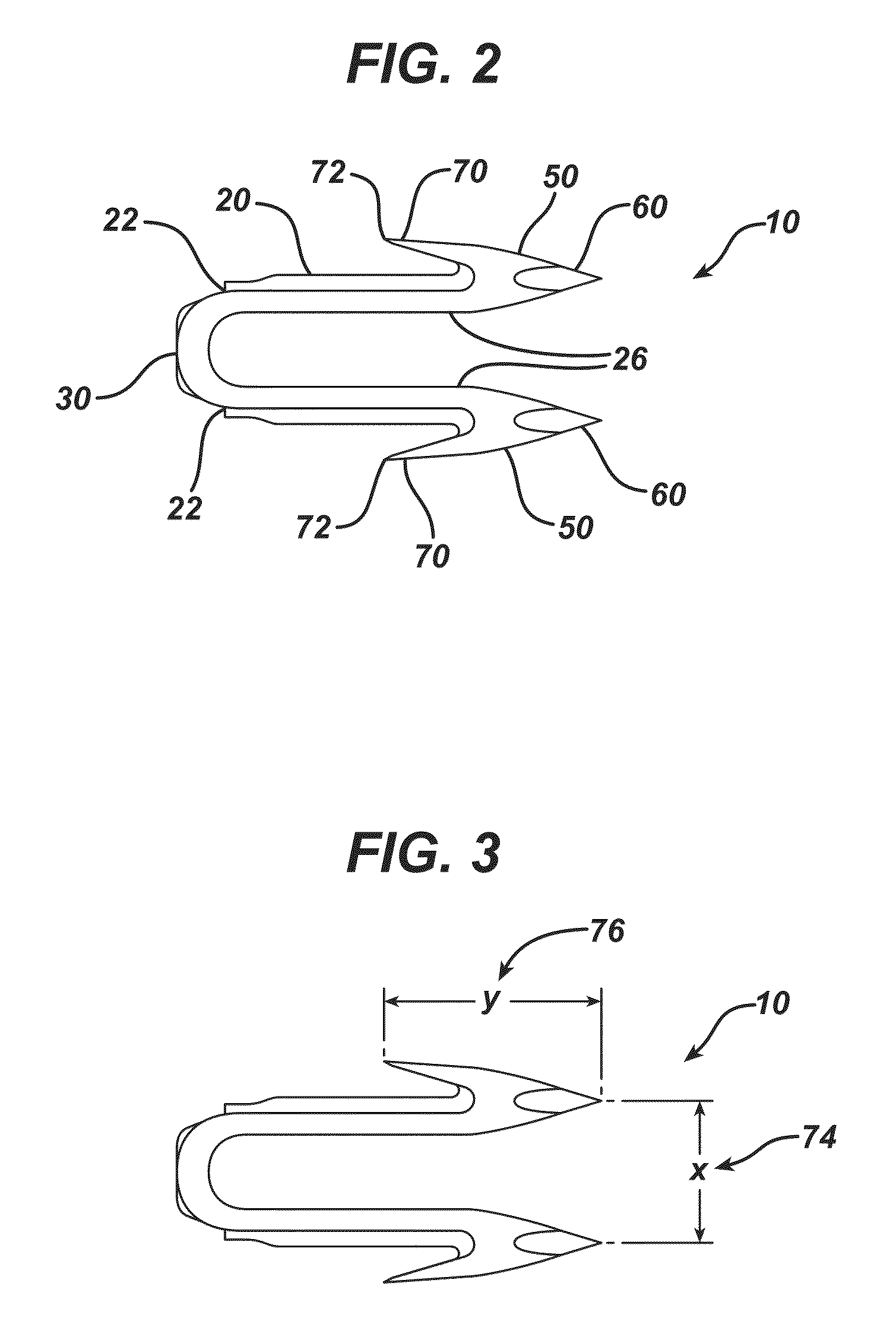

InactiveUS7819439B2Good strength retentionMaximize rangeSleeve/socket jointsEngine sealsInternal pressureThermal spraying

A bore seal for connecting and sealing oil and gas tubular members is disclosed which has a metal core manufactured from a high yield strength ferrous material and a protective overlay of corrosion and abrasion resistant stainless steel and / or nickel based alloy. The protective overlay is applied to the entire outer surface of the bore seal by a metal thermal spray process, such as plasma thermal spraying. In a preferred embodiment of the invention, the bore seal has a fishtail profile which facilitates the use of resilient seals to provide resistance to external pressures in addition to the traditional metal-to-metal seal between the bore seal and the tubular members. In an alternative embodiment, a pressure relief valve is disposed within the bore seal to verify the integrity of the metal-to-metal seal with respect to internal bore pressure.

Owner:SUB DRILL SUPPLY

Glass fiber impregnating compound and preparation method and application thereof

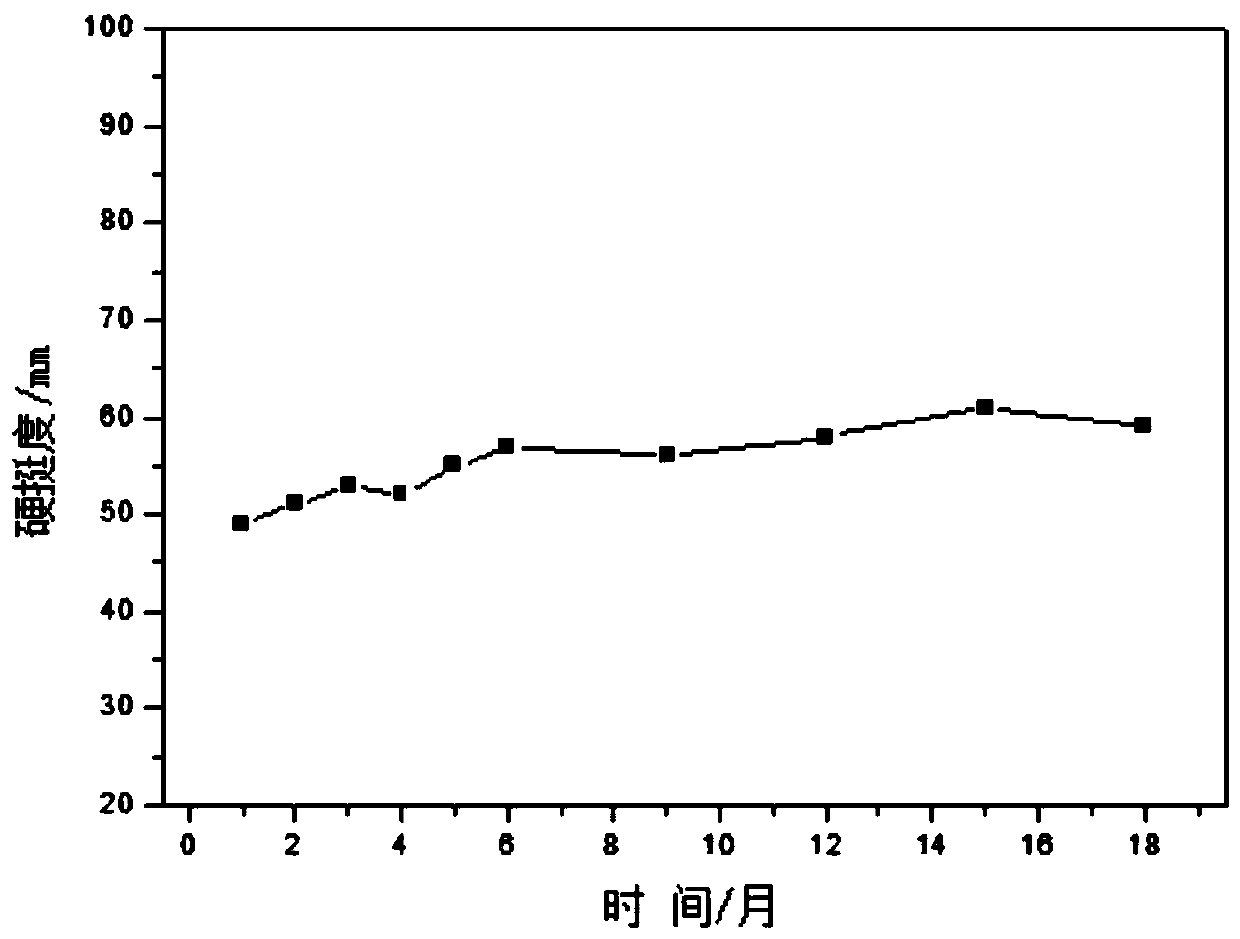

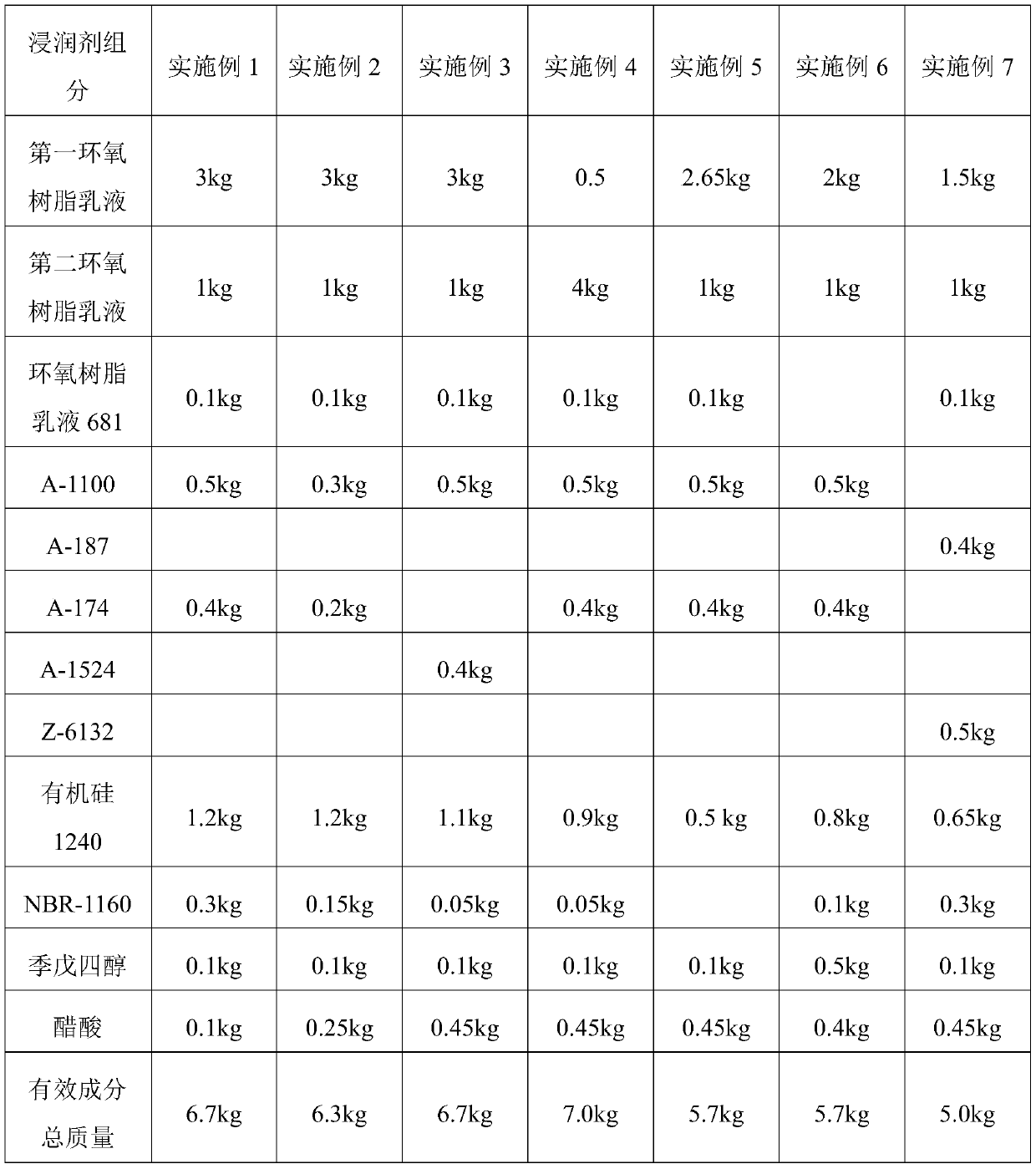

The invention belongs to the technical field of impregnating compounds, and discloses a glass fiber impregnating compound and a preparation method and application thereof. The impregnating compound comprises a film-forming agent, a coupling agent, a lubricant, a wetting agent and a pH regulator, wherein the film-forming agent comprises two bisphenol A type epoxy resin emulsions with different epoxy equivalents. Compared with usage of an epoxy resin emulsion with a single epoxy equivalent as a film-forming agent, the film-forming agent disclosed by the invention has the advantages that the film-forming agent can ensure sufficient coating force of the epoxy resin emulsions on the surfaces of yarns and allow the yarns to have better softness; even if the yarns are stored for a long time, theyarns still have low stiffness, which is beneficial for subsequent processing and mechanical strength of a composite material; and meanwhile, the yarns have better damp-heat resistance and still havea good strength retention rate in a high-temperature and high-humidity environment due to matched use of the film-forming agent and the coupling agent.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD +1

Non-efflorescing cementitious bodies

InactiveUS20040035328A1Satisfied levelReduce weatheringSolid waste managementCeramic shaping apparatusCalcium silicateHydrated alumina

A non-efflorescing cementitious body is formed from sources of calcium aluminate, calcium silicate, calcium sulphate and reactive silica, these ingredients being present in such relative proportions that, upon hydration, both monosulphate (C3A.Cs.12H) and hydrated alumina (AH3) are formed. Also disclosed is a hydraulic binder and a paste from which such bodies can be formed and a method for forming such bodies. In addition to exhibiting low efflorescence, these bodies retain satisfactory physical properties, especially good durability to natural weathering conditions.

Owner:LAFARGE ALUMINATES

Polyester fiber and method for preparing same

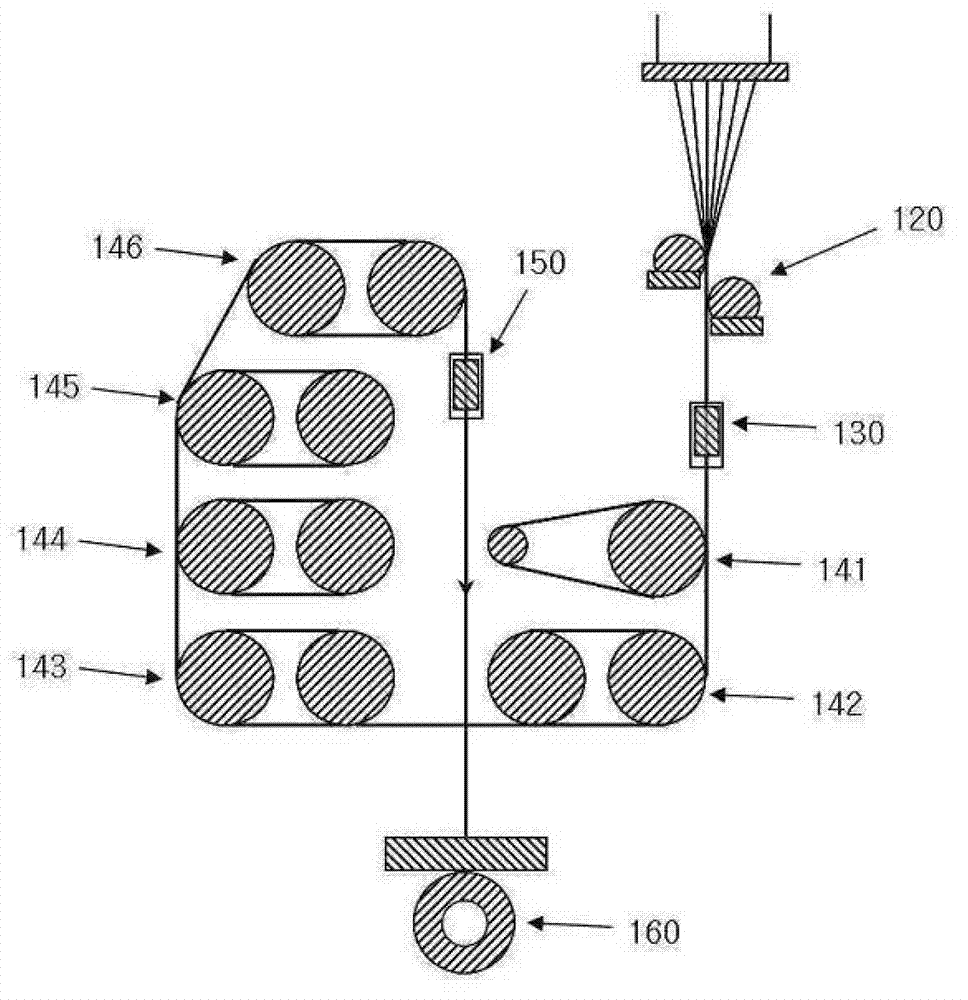

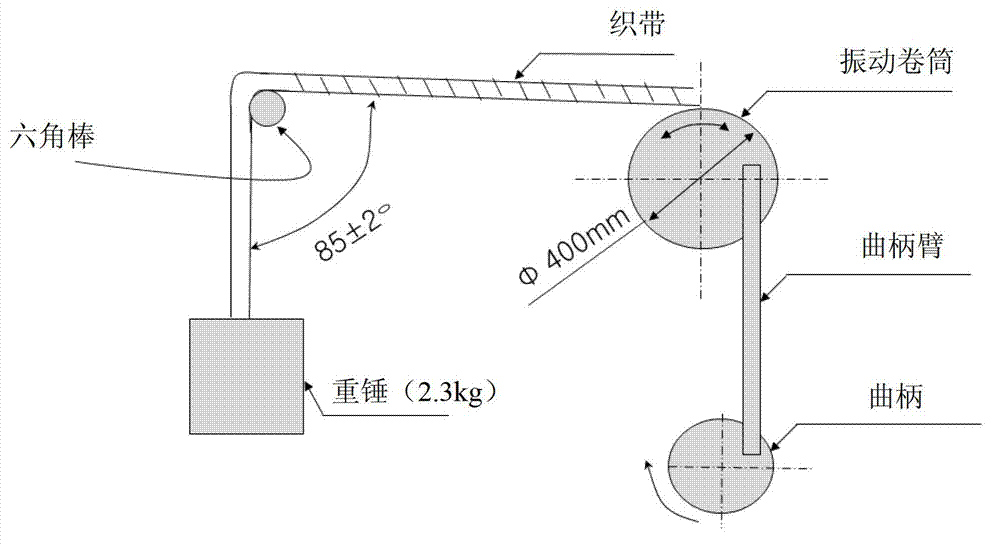

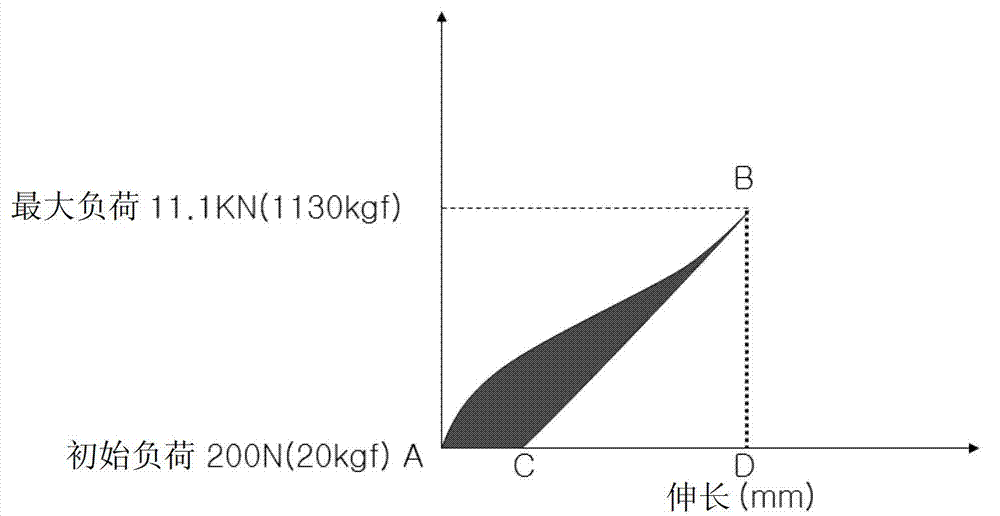

InactiveCN102959146AImprove mechanical propertiesImprove wear resistanceArtificial filament heat treatmentWoven fabricsFiberPolyester

The present invention relates to industrial high-strength polyester fiber to be used in a seatbelt, webbing, and the like. More particularly, the present invention relates to polyester fiber and to a method for preparing same, wherein the polyester fiber has an elongation of 0.5% or higher at a stress of 1.0 g / d measured at room temperature, an elongation of 4.3% or higher at a stress of 4.0 g / d, and an elongation of 7.5% or higher at a stress of 7.0 g / d. The polyester fiber of the present invention is optimized to have high strength, a low modulus and high elongation, thus ensuring superior mechanical physical properties. Therefore, a seatbelt having superior shock-absorbing properties and significantly improved wear resistance and heat-aged breaking strength retention can be prepared from the polyester fiber of the present invention.

Owner:KOLON IND INC

Hydrated alumina molded matter and preparation method thereof, alumina molded matter and applications of hydrated alumina molded matter and alumina molded matter

ActiveCN103480428AGood strength retentionHigh strengthCatalyst carriersCatalyst activation/preparationCelluloseHydrated alumina

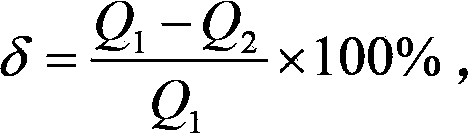

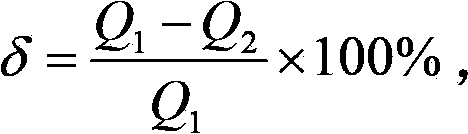

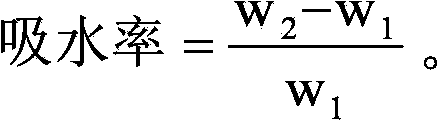

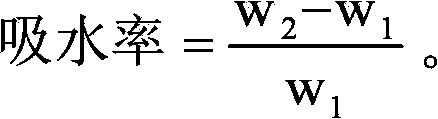

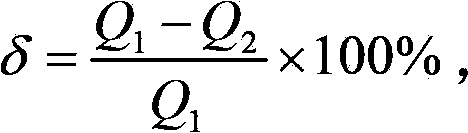

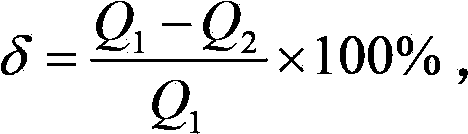

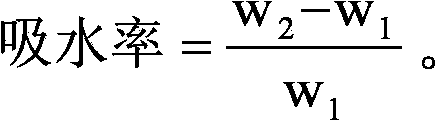

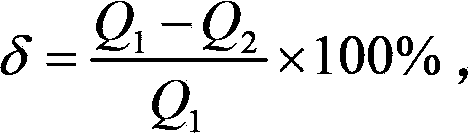

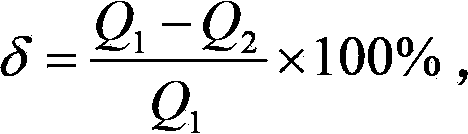

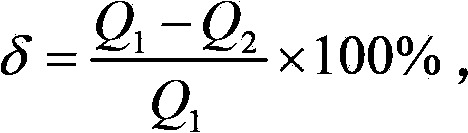

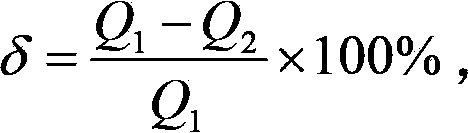

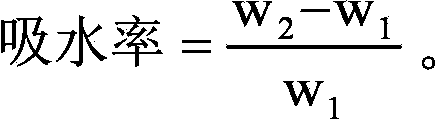

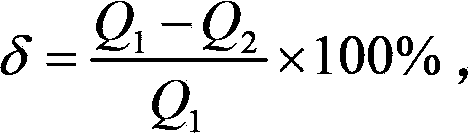

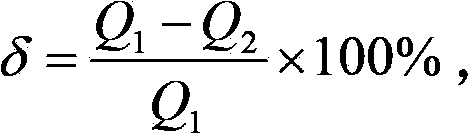

The invention provides a hydrated alumina molded matter, and a preparation method and an application thereof. The hydrated alumina molded matter is prepared from raw materials comprising at least one hydrated alumina, at least one group IVB metal element-containing compound and at least one cellulose ether. The water absorption rate of the hydrated alumina molded matter is 0.4-1.5, the delta value is below 10%, and the Q1 is more than 12 N / mm. The invention also provides an alumina molded matter and an application thereof. The alumina molded matter is prepared by calcination of the hydrated alumina molded matter. The molded matters provided by the invention have high strength and good strength retention rate. According to the method of the invention, a peptizing agent is not used during the molding process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Special high-performance additive for underwater masonry mortar

The invention discloses a special high-performance additive for underwater masonry mortar. The special high-performance additive is composed of, by weight, 2-5 parts of a thickening agent, 0.5-1 part of super plasticizer, 5-8 parts of a thixotropic agent, 5-8 parts of special cement, 12-15 parts of a set controlling agent and 5-8 parts of an early strength agent. In the special high-performance additive for the underwater masonry mortar, the thickening agent can improve the adhesiveness of a mixed product, and therefore the underwater non-disperse mortar is endowed with the properties of dispersing and separating resistance. The super plasticizer can improve the fluidity and workability of the mixed product, and therefore the material is endowed with good self-leveling and self-compacting properties. The frequently-used super plasticizer mainly includes sulfonated resin or sulfonate, and therefore the material has the properties of underwater dispersing and separating resistance. Through the combined action of the doped special cement and the set controlling agent, the material is endowed with early strength and rapid hardening.

Owner:北京建工新型建材有限责任公司

Hydrated alumina molded matter and preparation method thereof, alumina molded matter and applications of hydrated alumina molded matter and alumina molded matter

ActiveCN103480326AGood strength retentionHigh strengthCatalyst carriersMolecular sieve catalystsCelluloseMolecular sieve

The invention provides a hydrated alumina molded matter, and a preparation method and an application thereof. The hydrated alumina molded matter is prepared by molding raw materials comprising at least one hydrated alumina, at least one Y molecular sieve and at least one cellulose ether. The water absorption rate of the hydrated alumina molded matter is 0.4-1.5, the delta value is 10% or less, and the Q1 is 12 N / mm or more. The invention also provides an alumina molded matter and an application thereof, wherein the alumina molded matter is prepared by calcination of the hydrated alumina molded matter. The molded matters provided by the invention have high strength and good strength retention rate. According to the method of the invention, a peptizing agent is not used during the molding process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Masonry mortar used in underwater alkaline environment

The invention discloses masonry mortar used in an underwater alkaline environment. The masonry mortar comprises the following components, according to a weight ratio, 180-220 parts by weight of Portland cement, 30-50 parts by weight of special cement, 705-715 parts by weight of natural medium sand, 13-18 parts by weight of resin glue powder, and 30-40 parts by weight of a special additive. The special additive is mixed from 2-5 parts by weight of a thickening agent, 0.5-1 part by weight of a super-plasticizer, 5-8 parts by weight of a thixotropic agent, 12-15 parts by weight of an adjusting admixture, and 5-8 parts by weight of an early strength agent. The masonry mortar is adjusted by high-performance additives special for underwater masonry mortar, and resin materials good in alkaline resistance are added, so that the masonry mortar is prevented from undergoing a reaction in the alkaline condition, and hardening and mortar performance aren't affected. At last, the masonry mortar is not prone to disperse, good in construction, resistant to alkaline, normal in underwater hardening, and high in strength in a working condition with water.

Owner:北京建工新型建材有限责任公司

Masonry mortar for underwater acid environment

The invention discloses masonry mortar for an underwater acid environment. The masonry mortar comprises, by weight, 180-220 parts of common cement, 30-50 parts of special cement, 695-705 parts of natural medium sand, 20-30 parts of resin adhesive powder and 30-40 parts of special additives, wherein the special additives are mixed by, by weight, 2-5 parts of thickening agent, 0.5-1 part of super plasticizer, 5-8 parts of thixotropic agent, 12-15 parts of thickening time control agent and 5-8 parts of early strength agent. The masonry mortar has the advantages that by regulating the additives special for high-performance underwater masonry mortar and adding resin materials good in acid resistance, masonry mortar components are prevented from have reaction under acid conditions, the hardening and performance of the mortar cannot be affected, and the masonry mortar is less prone to dispersing, good in constructability, resistant to acid, capable of being normally hardened under water and high in strength under water operation conditions.

Owner:北京建工新型建材有限责任公司

Hydrate alumina forming product, production method thereof, alumina forming product, applications thereof, catalyst, preparation method thereof, and hydrogenation processing method

ActiveCN103480337AGood strength retentionPromote absorptionCatalyst carriersOther chemical processesCelluloseCatalytic function

The invention provides a hydrate alumina forming product, a preparation method, and applications thereof. The forming product is prepared from following raw materials: at least a hydrate alumina, at least a compound containing magnesium, and at least a cellulose ether, the water absorption rate of the forming product is 0.4 to 1.5, delta value is smaller than 10%, and Q1 is more than 12 N / mm. The invention also provides an alumina forming product and applications thereof, and the forming product is prepared from the hydrate alumina forming product provided by the invention through burning. The invention further provides a catalyst, which has a hydrogenation catalytic function and is prepared by taking the hydrate alumina forming product or alumina forming product provided by the invention as the carrier, a preparation method, and applications thereof. The invention also provides a hydrogenation processing method of hydrocarbon oil by using the catalyst provided by the invention. The forming product provided by the invention has a high strength and a strength retention rate. The catalyst provided by the invention has a higher catalytic activity in the hydrogenation processing of hydrocarbon oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alkali-free concrete accelerator and processing method thereof

The invention discloses an alkali-free concrete accelerator and a processing method thereof. The alkali-free concrete accelerator comprises the following raw materials in parts by weight: 30-65 partsof aluminum sulfate, 2-8 parts of an organic amine, 1-3% of a stabilizer, 1-5 parts of a suspending agent, 20-35 parts of water, 2-5 parts of bentonite and 4-6% of magnesium fluosilicate. In the present invention, the caulking agent for building decoration of prefabricated parts is simple in preparation method, low in cost, is liquid after preparation, can be uniformly mixed with concrete conveniently, contains no alkali or chlorine or pungent smell, is high in safety, is harmless to human body, is excellent in cohesiveness; adding of a stabilizing agent can prolong the storage time, preventdeterioration; magnesium fluosilicate and aluminum sulfate are adopted for cooperative using, so that the resilience value is low, later strength retention rate is high, and impermeability grade is high; adding of the alkali-free concrete accelerator in sprayed concrete is capable of achieving a preferable working environment and considerable market value.

Owner:湖南加美乐素新材料股份有限公司

Epoxy conductive silver glue for LED and method for manufacturing same

ActiveCN101245227BSolve the problem of thixotropySolve coordination problemsSemiconductor/solid-state device detailsSolid-state devicesEpoxySilver colloid

The invention relates to an epoxy conductive silver colloid used in LED, the raw material formula of which comprises the following components according to weight percentage content: 70 to 80 percent of silver powder, 8 to 15 percent of epoxy resin, 4 to 10 percent of toughening agent, 0.5 to 2 percent of curing agent, 0.05 to 0.3 percent of accelerator, 3 to 7 percent of solvent, and 0.1 to 2 percent of additive; the epoxy conductive silver colloid is prepared by (1) preparation pf substrate; (2) preparation of silver colloid; (3) production process of silver colloid. Compared with the prior art, the epoxy conductive silver colloid used in LED causes the curing condition of the conductive silver colloid and shear strength to be coordinated better, is more suitable for the industrialization production, and improves production efficiency and the reliability of products.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Bioabsorbable polymeric compositions, processing methods, and medical devices therefrom

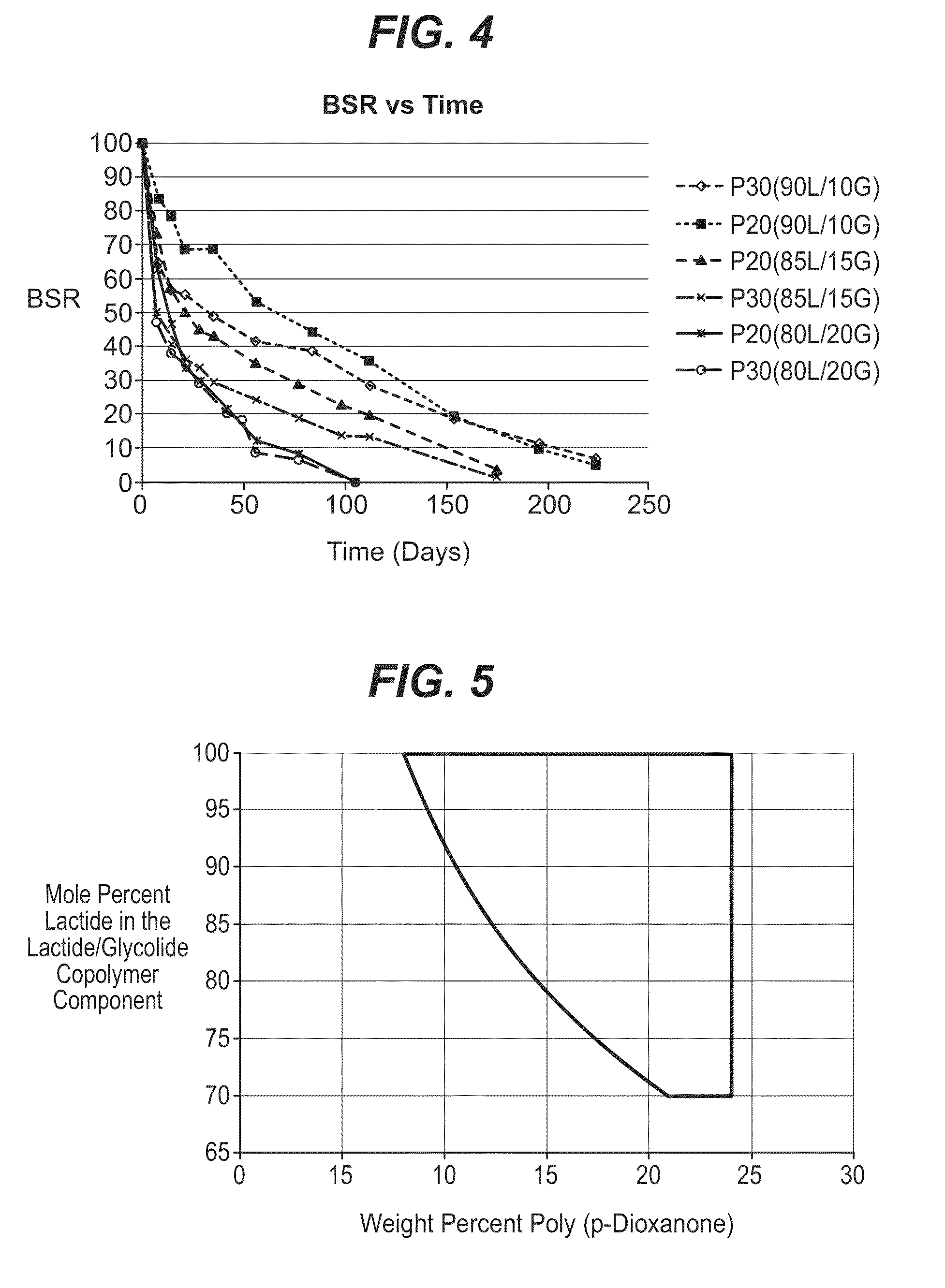

ActiveUS20140073705A1Improve mechanical propertiesHigh stiffnessSuture equipmentsCosmetic preparationsP-dioxanoneLactide

Novel bioabsorbable polymeric blends are disclosed. The blends have a first component that is a polylactide polymers or a copolymer of lactide and glycolide and a second component that is poly(p-dioxanone) polymer. The novel polymeric blends provide medical devices having dimensional stability. Also disclosed are novel bioabsorbable medical devices made from these novel polymer blends, as well as novel methods of manufacture.

Owner:ETHICON INC

A special admixture for high-performance underwater masonry mortar

The invention discloses a special high-performance additive for underwater masonry mortar. The special high-performance additive is composed of, by weight, 2-5 parts of a thickening agent, 0.5-1 part of super plasticizer, 5-8 parts of a thixotropic agent, 5-8 parts of special cement, 12-15 parts of a set controlling agent and 5-8 parts of an early strength agent. In the special high-performance additive for the underwater masonry mortar, the thickening agent can improve the adhesiveness of a mixed product, and therefore the underwater non-disperse mortar is endowed with the properties of dispersing and separating resistance. The super plasticizer can improve the fluidity and workability of the mixed product, and therefore the material is endowed with good self-leveling and self-compacting properties. The frequently-used super plasticizer mainly includes sulfonated resin or sulfonate, and therefore the material has the properties of underwater dispersing and separating resistance. Through the combined action of the doped special cement and the set controlling agent, the material is endowed with early strength and rapid hardening.

Owner:北京建工新型建材有限责任公司

Molded siliceous hydrated alumina, preparation method thereof, and molded siliceous alumina

ActiveCN103418351AHigh radial crush strength and radial crush strength retentionGood absorptionCatalyst carriersOther chemical processesStrength lossCellulose

The invention provides a molded siliceous hydrated alumina, and a preparation method and an application thereof. The molded siliceous hydrated alumina is prepared through using raw materials containing at least one hydrated alumina, at least one siliceous compound and at least one cellulose ether, and has a water absorption of 0.4-1.5, a radial crushing strength of above 12N / mm and a strength loss rate after immersion in water of below 10%. The invention also provides a molded siliceous alumina. The molded siliceous alumina is prepared through roasting the molded siliceous hydrated alumina. The invention further provides an application of the molded siliceous hydrated alumina and the molded siliceous alumina as a dryer or a carrier of a supported catalyst. The above molded materials have good strength retention rates and absorption properties, and catalysts prepared by using the molded materials as the carrier have high catalysis properties. No peptizing agents are used in the preparation method.

Owner:CHINA PETROLEUM & CHEM CORP +1

Bioabsorbable polymeric compositions, processing methods, and medical devices therefrom

ActiveUS9173979B2Improve mechanical propertiesHigh stiffnessStentsSuture equipmentsP-dioxanoneLactide

Novel bioabsorbable polymeric blends are disclosed. The blends have a first component that is a polylactide polymer or a copolymer of lactide and glycolide and a second component that is poly(p-dioxanone) polymer. The novel polymeric blends provide medical devices having dimensional stability. Also disclosed are novel bioabsorbable medical devices made from these novel polymer blends, as well as novel methods of manufacture.

Owner:ETHICON INC

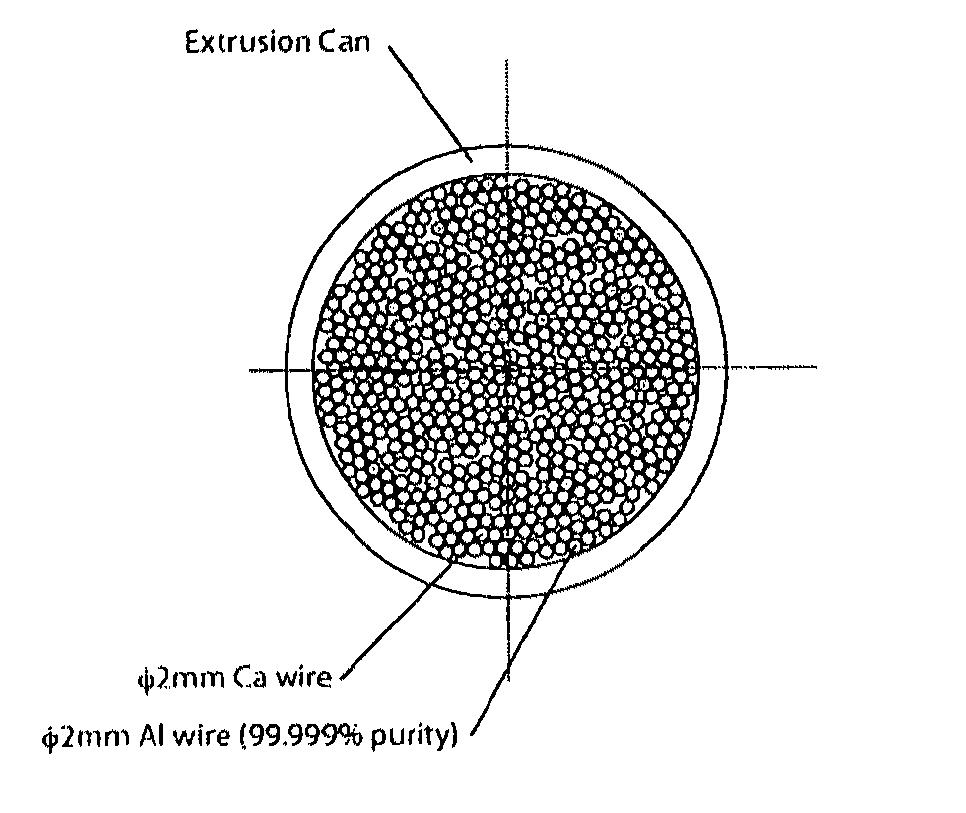

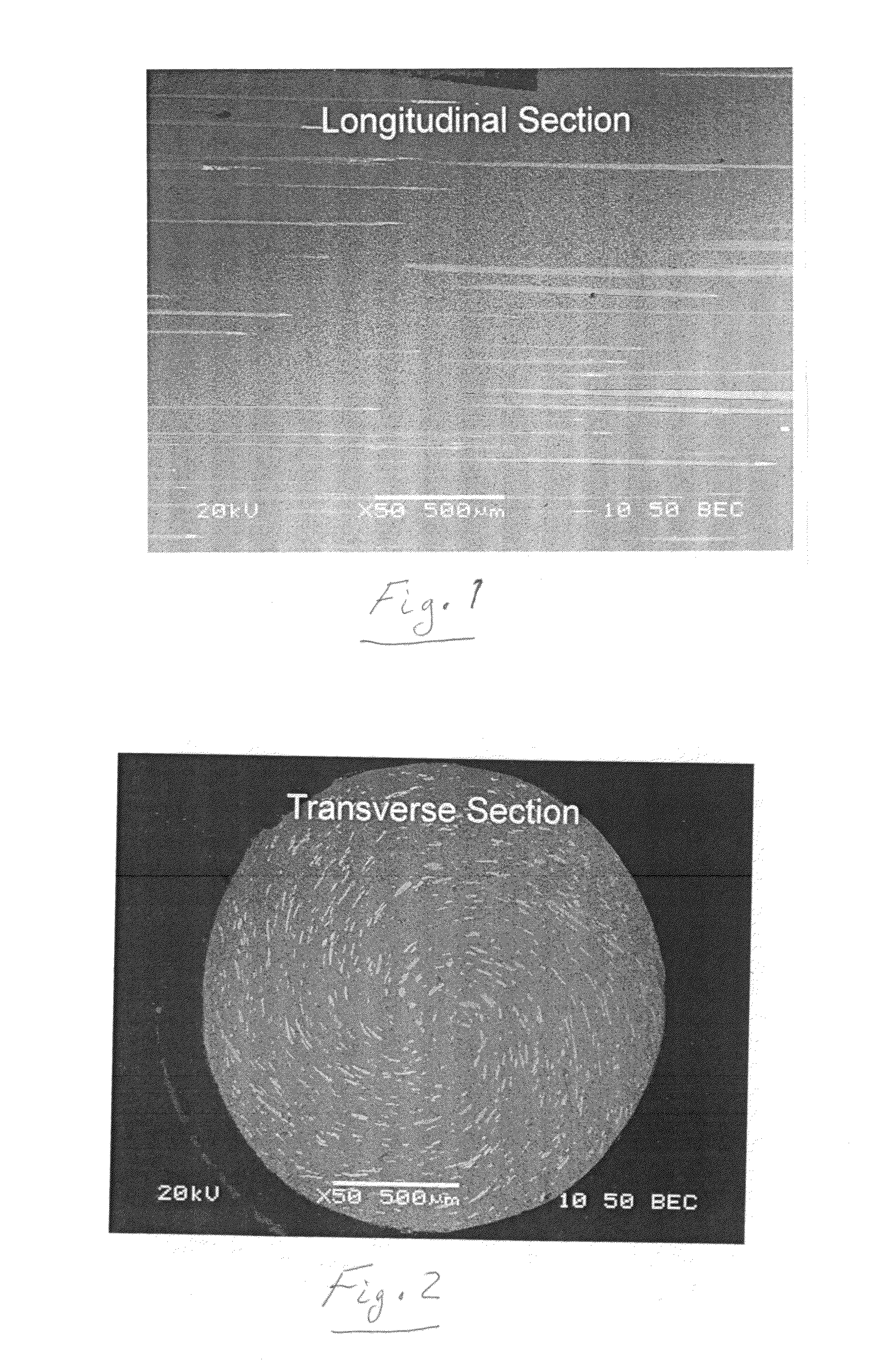

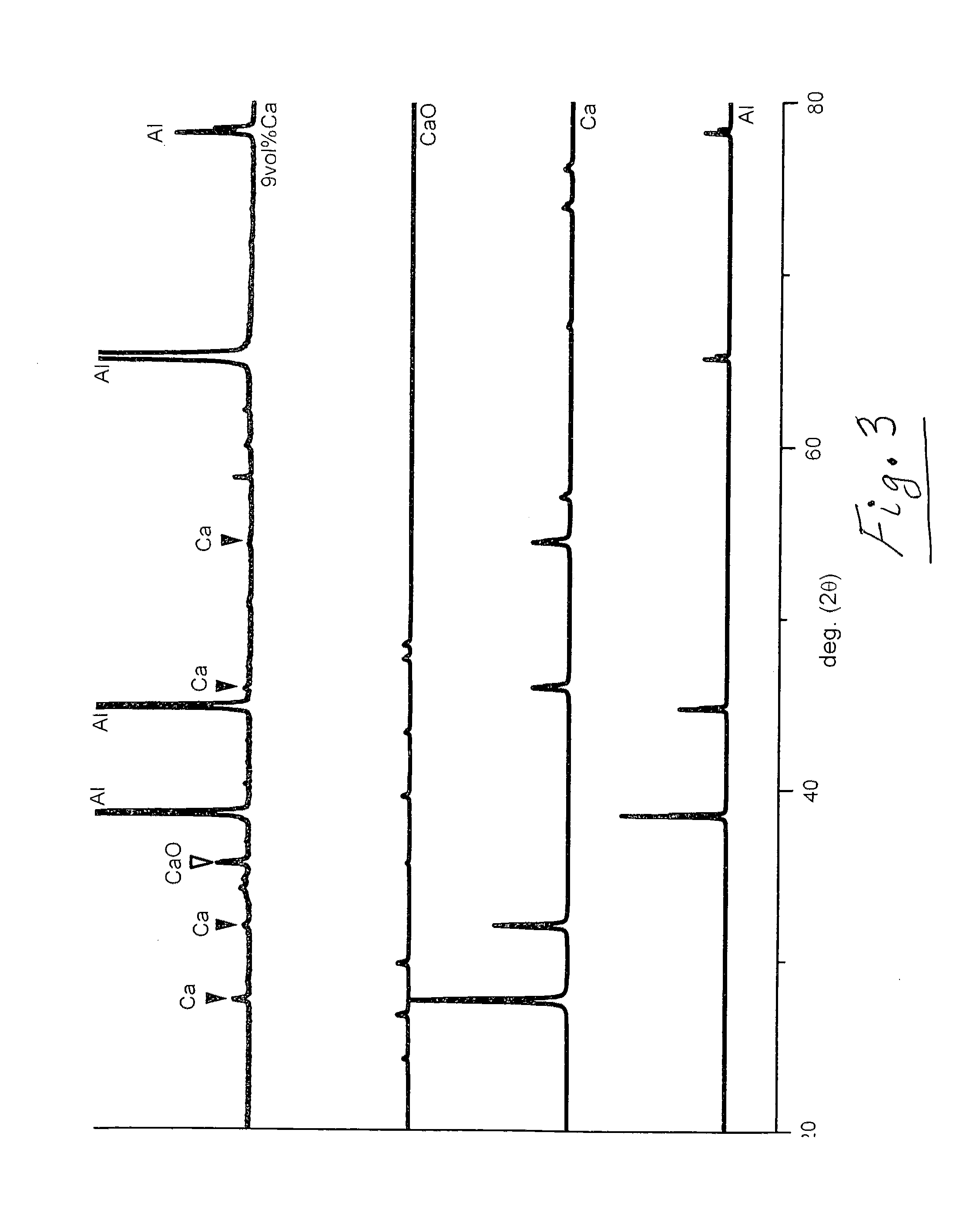

Aluminum/alkaline earth metal composites and method for producing

ActiveUS8647536B2High strengthImprove strength propertiesLine/current collector detailsConductive materialAlkaline earth metalElectrical conductor

Owner:IOWA STATE UNIV RES FOUND

Method for making high-bulk paper by adopting chemical wood pulp

InactiveCN102605668BHigh whitenessHigh strengthChemical/chemomechanical pulpInorganic compound additionFilling materialsPulp and paper industry

The invention relates to high-bulk paper manufactured by adopting chemical wood pulp and a manufacture method of the high-bulk paper. The high-bulk paper is mainly characterized in that the mass mixture ratio of the pulp of chemical needle-point leaf wood pulp to chemical broad leaf wood pulp is (15-30):(70-85), filling materials are silicate base high-bulk great-particle filling materials with the addition being 20 percent to 40 percent, the consumption of retention aid is 0.3 to 0.5kg / ton paper, and the consumption of cationic starch is 8 to 15kg / ton paper. Handsheets made by adopting the method have the characteristics that the bulk is high, the filling content is high, and the paper intensity retention is good.

Owner:SHAANXI UNIV OF SCI & TECH

Hydrated alumina forming matter and preparation method thereof, alumina forming matter, catalyst and preparation method and application thereof and hydrotreating method

ActiveCN103480249AGood strength retentionPromote absorptionCatalyst carriersDispersed particle separationLithiumCellulose

The invention provides a hydrated alumina forming matter and a preparation method and application thereof, the hydrated alumina forming matter is prepared from raw materials comprising at least one hydrated alumina, at least one lithium containing compound and at least one cellulose ether, the water absorption rate of the forming matter is 0.4 - 1.5, the delta value is less than 10%, and Q1 is more than 12N / mm. The invention also provides an alumina forming matter and application thereof, the alumina forming matter is prepared by roasting the hydrated alumina forming matter of the invention. The invention further provides a catalyst prepared by using the hydrated alumina forming matter or the alumina forming matter as a carrier and having hydrogenation catalysis effect and a preparation method and application thereof. The invention also provides a hydrocarbon oil hydrotreating method using the catalyst. The alumina forming matter has high strength and strength retention. The catalyst shows a higher catalytic activity in hydrocarbon oil hydrotreating.

Owner:CHINA PETROLEUM & CHEM CORP +1

Iron-containing hydrated alumina molded matter and preparation method thereof, and iron-containing alumina molded matter and applications of iron-containing hydrated alumina molded matter and iron-containing alumina molded matter

ActiveCN103480327AGood strength retentionPromote absorptionCatalyst carriersOther chemical processesCelluloseHydration reaction

The invention provides an iron-containing hydrated alumina molded matter, and a preparation method and an application thereof. The iron-containing hydrated alumina molded matter is prepared from raw materials comprising at least one hydrated alumina, at least one iron-containing compound and at least one cellulose ether. The water absorption rate of the iron-containing hydrated alumina molded matter is 0.4-1.5, the delta value is 10% or less, and the Q1 is 12 N / mm or more. The invention also provides an iron-containing alumina molded matter prepared by calcination of the iron-containing hydrated alumina molded matter. The invention also provides an application of the molded matters as a drying agent or as a carrier of a supported catalyst. The iron-containing hydrated alumina molded matter contains no peptizing agent, has good strength retention rate, and cannot or basically cannot generate phenomena of dissolving, powdering or pore collapsing even being immersed in an impregnating solution for a long time. The method of the invention does not adopt the peptizing agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Alkali-dispersible hot melt pressure-sensitive adhesive

PendingUS20220298392A1Good strength retentionHigh alkali-dispersibilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceHot melt

The object of the present invention is to provide an alkali-dispersible hot melt pressure-sensitive adhesive which (i) has a high alkali-dispersibility, (ii) is excellent in strength to retain a label, (iii) hardly causes an adhesive residue problem and (iv) is capable of reducing stringing. The present invention relates to an alkali-dispersible hot melt pressure-sensitive adhesive comprising: (A) a thermoplastic block copolymer which is a copolymer of a vinyl-based aromatic hydrocarbon and a conjugated diene compound, (B) a tackifier resin and (C) at least one selected from the group consisting of a fatty acid and a derivative thereof, wherein the component (C) comprises (C1) a fatty acid derivative having a melting point of 40° C. or more.

Owner:HENKEL KGAA

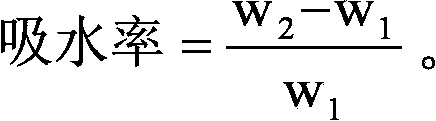

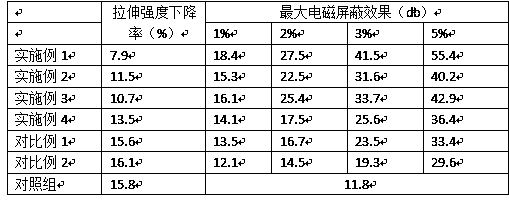

Macromolecular material additive with electromagnetic shielding function and preparation method thereof

The invention relates to a macromolecular material additive with an electromagnetic shielding function and a preparation method thereof. The preparation method comprises the following steps of (1) preparing a mixed filler; (2) soaking graphene by hydrochloric acid of 10% mass fraction for 1 to 2 h, and respectively cleaning by acetone and anhydrous ethanol; (3) mixing the treated graphene and themixed filler obtained in step (1) according to a weight ratio of (5 to 6):1; (4) mixing the product obtained in step (3) and nanocopper powder, stirring under the protection of inert gas, treating for30 to 40 min by ultrasonic waves, and baking for 1 to 2 h at the temperature of 100 to 120 DEG C, so as to obtain the additive. The macromolecular material additive with the electromagnetic shieldingfunction has the advantages that the electromagnetic shielding effect is good; the macromolecular material additive can be added into multiple types of macromolecular materials, so that the application range of the additive is increased; by mixing the graphene and the nanocopper powder, the electromagnetic shielding effect is effectively improved.

Owner:DECORIA MATERIALS JIANGSU CO LTD

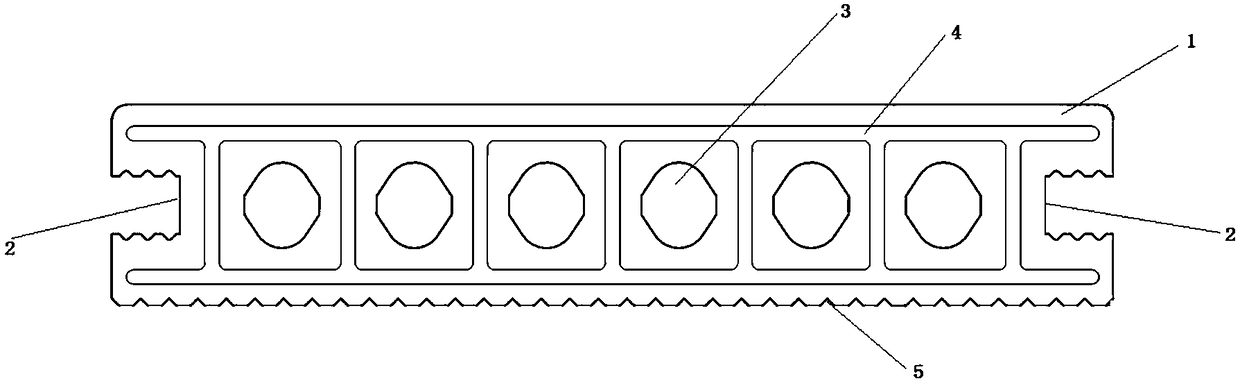

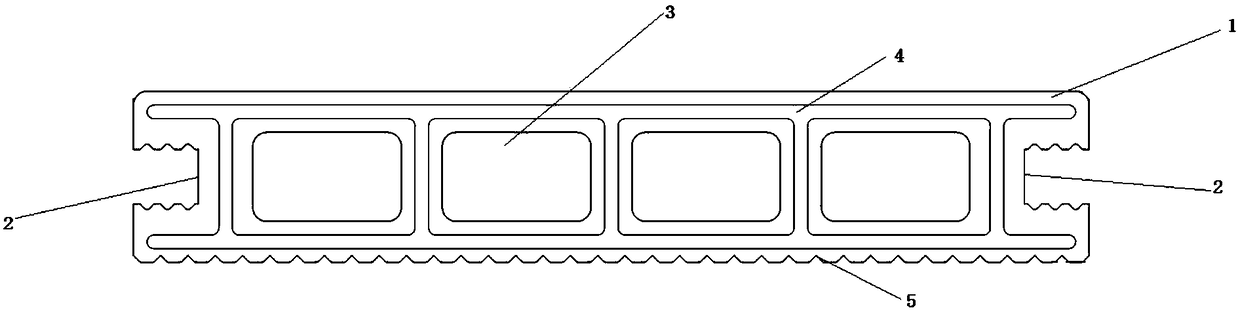

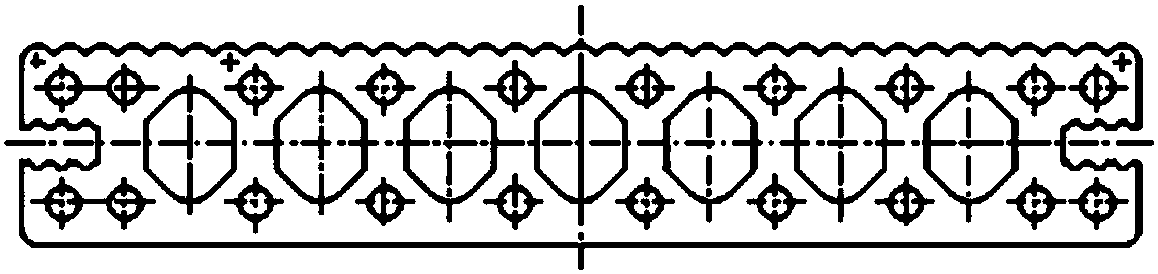

Inner fiber reinforced wood-plastic product

PendingCN108458242AImprove carrying capacityHigh strengthSheets/panelsFlooringSurface layerWave shape

The invention discloses an inner fiber reinforced wood-plastic product. The inner fiber reinforced wood-plastic product comprises a product body, and clamping grooves which are formed in the left sideand the right side of the product body, wherein a plurality of through holes which pass through the front end and the rear end of the product body are formed in the product body; and a fiber reinforced material, which is close to the surface layer of the product body and encloses each through hole, is arranged between each through hole and the surface layer of the product body. According to the inner fiber reinforced wood-plastic product adopting the abovementioned structure design, the fiber reinforced materials are distributed to the surrounding side edges of a profile in a longitudinal andtransverse net form, so that the plane supporting and longitudinal supporting effects can be achieved, and as a result, the bearing capacity of the surface of a board as well as the overall intensityof the product can be improved. Additionally, the deformation resistance of the product is effectively improved, so that the durability of the product is improved; and moreover, the double-plane supporting effect enables high intensity holding effect of the product whether any one of the upper surface and the lower surface is treated as the using surface; and the decoration effect of upper and lower pattern splicing combination or plane or wave-shaped surface can be achieved.

Owner:江苏金发再生资源有限公司

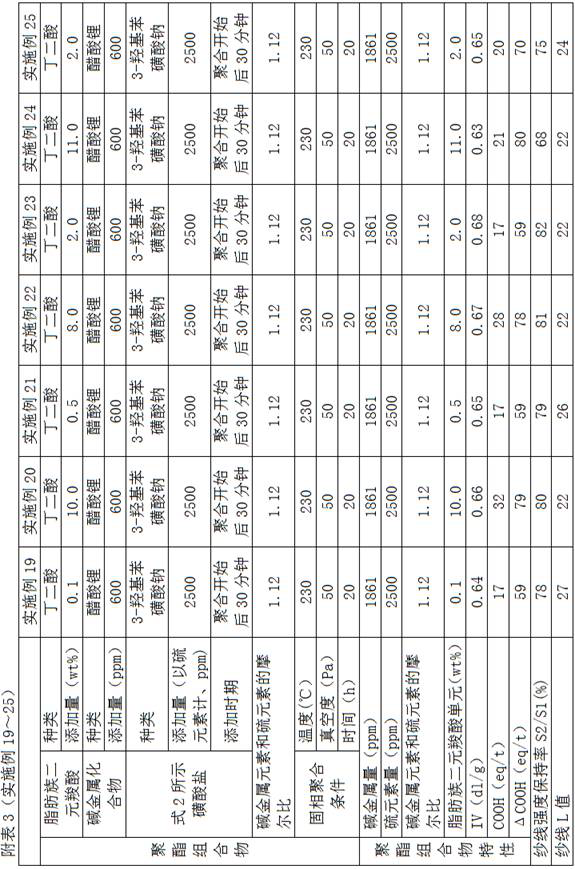

Cationic dyeable polyester composition as well as preparation method and application thereof

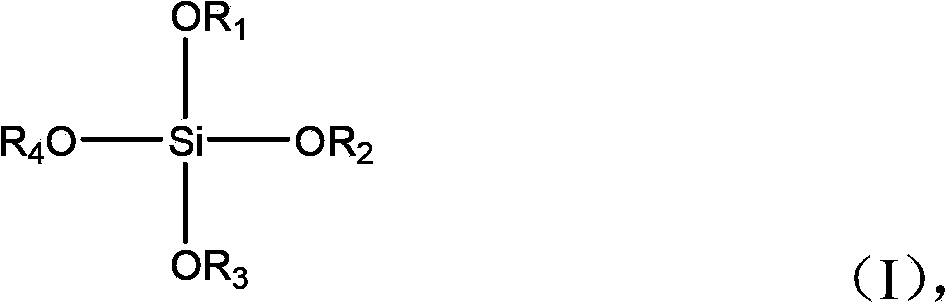

PendingCN114573800AEasy to dyeImprove hydrolysis resistanceMonocomponent copolyesters artificial filamentPolyesterSulfonate

The invention discloses a cationic dyeable polyester composition and a preparation method thereof. The cationic dyeable polyester composition is mainly composed of an aromatic dicarboxylic acid structural unit and an aliphatic dihydric alcohol structural unit, and contains a sulfonate group as shown in a formula 1 (formula 1), the content of the group as shown in the formula 1 accounts for 1000-5000 ppm of the total amount of the polyester composition in terms of sulfur element, and the cationic dyeable polyester composition also contains the aliphatic dicarboxylic acid structural unit. The cationic dyeable polyester composition is good in physical property, easy to dye, good in hydrolysis resistance and excellent in strength retention rate after dyeing.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

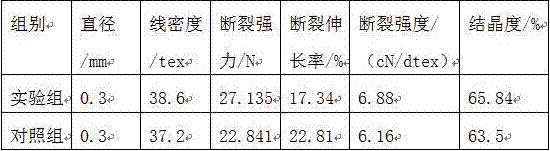

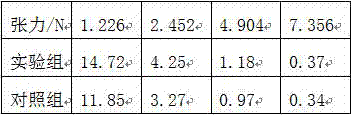

Manufacturing method for high-wear-resistance polyethylene fishing net

InactiveCN107099879AGood strength retentionOvercome softeningArtificial filament heat treatmentMelt spinning methodsFiberEngineering

The invention specifically relates to a manufacturing method for a high-wear-resistance polyethylene fishing net, belonging to the technical field of manufacturing of fishing gear materials. The manufacturing method comprises the following steps: preparation of auxiliary agents; batching; granulation; wire drawing; and shaping. Compared with the prior art, the invention has the following advantages: through addition of the auxiliary agents and reasonable control of conditions in each step, amorphous parts in netting twines are obviously oriented, shish-kebab and fibrous structures are formed in a sample, and the degree of crystallization reaches 65.84%, 63.5% higher than the crystallization degree of polyethylene filaments; and due to changes of conditions like water cooling, the manufacturing cost of the fishing net is increased by about 1200 yuan / ton, but the prepared polyethylene fishing net overcomes the disadvantage of softening and adhesion fatigue of polyethylene filament materials caused by the action of frictional heat, has resistance to frictional heat and wear resistance stability, presents good strength retention ratio under the condition of dry friction or water lubrication and is improved in the usage performance of fishing net threads.

Owner:CHAOHU XIANGYU FISHING GEAR

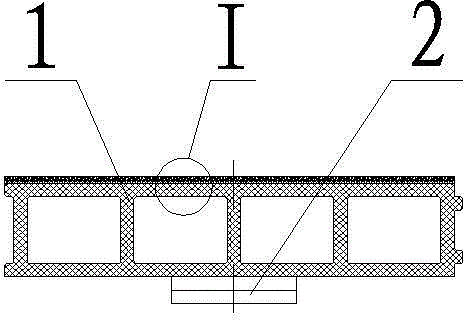

Bonding type antiskid road and bridge panel made of glass fiber reinforced plastics

InactiveCN104911997APrevent agingMaintain light weight and high strengthBridge structural detailsGlass fiberGlue line

The present invention relates to a bonding type antiskid road and bridge panel made of glass fiber reinforced plastics, including a panel body, a connective fixture block, a bonding glue line and an antiskid coating, wherein, the antiskid coating is composed of a binding agent and wear-resisting particles. The bonding glue line is coated on the road and bridge face of the panel body; the wear-resisting particles in the antiskid coating are uniformly distributed on the bonding glue line, and bond with the bonding glue line by spraying the bonding agent; the connective fixture block is connected to the panel body by bonding. The wear-resisting particles are uniformly distributed on the bonding glue line in a manner that the bonding glue line is sprayed on the road and bridge face of the panel body and the bonding agent is sprayed on the bonding glue line, and thereby forming an antiskid face of the panel body. The antiskid face not only has advantages of skid resistance and wear resistance, but also can avoid panel aging. Simultaneously, the bonding connection manner between the connective fixture block and the panel body farthest retains the characteristics of light weight and high strength existing in the road and bridge panel made of glass fiber reinforced plastics.

Owner:YANCHENG HENGTONG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com