Hydrated alumina forming matter and preparation method thereof, alumina forming matter, catalyst and preparation method and application thereof and hydrotreating method

A technology of hydrated alumina and moldings, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, catalyst carriers, etc., can solve the problems of unhealthy operators and unfavorable environmental protection, etc., and achieve Conducive to environmental protection, reduce impact, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

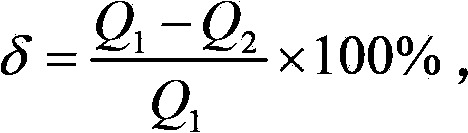

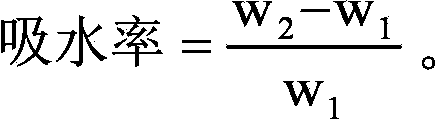

[0110] With stirring, 5.0g LiNO 3 Dissolve in 95mL deionized water to obtain lithium-containing aqueous solution. 100.0g of pseudo-boehmite (purchased from Sinopec Catalyst Changling Branch, with a dry basis content of 69.5% by weight), 4.0g of hydroxyethyl methylcellulose (purchased from Shanghai Huiguang Fine Chemical Co., Ltd.), 3.0 g scallop powder and the above-mentioned lithium-containing aqueous solution are stirred evenly. The resulting mixture is fed into an extruder and extruded to obtain a wet strip. The obtained wet strip was placed in an oven and dried at 150° C. for 12 hours, thereby obtaining the hydrated alumina molding according to the present invention. The radial crushing strength, water absorption rate and δ value of the obtained moldings were measured, and the results are listed in Table 1.

Embodiment 2

[0118] (1) In a 2L reaction tank, add 2000mL of aluminum sulfate solution with a concentration of 48g / L and sodium metaaluminate solution (alumina content of 200g / L, caustic coefficient of 1.58) in parallel to carry out precipitation reaction. The temperature is 50°C, the pH value is 6.0, and the reaction residence time is 15 minutes; the obtained slurry is filtered with a vacuum filter, and after the filtration is completed, 20L deionized water is added to the filter cake (the temperature is 40±5°C ) to rinse the filter cake for about 60 minutes. Add the washed filter cake to 1.5L deionized water and stir to form a slurry, then pump the slurry into the spray dryer for drying, control the outlet temperature of the spray dryer within the range of 100-110°C, and the material drying time For 2 minutes, hydrated alumina was obtained, wherein the content of alumina was 63% by weight, and it was determined to be amorphous by XRD analysis.

[0119] (2) Mix 3.0g LiNO with stirring 3...

Embodiment 3

[0121]With stirring at a temperature of 60° C., 9.8 g of lithium oxalate was dissolved in 95 mL of deionized water to prepare a lithium-containing aqueous solution. 60.0g of pseudo-boehmite (purchased from Sinopec Catalyst Changling Branch, with a dry basis content of 69.5% by weight), 40.0g of gibbsite (purchased from Guangxi Pingguo Aluminum Company, with a dry basis content of 64.5% by weight %), 1.0g methyl cellulose (purchased from Zhejiang Haishen Chemical Co., Ltd.), 2.0g hydroxypropyl methylcellulose (purchased from Zhejiang Haishen Chemical Co., Ltd.), 3.0g squash powder and the above lithium-containing aqueous solution Stir well. The resulting mixture is fed into an extruder and extruded to obtain a wet strip. The obtained wet strip was placed in an oven and dried at 80° C. for 12 hours to obtain the hydrated alumina molding according to the present invention. The radial crushing strength, water absorption rate and δ value of the obtained moldings were measured, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com