Manufacturing method for high-wear-resistance polyethylene fishing net

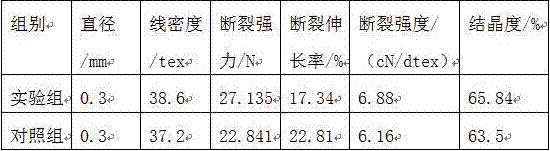

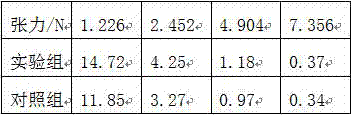

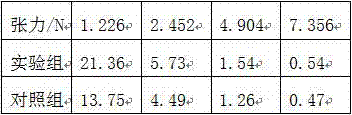

A production method, polyethylene technology, applied in the direction of melt spinning, stretch spinning, conjugated synthetic polymer artificial filaments, etc., can solve the problem of increasing the diameter density of fishing nets and the weight of fishing nets, increasing the weight of net sheets, and using Large limitations and other problems, to achieve the effect of overcoming softening and adhesion fatigue, good anti-friction heat performance, and good strength retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A method for making a high wear-resistant polyethylene fishing net, comprising the following:

[0016] (1) Manufacturing of additives: add malic acid, propanol, and concentrated sulfuric acid in sequence in the reaction bottle, the molar ratio of which is 4:11:3, and reflux for 6 hours at a temperature of 120-135°C under stirring conditions, and then cool After reaching room temperature, wash with 1 times the volume of distilled water, let stand to separate the liquid, take the lower layer and wash it with saturated sodium bicarbonate solution for several times until the acidity is neutral, then wash with a small amount of deionized water, let stand to separate the liquid, take the lower layer to filter, separate liquid to obtain the intermediate liquid; then the intermediate liquid and the fatty amine were mixed in a molar ratio of 1:3, stirred and refluxed for 10 hours under the condition of 85-120°C, and the propanol and residual reactants generated by the reaction we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com