Production technology of high-strength and anti-wrinkle spunlace non-woven fabric

A technology of spunlace non-woven fabric and production process, which is applied in the processing of textile materials, non-woven fabrics, textiles and paper making, etc., can solve the problems of low strength and low yield of spunlace non-woven fabrics, and achieves soft gloss , High forming rate, not easy to wrinkle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

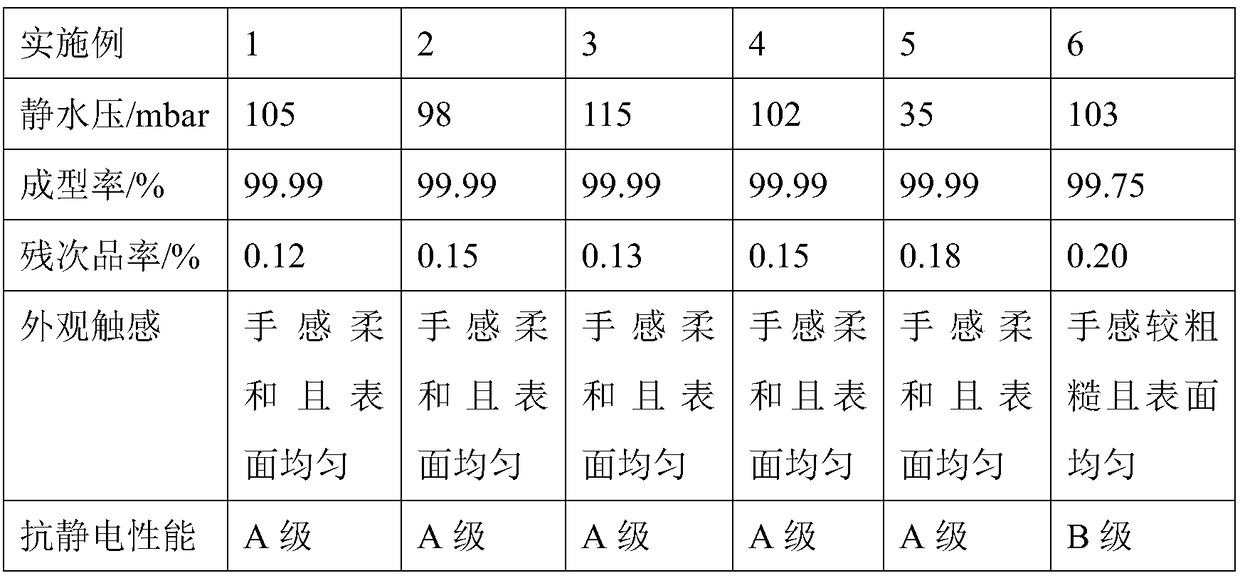

Examples

Embodiment 1

[0028] A production process of high-strength anti-wrinkle spunlace nonwoven fabric, comprising the following steps:

[0029] Preparation of S1 fiber raw materials: prepare fiber raw materials by weight: 10 parts of bamboo fiber, 8 parts of viscose fiber, 20 parts of polypropylene, 15 parts of polyisobutylene and 2 parts of anti-wrinkle agent DPW, the fiber raw materials are mixed and opened, and then The carding machine is carded into a web to obtain a fiber web, and the fiber web is drafted by a drafting machine with a draft ratio of 2.8;

[0030] S2 Spunlace: Feed the fiber web drawn in S1 step into the spunlace zone to form a non-woven fabric and dry it;

[0031] S3 cold stacking: cold stacking treatment is performed after the non-woven fabric dried in step S2 is immersed in the auxiliary agent;

[0032] S4 washing: wash the cold-stacked non-woven fabric twice with water in step S3 to remove residual additives;

[0033] S5 drying: put the non-woven fabric washed in step S...

Embodiment 2

[0039] A production process of high-strength anti-wrinkle spunlace nonwoven fabric, comprising the following steps:

[0040] Preparation of S1 fiber raw materials: prepare fiber raw materials by weight: 15 parts of bamboo fiber, 12 parts of viscose fiber, 30 parts of polypropylene, 20 parts of polyisobutylene and 5 parts of anti-wrinkle agent DPW, the fiber raw materials are mixed and opened, and then The carding machine is combed into a web to obtain a fiber web, and the fiber web is drafted by a drafting machine with a draft ratio of 3.2;

[0041] S2 Spunlace: Feed the fiber web drawn in S1 step into the spunlace zone to form a non-woven fabric and dry it;

[0042] S3 cold stacking: cold stacking treatment is performed after the non-woven fabric dried in step S2 is immersed in the auxiliary agent;

[0043] S4 washing: wash the non-woven fabric cold-stacked in step S3 three times to remove residual additives;

[0044] S5 drying: put the non-woven fabric washed in step S4 in...

Embodiment 3

[0050] A production process of high-strength anti-wrinkle spunlace nonwoven fabric, comprising the following steps:

[0051] Preparation of S1 fiber raw materials: prepare the fiber raw materials by weight: 10 parts of bamboo fiber, 10 parts of viscose fiber, 25 parts of polypropylene, 18 parts of polyisobutylene and 4 parts of anti-wrinkle agent DPW, the fiber raw materials are mixed and opened, and then A carding machine is carded into a web to obtain a fiber web, and the fiber web is drafted by a drafting machine with a draft ratio of 3.0;

[0052] S2 Spunlace: Feed the fiber web drawn in S1 step into the spunlace zone to form a non-woven fabric and dry it;

[0053] S3 cold stacking: cold stacking treatment is performed after the non-woven fabric dried in step S2 is immersed in the auxiliary agent;

[0054] S4 washing: wash the non-woven fabric cold-stacked in step S3 three times to remove residual additives;

[0055] S5 drying: put the non-woven fabric washed in step S4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com