High-performance polypropylene material and preparation method thereof

A polypropylene material and high-performance technology, which is applied in the field of high-performance polypropylene materials and their preparation, can solve the problems of difficult simultaneous improvement and limited rigidity and toughness of modified polypropylene materials, so as to improve rigidity and toughness and increase strength , the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

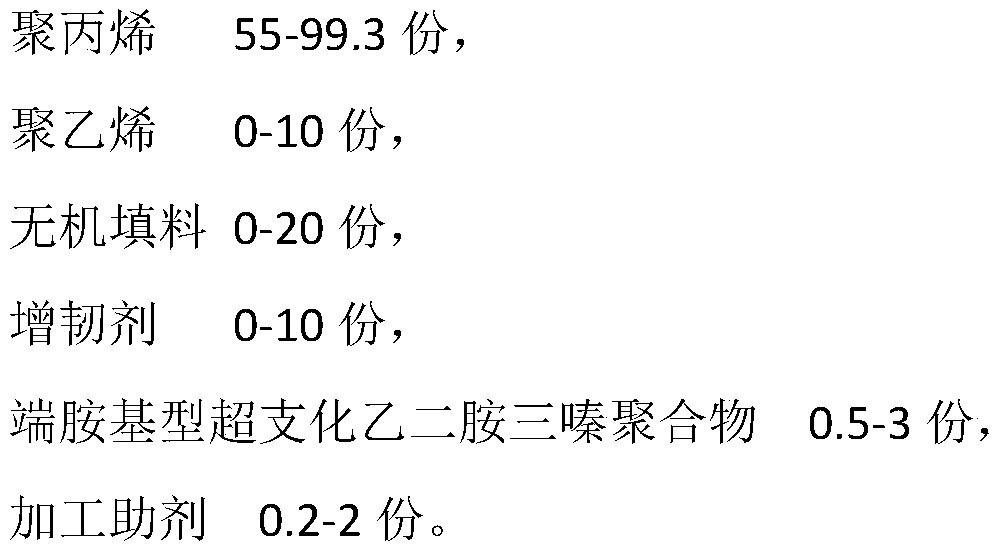

[0030] 77.5 parts by weight of melt index is 30g / 10min copolymerized polypropylene, 5 parts by weight of melt index is high-density polyethylene of 0.5g / 10min, 10 parts by weight of talc, 5 parts by weight of POE, 1.5 parts by weight of terminal amino groups Type hyperbranched ethylenediamine triazine polymer, 0.2 parts by weight of antioxidant 1010, 0.2 parts by weight of antioxidant 168 and 0.2 parts by weight of calcium stearate.

[0031] Its preparation process is as follows:

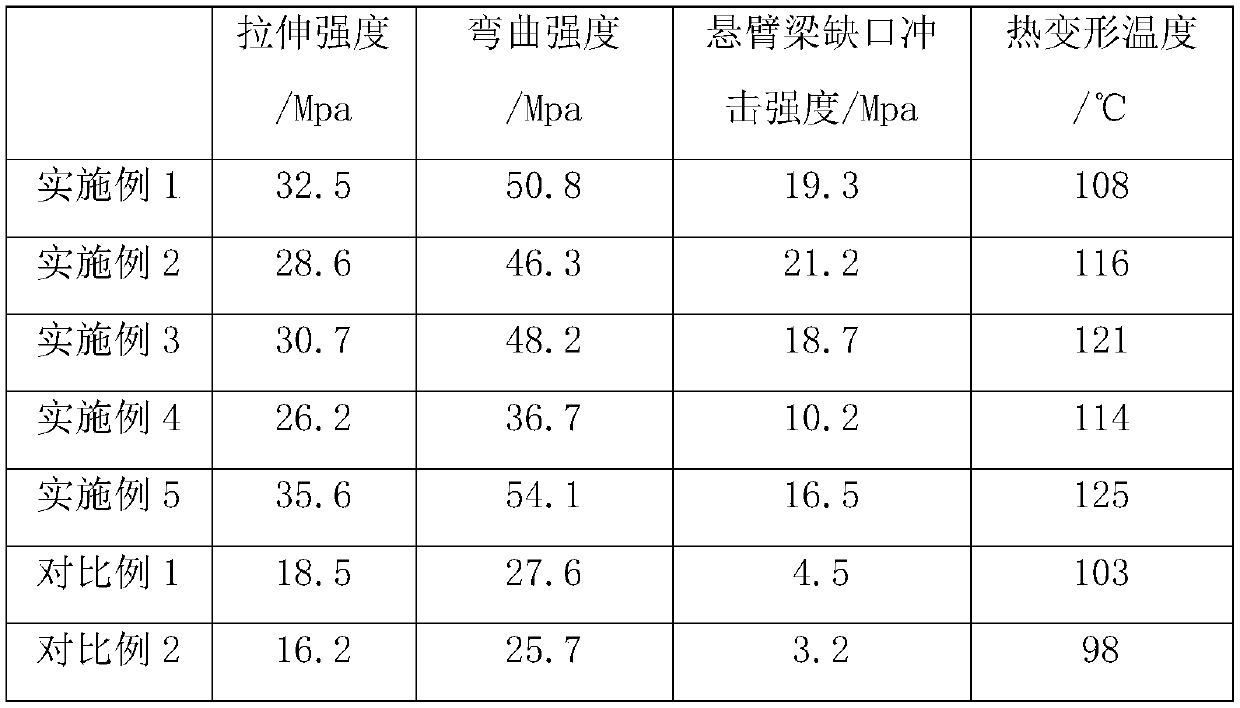

[0032] After uniformly mixing the above ingredients, put them into the twin-screw extruder, the temperature of the extruder is set at 190°C-210°C, and the rotation speed is 200rpm; Acrylic material. Its mechanical properties are listed in Table 1.

Embodiment 2

[0034] 65.3 parts by weight of homopolypropylene with a melt index of 60g / 10min, 8 parts by weight of low density polyethylene with a melt index of 20g / 10min, 15 parts by weight of calcium carbonate, 8 parts by weight of POE, and 2.2 parts by weight of terminal amino groups Type hyperbranched ethylenediamine triazine polymer, 0.3 parts by weight of antioxidant 1010, 0.3 parts by weight of antioxidant 168 and zinc stearate of 0.4 parts by weight.

[0035] Its preparation process is as follows:

[0036] After uniformly mixing the above ingredients, put them into the twin-screw extruder, the temperature of the extruder is set at 200°C-220°C, and the speed is 300rpm; the extruded product is cooled by water and pelletized to obtain high-performance polymer Acrylic material. Its mechanical properties are listed in Table 1.

Embodiment 3

[0038] 87.2 parts by weight of melt index of polypropylene copolymer of 80g / 10min, 1 part by weight of linear low density polyethylene with a melt index of 5, 2 parts by weight of linear low density polyethylene with a melt index of 30g / 10min, 5 parts of mica, 3 parts by weight of POE, 1 part by weight of amino-terminated hyperbranched ethylenediamine triazine polymer, 0.5 part by weight of antioxidant 168 and 1 part by weight of calcium stearate.

[0039] Its preparation process is as follows:

[0040] After mixing the above ingredients evenly, put them into the twin-screw extruder, the temperature of the extruder is set at 210°C-230°C, and the rotation speed is 300rpm; Acrylic material. Its mechanical properties are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com