Foaming-grade biodegradable polyester material and preparation method thereof

A biodegradable polyester and raw material technology, applied in the field of polymer materials, can solve the problems of limited application and high dosage of organic peroxide, achieve low processing costs, meet the needs of large-scale production, and expand the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

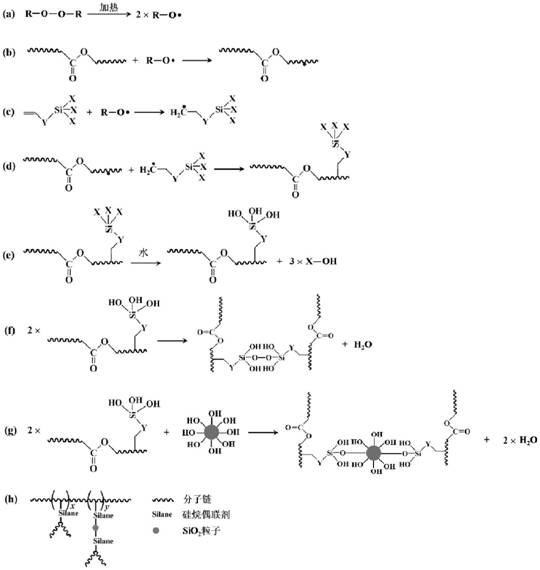

Method used

Image

Examples

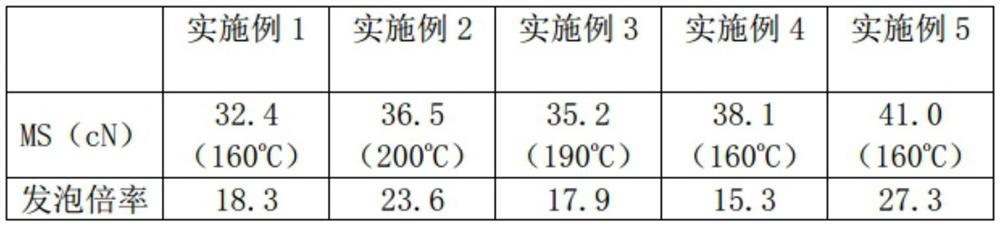

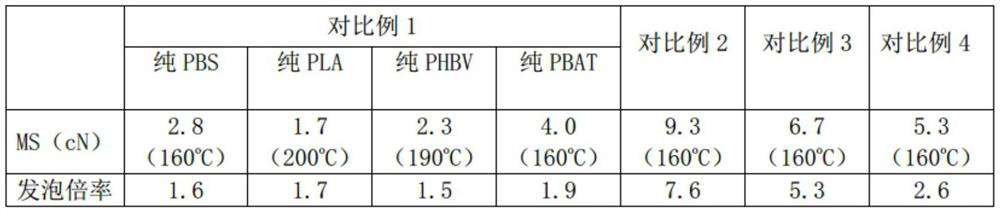

Embodiment 1

[0046] In this embodiment, the preparation method of this foam grade biodegradable polyester material includes the following steps in sequence:

[0047] (1) By weight, the following raw materials are equipped: 97.75% of biodegradable polyester (polybutylene succinate), 0.15% of organic peroxide (tert-butyl peroxy-2-ethylhexanoate) , 0.80% silane coupling agent (vinyl triethoxysilane), 1.00% silica particles (nano-scale silica particles), 0.30% lubricant (glycerol monostearate);

[0048] (2) Dry the biodegradable polyester at 90°C for 90 minutes so that the moisture content of the biodegradable polyester is lower than 200ppm, and cool to 25°C;

[0049] (3) Add organic peroxide and 0.40% silane coupling agent to biodegradable polyester, and mix uniformly to obtain mixed material;

[0050] (4) Dry the silica particles at 110°C for 120 minutes to make the moisture content of the silica particles lower than 200ppm, and cool to 30°C;

[0051] (5) Spray the remaining 0.4% silane co...

Embodiment 2

[0059] In this embodiment, the preparation method of this foam grade biodegradable polyester material includes the following steps in sequence:

[0060] (1) By weight, the following raw materials are equipped: 97.80% (polylactic acid) of biodegradable polyester, 0.20% (tert-butyl peroxybenzoic acid ester) of organic peroxide, 0.50% of silane coupling agent (γ- Methacryloxypropyl trimethoxysilane), silica particles 0.50% (nano-scale silica particles), lubricant 1.00% (ethylene bis-12-hydroxystearamide);

[0061] (2) Dry the biodegradable polyester at 100°C for 120 minutes to make the moisture content of the biodegradable polyester lower than 200ppm, and cool to 20°C;

[0062] (3) Add organic peroxide and 0.30% silane coupling agent to biodegradable polyester, and mix uniformly to obtain mixed material;

[0063] (4) Dry the silica particles at 120°C for 100 minutes to make the moisture content of the silica particles lower than 200ppm, and cool to 20°C;

[0064] (5) Spray the ...

Embodiment 3

[0072] In this embodiment, the preparation method of this foam grade biodegradable polyester material includes the following steps in sequence:

[0073] (1) By weight, the following raw materials are equipped: 98.10% of biodegradable polyester (poly(3-hydroxybutyrate-co-3-hydroxyvalerate)), 0.30% of organic peroxide (tert-amyl peroxide) Oxygen-2-ethylhexyl carbonate), silane coupling agent 0.60% (γ-methacryloxypropyltrimethoxysilane), silica particles 0.50% (nano-scale silica particles), lubrication Agent 0.50% (pentaerythritol tetrastearate);

[0074] (2) Dry the biodegradable polyester at 95°C for 80 minutes so that the moisture content of the biodegradable polyester is lower than 200ppm, and cool to 25°C;

[0075] (3) Add organic peroxide and 0.2% silane coupling agent to biodegradable polyester, and mix uniformly to obtain mixed material;

[0076] (4) Dry the silica particles at 100°C for 100 minutes to make the moisture content of the silica particles lower than 200ppm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com