Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

205results about How to "Guaranteed water absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

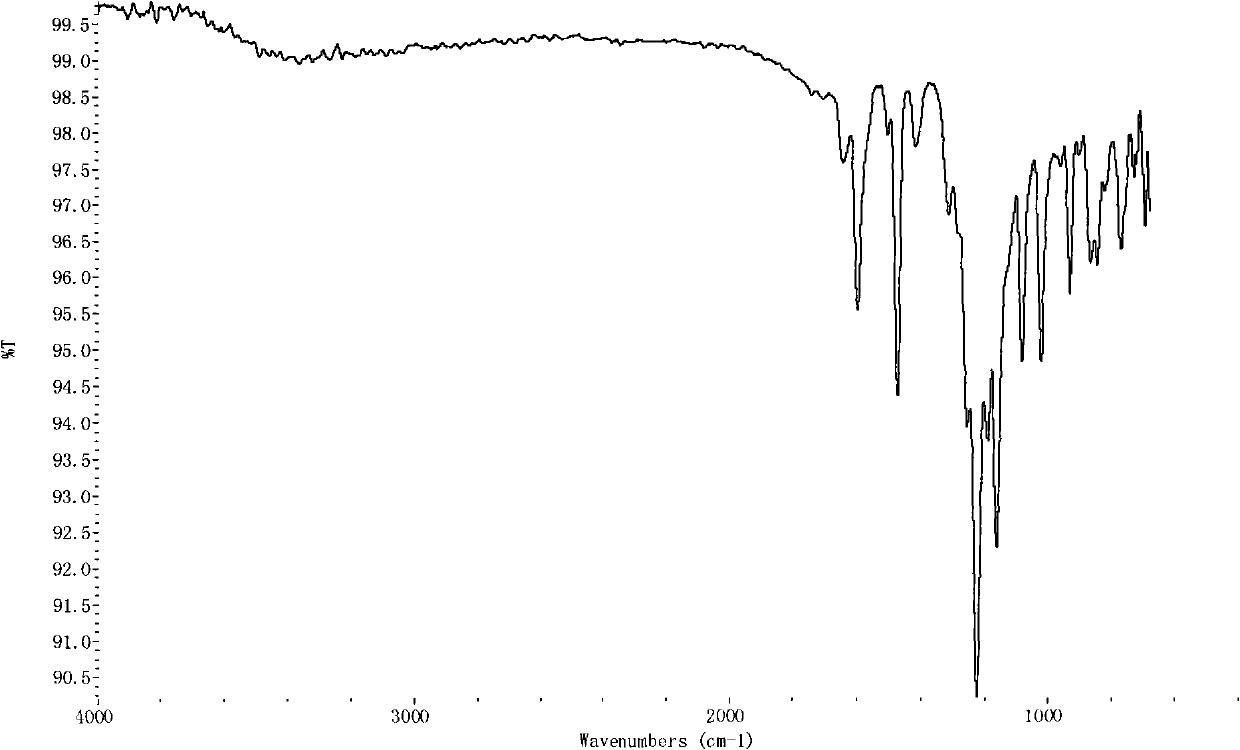

Ternary doping modified SPEEK proton exchange membrane and preparation method

InactiveCN101908632AImprove overall performanceImprove proton conductivitySemi-permeable membranesCell component detailsIonYttrium

The invention relates to a ternary doping modified SPEKK proton exchange membrane and a preparation method thereof. The exchange membrane comprises the following components by mass percent: 80-98.5% of SPEEK with 40%-80% of sulfonation degree and 1.5-20% of ternary adulterant. The preparation method comprises the following steps: 1, adopting the SPEEK with medium sulfonation degree as a matrix material so as to overcome the over high water absorption and poor stability of the composite membrane of the SPEEK with over high sulfonation degree, and ensure that the composite membrane has a certain water absorption; 2, adopting a three ternary doping mode of ion liquid, rare-earth oxide yttrium oxide and phosphotungstic acid so as to enable the SPEEK substrate to act with the dopant materials so as to improve the combination property of the composite membrane; and 3, by the process of high temperature high-intensity magnetic field, enabling the dopant materials to be orientated under the action of a magnetic field to form a proton conduction passage to improve the proton conduction rate of the composite membrane.

Owner:SHANGHAI UNIV

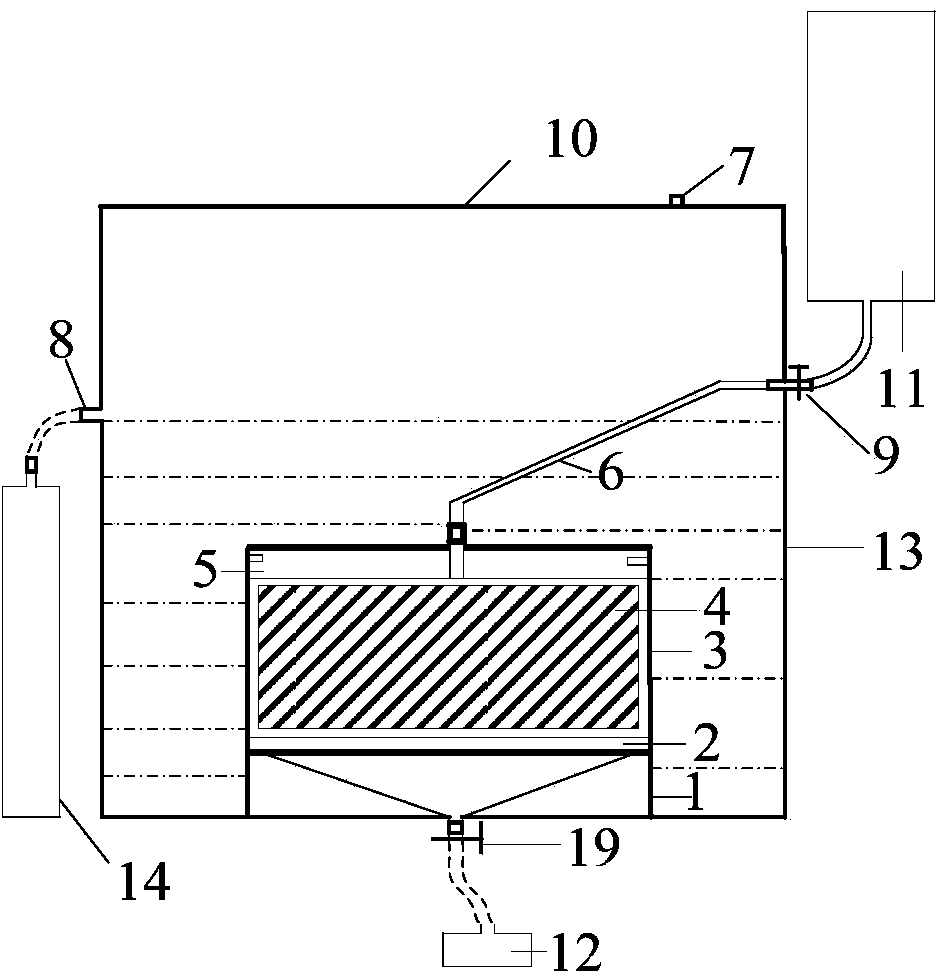

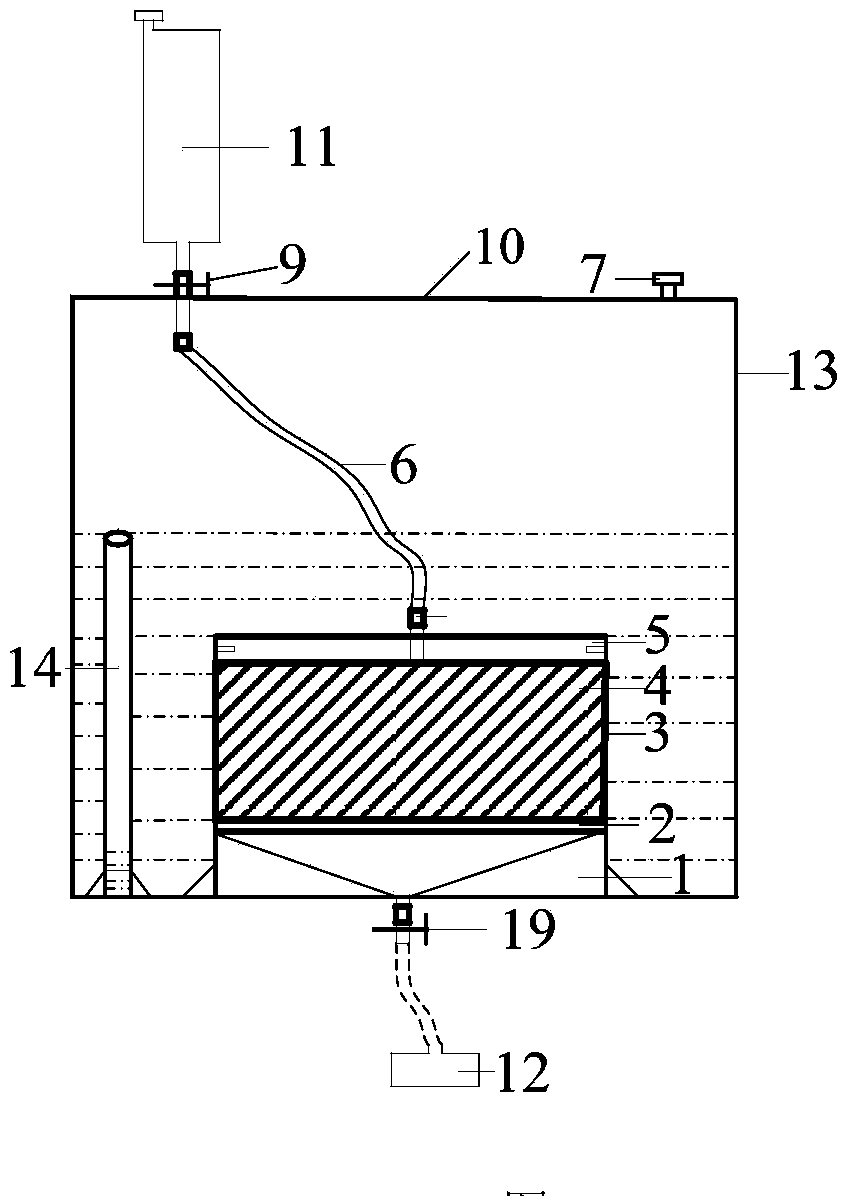

Device for measuring the free swelling rate and the water content of rock and using method thereof

The invention discloses a device for measuring the free swelling rate and the water content of a rock and a using method thereof. By adoption of the Archimedes principle as a reference, the device utilizes a basic principle that the volume of displaced water of the rock changes with the volume change of the rock in water after the rock swells by water absorption. The structure of the device for measuring the free swelling rate and the water content of the rock is largely simplified by adoption of technical means such as sealing and packaging of a rock sample to be measured with rubber film. The device has characteristics of simple structure, convenient raw material selection, low manufacturing cost, convenient operation, and the like. The whole experiment device is small in systemic error. Experiment results are true, reliable and accurate. The device is suitable for laboratory use, and particularly can be used for simultaneously perform measurement of the free swelling rate and the water content of soft rocks.

Owner:SHANDONG UNIV OF SCI & TECH

Low-density high-strength solid buoyancy material and preparation method thereof

The invention discloses a low-density high-strength solid buoyancy material and a preparation method thereof, belongs to the field of solid buoyancy materials for marine environments, and can be used for marine submersible buoys, marine drilling platforms, various deep submergence vehicles, seabed space stations and the like. The low-density high-strength solid buoyancy material comprises the following raw materials in parts by weight: 100 parts of epoxy resin, 0-20 parts of a toughening modification agent, 10-80 parts of a curing agent, 0.5-5 parts of a catalyst, 0.2-10 parts of a dispersion agent, 10-200 parts of micron hollow glass beads, 10-150 parts of millimeter hollow glass beads and 0.2-5 parts of a coupling agent. The preparation method comprises the following steps: adding the accurately weighed raw materials into a kneading machine, heating to 80-100 DEG C, and stirring for 30 minutes at a uniform speed to obtain a mixture; taking out and putting the mixture into a mould, compacting, putting on a pressure curing machine, pressing, heating and deflating, curing for a certain time, and shaping to prepare a buoyancy material standard module. The low-density high-strength solid buoyancy material is used for solving the problem of higher density of a solid buoyancy material and increasing the net buoyancy of the solid buoyancy material.

Owner:滕州市华海新型保温材料有限公司

Three-layer composite water-absorption pad non-woven fabric and production method

InactiveCN107323011AImprove fitStay cohesiveSynthetic resin layered productsPulp and paper industryNonwoven fabric

The invention relates to a three-layer composite water-absorption pad non-woven fabric and a production method. According to the three-layer composite water-absorption pad non-woven fabric, polypropylene spunbond cloth and pulp composite cloth are taken as base materials and coated with a low-density polypropylene film. By taking a polypropylene spunbond cloth layer as a support layer, a product has very strong power, one side of the composited product has excellent water absorption property, and the other side of the composited product has anti-sliding and waterproof effects. Pulp fibers have super-hygroscopicity, the non-woven fabric is endowed with the super-hygroscopicity through spunlacing, and one side of the polypropylene spunbond cloth of the spunlaced product is coated with the film, so that the integral adhesiveness of the composite product is guaranteed, and the hygroscopicity and barrier property of the composite product are guaranteed. By utilizing a cross-pattern embossing roller, each layer of the product is well laminated, and meanwhile, the product has good skid resistance and wear resistance and a novel pattern appearance. The polypropylene spunbond cloth and the polyethylene film can be prepared into colored products, so that the composite product is integrally colorful and can meet various requirements of customers.

Owner:DALIAN RUIGUANG NONWOVEN GROUP

Piece dyeing method of cotton binding textiles

InactiveCN101864677AUniform surfaceUniform colorBleaching apparatusDyeing processShrinkage rateEngineering

The invention discloses a piece dyeing method of cotton binding textiles, which is characterized in that the invention has the concrete processing process comprising the steps of singeing, desizing, light scouring and bleaching, pre-setting, rendering, color fixation soap washing, forming and preshrinking. The invention has the advantages that the cotton binding textiles obtained through being processed by the method have the advantages of uniform cloth surface color, good luster, high intensity and low washing shrinkage rate, and in addition, the production processing efficiency of the method is high. In addition, the mixed alkali treatment is adopted in the light scouring and bleaching process, so the invention ensures that the processed cotton binding textiles have certain whiteness and water absorption performance, in addition, the plant intensity of the textiles can not be damaged to the furthest extent, and the narrow width of the textiles caused by shrinkage in the following processing work procedure can be avoided through improving the hydrophilicity of the textiles and widening the width of the textiles via the pre-setting process.

Owner:浙江盛泰服装集团股份有限公司

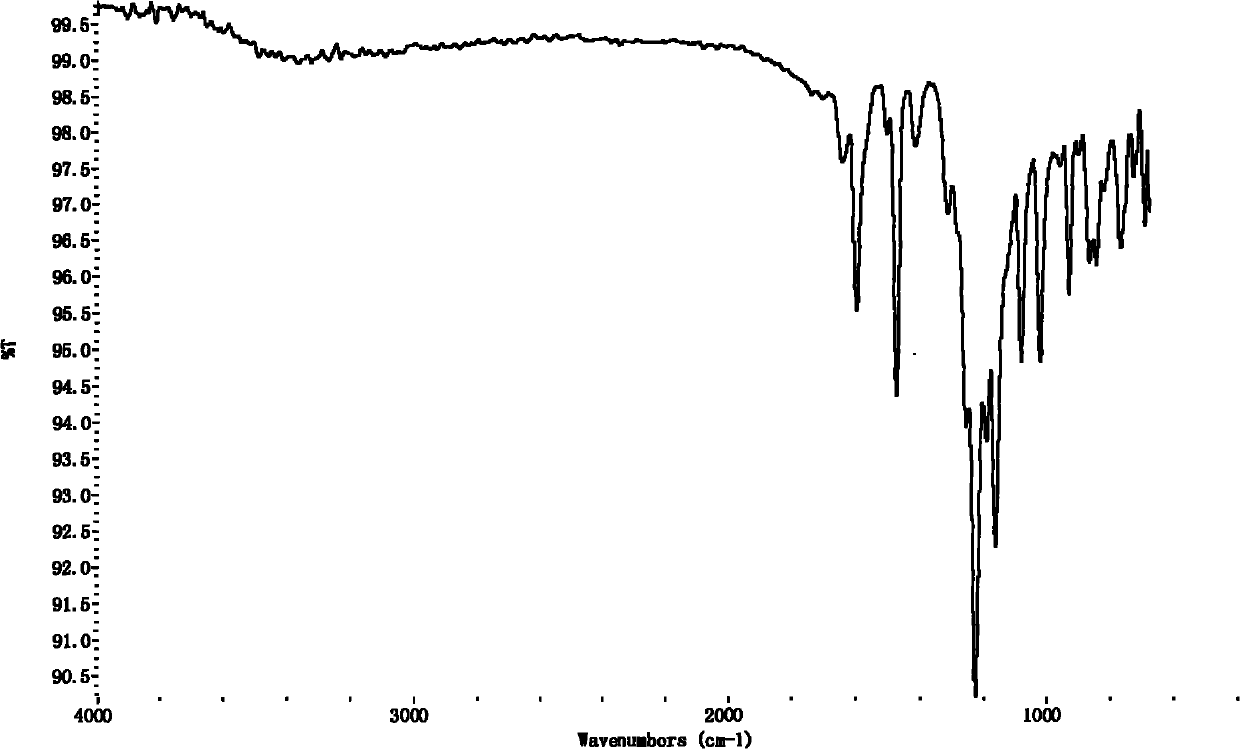

Binary doped modified sulfonated poly-ether-ether-ketone (SPEEK) proton exchange membrane (PEM) and preparation method thereof

InactiveCN101719553AGuaranteed water absorptionThe water absorption rate ensures that the composite film hasCell component detailsFuel cell detailsPoly ether ether ketoneVulcanization

The invention relates to a binary doped modified sulfonated poly-ether-ether-ketone (SPEEK) proton exchange membrane (PEM) and a preparation method thereof. The PEM comprises the following components in percentage by weight: 80-99% of SPEEK with the vulcanization degree being 40-80%: and 1-20% of binary doped solid:, wherein the binary doped solid comprises cerium oxide or yttrium oxide and phosphotungstic acid in a mol rate of 1:(1-3).

Owner:SHANGHAI UNIV

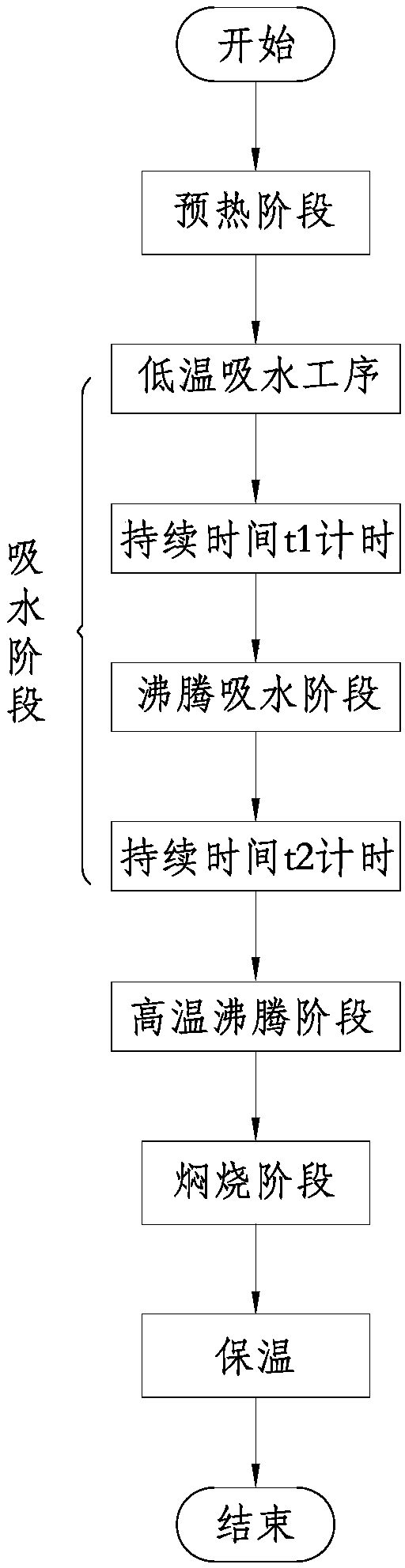

Cooking utensil and control method thereof

ActiveCN110353497AImprove cooking resultsImprove cooking efficiencyPressure-cookersProcess engineeringRice grain

The invention discloses a cooking utensil and a control method thereof. The control method comprises the following steps thatin a water absorption stage, a heating device is controlled to heat rice water in a cooking cavity to a preset temperature; a current rice water amount in the cooking cavity is obtained, and air extraction time of an air extraction device when thepressure in the cooking cavity reaches a first preset pressure is obtained according to the current rice water amount; the air extraction device is controlled to carry out air extraction on the cooking cavity, and timing is started; and when the timing time reaches the air extraction time, the air extraction of the cooking cavity is stopped for maintaining the pressure in the cooking cavity to be the first preset pressure. According to the control method of the cooking utensil disclosed by an embodiment of the invention, by the adoption of the control method, the cooking utensil can control the air extraction time of theair extraction device according to different rice water amounts in the cooking cavity, so that the pressure in the cooking cavity can reach the first preset pressure regardless of the rice water amount in the cooking cavity, and the control is accurate; and moreover, the water absorption efficiency of rice grains can be improved, so that the cooking efficiency of the cooking utensil is improved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

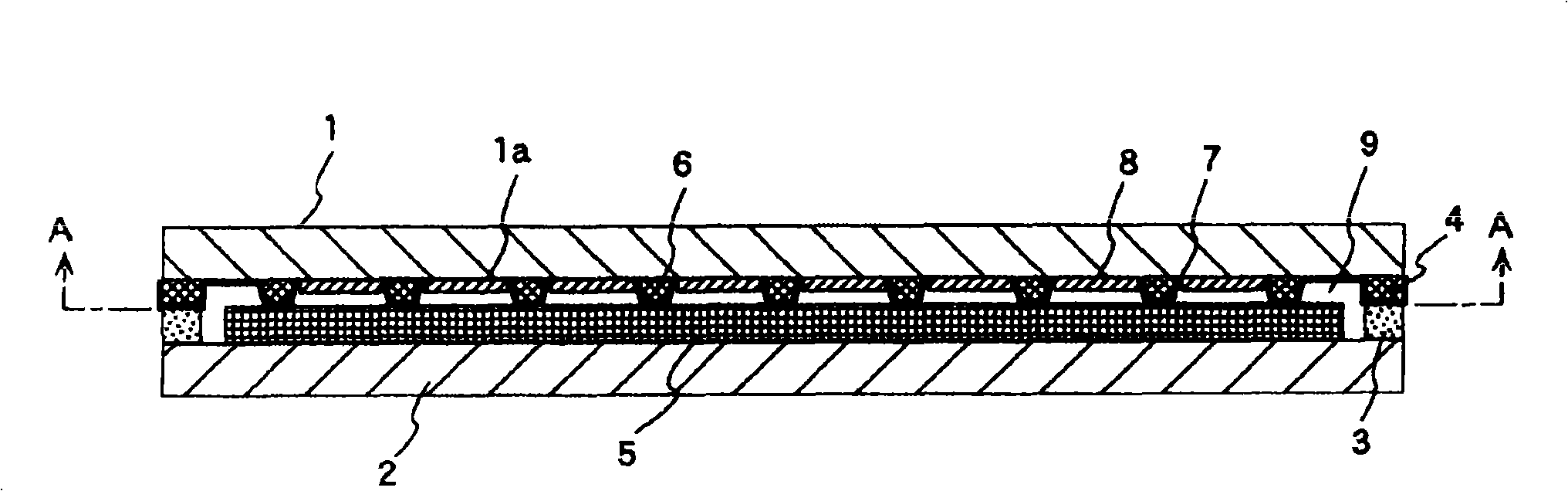

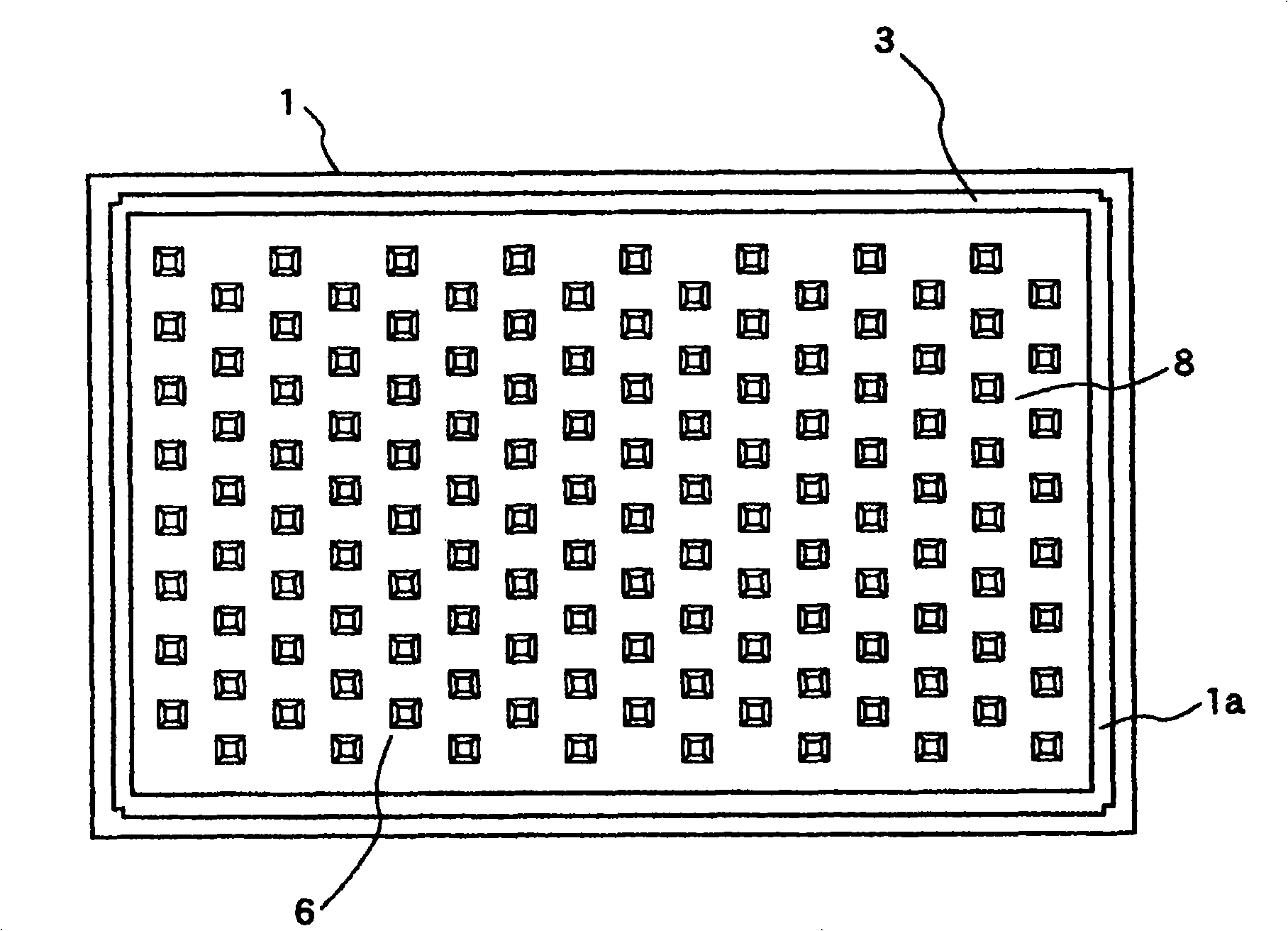

Organic electroluminescence display device

InactiveCN101257036AEx situ control arrangementAvoid dischargeSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceOptoelectronics

There is provided an organic electroluminescence display device with sufficient sealability that reduces discharge of gas and moisture infiltration into sealed space. An organic EL display device structured to coat the surface of a spacer fixed to the inner surface of a sealing substrate and a bonded surface of the side wall to a sealing member with an inorganic insulation film.

Owner:HITACHI DISPLAYS

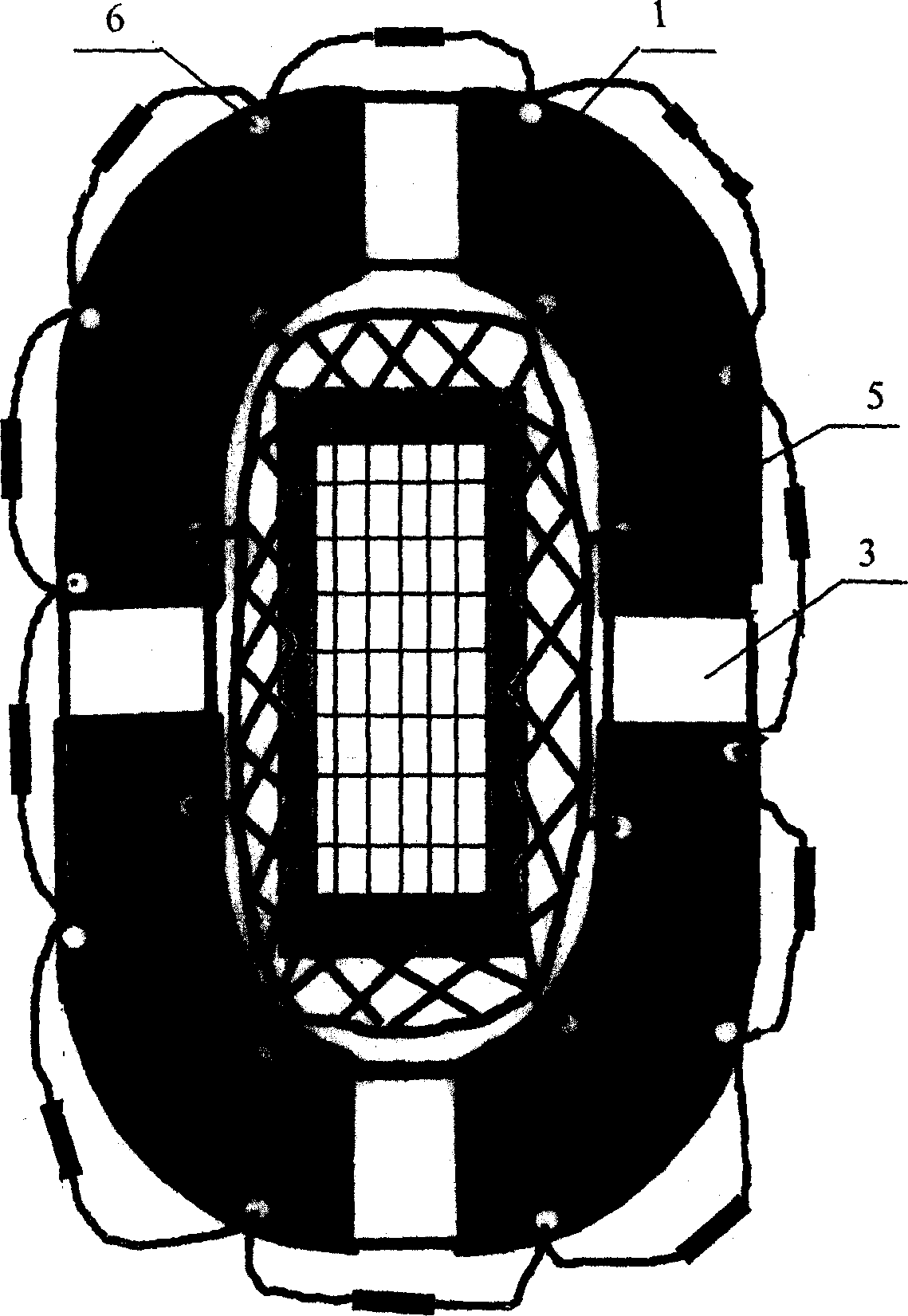

Composite life-saving float and its producing method

InactiveCN1554554AHigh mechanical strengthGuaranteed wear resistanceVessel salvagingFoldable/inflatable hullsHigh resistanceEngineering

The composite life-saving float consists of casing of high density polyethylene plastic and float core of hard foamed polyurethane and filling the casing. The casing is provided with notches for installing reflecting material, is assembled with sections and has inside reinforcing ribs. The manufacture process includes extruding hollow casing sections, assembling the casing, filling the casing with hard polyurethane and foaming. The present invention has high mechanical strength, high shock resistance, high oil resistance, high wear resistance, and high floating and water resistant performance.

Owner:黄锡安

Silk non-woven fabric applicable to baby wet wipes

InactiveCN105420930AStrong water absorptionGuaranteed water absorptionUltrasonic/sonic fibre treatmentAbsorbent padsNonwoven fabricLow temperature plasma

The invention discloses silk non-woven fabric applicable to baby wet wipes and a preparation method of the silk non-woven fabric. The preparation method comprises steps as follows: (1), impurities in silk fibers are removed, the silk fibers after degumming and drying is placed in a low-temperature plasma apparatus for low-temperature plasma processing, the silk fibers are taken out and impregnated in a surfactant-containing solution for oscillation at the constant temperature, then the silk fibers are taken out, a redundant liquid on the surface is removed, the silk fibers are placed in a drying oven for drying, and the silk fibers subjected to hydrophilic modification processing are obtained; (2), the silk fibers after hydrophilic modification processing and bamboo fibers are teased out and spread to form a silk fiber mesh and a bamboo fiber mesh, the silk fiber mesh is placed above the bamboo fiber mesh, the silk fiber mesh and the bamboo fiber mesh are tightly composited in a spunlace cross lapping mode, and silk / bamboo fiber non-woven fabric with an even or uneven surface is formed; (3), the silk / bamboo fiber non-woven fabric after cutting is left to stand in constant-temperature and constant-humidity space, and the silk non-woven fabric applicable to the baby wet wipes is obtained.

Owner:SUZHOU WILDER IND & TRADE

Microneedle capable of extracting skin tissue fluid and preparation method thereof

ActiveCN110664439AFlexible adjustment of porosityFlexible adjustment of apertureSurgeryVaccination/ovulation diagnosticsFoaming agentTissue fluid

The invention discloses a microneedle capable of extracting skin tissue fluid and a preparation method thereof. The microneedle comprises porous network frameworks and hydrophilic polymer layers modified at the internal and external surfaces of the framework, wherein the porous network frameworks penetrate through each other. The preparation method specifically comprises the following steps: preparing a mixed solution of a polymer and a pore-foaming agent, filling the mixed solution into a microneedle mold, removing the pore-foaming agent to obtain the porous network framework with interpenetration, and finally modifying hydrophilic polymer layers on the inner surface and the outer surface of the porous network framework. The microneedle capable of extracting the skin tissue fluid is obtained by improving the thickness of the hydrophilic polymer layer adopted by the microneedle, the porosity and the aperture of the microneedle and the overall process flow design of the corresponding preparation method. The microneedle provided by the invention is good in biocompatibility and high in skin tissue fluid extraction speed, does not need an additional negative pressure device, does not cause obvious pain and skin infection, and does not need to be operated by professionals.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Method for preparing water swelling rubber with good weather resistance

ActiveCN104277258AImprove water absorptionGuaranteed water absorptionSodium polyacrylatePolypropylene

The invention relates to a method for preparing water swelling rubber with good weather resistance and belongs to the technical field of high-molecular materials. The method comprises the following steps of: 1, crushing 30-50 parts by weight of nitrile rubber, and then implanting C ions into the nitrile rubber by using an ion implanter to obtain modified nitrile rubber; 2, uniformly mixing the modified nitrile rubber obtained in the step 1 with 3-5 parts by weight of sodium polyacrylate and 4-6 parts by weight of chlorinated polypropylene, and uniformly milling by using an open mill; 3, then adding 2-4 parts by weight of polyvinyl pyrrolidone, 2-4 parts by weight of carbon black and batching off, and standing for later use; 5, vulcanizing by a flat vulcanizing machine, opening a mould and standing. The water swelling rubber prepared through the method disclosed by the invention has the advantages of good water absorption property and excellent weather resistant property and can still have good water absorption property after being used in an acidic aqueous solution for multiple times.

Owner:江苏悠谷未来科技有限公司

Multi-cyandiamine monomer and preparation and application thereof

InactiveCN103193674AHigh degree of sulfonationSmall swelling coefficientCarboxylic acid nitrile preparationOrganic compound preparationFuel cellsProton

The invention relates to a multi-cyandiamine monomer and preparation and application thereof, and belongs to the technical field of polymer materials and synthesis thereof. The multi-cyandiamine monomer includes tricyandiamine monomers and tetrocyandiamine monomers. The multi-cyandiamine monomer is polymerized with anhydride to obtain polyimide. Various multi-cyanpolyimide polymers are obtained by chemistry ring-closure and heat ring-closure methods. The polyimide polymer is dissolved in a solvent and a plate coating method is used for paving a film to obtain a desired polyimide film material. The multi-cyanpolyimide material of the invention possesses high thermal stability, excellent film-forming property and excellent adsorbability and dimension stability caused by microscopic intermolecular interaction. The cyan can also be introduced to a sulfonate polyimide material to enhance intermolecular forces between main chains, reduce a swelling coefficient of the sulfonate polyimide material, and enhance dimension stability of the film material which can be used as a proton conduction film material for a fuel cell.

Owner:JILIN UNIV

Softening agent for processing clothing

InactiveCN103668960AImprove antistatic performanceNot easy to get dustyFibre treatmentPolymer scienceAcrylate ester

The invention relates to a softening agent for processing clothing. The softening agent contains the following components in parts by mass: 12-20 parts of esterquats, 1-2.4 part(s) of ylate emulsion, 3-10 parts of sodium myristoyl sarcosinate, 0.5-0.85 part of polyethyleneimine, 0.5-4 part(s) of silicone oil, 0.4-2.7 part(s) of stearic acid, 0.02-0.08 part of a preservative, 0.05-0.12 part of natural essence, 0.01-0.03 part of a coloring matter and 145-160 parts of deionized water. When the softening agent provided by the invention is used for processing the clothing washed for multiple times, the bacteria on the clothing are killed, and the clothing is not yellowed; meanwhile, the clothing becomes floppy, dry and clean and not oily, and the water absorbing capacity is kept; the processed clothing has excellent anti-static performance during using and wearing, and has less possibility of sticking with dust.

Owner:南通信一服饰有限公司

Antibacterial ceramic product and preparation method thereof

The invention discloses an antibacterial ceramic product. The antibacterial ceramic product comprises a body and a surface glaze layer; the body is prepared from, by weight, 21-28 parts of potash feldspar, 14-16 parts of marbles, 16-22 parts of fluorite, 18-25 parts of purple gold soil, 12-14 parts of kaolin, 9-12 parts of quartz and 3.5-4.5 parts of silicon carbide fiber; and the surface glaze layer is prepared from, by weight, 16-20 parts of albite, 7-9 parts of fluorite, 12-16 parts of glass, 20-24 parts of quartz, 5.5-7.5 parts of talcum, 19-22 parts of zinc oxide, 4-6 parts of barium oxide, 8-13 parts of kaolin, 4-7 parts of high-boron frits and 12-17 parts of a silver-supported antibacterial agent. The antibacterial ceramic product of the invention has a good antibacterial effect, and also has functions of sterilization, disinfection and deodorization; and the comprehensive performances such as the appearance, the strength, the weight and the water absorption rate of the ceramicproduct are ensured; and the sintering molding temperature is low, so energy saving and environmental protection are achieved.

Owner:福建省德化县臻晖陶瓷有限公司

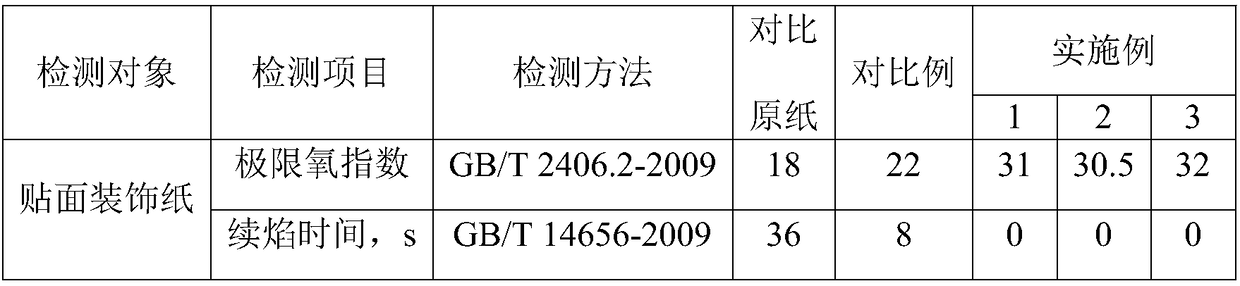

Veneering decorative paper having flame-retardant effect and flame-retardant veneering artificial board using same

ActiveCN108130808AFlame retardantIncrease temperatureSpecial paperWater-repelling agents additionLimiting oxygen indexPulp and paper industry

The invention relates to veneering decorative paper having a flame-retardant effect and a flame-retardant veneering artificial board using the same. The veneer decorative paper is prepared by the following method: 1) taking needle leaf wood pulp and broad leaf wood pulp, respectively beating, mixing and defibering, adding a titanium dioxide dispersion liquid, a retention aid, a wet strength agentand modified starch paste, to prepare original paper; 2) carrying out double-side coating on the obtained original paper with silica sol to obtain modified paper A; (3) carrying out impregnation treatment on the modified paper A with a borax solution to obtain modified paper B; and 4) carrying out double-side coating and gluing on the modified paper B with a soybean protein glue liquid with the gluing amount of 12-15 g / m<2>, and then carrying out press polishing with a press polishing machine. The obtained veneering decorative paper makes a flame-retardant agent added to the paper by using silica sol coating and borax solution impregnating, so the limit oxygen index of the decorative paper and the ignition time of the veneering artificial board are improved, and a good effect on preventingthe expansion and spreading of fire is achieved. The decorative paper does not contain formaldehyde, can greatly reduce the formaldehyde release amount of the veneering artificial board, and is suitable for promotion and use.

Owner:佛山市板缘装饰材料有限公司

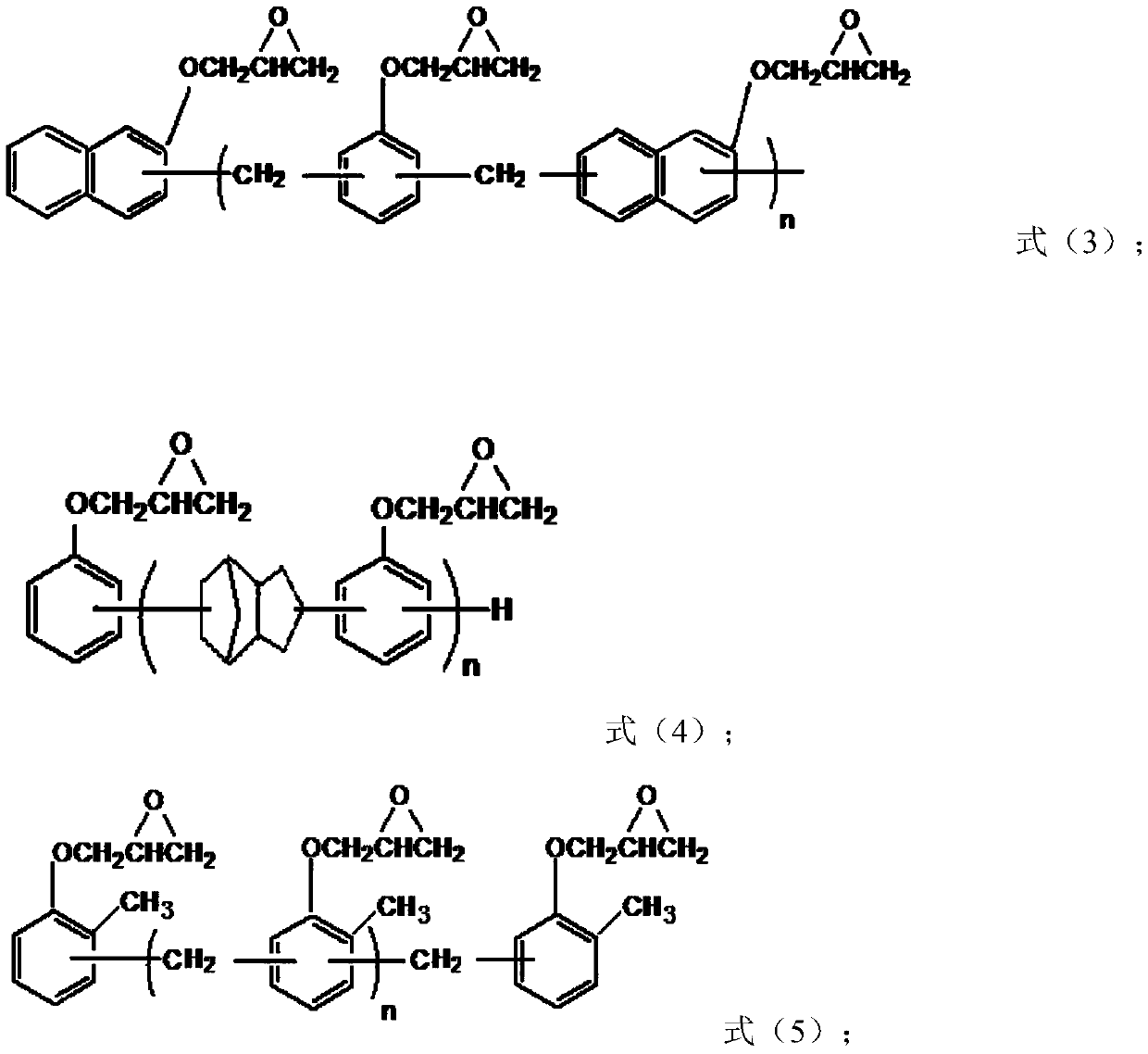

Epoxy molding compound for high thermal conductivity and high magnetic induction packaging, preparation method and applications thereof

PendingCN110776716AStratification rate is smallGood formabilitySemiconductor/solid-state device detailsSolid-state devicesPolymer scienceFirming agent

The invention relates to an epoxy molding compound for high thermal conductivity and high magnetic induction packaging, wherein the epoxy molding compound is prepared from an epoxy resin, a curing agent, a curing accelerator, an inorganic filler, a demolding agent, a modifier and a composite coupling agent. According to the invention, after the epoxy molding compound is subjected to 260 DEG reflowsoldering, the epoxy molding compound can meet the JEDEC level 2 reliability requirement, the layering rate is less than 5%, and the epoxy molding compound has excellent formability, excellent reflowresistance and excellent reliability; and the obtained epoxy molding compound is used for high-thermal-conductivity magnetic induction packaging bodies, is uniform in crystallization, has unique high-magnetic-conductivity performance, and has good low-magnetic-conductivity loss.

Owner:天津凯华绝缘材料股份有限公司

Spunlace nonwoven fabric structure and manufacturing method thereof

PendingCN107351491ASimple structureIncrease production capacityPersonal careSynthetic resin layered productsPolymer scienceNonwoven fabric

The invention relates to a spunlace nonwoven fabric structure and a manufacturing method thereof. The spunlace nonwoven fabric structure comprises an external hydrophilic nonwoven fabric layer, an internal hydrophilic nonwoven fabric layer, an ES fiber bonding layer, an internal water-repellent non-woven fabric layer and an external water-repellent non-woven fabric layer, wherein the internal hydrophilic nonwoven fabric layer and the internal water-repellent non-woven fabric layer are wavy, and the ES fiber bonding layer is arranged between the external hydrophilic nonwoven fabric layer and the external water-repellent non-woven fabric layer; the internal hydrophilic nonwoven fabric layer is arranged between the external hydrophilic nonwoven fabric layer and the ES fiber bonding layer; the internal water-repellent non-woven fabric layer is arranged between the external water-repellent non-woven fabric layer and the ES fiber bonding layer; the external hydrophilic non-woven fabric layer, the internal hydrophilic non-woven fabric layer, the ES fiber bonding layer, the internal water-repellent non-woven fabric layer and the external water-repellent non-woven fabric layer are bonded together through high-temperature hot melting after being overlapped.

Owner:ANHUI JINCHUN NONWOVEN CO LTD

Method for manufacturing building material by using high-water content sludge in urban sewage treatment plant

The invention relates to a method for producing a wall material by mixing fresh sludge in an urban sewage treatment plant and other raw materials. A large amount of sludge discharged by the urban sewage treatment plant is utilized and digested, and heat produced by combustion of organic matter in the sludge discharged by the sewage treatment plant be supplemented to a high-temperature roasting sintering product, so the heat value of the sludge is utilized, harmful and cancer-causing toxins are decomposed at high temperature, the problem of secondary pollution caused by sludge in the urban sewage treatment plant is solved completely, and the method is the current optimum way which realizes innocence, recycling and industrialization of sludge in the urban sewage treatment plant.

Owner:陈宏胜

Production process of antibacterial blended fiber towels

InactiveCN105231933AGuaranteed water absorptionSoft touchSolvent-treatmentDomestic applicationsYarnFiber

The invention relates to a production process of antibacterial blended fiber towels. Bamboo fiber, cotton fiber and Modal fiber are made into blended yarns, the blended yarns are subjected to warping, the warped blended yarns are subjected to sizing, the sized blended yarns are spun into gray fabric, the gray fabric is flushed to remove water-soluble threads, the gray fabric is boiled and bleached and is dyed, the dyed gray fabric is dried with a drying appliance, the dried gray fabric is cut and sewn to form blended fiber towels, and the blended fiber towels are subjected to antibacterial finishing using an antibacterial finishing agent. According to the production process, antibacterial finishing is carried out, thus germ growth can be prevented effectively and towel fabric is protected from contamination by microorganisms; features such as water retention and softness are retained, the towel fabric has excellent moisture-absorbing and sweat transfer performances, outstanding high temperature resistance and outstanding stink-absorbing and foul-eliminating performances and is green and long in service life, a processing technique is simple, and production efficiency is high.

Owner:陈剑

High-melt-strength biodegradable polyester material and preparation method thereof

ActiveCN112920565AStrong water absorptionEvenly dispersedBio-packagingSilane couplingPolymer chemistry

The invention discloses a high-melt-strength biodegradable polyester material which is characterized by being prepared from the following raw materials in percentage by weight: 91.00-99.88% of biodegradable polyester; 0.01-1.00% of an organic peroxide; 0.01-3.00% of a silane coupling agent; and 0.10-5.00% of silicon dioxide particles. The invention also provides a preparation method of the high-melt-strength biodegradable polyester material. The high-melt-strength biodegradable polyester material has high melt strength, is green and environment-friendly, and can completely meet the requirements of processing and forming modes related to melt stretching.

Owner:汕头市三马塑胶制品有限公司

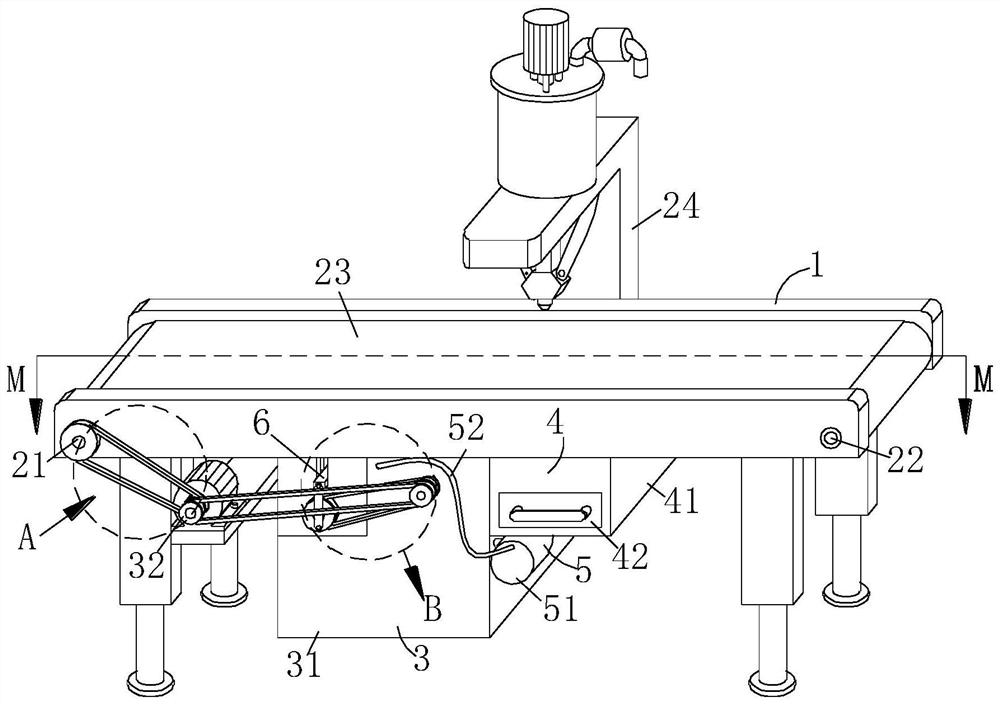

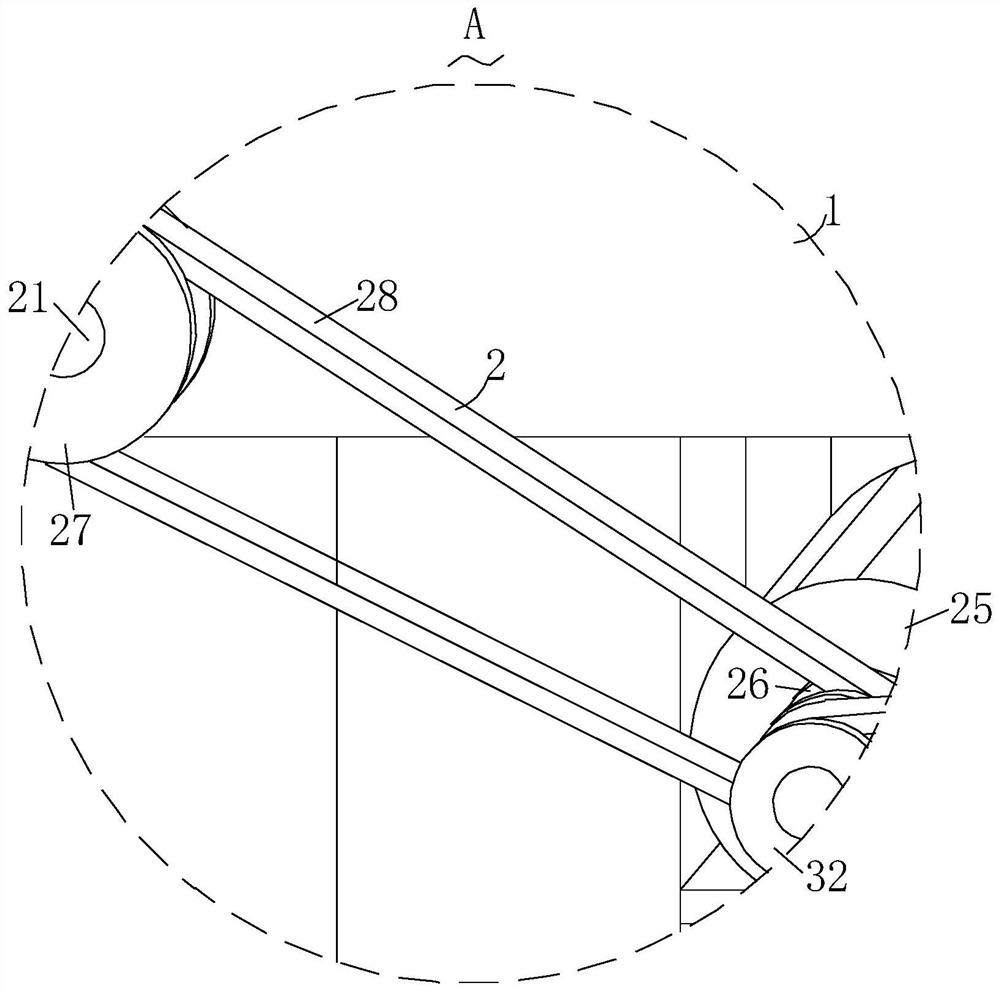

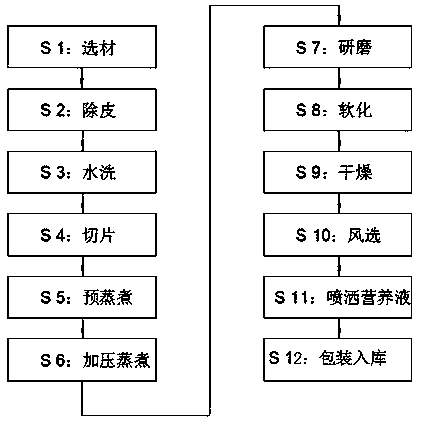

Polyurethane waterproof coating production and processing equipment

InactiveCN113213407AGuaranteed cleanlinessImprove filling efficiencyConveyorsCleaningChemistryManufacturing engineering

The invention relates to the field of waterproof coating production and processing equipment, in particular to polyurethane waterproof coating production and processing equipment. The equipment comprises a support, a conveying structure, a sweeping structure, a scraping structure, a circulating structure and a dewatering structure. When the conveying structure continuously conveys packaging barrels, the sweeping structure can be synchronously driven to work, through work of the sweeping structure, a coating adhering to a conveying assembly on the conveying structure can be swept, and therefore the cleanliness of the conveying structure is guaranteed; and by installing the scraping structure at the bottom end of the support, the coating adhering to the conveying assembly can be scraped and cleared, the scraped coating can be collected, the cleanliness of the conveying assembly can be guaranteed, the scraped coating can be prevented from polluting the workshop ground, and the sweeping structure can synchronously drive the dewatering structure to work while working, so that the cleaned conveying assembly is wiped and dried, and a wiped assembly can be extruded and dehydrated.

Owner:汤健

Water-absorbing and drying integrated type domestic floor accumulation water treatment equipment

The invention relates to water-absorbing and drying integrated type domestic floor accumulation water treatment equipment. The equipment comprises an accumulation water treatment equipment body, a pulling rod, pressing blocks, a drying fan and second hydraulic air cylinders, the upper left end of the accumulation water treatment equipment body is fixedly provided with a bracket, a water suction pipe is arranged on the bracket, a dust collection box is arranged at the upper right corner in the accumulation water treatment equipment body, the upper right end of the dust collection box is fixedlyprovided with a convex block, a dust suction pipe penetrates through the interior of the dust collection box, the bottom end of the dust suction pipe is connected with an extendable pipe, first hydraulic air cylinders are fixedly arranged on the inner wall of the accumulation water treatment equipment body, and the inner wall of each first hydraulic air cylinder is fixedly provided with a first connecting rod. The water-absorbing and drying integrated type domestic floor accumulation water treatment equipment has the advantages that the water-absorbing and drying integrated type domestic floor accumulation water treatment equipment is provided with water suction rolling columns, the water suction rolling columns can roll on the ground to quickly adsorb accumulation water on the ground, the tedious manual operation is avoided, and the accumulation water treatment efficiency is improved.

Owner:微微(杭州)信息技术有限公司

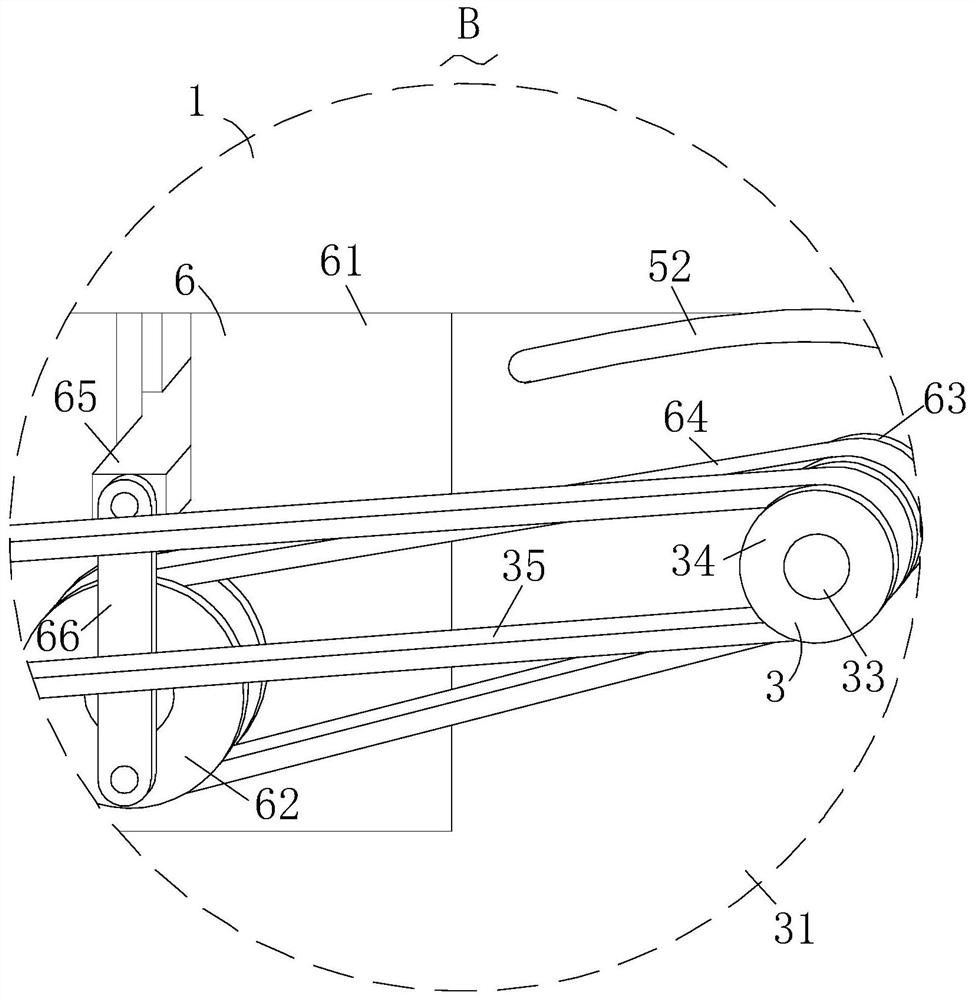

Polyester-wood pulp wet process spunlace material

ActiveCN106283839AGuaranteed water absorption performanceLow raw material costPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperGramPolyester

The invention relates to a spunlace material which is processed and formed by adopting polyester ultra-short fibers and wood pulp as main raw materials through a wet process spunlace technology. The material is prepared by mixing 10%-80% by weight of polyester ultra-short fibers, 0%-5% by weight of reinforced ultra-short fibers and 15%-90% by weight of wood pulp subjected to grinding, devillicate and brooming. A forming method of the material comprises the steps that the wood pulp is pulped and then subjected to devillicate and brooming, the polyester ultra-short fibers and the reinforced ultra-short fibers are unpacked and then subjected to liquid-phase dispersion, and the three liquid phases are mixed, subjected to wet forming and then subjected to pre-spunlace, spunlace, suction, drying, stain detection, rolling after gram weight detecting, slitting and packaging on an inclined-wire forming net. The material has the advantages that the milled wood pulp is subjected to devillicate and brooming, so that higher hydrogen bonding is formed among wood pulp fibers to solve the high cohesive force problem caused by length limitation; viscose is replaced with the wood pulp, the water absorption performance of the material used as a wet tissue material is guaranteed, and the raw material cost is greatly reduced.

Owner:HANGZHOU NBOND NONWOVENS

Manufacture method of square bricks

ActiveCN107473713AHigh strengthReduce manufacturing costCeramic materials productionClaywaresFerrosiliconBuilding material

The invention relates to the technical field of building materials and particularly relates to a manufacture method of square bricks. The manufacture method comprises the following steps: 1) preparing raw materials, and uniformly mixing the raw materials to obtain a first material mixture, wherein the raw materials comprise the following components in percentage by mass: 58%-65% of vanadium extracting tailings, 1%-3% of aluminate cement, 18%-22% of clay, 3%-10% of ferrosilicon ash, 6%-10% of aluminium oxide powder and 4%-8% of coal ash; 2) adding a certain amount of water into the first material mixture, and uniformly mixing the mixture with the water to obtain a second material mixture; 3) pouring the second material mixture into a mold, and performing hitting forming to obtain square brick semi-products; and 4) calcining the square brick semi-products at a high temperature to obtain square brick products. The method can be used for manufacturing square bricks with low cost.

Owner:PANZHIHUA UNIV

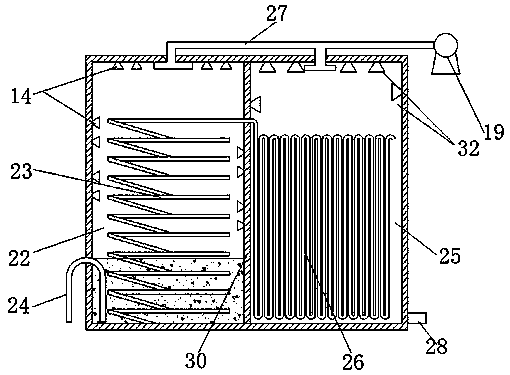

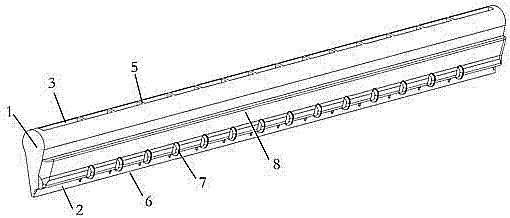

Pulp moisture absorption removal type overturning and anti-deformation pressing roll papermaking machine device

The invention discloses a pulp moisture absorption removal type overturning and anti-deformation pressing roll papermaking machine device. The structure comprises a controller, a driving cavity, a shaft fixing box, a worktable, a supporting framework, a pulp anti-deformation device and a rear separation plate. A wiping sleeve is in contact with an outer surface of a lower pressing roll to wipe andabsorb water, so that the adhesion degree of the surface of the lower pressing roll is reduced; wet pulp paper is not stuck to the outer side and the adhered wet pulp paper also can be cleaned, so that the paper quality of paper sheets is prevented from being influenced and the vibration absorption of equipment is reduced; a wet paper conveyor belt drives a guide wheel and traction steel to moveso that a squeezing pulley moves back and forth and water absorption cotton is squeezed to release water, so that the water absorption performance is kept; when the pressing roll needs to rotate to turn over, the position of a tensioning wheel is changed, and a connection engagement belt is tightly connected with an upper engagement wheel and a lower engagement wheel; and then the lower pressing roll is rotated singly, and the connection engagement belt drives an upper pressing roll to commonly rotate for 180 degrees to turn over the upper pressing roll, so that a condition that the pressing roll is concave and deformed under the action of gravity after the pressing roll is stored for long time so that the wet paper pulp is not uniformly squeezed is prevented.

Owner:苏州市相城区阳澄产业园发展有限公司

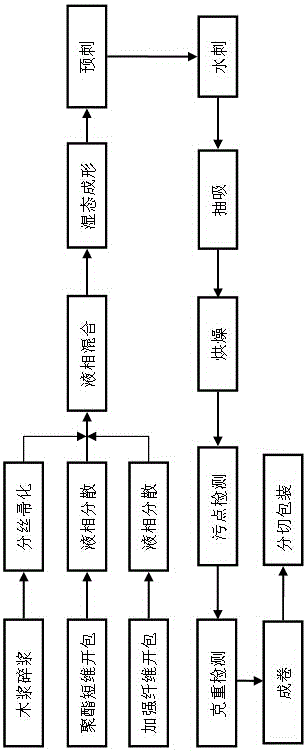

Wood fiber production method

ActiveCN110195372AImprove water absorptionImprove water retentionPretreatment with water/steamImpregnation spraying apparatusWood fibreNutrient solution

The invention discloses a wood fiber production method, which comprises: S1, material selection; S2, skin removal; S3, water washing; S4, slicing; S5, pre-cooking; S6, pressurizing cooking; S7, grinding; S8, softening; S9, drying; S10, air selection; S11, nutrient solution spraying; and S12, packaging warehousing. According to the present invention, the wood fiber produced through material selection, skin removal, water washing, slicing, pre-cooking, pressurizing cooking, grinding, softening, drying, air selection, nutrient solution spraying, packaging warehousing and other steps can be well used in spray seeding technologies; the wood fiber produced by the method has good softness; and during the spray seeding, when the wood fiber, the water and the binder are mixed, the wood fiber has good water absorption, such that each wood fiber can absorb a large amount of water so as to achieve good water content.

Owner:东南生态修复有限公司

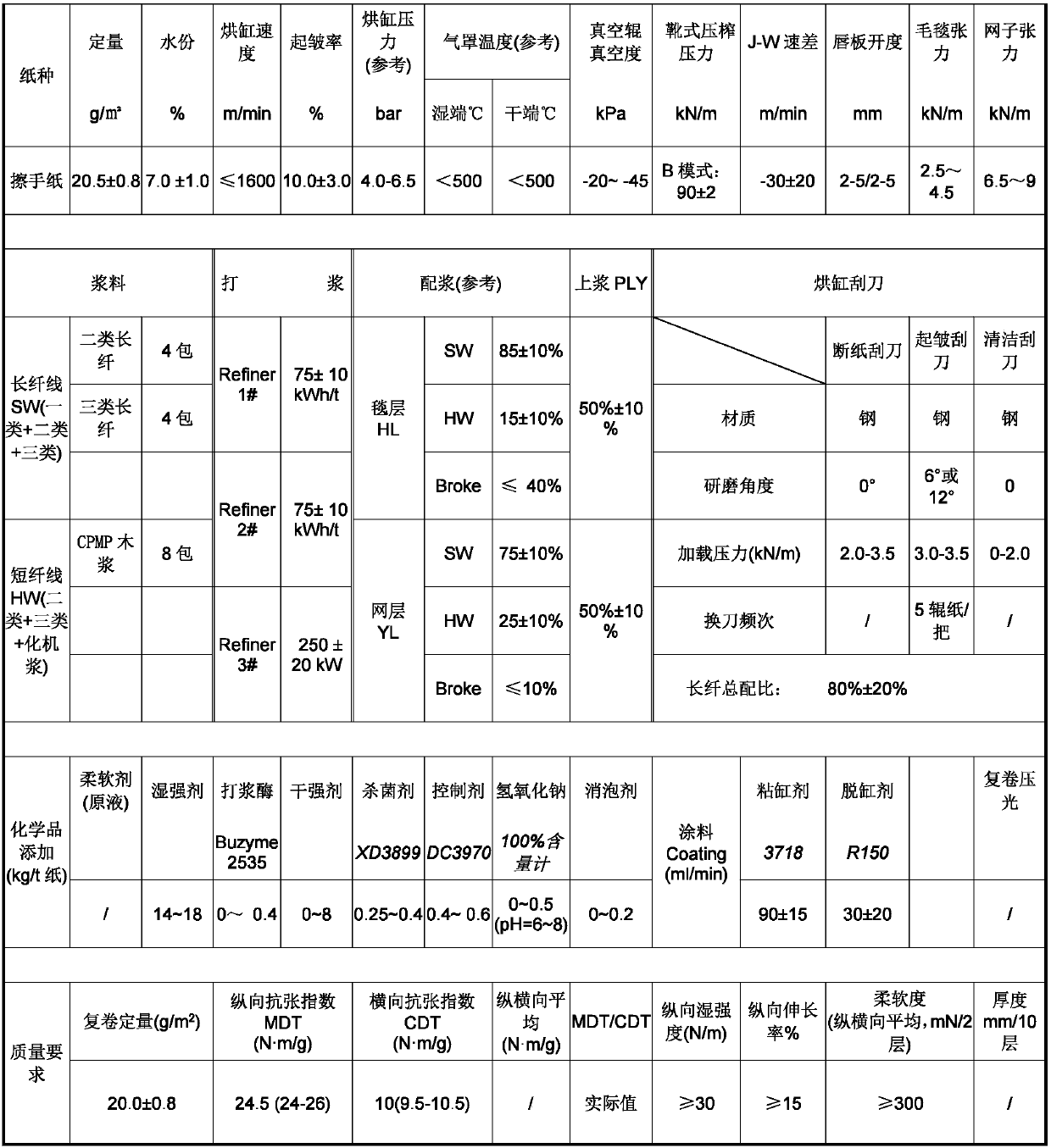

Sterile tissue and production process thereof

ActiveCN107663805AReduce porosityIncrease liquid absorptionSpecial paperPaper/cardboardFungicideSulfate

The invention discloses a sterile tissue and a production process thereof, and belongs to the technical field of tissue production. The tissue is prepared from, by weight, 20-60% of bleached sulfate softwood pulp, 30-70% of CPMP and 0-10% of broken paper pulp. According to the method, by adopting an appropriate principle and ratio, wet strength agents with low organic chlorine, biodegradable non-toxic fungicides and FDA-authenticated coatings, adopting forming equipment with a low vertical-horizontal tension ratio, a drying and sterilization process at the temperature higher than 40 DEG C andsafe non-toxic chemicals, and combining appropriate pressing printing processes, the produced tissue has the advantages of being low in quantification, low in vertical-horizontal tension ratio, sterile, environmentally friendly and high in water absorption performance.

Owner:SHANDONG HENGAN PAPER IND CO LTD

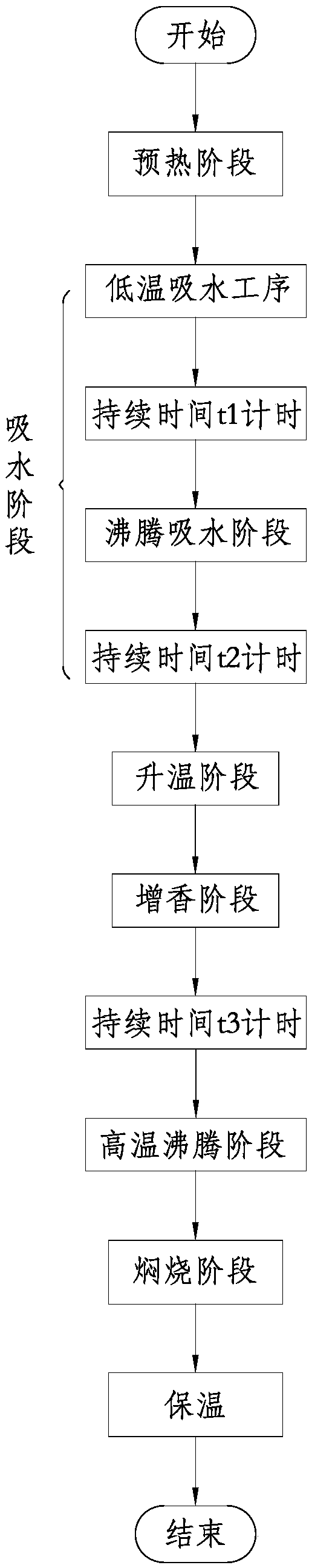

Cooking control method of vacuum electric cooker

InactiveCN111449487ASufficient water absorptionFast water absorptionCooking vesselsThermodynamicsProcess engineering

The invention discloses a cooking control method of a vacuum electric cooker, belongs to the field of kitchen appliances, and solves the problem of overlong cooking time of the existing electric cooker. The cooking control method of the vacuum electric cooker comprises a preheating stage, a water absorption stage and a high-temperature boiling stage, wherein the water absorption stage comprises: alow-temperature water absorption process, wherein food materials in a cooking cavity are kept at a first water absorption temperature T1 for a duration t1; and a boiling water absorption process, wherein an air sucking device works to enable the cooking cavity to be kept at a preset negative pressure, the food materials in the cooking cavity are heated to a second water absorption temperature T2and kept for a duration time t2, and the second water absorption temperature T2 is the boiling point temperature under the preset negative pressure. According to the invention, food materials are boiled in advance in the water absorption stage through the boiling water absorption procedure, so that the purpose of shortening the cooking time is achieved.

Owner:JOYOUNG CO LTD

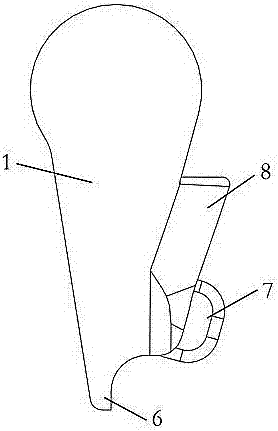

Scraper blade with water-absorbing function and cleaner using scraper blade

ActiveCN106923759AReduce steps during assemblyGuaranteed suctionCarpet cleanersFloor cleanersEngineering

The invention discloses a scraper blade with a water-absorbing function and a cleaner using the scraper blade and belongs to the field of cleaning tools. The scraper blade comprises a scraper blade main body; the lower end of the scraper blade main body is configured as a water-absorbing end; the upper end of the scraper blade main body is configured as a water draining end; the water-absorbing end is communicated with the water draining end through a water-absorbing channel; a water absorbing port at the water-absorbing end is configured as an inclined port; a scraper blade for scraping water is arranged on longer side and a lug is arranged on the outer surface of the shorter side; a fixing block which is in sliding fit with the cleaner is arranged on the scraper blade main body; a sliding slot is formed on the cleaner; the upper end of the scraper blade main body and the fixing block are in sliding connection with the sliding slot. The structure of the scraper blade disclosed by the invention is integrally formed in the manner of silica gel injection molding; the technical steps of forming and mounting are saved; the cost is saved; the inclined port is used as the water absorbing port and the lug is arranged for limiting the inclined angle of the water absorbing port in a water scraping process, so that the close suction of the water absorbing port and a to-be-cleaned surface can be avoided and the smooth working process can be guaranteed.

Owner:QINGYUAN LANHAI HUIGU INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com