Wood fiber production method

A production method and wood fiber technology, applied in the field of fiber production, can solve the problems of uneven coverage of the base layer and difficult operation, and achieve the effects of ensuring water absorption, better bulkiness, and increasing water retention performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

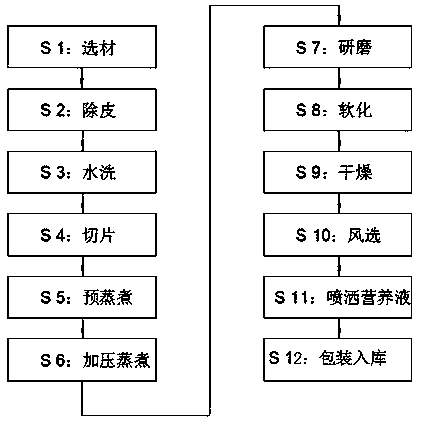

[0064] A kind of wood fiber production method, comprises the steps:

[0065] S1: Material selection, choose wood with a diameter of 10-15cm or more; among them, the wood can be pine, willow, eucalyptus and other wood;

[0066] S2: Debarking, using a debarking machine to debark the selected wood;

[0067] S3: Washing, using water washing equipment to clean the peeled wood;

[0068] S4: slicing, using a chipper to cut the cleaned wood into flakes;

[0069] S5: Pre-cooking, use a swing sieving machine to sort the flake wood, put it into the preheating bin for pre-cooking, the pre-cooking temperature is 100°C, and the pre-cooking time is 5 minutes;

[0070] S6: Pressure cooking, put the pre-cooked wood in S5 into the cooking chamber for pressure cooking, the cooking pressure is 5.6bar, the cooking time is 3min, and the cooking temperature is 95°C;

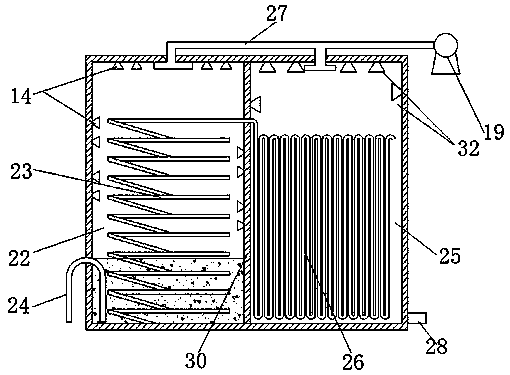

[0071] S7: Grinding, putting the wood cooked in S6 into the heat mill 3 for grinding, grinding the wood into wood fibers; and stea...

Embodiment 2

[0082] This embodiment is basically the same as Embodiment 1, the difference is that:

[0083] In S5: pre-cooking temperature: 110°C, pre-cooking time: 8min;

[0084] In S6: cooking pressure: 6.2bar, cooking time: 4min, cooking temperature: 105°C;

[0085] In S9: moisture content: up to 17%;

[0086] In S11: spraying amount: 210kg / m³; spraying amount of water retaining agent: 6.5 kg / m³.

[0087] Wherein, in S8, the wood fiber is put into boiling water and boiled for 15 minutes, and the wood fiber is taken out after being soft.

Embodiment 3

[0089] This embodiment is basically the same as Embodiment 1, the difference is that:

[0090] In S5: Precooking temperature: 120°C, precooking time: 10min;

[0091] In S6: cooking pressure: 7bar, cooking time: 6min, cooking temperature: 110°C;

[0092] In S9: moisture content: 18%;

[0093] In S11: the spraying amount is: 220kg / m³; the spraying amount of the water retaining agent is 8kg / m³.

[0094] Wherein, in S8, the wood fiber is put into boiling water and boiled for 20 minutes, and the wood fiber is taken out after being soft.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com