Anti-deformation acrylic plate with heat insulation and heat preservation functions and preparation method of anti-deformation acrylic plate

A technology of thermal insulation and acrylic board, applied in chemical instruments and methods, lamination, coating, etc., can solve the problems of difficult application, unsatisfactory thermal insulation, single function, etc., to improve mechanical properties and reduce surface tension , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

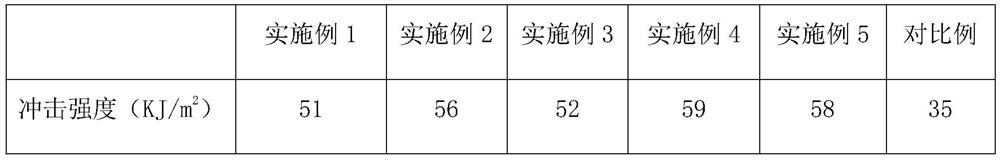

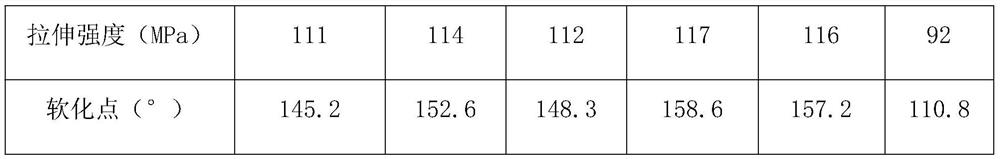

Examples

Embodiment 1

[0039] A preparation method of an anti-deformation acrylic plate with thermal insulation function comprises the following steps:

[0040] S1. Preparation of acrylic base layer

[0041](1) Ultrasonic agitate methyl methacrylate, butyl acrylate, dipropylene adipate, and XT-2 rare earth stabilizer, mix them evenly, put them into a reaction kettle, heat up to 160°C, and form a glue; cool to Add benzoyl peroxide and stearic acid at 60°C, stir evenly and heat up to 280°C to obtain a reaction slurry;

[0042] In parts by weight, 80 parts of methyl methacrylate, 10 parts of butyl acrylate, 5 parts of dipropylene adipate, 5 parts of benzoyl peroxide, and 5 parts of stearic acid; XT- 2 Rare earth stabilizer is 1 part;

[0043] (2) Inject the reaction slurry into the mold, solidify at 60°C for 7 hours, then raise the temperature to 90°C and solidify for 40 minutes, cool to 18°C, and demould to obtain an acrylic blank;

[0044] (3) Polishing the surface of the acrylic blank described i...

Embodiment 2

[0054] A preparation method of an anti-deformation acrylic plate with thermal insulation function comprises the following steps:

[0055] S1. Preparation of acrylic base layer

[0056] (1) Ultrasonic agitate methyl methacrylate, butyl acrylate, dipropylene adipate, and XT-3 rare earth stabilizer, mix them evenly, put them into a reaction kettle, heat up to 180°C, and form a glue; cool to Add benzoyl peroxide and stearic acid at 70°C, stir evenly and heat up to 285°C to obtain a reaction slurry;

[0057] In parts by weight, 80 parts of methyl methacrylate, 20 parts of butyl acrylate, 15 parts of dipropylene adipate, 8 parts of benzoyl peroxide, and 7 parts of stearic acid; XT- 3 Rare earth stabilizer is 4 parts;

[0058] (2) Inject the reaction slurry into the mold, solidify at 70°C for 6.5 hours, then raise the temperature to 93°C and solidify for 35 minutes, cool to 22°C, and demould to obtain an acrylic blank;

[0059] (3) Polishing the surface of the acrylic blank descri...

Embodiment 3

[0069] A preparation method of an anti-deformation acrylic plate with thermal insulation function comprises the following steps:

[0070] S1. Preparation of acrylic base layer

[0071] (1) Stir methyl methacrylate, butyl acrylate, dipropylene adipate, and XT-2 rare earth stabilizer ultrasonically, mix them evenly, put them into a reaction kettle, heat up to 250°C, and form a glue; cool to Add benzoyl peroxide and stearic acid at 80°C, stir evenly and heat up to 290°C to obtain a reaction slurry;

[0072] In parts by weight, 80 parts of methyl methacrylate, 30 parts of butyl acrylate, 20 parts of dipropylene adipate, 10 parts of benzoyl peroxide, and 10 parts of stearic acid; XT- 2 Rare earth stabilizer is 5 parts;

[0073] (2) Inject the reaction slurry into the mold, solidify at 80°C for 6 hours, then raise the temperature to 95°C and solidify for 30 minutes, cool to 25°C, and demould to obtain an acrylic blank;

[0074] (3) Polishing the surface of the acrylic blank descr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com