Antibacterial fabric and preparation method thereof

A technology for fabrics and antibacterial raw materials, applied in the field of textile production, can solve the problems of the influence of fabric mechanical properties and the high toxicity of antibacterial additives, and achieve the effects of increasing washing resistance, reducing cytotoxicity, and enhancing bacteriostatic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

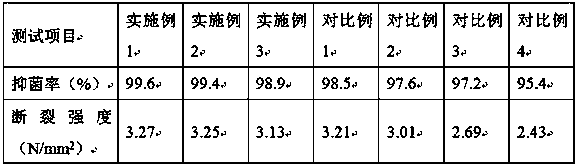

Examples

preparation example Construction

[0027] The preparation method of the antibacterial modifier is as follows: take tetraethylenepentamine and add methanol and methyl acrylate in a mass ratio of 5~10:10~15:2~5, stir and mix at 20~25°C for 2~4h, and then heat up to 140°C Stir and mix at ~150°C for 2~4 hours, cool to room temperature to obtain a cooling product, take the cooling product and add methanol at a mass ratio of 2~5:10~15, stir and mix for 20~30min, add acid additives with a mass ratio of 20~40% of the cooling product Add 1-5% boron trifluoride diethyl ether as the cooling material, heat at 140-150°C for 1-3 hours, cool to room temperature, and distill under reduced pressure to obtain the antibacterial modifier.

[0028] The solvent is: take isopropyl ether and mix it with propylene glycol at a mass ratio of 2~5:1~3.

[0029] The preparation method of antibacterial raw materials is as follows: take N,N-dimethyl n-octadecylamine at a mass ratio of 1~5:2~6:20~30, add substitution additives and dichlorometh...

Embodiment 1

[0036] The replacement additive is: bromobutane.

[0037] The acid additive is obtained by mixing lauric acid and myristic acid in any mass ratio.

[0038] The preparation method of the antibacterial modifier is as follows: take tetraethylenepentamine, add methanol and methyl acrylate in a mass ratio of 5:10:2, stir and mix at 20°C for 2 hours, then heat up to 140°C and stir and mix for 2 hours, and cool to room temperature to obtain Coolant, take the cooling substance and add methanol at a mass ratio of 2:10, stir and mix for 20 minutes, add 20% of the cooling substance as an acid additive and 1% of the cooling substance as boron trifluoride ether, keep it at 140°C for 1h, and cool to room temperature , Distilled under reduced pressure to obtain the antibacterial modifier.

[0039] The solvent is: take isopropyl ether and mix it with propylene glycol at a mass ratio of 2:1.

[0040] The preparation method of antibacterial raw materials is as follows: take N,N-dimethyl n-oct...

Embodiment 2

[0047] The replacement additive is: bromooctane.

[0048] The acid additive is obtained by mixing citric acid and palmitic acid in any mass ratio.

[0049] The preparation method of the antibacterial modifier is as follows: take tetraethylenepentamine and add methanol and methyl acrylate in a mass ratio of 8:12:3, stir and mix at 22°C for 3 hours, then heat up to 145°C and stir and mix for 3 hours, and cool to room temperature to obtain Coolant, take the cooling substance and add methanol at a mass ratio of 4:12, stir and mix for 25 minutes, add 30% of the cooling substance as an acid additive and 3% of the cooling substance as boron trifluoride ether, keep at 145°C for 2 hours, and cool to room temperature , Distilled under reduced pressure to obtain the antibacterial modifier.

[0050] The solvent is: take isopropyl ether and add propylene glycol in a mass ratio of 3:2 to mix.

[0051] The preparation method of antibacterial raw materials is as follows: take N,N-dimethyl n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com