Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143results about How to "Tough and strong" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barrier film and method for production thereof

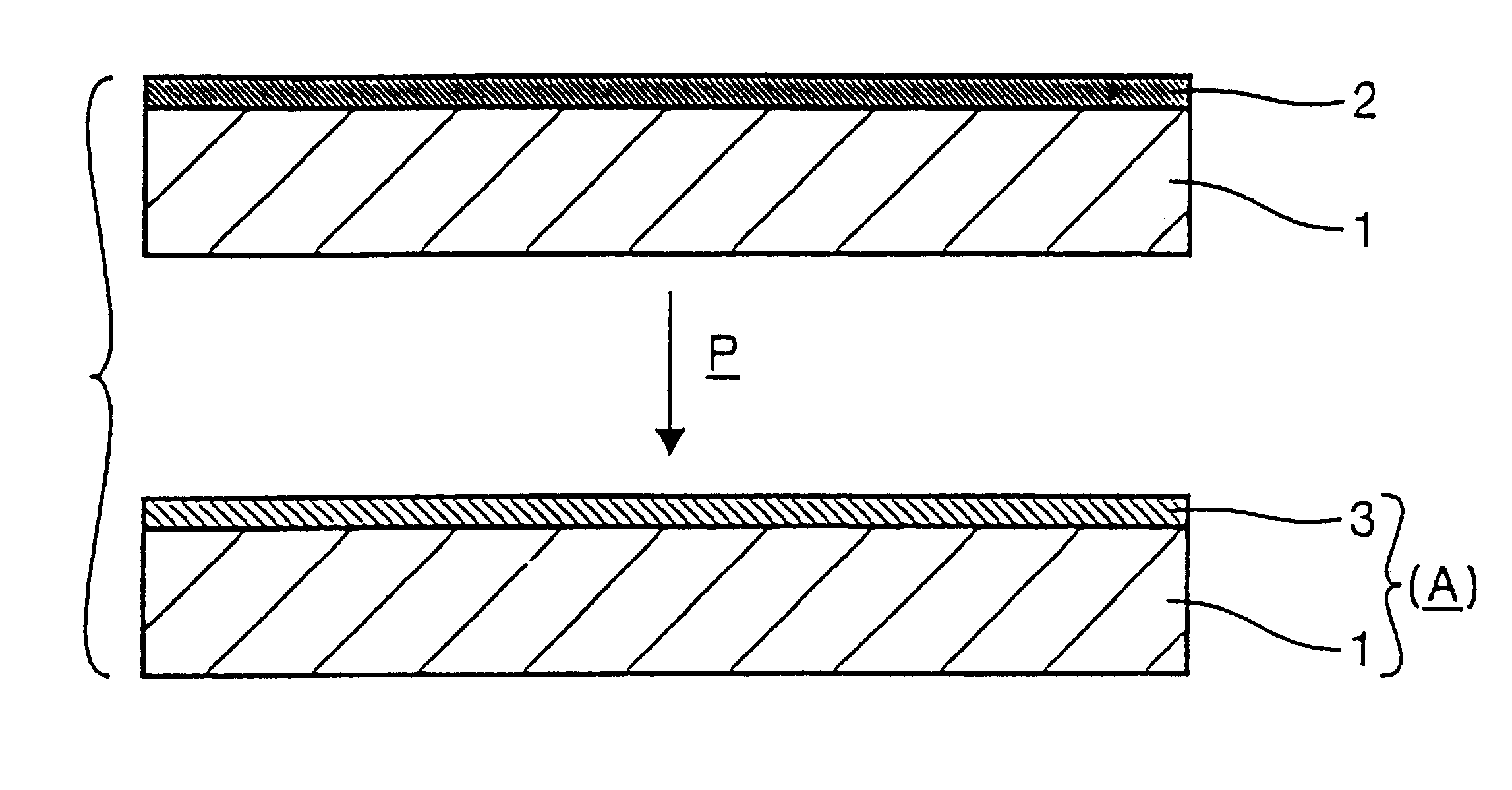

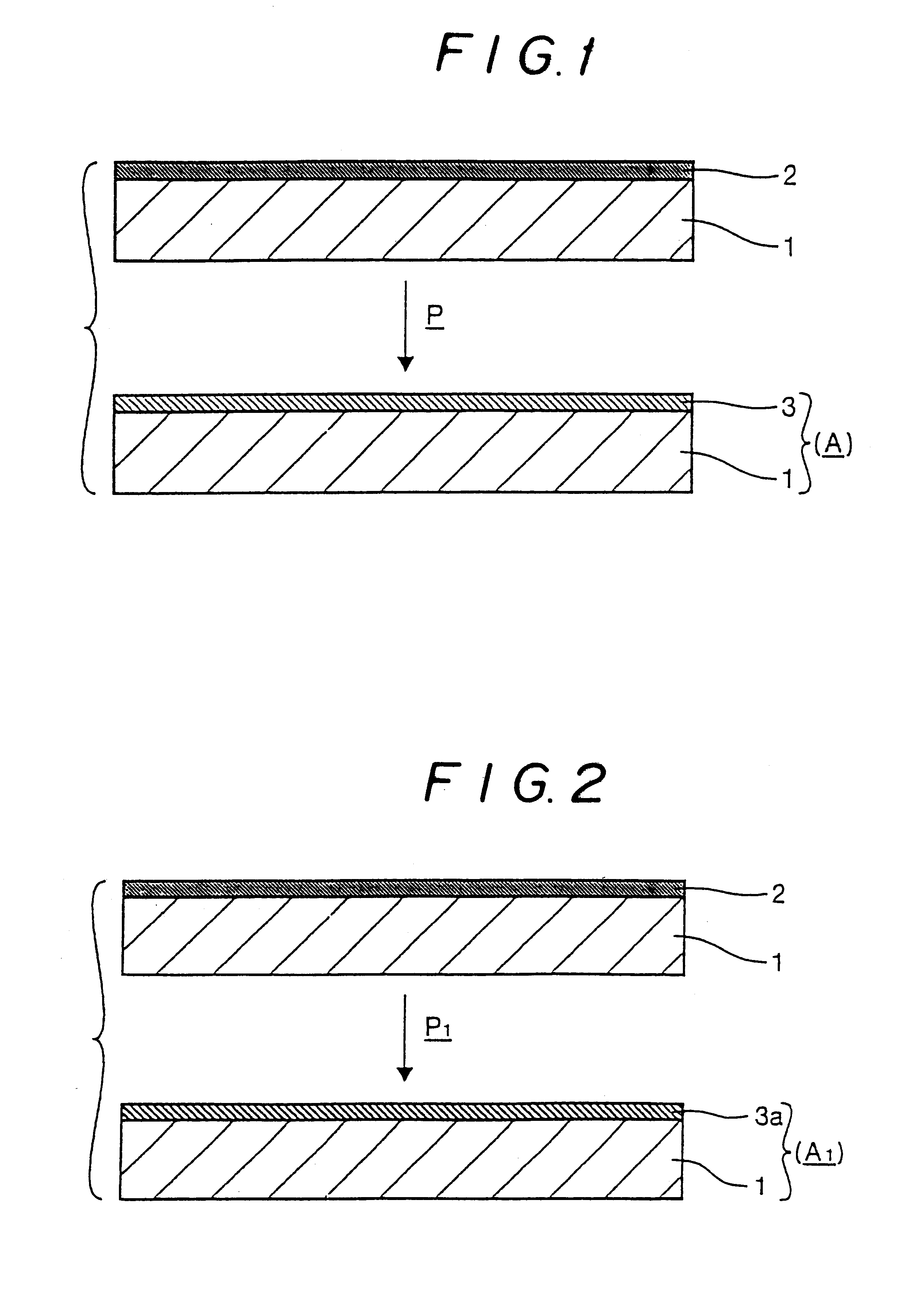

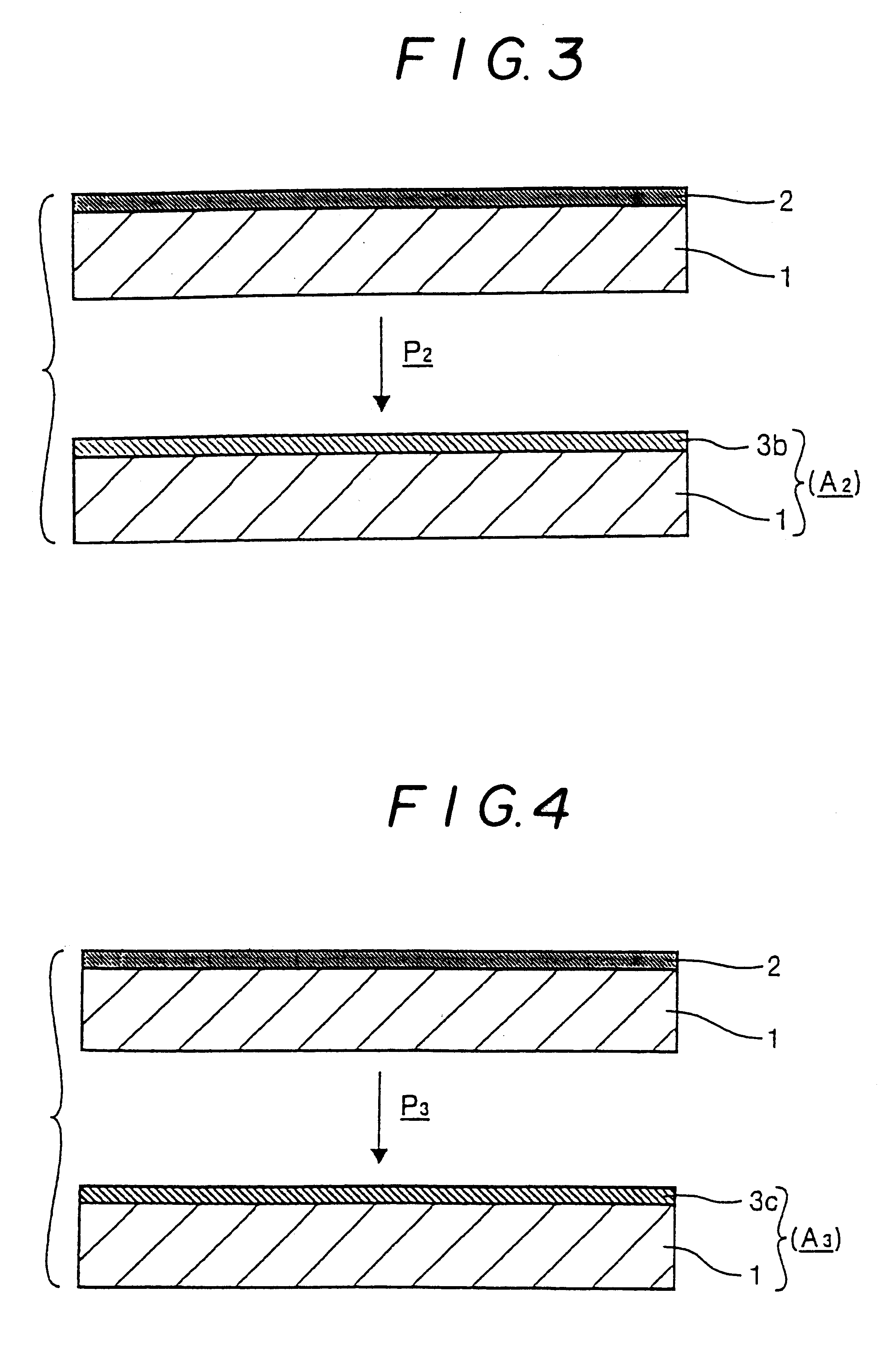

InactiveUS6720097B2Degree of improvementHigh transparencyFlexible coversWrappersPermeationOxygen permeability

Owner:DAI NIPPON PRINTING CO LTD

Method for welding Q500qE ultralow-carbon bainite steel for bridge

ActiveCN103286427ASolve welding process problemsAvoid cold cracksArc welding apparatusWelding/cutting media/materialsShielded metal arc weldingChemical composition

The invention provides a method for welding Q500qE ultralow-carbon bainite steel for a bridge. The method is excellent in joint mechanical performance and high in welding efficiency and specifically includes that aiming at specific chemical components, applicable technical conditions and different plate thicknesses of the Q500qE ultralow-carbon bainite steel for the bridge, preheating temperature before welding, groove types and welding process parameters are determined; a welding joint type adopts butt joint, penetration angle joint or ship position T-shaped angle joint; a welding method adopts submerged arc welding, CO2 gas shielded semiautomatic welding or shielded metal arc welding. By the welding method, the joint type and thickness specifications of a bridge structure are comprehensively covered, the technical scheme is simple, convenient and high in adaptivity, all implementing effects meet technical requirements of standards related to building of bridge steel and the bridge structure, and the method is of great significance in promoting upgrading of the bridge steel and development of large-span steel bridge building technology. The method can be applied to building of the bridge structure, can also be applied to welding of other ultrathin-carbon bainite steel and is high in adaptivity.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

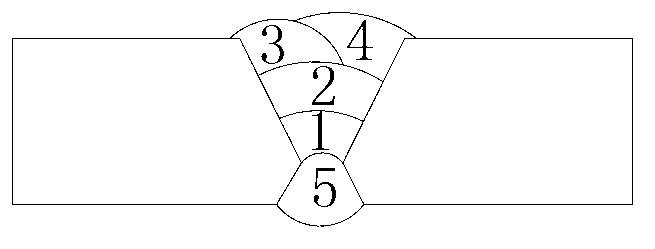

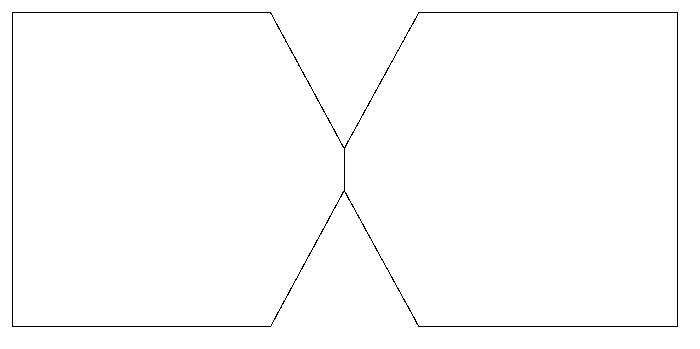

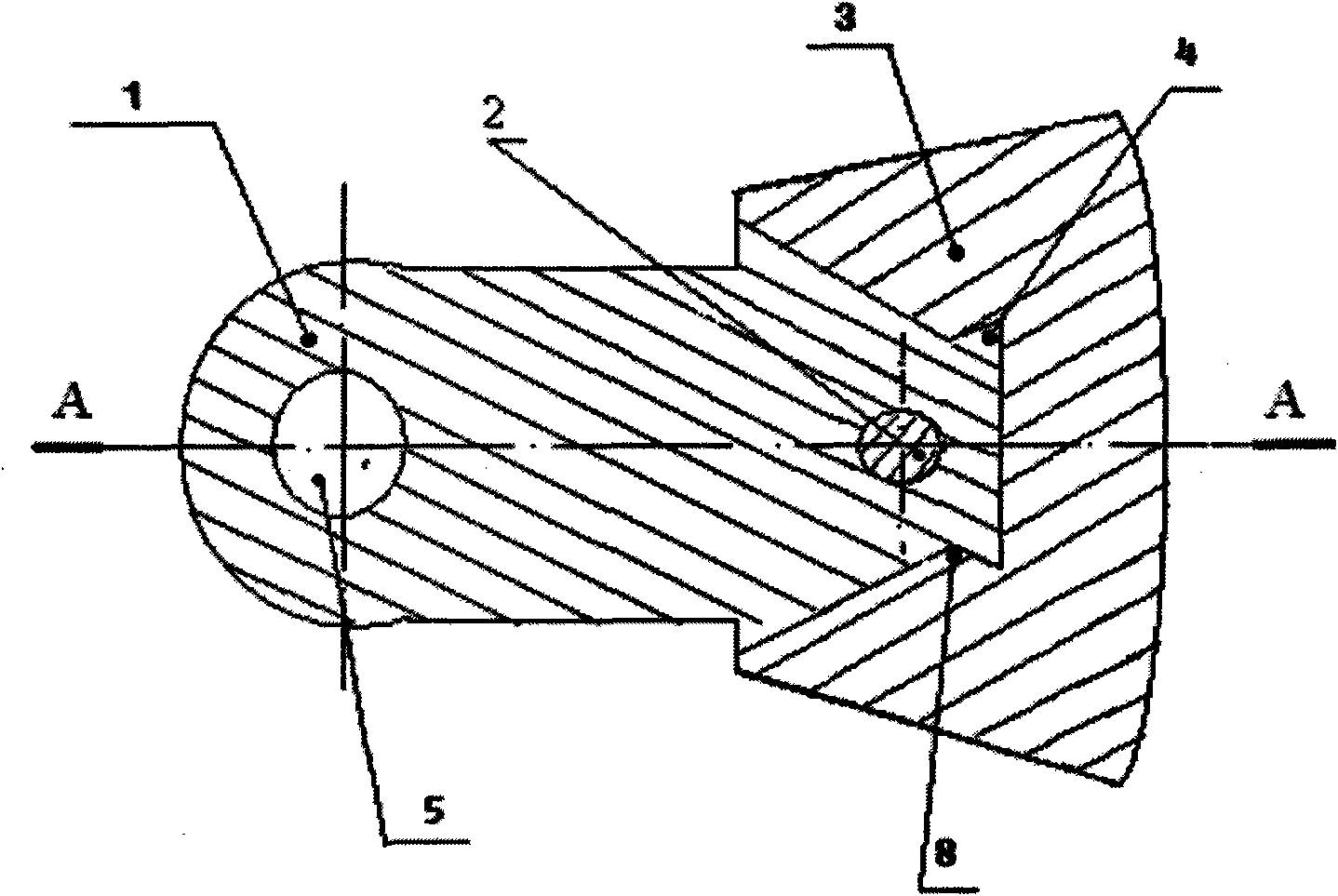

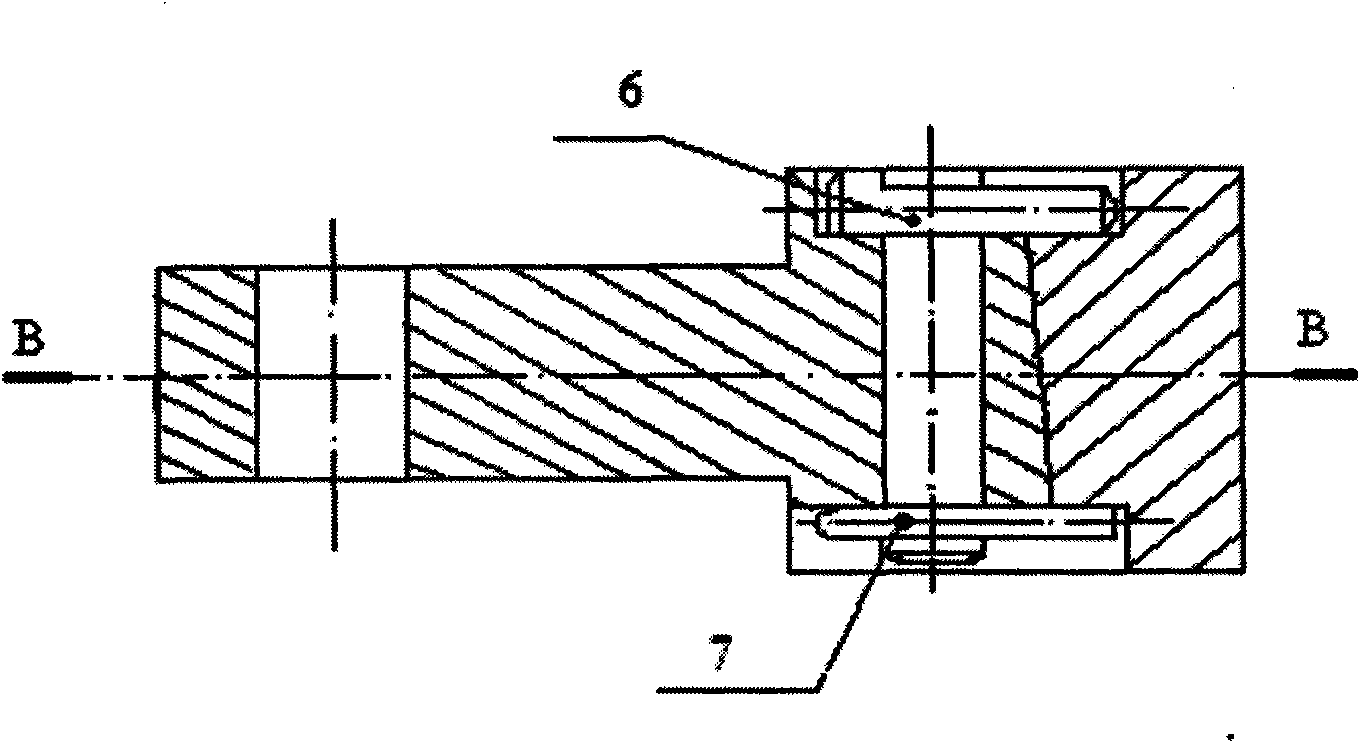

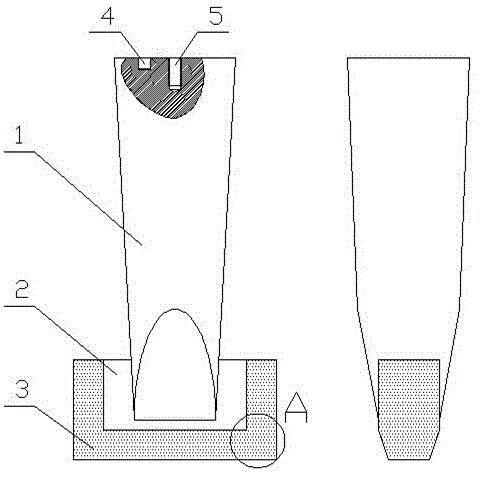

Combined type mechanically crushing machine hammer and manufacturing method thereof

The invention discloses a combined type mechanically crushing machine hammer and a manufacturing method thereof. The hammer comprises a head part (3) and a handle part (1) which are mechanically combined for forming the hammer, the head part (3) is formed by high-chromium cast iron lost foam casting, the handle part (1) is formed through high-manganese steel lost foam casting, an installing hole (5) connected with a circular disc of a crushing machine is arranged above the handle part (1), a rabbet (4) is arranged under the handle part (1), the head part (3) is provided with a mortice (8) matched with the rabbet (4) of the handle part, and the handle part (1) and the head part (3) are connected through the mutually matched rabbet (4) and the mortice (8) for forming the integral hammer. The hammer of the invention has the advantages of simple manufacture, wear resistance, good toughness, fast replacement of the head part, repeated use of the handle part, production efficiency improvement and metal material saving. The invention is particularly suitable for manufacturing reversible hammer type crushing machine hammers.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Formula of water glass modifying additive and production process and using method thereof

InactiveCN101885035AImprove adhesionImprove sand performanceFoundry mouldsFoundry coresEmulsionMetallurgy

The invention relates to a water glass modifying additive for casting and a production process and a using method thereof. The modifying additive consists of the following components in percentage by mass: 40 to 65 percent of styrene-acrylate emulsion, 0 to 10 percent of urea resin, 0.1 to 0.5 percent of quaternary ammonium salt and 25 to 55 percent of water. Used water glass sand is subjected to dry reclamation, the residual Na2O content of the used sand is controlled in a certain range and the water galls with ultra-low modulus is matched with the modifying additive so that the available time for preparing molding sand by mixing all or partial reclaimed sand can be prolonged and the molding sand has good process performance; and the reclamation rate of the used water glass sand can reach over 85 percent. The water glass modifying additive is directly added into the water glass at normal temperature and stirred uniformly without a fussy heating-cooling process so as to facilitate the operation on a molding site.

Owner:深圳市景鼎现代科技有限公司

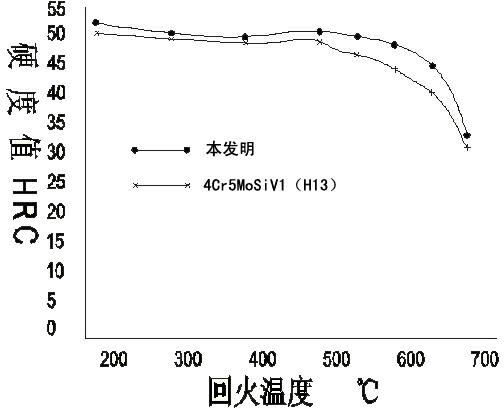

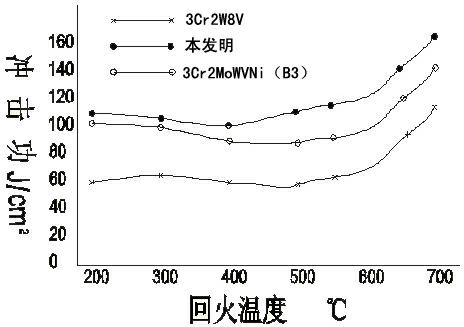

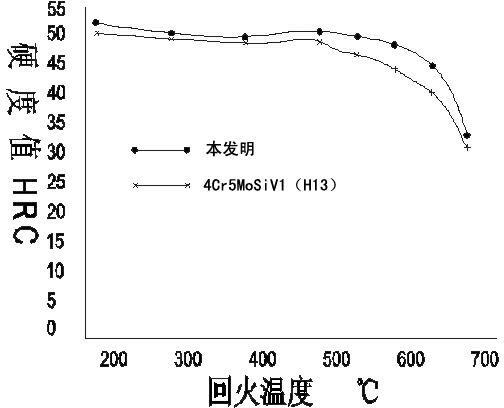

B3R hot work die steel with high strength and toughness and resistance to tempering, and preparation process thereof

The invention provides 4Cr3MoWVNi (B3R) hot work die steel with high strength and toughness and resistance to tempering, and a preparation process thereof. Raw materials for preparing the B3R hot work die steel comprise, by weight, C 0.35 to 0.42%, Si 0.15 to 0.35%, Mn 0.3 to 0.5%, Cr 2.50 to 3.50%, Mo 1.00 to 1.50%, W 0.50 to 0.80%, V 0.50 to 0.80%, Ni 1.45 to 1.85%, S 0.003 to 0.010% and P 0.008 to 0.018%, with the balance being Fe. The preparation process comprises the following steps: smelting at intermediate frequency--remelting (refining) of electroslag-diffusion hydrogen of electroslagingots, annealing treatment of electroslag ingots--forging--annealing of forging stocks--rough machining--vacuum heat treatment, and secondary tempering so as to obtain the novel product of die steel. The hot work die steel prepared in the invention has high Rockwell hardness, excellent impact toughness and tempering (thermal fatigue) resistance, and the advantages of optimized collocation of components, pure steel quality, a uniform structure, high strength, strong toughness, good tempering resistance, etc.

Owner:SHANDONG YUANDA MATERIAL TECH CO LTD

Process for producing rotary drill creeper tread material

The present invention is process of preparing material for track block of rotary drilling machine. The material contains C 0.28-0.34 wt%, Cr 0.6-0.8 wt%, Mn 1.0-1.2 wt%, Si 0.5-0.9 wt%, Mo 0-0.4 wt%, RE 0.03-0.05 wt% and P+S less than 0.04 wt% and is smelted in MF inducing electric furnace. The preparation process includes deoxidation with Al in the amount of 0.3-0.6 wt% of molten steel while the molten steel is heated to overheat of 1600-1620 deeg.c, tapping at 1580-1600 deg.c, casting at 1530-1560 degg.c, forming in surface dry water glass sand mold, heating to 840-860 deg.c, maintaining for 50-70 min, lowering in the furnace to 720-750 deg.c, temperature equalization for 0.5 hr, water quenching outside the furnace, tempering at 520-540 deg.c for 50-70 min. The present invention has the advantages of high toughness, low cost, simple production process and long service life.

Owner:UNIV OF SCI & TECH BEIJING

Method for manufacturing nanometer antibacterial ceramic glaze layers

The invention belongs to the field of inorganic nonmetal materials, particularly discloses a method for manufacturing nanometer antibacterial ceramic glaze layers, and relates to methods for manufacturing ceramic glaze layers. Antibacterial elements are added into ceramic glaze layer bases to carry out antibacterial disinfection on the ceramic glaze layers. Precursors for superfine powder of the nanometer antibacterial ceramic glaze layers comprise 45-60% of SiO<2>, 10-14%of Al<2>O<3>, 7-10% of CaO, 5-7% of ZnO, 2-5% of CuO, 3-6% of MgO, 1-3% of TiO<2> and 0.2-2% of Ag<2>O. The method includes filling graphite containers with the precursors for proportionally preparing the superfine powder of the nanometer antibacterial ceramic glaze layers; preserving heat for 120min-240min under argon atmosphere protection and the condition of temperatures of 1250-1400 DEG C to carry out synthesis; adding absolute ethyl alcohol into a ball-mill to carry out mechanical ball-milling for 24 hours so as to obtain the superfine precursor powder with crystal grain sizes of 30-80nm. The method has the advantages that metal grains of zinc, copper, magnesium and silver are fine and are uniformly distributed in glaze layers, the diameters of the metal grains are 30-80nm, and antibacterial elements can be quickly, durably and continuously released.

Owner:SHANDONG JIANZHU UNIV

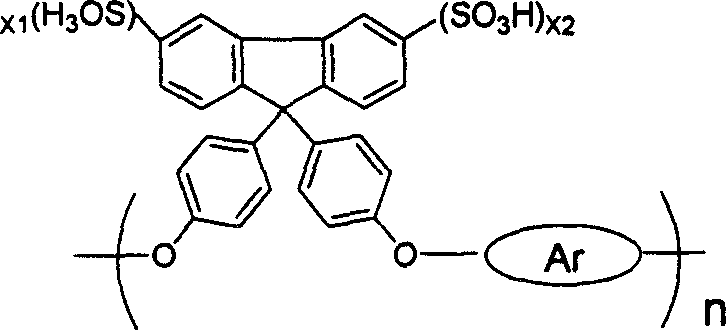

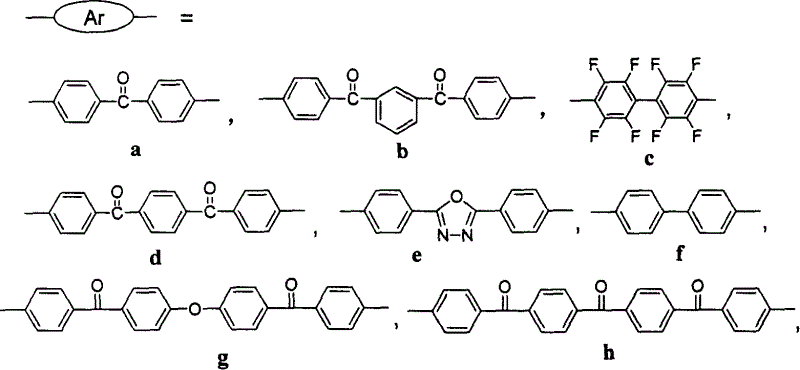

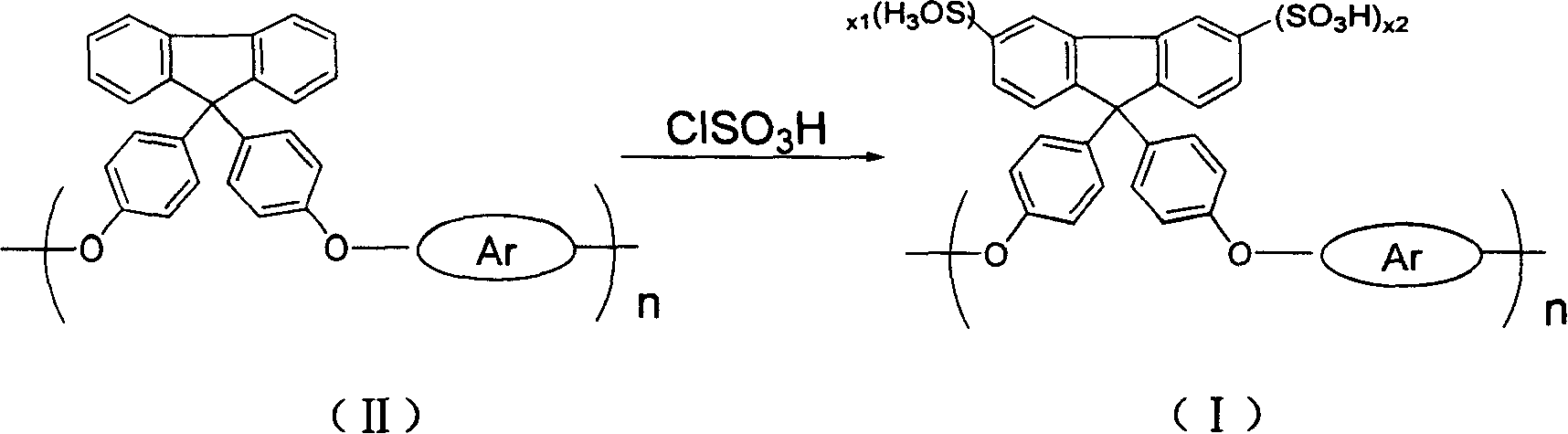

Sulfonated fluorine-containing poly-arylether (arone) and its preparing method and use

InactiveCN1621431ALow costLow priceChemical recyclingFuel cell detailsComposite filmChlorosulfuric acid

The present invention relates to one kind of sulfonated fluorene-containing polyaryl ether (ketone) and its application in preparing proton exchanging film. The sulfonated fluorine-containing polyaryl ether (ketone) may be prepared through polymerization of 9, 9-(4, 4-dihydroxyphenyl) fluorene and chloric or fluorous arone (arene) to form polyaryl ether (ketone); and the subsequent sulfonation with chlorosulfonic acid in the controlled consumption for controlled product sulfonation degree. The sulfonated fluorine-containing polyaryl ether (ketone) may be dissolved in different polar solvents before being cast to form single-component film, or be mixed with other polymer material for preparing composite film, or be mixed with heteropoly acid and other inorganic matter for preparing hetero film; and all these kinds of film have the advantages of low cost, high stability, high water absorption, small equivalent molecular weight, etc. and are expected to find use in fuel cell.

Owner:SUN YAT SEN UNIV

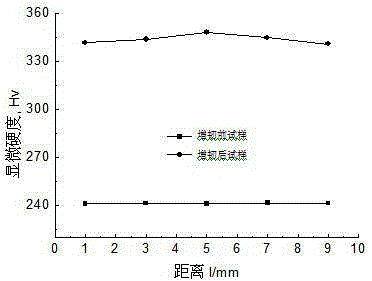

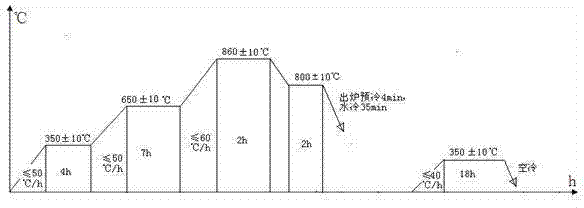

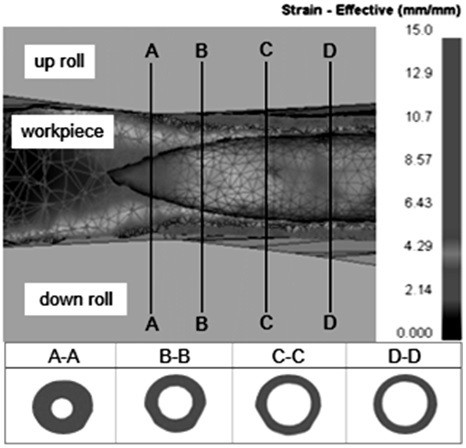

Integral thermal treatment process for roller shell of high-pressure roller mill

ActiveCN102560064AQuality improvementExtend your lifeFurnace typesHeat treatment furnacesHardnessEngineering

The invention discloses an integral thermal treatment process for a roller shell of a high-pressure roller mill. The method comprises the following specific steps of: leaving allowances for the outer circle diameter, inner hole diameter and each end face of a roller shell workpiece; putting an equal-height sleeve into the roller shell, compacting between the inner hole of the roller shell and thesleeve as well as the inner hole of the sleeve with heat-preserving cotton, and arranging an upper cover plate and a lower cover plate on the upper end face and lower end face of the roller shell; putting the sleeve workpiece into a thermal treatment furnace through a hanger, and performing normalizing treatment; quenching; putting into water for cooling; charging in time after cooling, and tempering; and tempering, preserving heat, discharging, and cooling in the air. In the thermal treatment process, the process requirements of high hardness and wear resistance on the surface of the roller shell of the high-pressure roller mill as well as toughness of a core part can be met by only using the conventional thermal treatment equipment.

Owner:CITIC HEAVY INDUSTRIES CO LTD

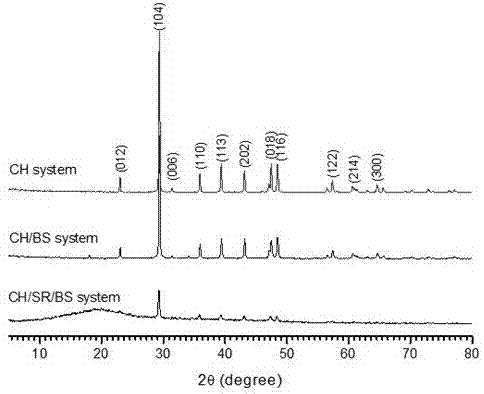

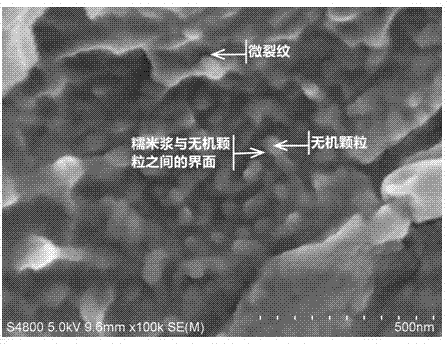

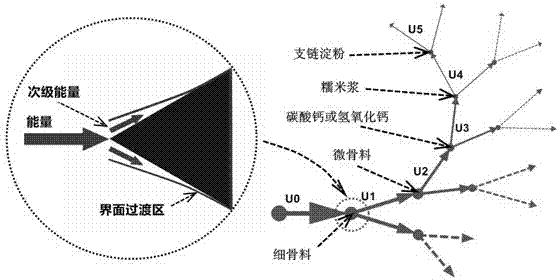

High-performance historic site repair material and preparation method thereof

The invention provides a high-performance historic site repair material and a preparation method thereof. The repair material comprises the following raw materials: 191-287 parts of sticky rice pulp, 115-185 parts of lime, 0-4 parts of brown granulated sugar, 344-398 parts of fine aggregates, 204-268 parts of complex mineral admixture, 11-12 parts of reinforcing agent, and 0-19 parts of mineral pigment. The invention further provides a preparation method of the repair material. The preparation method comprises the following steps: weighing all the raw material according to weight, and forcibly stirring evenly to obtain the repair material. Amylopectin in the sticky rice pulp is a highly branched macromolecule, the setting and hardening processes of the lime and the pozzolanic reaction of the complex mineral admixture are influenced, the strength development of the material is similar to biomineralization process, and a microstructure formed in the process endows the repair material with higher strength and toughness. Furthermore, the material has good compatibility with materials of a historic site body.

Owner:WUHAN UNIV

Three-dimensional ink for wall paper and preparation method thereof

The invention relates to a three-dimensional ink for wall paper. The three-dimensional ink is prepared from the following raw materials in parts by weight by adding the raw materials into an agitating vessel and uniformly mixing and stirring the raw materials: 100 parts of acrylic resin emulsion, 0.1 to 25 parts of a filler, 0 to 15 parts of a pigment, 1 to 20 parts of thermal expansion micro-balloons, 0.5 to 10 parts of a film-forming agent, 0.5 to 3 parts of a defoaming agent and 0.5 to 2 parts of a thickening agent, wherein the filler is titanium pigment, and the pigment is an organic tinting pigment. The preparation method of the three-dimensional ink for wall paper comprises the following steps of: taking the raw materials in parts by weight, firstly adding the acrylic resin emulsion into the agitating vessel, adding the titanium pigment into the acrylic resin emulsion, and agitating the mixture uniformly; grinding the mixture of the titanium pigment and the acrylic resin emulsion in the agitating vessel by using grinding equipment; adding the film-forming agent, the defoaming agent and the thickening agent into the agitating vessel, and agitating the mixture uniformly; adding the thermal expansion micro-balloons into the agitating vessel, and agitating the mixture uniformly; and finally, adding the organic tinting pigment into the agitating vessel, and agitating the mixture uniformly to obtain the three-dimensional ink for wall paper.

Owner:GUANGDONG YULAN GRP

Shrinkable bag with a protective patch

InactiveUS6183791B1Minimize eliminate puncturingEasy to stickReady-for-oven doughsWrappers shrinkageEngineeringProcessed meat

Disclosed is an oriented, heat shrinkable, thermoplastic vacuum bag having a protective heat shrinkable patch attached thereto such that said heat shrinkable patch covers substantially all area exposed to bone, thereby protecting the bag from puncture by sharp protruding bones in bone-in cuts of meat which are vacuum packaged within the bags. The protection is especially directed to prevention of bag puncture by, bone-in cuts of both fresh and smoked or processed meat.

Owner:CRYOVAC ILLC

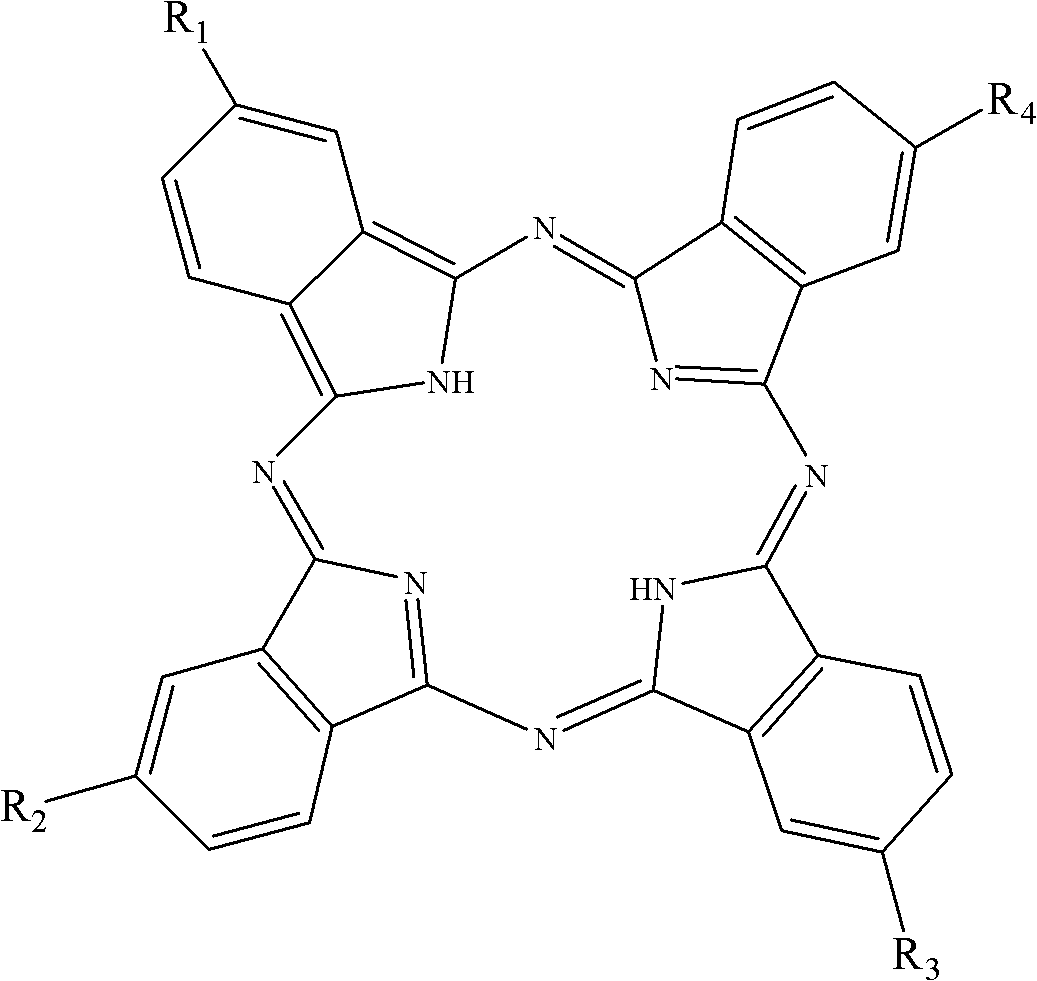

Polyaryl ether nitrile resin, polyaryl ether nitrile film and preparation method thereof

The invention belongs to the field of high polymer materials, and particularly relates to polyaryl ether nitrile resin, a polyaryl ether nitrile film and a preparation method thereof. The structure of the polyaryl ether nitrile resin is represented by formula I: n=40-80, m=10-20. Cross-linking groups are arranged at the chain end of the polyaryl ether nitrile resin, and the polyaryl ether nitrile resin has good curing reaction activity and can be used for preparing a corresponding polyaryl ether nitrile film. The polyaryl ether nitrile film is good in heat-resistant performance, the glass-transition temperature is 200 DEG C to 240 DEG C, the initial decomposition temperature is 560 DEG C to 580 DEG C, and carbon residue rate of thermal decomposition in nitrogen atmosphere at 800 DEG C is more than 69%. The polyaryl ether nitrile film is good in toughness, the elongation at break of the polyaryl ether nitrile film ranges from 8% to 12%, tensile strength is excellent, the tensile strength of the polyaryl ether nitrile film ranges from 80 MPa to 100 MPa.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Modified water-based acrylate laminating adhesive used for plastic film compositing and preparation method and application thereof

ActiveCN103059783AImprove stabilityStrong and toughNon-macromolecular adhesive additivesSynthetic resin layered productsWater basedKetone

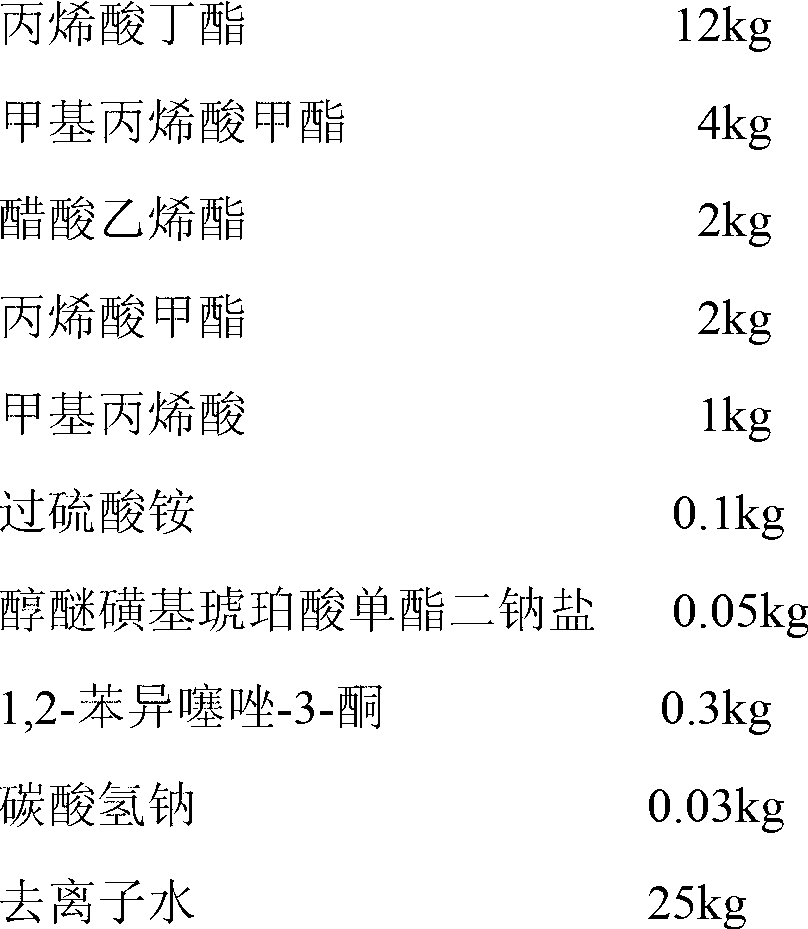

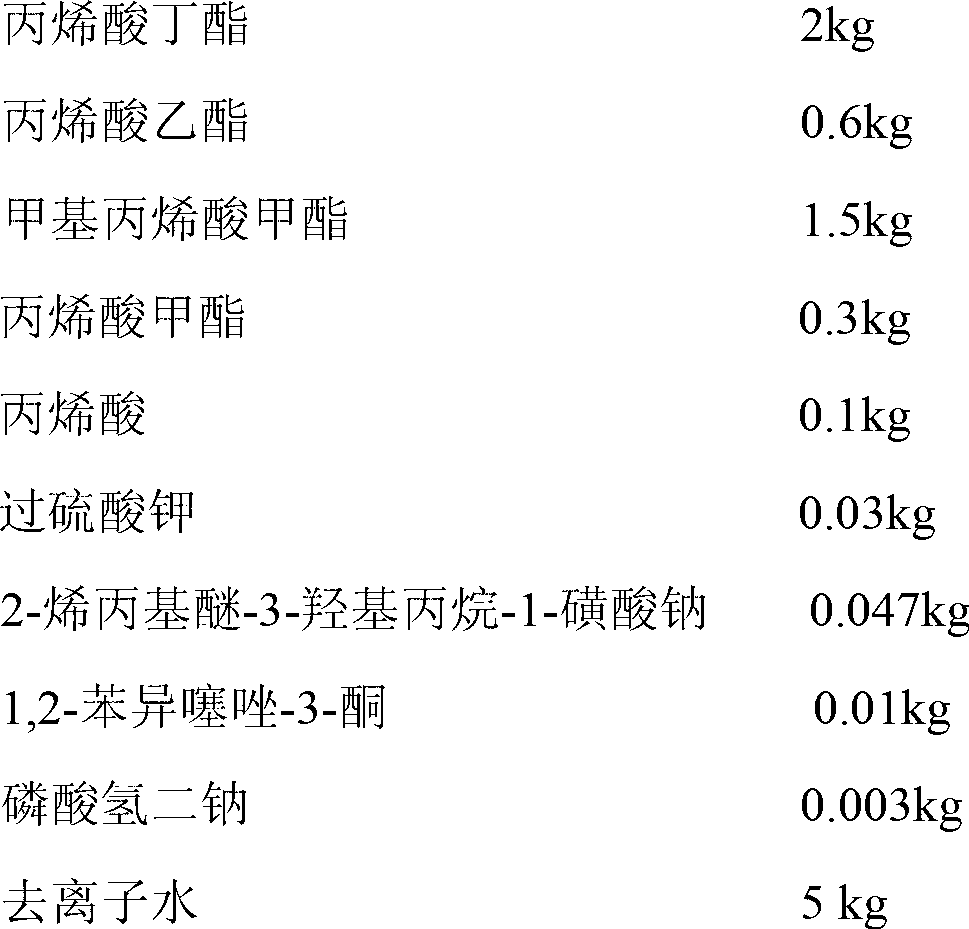

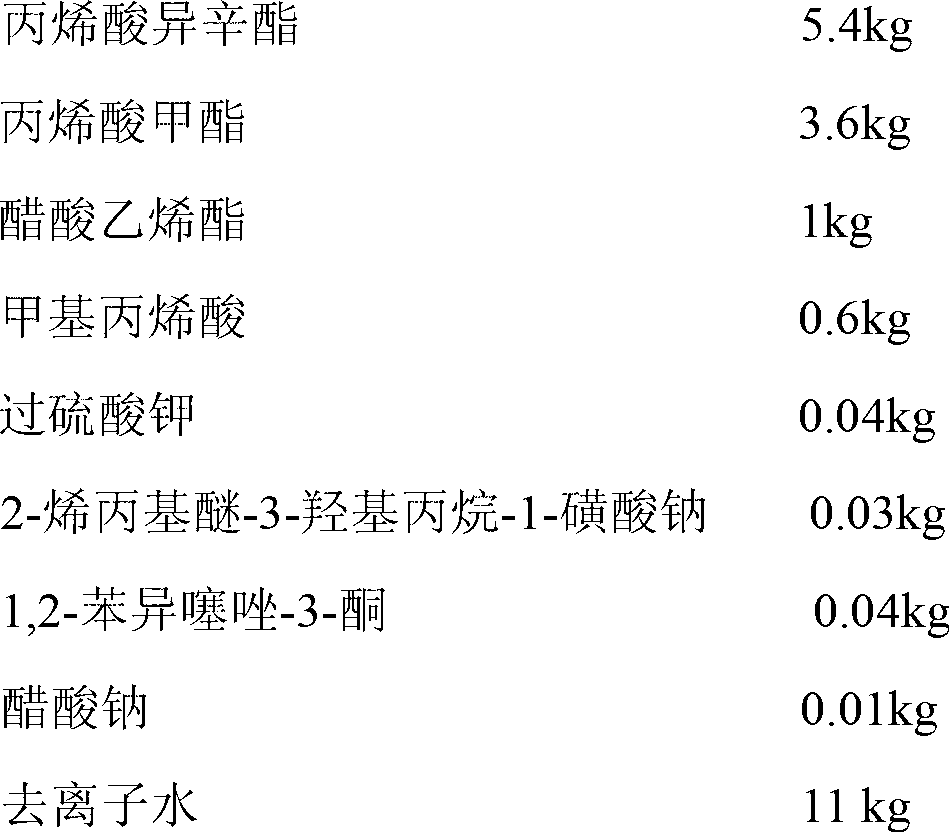

The invention discloses modified water-based acrylate laminating adhesive used for plastic film compositing, and a preparation method and application of the modified water-based acrylate laminating adhesive. The laminating adhesive is prepared from compound emulsion and crosslinking agent, wherein the compound emulsion contains ethylene-acrylic acid emulsion (EAA emulsion) and acrylate emulsion, and the acrylate emulsion is prepared from soft monomers, hard monomers, crosslinking monomers, initiator, emulsifier and antiseptic 1, 2-benzene isothiazole-3-ketone. Due to the fact that the EAA emulsion is strong in the adhesive capacity to film base material and good in compatibility with the acrylate emulsion system, moreover the crosslinking agent polyether imide and the antiseptic 1, 2-benzene isothiazole-3-ketone are added, the obtained modified water-based acrylate laminating adhesive is good in compatibility among the component, capable of enabling the EAA to be cross-linked with long-chain molecules of the acrylate when the modified water-based acrylate laminating adhesive is dried to form a film, good in adhesion to the film base material, high in bonding strength and peel strength, good in stability and coating property and capable of effectively restraining the phenomenon of latex moulding and prolonging the quality guarantee period, and meanwhile has stability of the acrylate emulsion and the obdurability of the EAA emulsion.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Blend of PPC, PBAT, PCL and PLA and preparation method thereof

InactiveCN101724242ATough and strongGood flexibilityPrecipitated calcium carbonatePhysical chemistry

The invention relates to a blend of PPC, PBAT, PCL and PLA and a preparation method thereof. The blend consists of PPC, PBAT, PCL, PLA, an end-capping reagent, a lubricating agent and modified precipitated calcium carbonate. The preparation method comprises the following steps of: carrying out cold mixing on the PPC, the PBAT, the PCL, the PLA, the end-capping reagent, the lubricating agent and the modified precipitated calcium carbonate in a high-speed stirrer at the temperature not above 35 DEG C; and extruding and granulating cold mixing materials by a screw extruder, wherein the temperature of extruding and granulating is not more than 200 DEG C. With simple process method and common equipment, the invention is especially suitable for industrial production; meanwhile, the used materials are simple and easily obtained and can also be purchased in the market; the temperature of pastiness caking blocks of the blend processed by the method is greatly improved in comparison with pure PPC and the mechanical property of the blend is greatly improved in comparison with the pure PPC; and the blend widens the application range of the pure PPC and can be completely biodegraded.

Owner:INNER MONGOLIA MENG XI HIGH TECH GRP CO LTD

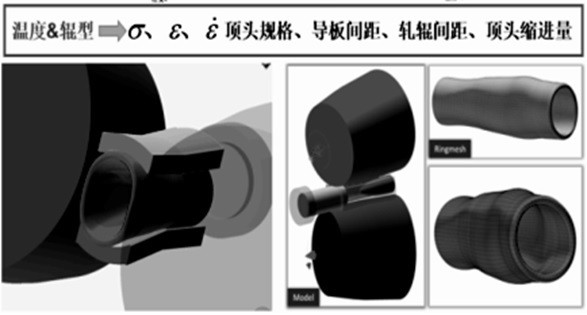

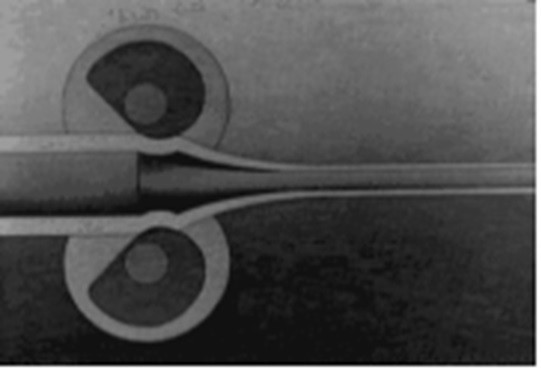

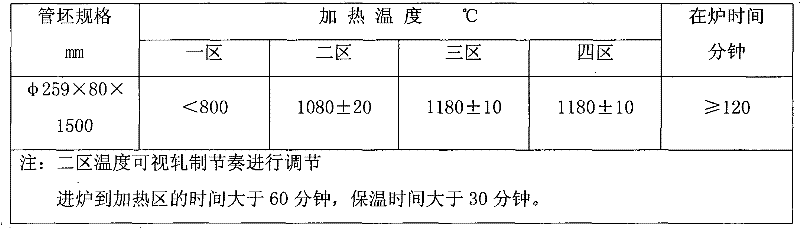

Stainless steel seamless tube for sodium-cooled fast reactor and preparation method of stainless steel seamless tube

The invention discloses a stainless steel seamless tube for a sodium-cooled fast reactor. Microalloying component fine adjustment is carried out based on a 316H stainless steel base material, the stainless steel seamless tube comprises the following components in percentage by mass: 0.04-0.05% of C, less than or equal to 0.6% of Si, 1.00-2.00% of Mn, less than or equal to 0.030% of P, less than or equal to 0.003% of S, 17.0-18.0% of Cr, 11.5-12.5% of Ni, 2.50-2.70% of Mo, less than or equal to 0.10% of Cu, 0.05-0.07% of N, less than or equal to 0.0015% of B, less than or equal to 30 ppm of O, less than or equal to 5.0 ppm of H and the balance of Fe and impurities, and the ferrite content is controlled to be less than or equal to 1%. The stainless steel seamless tube for the sodium-cooled fast reactor is manufactured through a high-purity smelting process, microalloying component fine adjustment, a stainless steel casting process, a hot perforation treatment process and finished product cold machining. By means of the mode, the stainless steel seamless pipe for the sodium-cooled fast reactor and a preparation method can meet the use standard of nuclear safety high-temperature nano pipelines, and the stainless steel seamless pipe has obdurability, corrosion resistance and durability.

Owner:高虹

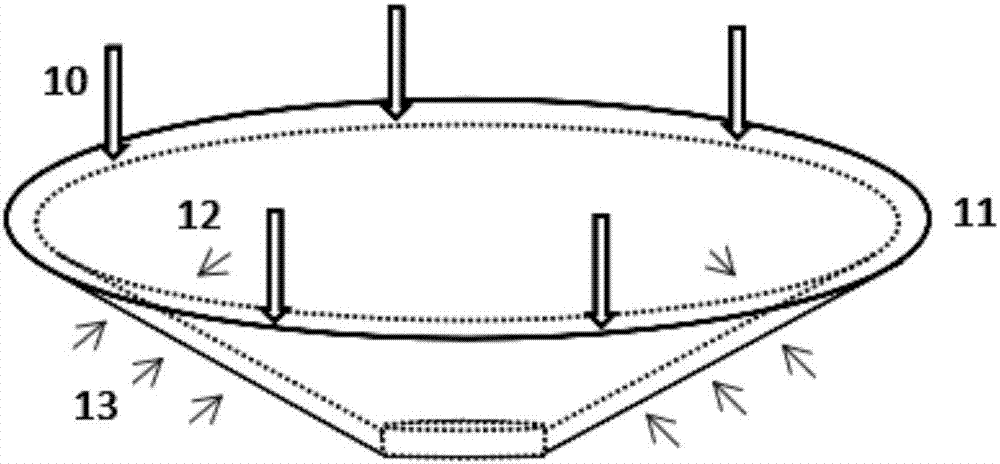

Loudspeaker diaphragm preparation method

InactiveCN105025428ATough and strongStrong impact resistanceElectrical transducersCvd grapheneLoudspeaker

The invention discloses a loudspeaker diaphragm preparation method, comprising: employing a high-molecular polymer as a base material; doping the base material with graphene materials through an in situ polymerization method or a solution mixing method to form a grapheme high-molecular polymer mixed material film; and preparing a loudspeaker diaphragm through laser cutting or punching. In the method, the graphene materials are introduced into the high-molecular polymer for mixing to form the grapheme high-molecular polymer mixed material film so as to prepare the loudspeaker diaphragm; because of the mechanical property of the graphene materials, the loudspeaker diaphragm has the characteristics of stronger robustness, shock resistance, abrasion performance and light weight.

Owner:福建省辉锐材料科技有限公司

Welding method of high-performance weather-proof bridge steel for extremely cold area

ActiveCN108057940AReduce workloadPreventing Weld LeakageArc welding apparatusWelding/cutting media/materialsChemical compositionEngineering

The invention discloses a welding method for bridge steel. The welding method is aimed at specific chemical components, the applicable technical condition and different plate thicknesses of the Q420qFNH high-performance weather-proof bridge steel for the extremely cold area. The welding process problem of the weather-proof steel is solved. Abut-joint or T-type angular joint is adopted in the welding joint manner, according to the welding method, submerged-arc welding and solid welding wire rich-argon gas protection welding are adopted, according to the different plate thicknesses, the before-welding preheating temperature is determined, according to different welding methods and different welding positions, welding process parameters are determined. The joint manner and the thickness specification of a bridge structure are comprehensively considered, the technical scheme is simple, convenient, and high in adaptation, the implementing effect meets the technical requirement of existing bridge steel and bridge structure building related standard, and the method can be actually applied to welding of a Q420qFNH weather-proof steel bridge.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD +1

Burnt stone-like sand-in-water environment-friendly paint with high stability and preparation method thereof

The invention discloses a burnt stone-like sand-in-water environment-friendly paint with high stability and a preparation method thereof. The paint is composed of a base paint, protective glue, a continuous phase and a mortar material, wherein a weight ratio of the base paint to the protective glue to the continuous phase is 1-2: 0.35-0.75: 0.5-0.75, and a weight ratio of the mortar material to the gross weight of the base paint, the protective glue and the continuous phase is 1: 1. In the paint, the mortar material and the continuous phase both have sandy texture, so the spraying effect of the paint has stone permeability and a high simulation degree, lichee-surface effect of a burnt stone-like material can be obtained through direct spraying without priming of an intermediate base, one-shot forming is realized, and construction and material cost is saved; since an emulsion is prepared by using a special silane grafting process and a soap-free system, an obtained film has good sealing performance as regard to a substrate and excellent weatherability and stability; as the pain contains a special silane group, colored masterbatch in the sand-in-water paint has certain strength and toughness, so wearing of the colored masterbatch is prevented; and since the emulsion does not contain APEO, the paint meets requirements on greenness and environmental protection.

Owner:FIRST NEW MATERIAL TECH DEV

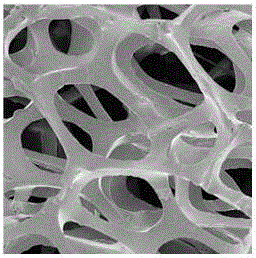

Three-dimensional porous micro-fluidic chip and preparing method and application thereof

ActiveCN105255719APorousHigh transparencyBioreactor/fermenter combinationsBiological substance pretreatmentsPorosityBiocompatibility Testing

The invention discloses a three-dimensional porous micro-fluidic chip and a preparing method and application thereof. Foam metal serves as a template, a micro-fluidic chip material is used for copying the structure of the template integrally, and the metal template is removed to obtain a three-dimensional porous material; the three-dimensional porous material is modified in a silanized mode, pores are filled with temperature sensing materials, and after being integrated with the micro-fluidic chip, the temperature sensing materials are removed to obtain the three-dimensional porous micro-fluidic chip; functional groups of the surface of the three-dimensional porous material are activated and coupled with biomolecules to obtain the three-dimensional porous micro-fluidic detection chip. The three-dimensional porous micro-fluidic chip can be applied to biomedicine analysis and used for separating circulating tumor cells; the three-dimensional porous micro-fluidic chip has the advantages of having porosity, and being high in transparency and toughness and good in biocompatibility; the three-dimensional porous structure can fix a large number of biomolecules, and materials to be detected can be separated with high efficiency and high throughput. Preparation of the three-dimensional porous micro-fluidic chip is easy and easy to implement, and the chip is low in cost and good in repeatability.

Owner:WUHAN UNIV

Shrinkable bag having side edge covered with protective patch

InactiveUS6254909B1Minimize eliminate puncturingEasy to stickReady-for-oven doughsWrappers shrinkageEngineeringProcessed meat

Disclosed is an oriented, heat shrinkable, thermoplastic vacuum bag having a protective heat shrinkable patch attached thereto such that said heat shrinkable patch covers substantially all area exposed to bone, thereby protecting the bag from puncture by sharp protruding bones in bone-in cuts of meat which are vacuum packaged within the bags. The protection is especially directed to prevention of bag puncture by, bone-in cuts of both fresh and smoked or processed meat. The bag produced by this method is also disclosed.

Owner:CRYOVAC ILLC

Method for manufacturing compound blade of agricultural harvester

InactiveCN102126007AGuaranteed toughnessGuaranteed the toughness of the bladeFurnace typesHeat treatment furnacesMartensitic stainless steelWire cutting

The invention discloses a method for manufacturing a compound blade of an agricultural harvester. The compound blade comprises three metal layers, wherein the outer layer and the inner layer are made of low-alloy high-strength structural steel, and the middle layer is made of martensitic stainless steel. The method comprises the steps of: firstly, eccentrically pouring the outer metal layer, the middle metal layer and the inner metal layer on an eccentric pipe die; secondly, pushing a pipe and thermally treating to obtain an eccentric pipe blank; thirdly, ring-rolling the eccentric pipe blank; fourthly, annealing and thermally treating the rolled blank, wherein the annealing temperature is 660-920 DEG C; fifthly, cutting the rolled blank into a formed metal blade by using cutting methods without a thermal reaction region, such as water cutting, wire-electrode cutting and the like; and finally thermally treating the formed blade. The compound blade manufactured through the method in the invention has high flexibility and high wear resistance, and has an automatic blade grinding function.

Owner:XINXING DUCTILE IRON PIPES CO LTD +1

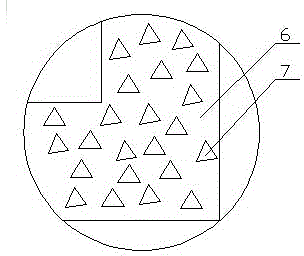

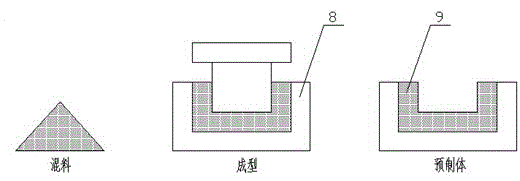

Composite material tamping tine and preparation method thereof

The invention discloses a composite material tamping tine and a preparation method thereof, and belongs to the technical field of preparation of components and parts. The composite material tamping tine comprises a tine body and a tine palm, wherein a layer of ceramic particle reinforcement metal matrix composites wraps the peripheral surface of the tine palm, the ceramic particle reinforcement metal matrix composite layer is 5-20mm in thickness, a volume fraction of particles is 20%-80%, the tine body is a metal matrix, the tine palm and the tine body are connected together through welding, and the tine palm of the composite material tamping tine is prepared through a pressure casting method. The composite material tamping tine is high in hardness, has high abrasion resistance and impact performance, comprises a thick abrasion resisting layer which can not fall off, greatly prolongs use life, substantially improves work efficiency of a tamper, is compact and flawless in tissue and good in synthesized mechanical performance by adopting a pressure casting method, and furthermore is simple in technology, low in cost, and capable of obtaining great economic benefit.

Owner:KUNMING UNIV OF SCI & TECH

Medical osteotome for mandible plastic surgery and preparation method thereof

InactiveCN106567002APromote changeRefined tempered structureFurnace typesHeat treatment furnacesCryogenic treatmentSurgery procedure

The invention discloses a medical osteotome for mandible plastic surgery and a preparation method thereof. The medical osteotome comprises the following material components: 0.20% to 0.55% of C, 12% to 20% of Cr, 0.2% to 0.8% of Si, 0.5% to 1.5% of Mn, 0.3% to 1.0% of Ni, 0.5% to 1.5% of Mo, 0.2% to 0.5% of N, Fe and a small amount of impurity elements. The preparation method comprises the steps of heating a roughly machined osteotome blank to 1000 DEG C to 1050 DEG C for austenitizing; then, carrying out cryogenic treatment on the osteotome at the temperature of minus 60 DEG C to minus 130 DEG C; then, carrying out tempering on the osteotome at the temperature of 150 DEG C to 200 DEG C two times, wherein tempering is carried out for not less than 2 hours each time; then, air cooling the osteotome to the room temperature; and carrying out finish machining treatment on the osteotome blank to obtain a final finished product. The osteotome is applicable to mandible plastic surgery and has relatively high hardness and toughness, the edge of the osteotome is not liable to curl during the surgery, the service life of the osteotome is greatly prolonged, and safety and reliability of the surgery are guaranteed.

Owner:SHANGHAI UNIV

Whitening glaze slurry for high wear-resistant ceramic, and preparation method thereof

The invention relates to a whitening glaze slurry for high wear-resistant ceramic, and a preparation method thereof. According to the present invention, raw materials and water are mixed and ball milling is performed to obtain the glaze slurry, wherein the raw materials comprise, by weight, 14-20 parts of albite, 13-17 parts of limestone, 14-18 parts of quartz, 8-12 parts of frit, 1-3 parts of soda ash, 0.5-2.5 parts of white feldspar, 4-6 parts of a whitening agent, and 0.5-2.5 parts of a wear-resistant agent, wherein the whitening agent is prepared from 40-60 parts by weight of kaolin, 40-60 parts by weight of titanium dioxide, 1-2 parts by weight of calcium stearate, and 1-3 parts by weight of gamma-chloropropyltrimethoxysilane, and the wear-resistant agent is prepared from 2-4 parts by weight of yttrium oxide, 8-12 parts by weight of hydroxyapatite, 8-18 parts by weight of calcined talc, and 0.2-0.4 part by weight of an aluminum zirconium coupling agent; and the whitening glaze slurry has characteristics of reasonable raw material, simple preparation method, low production cost and good performance, and is worthy of popularizing and applying.

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

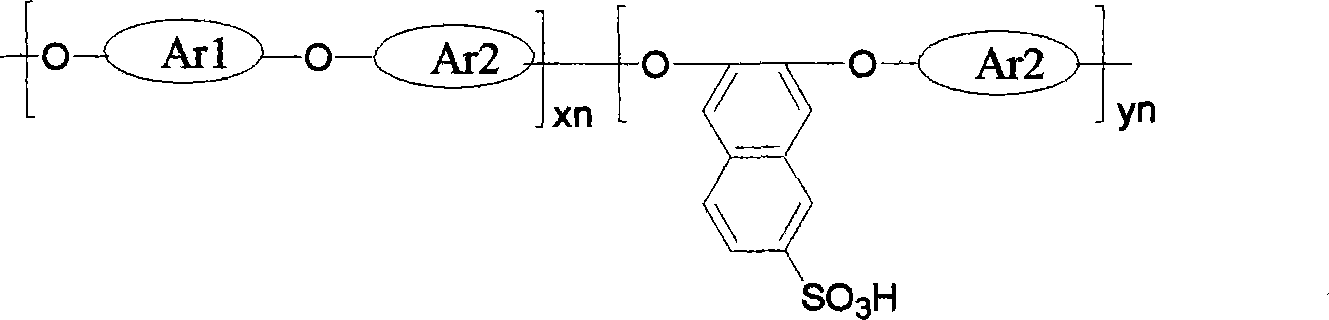

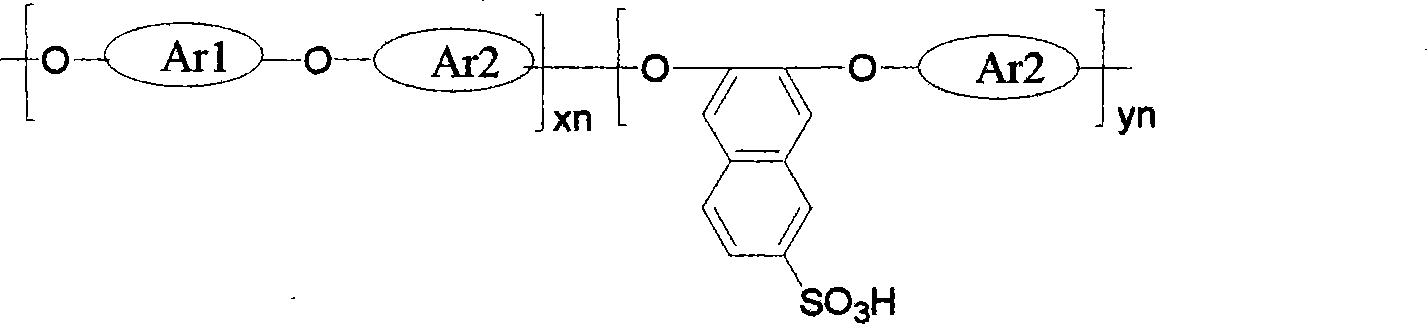

Sulfonated polyarylether with sulfonic group at side chain naphthalene ring and preparation method thereof

A sulfonated poly aryl ether with sulfonic group on naphthalene ring of side chain and preparation thereof, which is capable to solve technical problems of complexity in synthesis, hardness in controlling sulphonation position and degree, high possibility of side reaction in sulphonation, complexity in sulphonation and hardness to realize indutrialzation. The introduces binaphthyl bisphenol monomer on side-chain benzene ring of sulfonic group on molecular level, prepares sulfonated poly aryl ether with sulfonic group only on naphthalene ring of side chain, so that ensures chemical stability of main chain with high molecular weight, while having no influence on mechanical property thereof. Because of existence of conjugate benzene ring on side-chain of polymer material, sulfonic group has little impact on the main chain after introduction of sulfonic group, thus stability of the main chain is improved. The sulfonic group is linked to conjugate benzene ring, which make it easier to ionize to release hydrogen proton, so that proton exchange membrane produced from the material exhibits a good electricity conductivity. The electricity conductivity thereof is comparable to Nafion membrane.

Owner:SHENZHEN UNIV

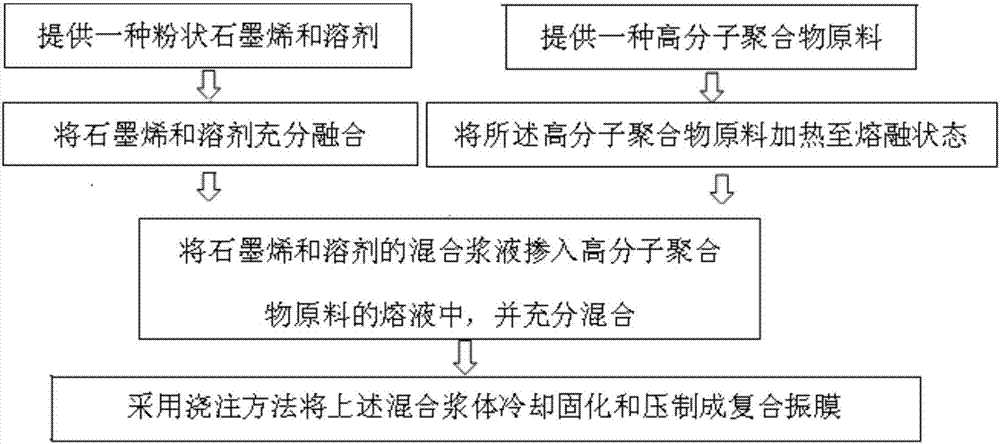

Preparation method of loudspeaker diaphragm based on graphene and polyetherimide

InactiveCN107454544AHigh electro-acoustic efficiencyTough and strongElectrical transducersPolyetherimideDoped graphene

The present invention discloses a preparation method of loudspeaker diaphragm based on graphene and polyetherimide. High-molecular polymer polyetherimide is taken as base materials to dope with graphene materials through the high-temperature fusion method to form PEI-graphene material mixed slurry, and a pouring method is employed to perform cooling and solidification of the mixed slurry and perform compaction so as to composite a loudspeaker diaphragm. The prepared composite diaphragm has high electroacoustic efficiency and high robustness, is simple in preparing technology and is suitable for popularization and application.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

High-temperature-resistant composite material with nuclear radiation shielding effect

The invention discloses a high-temperature-resistant composite material with a nuclear radiation shielding effect. The high-temperature-resistant composite material is prepared from, by weight, 50-90 parts of polyimide resin matrix, 5-15 parts of reinforcing materials, 2-10 parts of boron carbide, 1-20 parts of lead, 1-5 parts of a coupling agent and 1-5 parts of processing agents. The polyimide resin matrix, the reinforcing materials, boron carbide, lead, the coupling agent and the processing agents are stirred and uniformly mixed in a high-speed mixer to prepare plates, rods and workpieces by means of melt processing forming. The high-temperature-resistant composite material is 89%-98% in neutron shielding ratio, 75%-85% in gamma ray shielding ratio and 195-285DEG C in heat resistance temperature, can be used as a structural material, is available for shield protection of various radioactive sources such as isotope neutron sources, nuclear reactors and accelerators and is especially applicable to shield protection under complex nuclear radiation conditions.

Owner:ZHENJIANG YIQING COMPOSITE MATERIAL

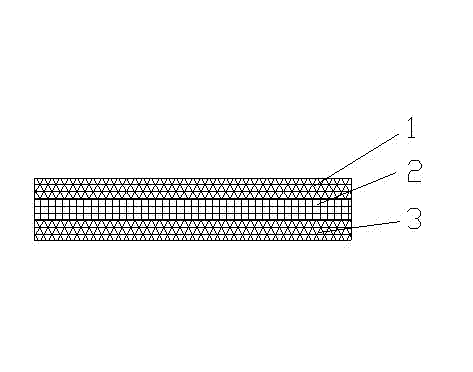

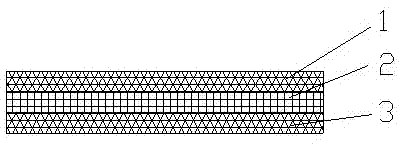

Water-based acrylic thermal-conductive double-sided tape and preparation method thereof

InactiveCN102559089AEfficient heat conductionAdhesive strengthNon-macromolecular adhesive additivesFilm/foil adhesivesWater basedConductive materials

The invention provides a water-based acrylic thermal-conductive double-sided tape and a preparation method of the double-sided tape, comprising an upper pressure-sensitive adhesive layer, a glass fiber fabric layer and a lower pressure-sensitive adhesive layer, wherein two sides of the glass fiber layer is coated with the upper pressure-sensitive adhesive layer and the lower pressure-sensitive adhesive layer, respectively, and the upper and lower pressure-sensitive adhesive layer are water-based acrylic thermal-conductive pressure-sensitive adhesive layers. The water-based acrylic thermal-conductive double-sided tape combines the characteristics of a thermal-conductive material and an adhesive tape, namely, high-effective thermal-conductivity, easy operation and powerful adhesion of an adhesive tape, and excellent electrical insulated effect, and is widely used in industries and fields such as high-power transistors, heat sinks, integrated circuits, filler of a gap between a metal structure and a chassis, LED (light-emitting diode) display screens, notebook computers, mobile phones and the like.

Owner:常熟市富邦胶带有限责任公司

Water-permeable concrete and preparation method thereof

The invention discloses water-permeable concrete and a preparation method thereof. The concrete is prepared from the following components in parts by weight: 10-15 parts of acrylate water-based laminating adhesive, 1500-1600 parts of crushed stone, 100-200 parts of super absorbent resin microspheres, 300-400 parts of cement, 5-7 parts of polyol, 5-10 parts of triisopropanolamine, 10-15 parts of nano calcium carbonate, 1-5 parts of nano silicon particles, 2-4 parts of sodium lignin sulfonate, 4-6 parts of an emulsifier and 130-160 parts of water. The acrylate water-based laminating adhesive isprepared from an ethylene-acrylic emulsion, an acrylate emulsion and a cross-linking agent; the cross-linking agent comprises polyetherimide. The water-permeable concrete can improve the water permeability and the bearing capacity, is not prone to breakage and has high freezing and thawing resistance and durability.

Owner:XIJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com