Modified water-based acrylate laminating adhesive used for plastic film compositing and preparation method and application thereof

A water-based acrylate and plastic film technology, which is applied in chemical instruments and methods, adhesives, adhesive types, etc., can solve the problems of low peel strength of substrates, affecting bonding strength, affecting material surface bonding, etc., to achieve inhibition Mold phenomenon, extended shelf life, high peel strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

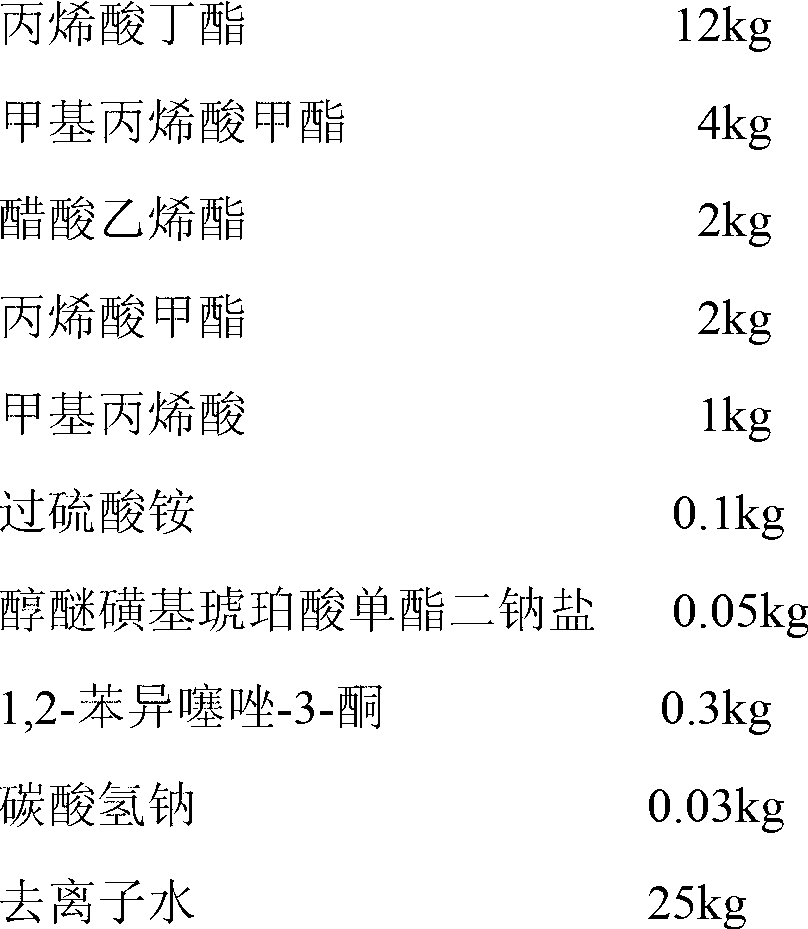

[0029] Acrylate emulsion reaction raw materials:

[0030]

[0031] 1. Fully mix 4kg of methyl methacrylate, 2kg of vinyl acetate and 2kg of methyl acrylate to obtain mixed monomer A for later use;

[0032] 2. Mix and stir 0.05kg alcohol ether sulfosuccinic acid monoester disodium salt, 12kg butyl acrylate, 7.3kg mixed monomer A and 1kg methacrylic acid for 0.5 hours, and control the stirring speed at 300 rpm to obtain pre-emulsion B ,spare;

[0033] 3. Dissolve 0.1kg of ammonium persulfate in 15kg of deionized water to make solution C, and set aside;

[0034] 4. Add the remaining 0.7kg of mixed monomer A, 1.0kg of solution C, 0.03kg of sodium bicarbonate and the remaining 10kg of deionized water into the reactor, control the stirring speed at 100 rpm, and raise the temperature to 78°C for about After 0.5 hour, a milky white bluish emulsion was obtained. At the same time, start to drop the pre-emulsion B and the remaining solution C, and finish the dripping within 4 hours...

Embodiment 2

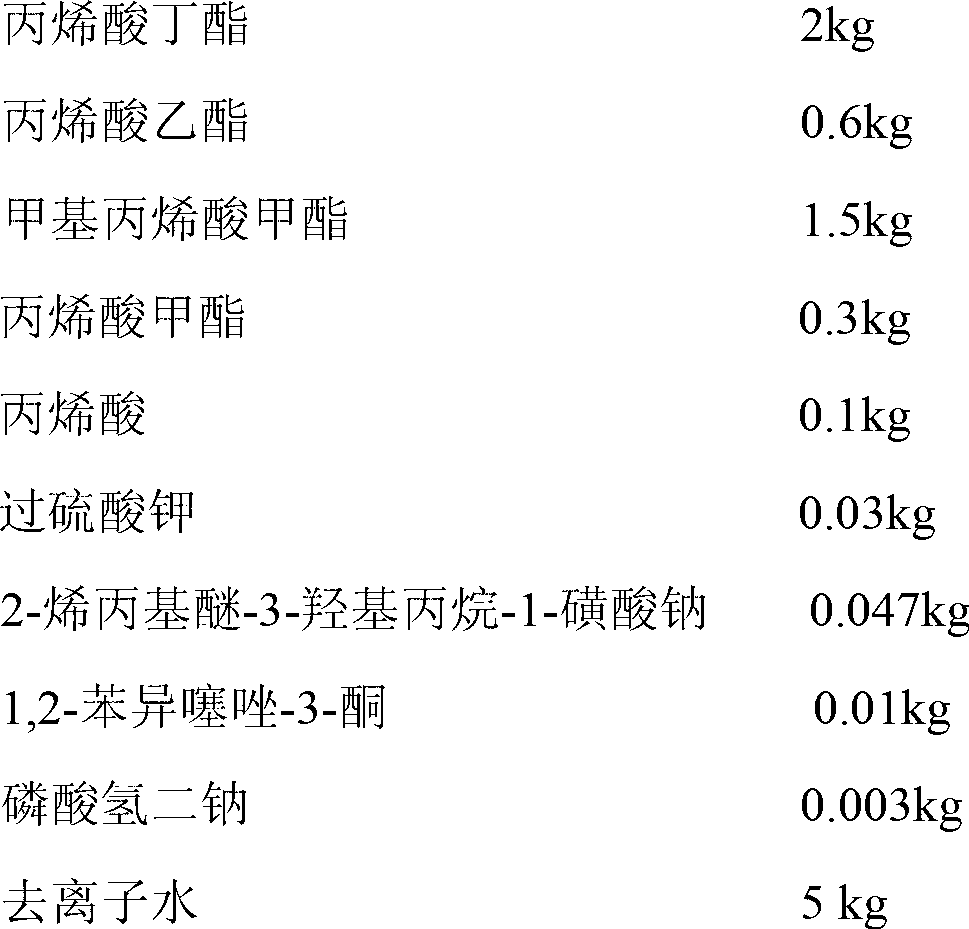

[0037] Acrylate emulsion reaction raw materials:

[0038]

[0039] 1. Fully mix 1.5kg of methyl methacrylate and 0.3kg of methyl acrylate to obtain 1.8kg of mixed monomer A for later use;

[0040] 2. Mix and stir 0.047kg 2-allyl ether-3-hydroxypropane-1-sodium sulfonate, 2kg butyl acrylate, 0.6kg ethyl acrylate, 1.65kg mixed monomer A and 0.1kg acrylic acid for 0.5 hours, the stirring speed Control 350 revs / min to obtain pre-emulsion B, standby;

[0041] 3. Dissolve 0.03kg of potassium persulfate with 4kg of deionized water (accounting for 80% of the total amount of deionized water) to make solution C, set aside;

[0042]4. Add the remaining 0.15kg of mixed monomer A, 0.4kg of solution C, 0.003kg of disodium hydrogen phosphate and the remaining 1kg of deionized water into the reaction kettle, control the stirring speed at 120 rpm, and raise the temperature to 78°C for reaction About 40 minutes to get milky white bluish emulsion. Start to drop the pre-emulsion B and the r...

Embodiment 3

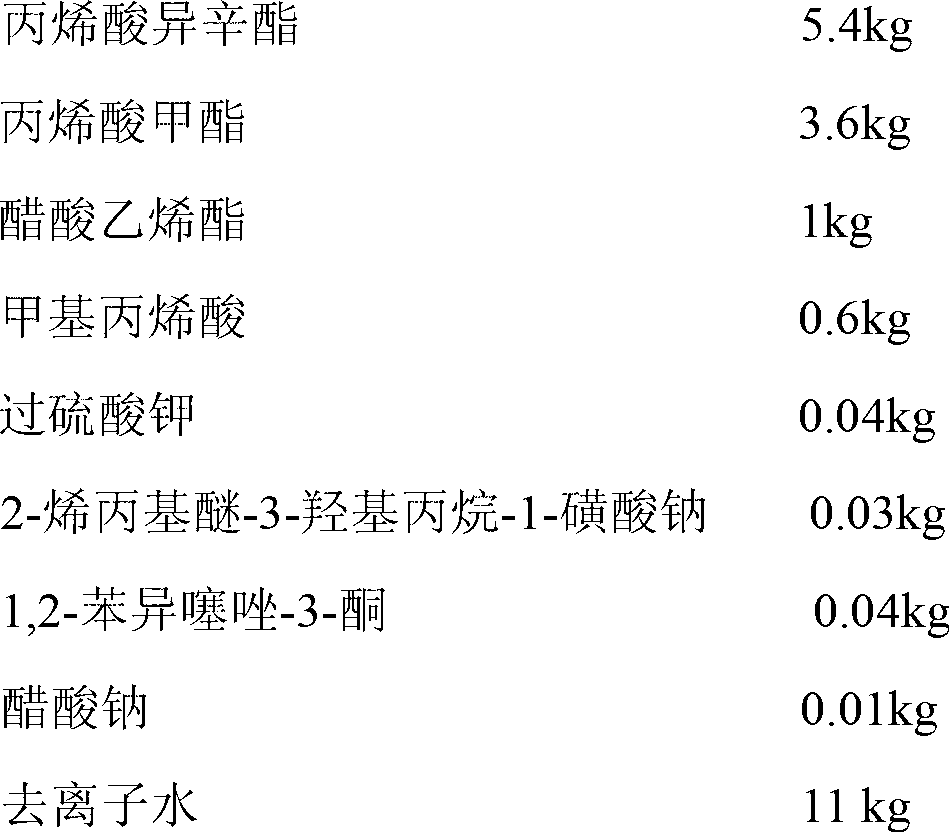

[0046] Acrylate emulsion reaction raw materials:

[0047]

[0048] 1. Fully mix 3.6kg of methyl acrylate and 1kg of vinyl acetate to obtain 4.6kg of mixed monomer A for later use;

[0049] 2. Mix and stir 0.03kg of 2-allyl ether-3-hydroxypropane-1-sodium sulfonate, 5.4kg of isooctyl acrylate, 4.2kg of mixed monomer A and 0.6kg of methacrylic acid for 0.5 hours. Control 400 rpm to obtain pre-emulsion B, and set aside;

[0050] 3. Dissolve 0.04kg of potassium persulfate with 8.25kg of deionized water (accounting for 75% of the total amount of deionized water) to make solution C for later use; 4. Mix the remaining 0.4kg of mixed monomer A, 0.6kg of solution C, 0.01kg of sodium acetate and the remaining 2.75kg of deionized water were added to the reactor, the stirring speed was controlled at 130 rpm, and the temperature was raised to 75°C for about 50 minutes to obtain a milky white bluish emulsion. Start to drop the pre-emulsion B and the remaining solution C at the same tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com