High-performance historic site repair material and preparation method thereof

A repair material and high-performance technology, applied in the field of high-performance monument repair materials and their preparation, can solve problems such as compatibility restricting the quality of repair projects, and achieve the effect of high strength, toughness and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

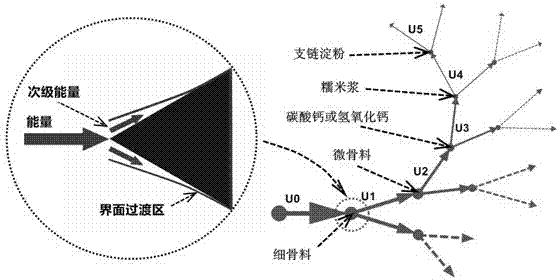

Problems solved by technology

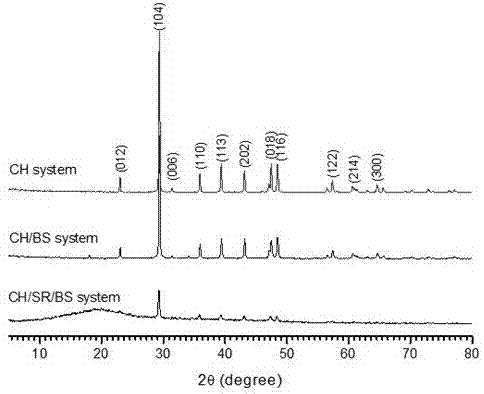

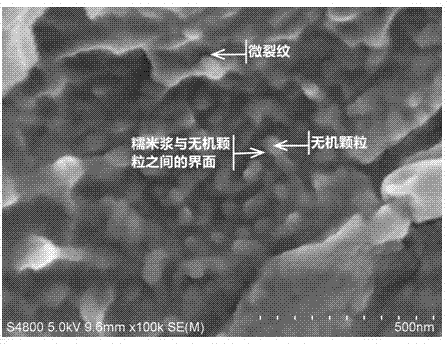

Method used

Image

Examples

Embodiment 1

[0034] 1. Weigh the corresponding quality of glutinous rice and deionized water according to the concentration of glutinous rice pulp to be prepared, soak the glutinous rice in deionized water for 24 hours, then boil it in a pot for 2 hours, use a cooking machine to make glutinous rice juice, and supplement the preparation process evaporated water.

[0035] 2. Weigh 287 parts of glutinous rice pulp with a mass concentration of 8%, 115 parts of lime, 344 parts of river sand, 243 parts of composite mineral admixture, CaSO 4 2H 2 O 11 parts, placed in a mortar mixer and forced to stir, that is, made into a high-performance monument repair material.

[0036] The above-mentioned composite mineral admixture contains 94.2% by mass percentage of slag powder and 5.8% of silica fume.

[0037] The superplasticizer is methacrylic acid main chain grafted with EO or PO branched polycarboxylic acid.

[0038] The fineness of the composite mineral admixture is less than 80 μm, and parti...

Embodiment 2

[0044]Take by weight 224 parts of glutinous rice pulp with a mass concentration of 8%, 124 parts of lime, 373 parts of fine aggregate, 268 parts of composite mineral admixture, CaSO 4 2H 2 O12 parts, placed in a mortar mixer and forced to stir, that is, made into a high-performance monument repair material.

[0045] The above-mentioned composite mineral admixture contains 92.5% by weight of slag powder, 6% of silica fume, and 1.5% of superplasticizer.

[0046] The superplasticizer is methacrylic acid main chain grafted with EO or PO branched polycarboxylic acid.

[0047] The fineness of the composite mineral admixture is less than 80 μm, and particles with a fineness of <400 nm account for 0-8%.

[0048] The particles of 1.0-5.0 mm, 0.5-1.0 mm and 0.08-0.5 mm each account for 1 / 3 of the fine aggregate.

[0049] The obtained repair material had a flexural strength of 3.3MPa and a compressive strength of 19.3MPa at 7d, a flexural strength of 3.1MPa at 14d, a compressive stren...

Embodiment 3

[0052] Take by weight 224 parts of glutinous rice pulp with a mass concentration of 8%, 125 parts of lime, 374 parts of river sand, 266 parts of composite mineral admixture, CaSO 4 2H 2 O12 parts are placed in a mortar mixer for forced stirring to make a high-performance monument repair material.

[0053]

[0054] The above composite mineral admixture contains 93.6% by mass of slag powder, 6% of silica fume, and 0.4% of superplasticizer.

[0055] The superplasticizer is methacrylic acid main chain grafted with EO or PO branched polycarboxylic acid.

[0056] The fineness of the composite mineral admixture is less than 80 μm, and particles with a fineness of <400 nm account for 0-8%.

[0057] The particles of 1.0-5.0 mm, 0.5-1.0 mm and 0.08-0.5 mm each account for 1 / 3 of the fine aggregate.

[0058]

[0059] The obtained repair material had a flexural strength of 3.1MPa and a compressive strength of 19.3MPa at 7d, a flexural strength of 3.7MPa at 14d, a compressive strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com