Negative photoresist composition containing carboxyl phenolic resin with high heat resistance

A negative photoresist and phenolic resin technology, applied in the field of functional polymer materials, can solve the problems of insufficient heat resistance, easy oxidation of phenolic hydroxyl groups and methylene groups, etc., to increase entanglement, reduce alkali solubility, and save energy. cost effect

Pending Publication Date: 2020-05-08

SUZHOU RUIHONG ELECTRONIC CHEM CO LTD

View PDF7 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional film-forming resin-novolac resin has insufficient heat resistance due to the easy oxidation of phenolic hydroxyl and methylene, so the protection of hydroxyl and methylene has become an important way to improve the heat resistance of phenolic resin

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0042]

Embodiment 2

[0044]

Embodiment 3

[0046]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Login to View More

Abstract

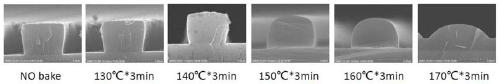

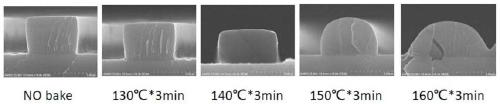

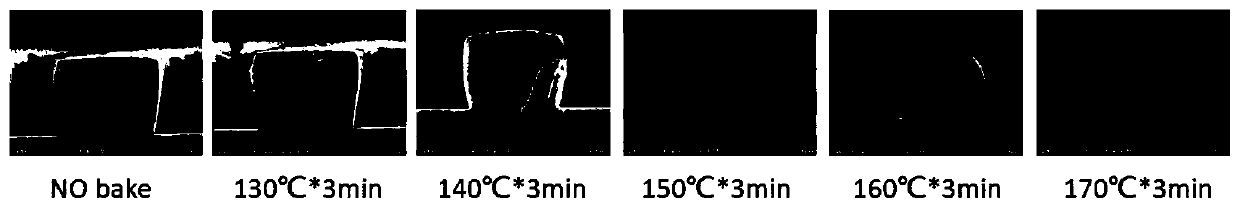

The invention discloses a negative photoresist composition containing carboxyl phenolic resin with high heat resistance. According to the high-heat-resistance carboxyl phenolic resin, the structural general formula is shown in the description, wherein x is 0-4, the ratio of m to n is 0.05-0.75: 1, R is H, phenyl or C1-C9 alkyl, and the weight-average molecular weight of the resin is 8,000-35,000g / mol. The film-forming resin is mixed with a photoacid generator, a curing agent, an additive, a solvent and other components to obtain the negative photoresist composition. Tests prove that the negative photoresist composition is high in resolution ratio, good in heat resistance and suitable for a lift-off metal stripping process under a high-temperature operation condition.

Description

technical field [0001] The invention relates to the technical field of functional polymer materials, in particular to a negative photoresist composition prepared by using high heat-resistant carboxyl phenolic resin as a film-forming resin. Background technique [0002] Photoresists are widely used in microelectronics manufacturing fields such as discrete devices, LEDs, integrated circuits, and TFT-LCDs. They affect major fields such as information engineering, energy and environmental protection, and national defense, and play a very important role in the development of high-tech industries and the national economy. effect. According to the development mechanism, it is divided into positive photoresist and negative photoresist. After exposure, the part of the photoresist that is cross-linked by the light and cannot be washed off during development belongs to the negative photoresist, and vice versa, it is the positive photoresist. [0003] The lift-off metal lift-off proces...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G03F7/038G03F7/004

CPCG03F7/038G03F7/004

Inventor 纪昌炜郑祥飞徐亮

Owner SUZHOU RUIHONG ELECTRONIC CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com