Heat-resistant salt-tolerate graft polyacrylamide and preparation method thereof

A technology of polyacrylamide and polyacrylamide oil displacement agent, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve the problem of no polyacrylamide products for oil displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Embodiment 1 poly (N-vinylpyrrolidone) acrylamide macromolecular monomer A

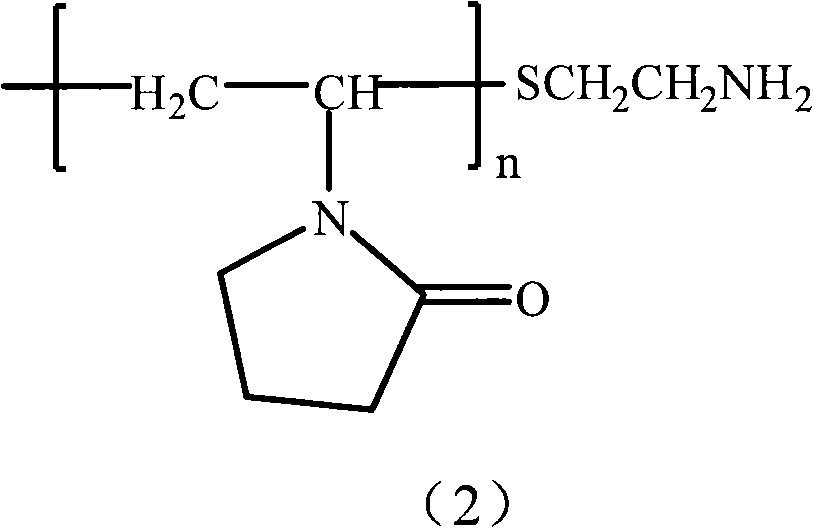

[0078] Dissolve 20.0 grams of N-vinylpyrrolidone in 80.0 grams of absolute ethanol, pass through high-purity nitrogen gas for deoxygenation for 20 to 30 minutes, add 1.16 grams of mercaptoethylammonium hydrochloride and 166 mg of azobisisobutyrolidinate at 60 At ~70°C, react for 6 hours, add sodium hydroxide solution to adjust the pH value to 8-9, remove most of the solvent under reduced pressure, centrifuge, precipitate in ether three times, and dry to obtain a white solid macromonomer precursor. Its structural formula is shown in formula (2). Add 20.0 grams of macromonomer precursor and 60.0 grams of tetrahydrofuran into the three-necked flask, dissolve 5.0 grams of acryloyl chloride in 15 grams of tetrahydrofuran, and add it to the above reaction solution while stirring. The ice-water bath controls the reaction temperature at 0-4 ° C. At the same time, a certain amount of 10% sodium carbona...

Embodiment 2

[0079] Embodiment 2 Poly(N-vinylpyrrolidone) acrylamide type macromonomer B

[0080] Dissolve 20.0 grams of N-vinylpyrrolidone in 80.0 grams of absolute ethanol, pass through high-purity nitrogen gas for deoxygenation for 20 to 30 minutes, add 116 mg of mercaptoethylammonium hydrochloride and 166 mg of azobisisobutyrolidinate at 60 At ~70°C, react for 6 hours, add sodium hydroxide solution to adjust the pH value to 8-9, remove most of the solvent under reduced pressure, centrifuge, precipitate in ether three times, and dry to obtain a white solid macromonomer precursor. Its structural formula is shown in formula (2). Add 20.0 grams of macromonomer precursor and 60.0 grams of tetrahydrofuran into the three-necked flask, dissolve 2.0 grams of acryloyl chloride in 15 grams of tetrahydrofuran, and add it to the above reaction solution while stirring, and control the reaction temperature at 0-4°C in an ice-water bath. At the same time, a certain amount of 10% sodium carbonate aque...

Embodiment 3

[0081] Embodiment 3 Preparation of temperature-resistant and salt-resistant grafted polyacrylamide oil displacement agent of the present invention

[0082] At room temperature, add 5.10 g of acrylamide, 4.90 g of 2-acrylamido-2-methylpropanesulfonic acid and 1.0 g of poly(N-vinylpyrrolidone) acrylamide type A (Mn=4800) into the polymerization reaction bottle , add 19 grams of water to dissolve, and after 20 minutes of nitrogen deoxygenation, add successively 1.0 grams of 2,2-azobis(2-amidinopropane) dihydrochloride aqueous solution with a mass concentration of 0.025%, and 1.0 grams of an aqueous solution of 0.1% mass concentration. 1.0 grams of ammonium sulfate aqueous solution, 1.0 grams of disodium edetate aqueous solution of mass concentration 0.3%, 1.0 grams of urea aqueous solution of mass concentration 0.6%, 3.7 grams of sodium hydroxide solution of mass concentration 25%, adjust the pH value to 7.5, After continuing to pass nitrogen to remove oxygen for 20 minutes, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com