Filament non-woven composite material and preparation method thereof

A technology of filament non-woven and composite materials, which is applied in filament/thread forming, textiles, papermaking, non-woven fabrics, etc. It can solve the problems of low breaking strength, stiff hand feeling, and poor hygroscopicity, so as to improve cohesion and increase Large storage space and improved hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092] A preparation method of filament non-woven composite material, comprising the following steps:

[0093] (1) Preparation of filament fiber web: first polymer slices are melted, and the resulting polymer melt is spun by a spinning device after filtration and metering. After spinning, it is cooled and drawn successively, and then passed through a deformation device (preferably The mechanical deformation device) deforms the obtained filament fiber to make the straight filament fiber into a crimped state; and then lays a web to make a filament fiber web.

[0094] (2) Preparation of ultra-short fiber web: disperse the ultra-short fiber in water for pulping, and use one or more disc mills to process the ultra-short fiber during the dispersion process; use a slit filter to remove impurities and fiber clusters; After the slurry is diluted, it is wet formed by a forming machine (preferably an inclined wire former), and the concentration of the slurry before and after dilution is ...

Embodiment 1

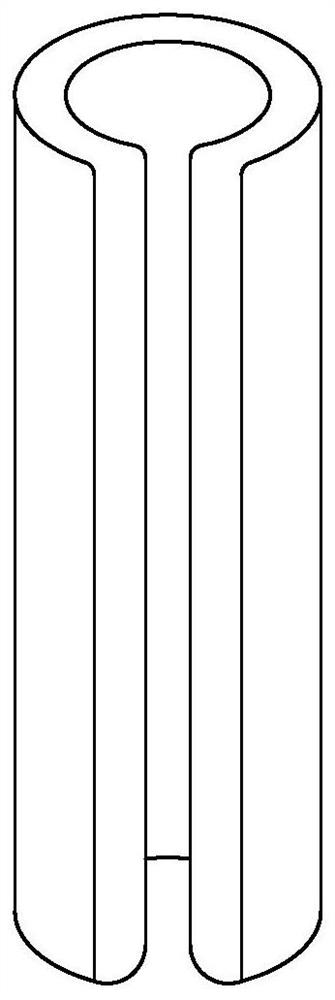

[0104] An ultrafine filament non-woven composite material with a mass per unit area of 50g / m 2 . Such as figure 1 As shown, including polyester / polyamide bicomponent synthetic fiber filaments and ultra-short fiber aggregates. Among them, the mass proportion of bicomponent synthetic fiber filament is 40%, and the proportion of ultra-short fiber is 60%; Figure 6 As shown, the cross-sectional shape of the bicomponent synthetic fiber filament is hollow and radial, and the surface of the filament is provided with micropores communicating with the hollow. The filament fineness is 3D; the two components of polyester (PET) and polyamide (PA) are arranged alternately, and the number of arrangements is 16.

[0105] The polyester (PET) / polyamide (PA) bicomponent synthetic fiber filament is a crimped textured filament; the ultra-short fiber 2 is 50% wood pulp and 50% viscose ultra-short fiber; viscose ultra-short fiber The fiber specification is: 1.2D*10mm; the wood pulp and viscos...

Embodiment 2

[0122] A two-component filament non-woven composite material with a mass per unit area of 40 g / m 2 . Such as figure 1 As shown, it includes continuous bicomponent synthetic fiber filaments and ultra-short fiber aggregates; wherein, the mass proportion of bicomponent synthetic fiber filaments is 50%, and the proportion of ultra-short fibers is 50%;

[0123] The bicomponent synthetic fiber filament is a crimped textured filament with a fineness of 1.2D, such as Figure 5 As shown, its cross-sectional shape is hexagonal, and the two components are polyethylene (PE) and polypropylene (PP) components; the two components are arranged side by side; the melting point of the polyethylene (PE) component is 120°C.

[0124] The ultra-short fibers 2 are Lyocell (Lyocell, Tencel) ultra-short fibers; the specification of the Lyocell ultra-short fibers is 1.2D*8mm; the Lyocell ultra-short fibers are distributed in a two-component synthetic In the fiber filament; the lyocell ultra-short f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com