Conjugated diolefin (co)polymer rubber, process for producing (co)polymer rubber, rubber composition, composite, and tire

一种共轭二烯、复合体的技术,应用在共轭二烯系均聚或共聚橡胶,共轭二烯均聚或共聚橡胶及其制造,橡胶组合物以及轮胎,橡胶·无机化合物复合体领域,能够解决流动性不足、药品分散性不能说充分、长时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

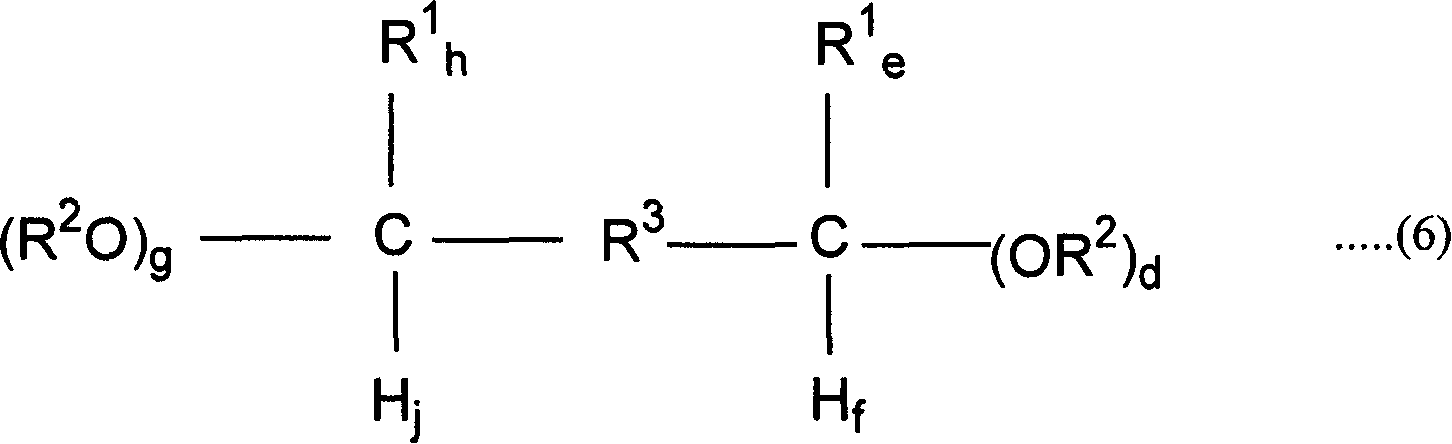

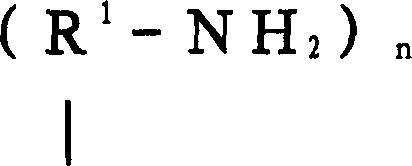

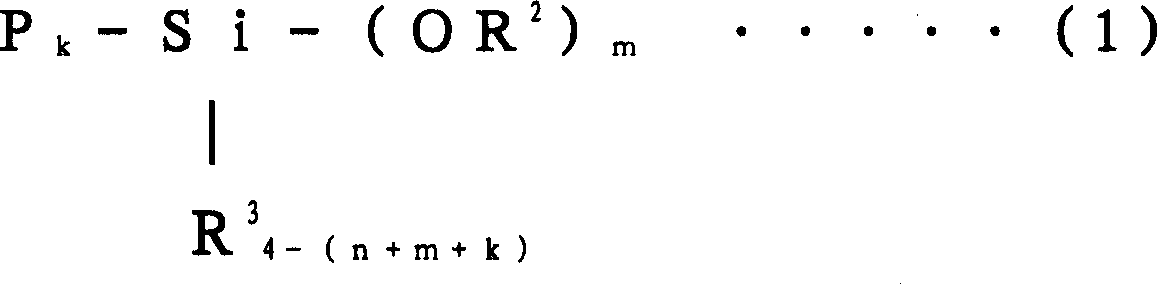

Method used

Image

Examples

Embodiment 1

[0357] Into an autoclave reactor with an internal volume of 5 liters replaced with nitrogen, 2,750 g of cyclohexane, 41.3 g of tetrahydrofuran, 125 g of styrene, and 365 g of 1,3-butadiene were charged. After adjusting the temperature of the contents of the reactor to 20°C, 325 mg of n-butyllithium (n-BuLi) was added to start polymerization. The polymerization was carried out under adiabatic conditions, and the maximum temperature reached 85°C.

[0358] When the polymerization conversion rate reached 99%, 10 g of butadiene was added, and after 5 minutes of polymerization, 1560 mg of N,N-bis(trimethylsilyl)aminopropylmethyldimethoxysilane was added to proceed. Response in 15 minutes. After adding 2,6-di-tert-butyl-p-cresol to the polymer solution after the reaction, an extender oil (manufactured by Fuji Kosan Co., Ltd., trade name "フツコ一ル·アロマツクス(AROMAX)#" was added 3", VGC=0.963) (hereinafter also referred to as "A-Oil") 187.5 g (37.5 parts with respect to 100 parts of rubber compon...

Embodiment 2

[0360] In Example 1, the type and amount of additives were changed to 1.120 mg of 1-trimethylsilyl-2,2-dimethoxy-1-aza-2-silacyclopentane. , The same procedure as in Example 1 was carried out to obtain copolymer rubber P-2. The composition and physical properties of the obtained copolymer rubber P-2 are shown in Table 3.

Embodiment 3

[0362] In Example 1, in order to introduce a tertiary amino group into the end of the polymerization start, the initiator was changed to piperidine and n-butyl lithium as the secondary amine, and the same procedure as in Example 1 was carried out to obtain copolymer rubber P-3. . The composition and physical properties of the obtained copolymer rubber P-3 are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery ratio | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| oil absorption value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com