Modified cellulose spunlace non-woven fabric and preparation method thereof

A technology of spunlace non-woven fabric and cellulose, applied in the direction of plant fiber, fiber treatment, fiber type, etc., can solve the problems of poor durability and poor mechanical properties of spunlace non-woven fabric, so as to improve the mechanical properties and improve the The effect of photocatalytic antibacterial performance and improving the performance of decomposing formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0035] Preparation Example 1 Modified Cellulose

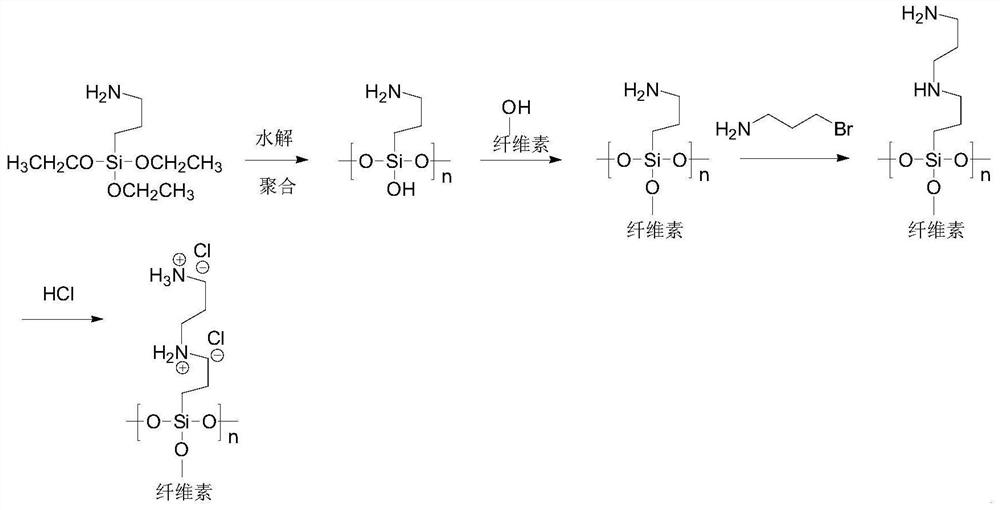

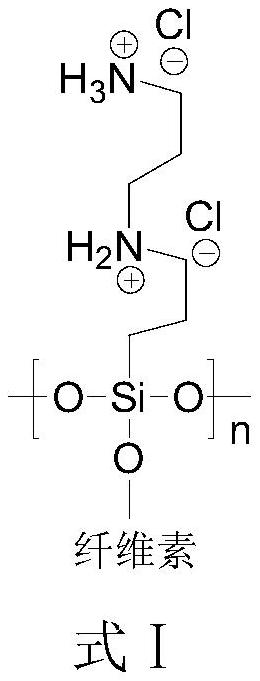

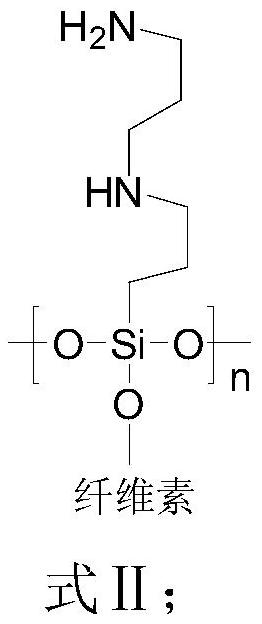

[0036] Synthetic route such as figure 1 , the preparation method is as follows:

[0037] S1. Cellulose treatment: Soak 50g of cellulose in 200mL of petroleum ether and ethyl acetate mixed solvent (the volume ratio of petroleum ether and ethyl acetate is 3:2) for 1h, filter, dry, and then add 100mL of silane In the aqueous ethanol solution of coupling agent KH550 (the content of KH550 is 3wt%, the content of ethanol is 35wt%, and the balance is water), add ammonia water dropwise to adjust the pH value to 8, react for 0.5h, filter, and dry at 120°C for 0.5 h, then placed in 100mL ethanol, ultrasonically cleaned for 0.5h, filtered, and dried to obtain surface-grafted cellulose;

[0038] S2. Preparation of intermediate: Dissolve 20g of 3-bromopropylamine in 200mL of dichloromethane, add 100g of surface-grafted cellulose prepared in step S1, heat to 30°C under nitrogen protection, stir for 2h, filter, and use Wash with ethanol an...

preparation example 2

[0040] Preparation Example 2 Modified Cellulose

[0041] Synthetic route such as figure 1 , the preparation method is as follows:

[0042] S1. Cellulose treatment: Soak 50g of cellulose in 200mL of petroleum ether and ethyl acetate mixed solvent (the volume ratio of petroleum ether and ethyl acetate is 5:2) for 2h, filter, dry, and then add 100mL of silane In the ethanol aqueous solution of coupling agent KH550 (the content of KH550 is 5wt%, the content of ethanol is 40wt%, and the balance is water), ammonia water is added dropwise to adjust the pH value to 9, react for 1h, filter, and dry at 140°C for 1h, Then placed in 100mL ethanol, ultrasonically cleaned for 1h, filtered, and dried to obtain surface-grafted cellulose;

[0043] S2. Preparation of intermediate: Dissolve 40g of 3-bromopropylamine in 200mL of dichloromethane, add 100g of surface-grafted cellulose prepared in step S1, heat to 50°C under nitrogen protection, stir for 4h, filter, and use Wash with ethanol and dr...

preparation example 3

[0045] Preparation Example 3 Modified Cellulose

[0046] Synthetic route such as figure 1 , the preparation method is as follows:

[0047] S1. Treatment of cellulose: Soak 50g of cellulose in 200mL of petroleum ether and ethyl acetate mixed solvent (the volume ratio of petroleum ether and ethyl acetate is 4:2) for 1.5h, filter, dry, and then add 100mL of Silane coupling agent KH550 in ethanol aqueous solution (the content of KH550 is 4wt%, the content of ethanol is 37wt%, and the balance is water), add ammonia water dropwise to adjust the pH value to 8.5, react for 1h, filter, and dry at 130°C for 1h , then placed in 100mL ethanol, ultrasonically cleaned for 1h, filtered, and dried to obtain surface-grafted cellulose;

[0048] S2. Preparation of intermediate: Dissolve 30g of 3-bromopropylamine in 200mL of dichloromethane, add 100g of surface-grafted cellulose prepared in step S1, heat to 40°C under nitrogen protection, stir for 3h, filter, and use Wash with ethanol and dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com