Thermoplastic fiber bonded palm fiber mattress core material and preparation method thereof

A thermoplastic fiber, mattress core technology, used in mattresses, spring mattresses, chemical instruments and methods, etc., can solve the problems of uneven network formation, influence on bonding effect, influence, etc., and achieve a wide range of sources, low prices, Anti-itching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

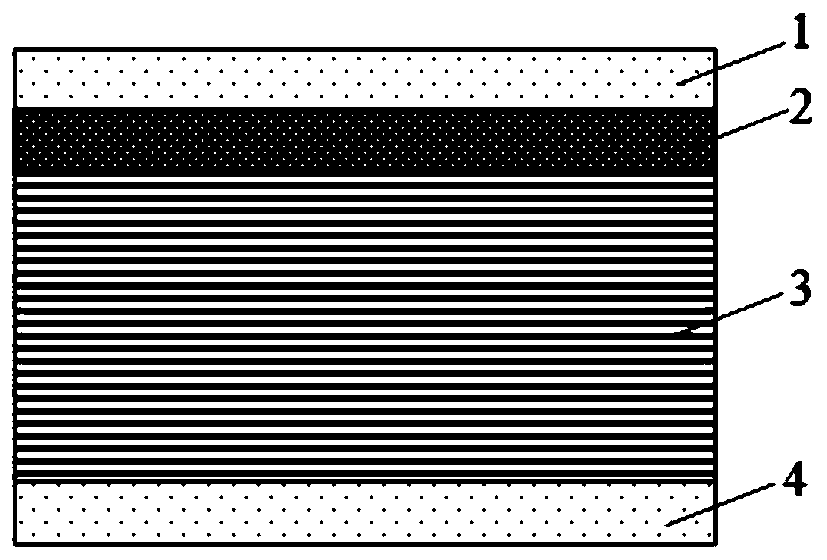

[0031] Example 1, such as figure 1 As shown, a thermoplastic fiber bonded brown silk mattress core material is made by the following process:

[0032] (1) The nonwoven surface layer 1 with a specification of 25 grams per square meter and the bottom layer 4 of a nonwoven fabric with a specification of 30 grams per square meter are prepared respectively by spun-laid technology and hot-rolled bonding technology;

[0033] (2) The PP melt-blown non-woven fabric layer 2 of 40 grams / square meter is prepared by melt-blown technology;

[0034] (3) Using carding technology, palm fibers are carded and laid to form a fiber web layer with a thickness of 8cm. In addition, PP fibers are carded and laid to form a thermoplastic fiber network layer of 100 grams per square meter by carding technology. The upper and lower surfaces of the fiber net layer are covered with a layer of thermoplastic fiber net layer, and then the PP fibers of the thermoplastic fiber net layer are all pierced into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com