Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

337 results about "Living free-radical polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Living free radical polymerization is a type of living polymerization where the active polymer chain end is a free radical. Several methods exist. IUPAC recommends to use the term "reversible-deactivation radical polymerization" instead of "living free radical polymerization", though the two terms are not synonymous.

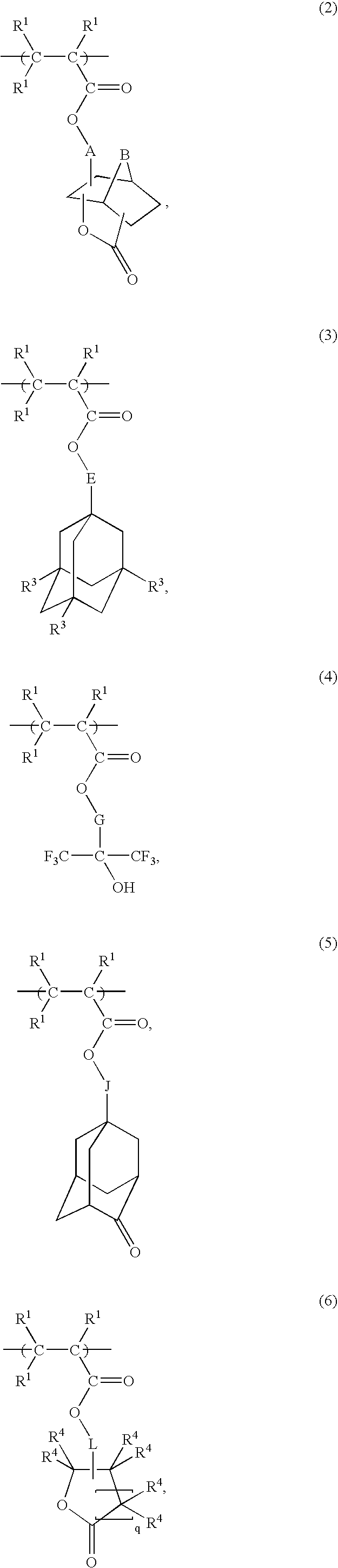

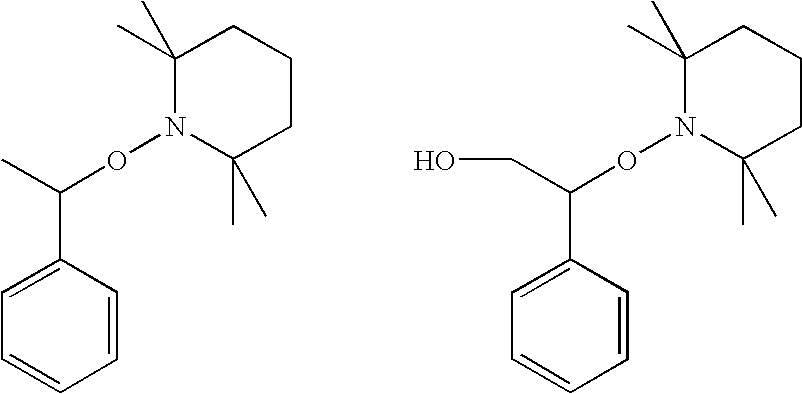

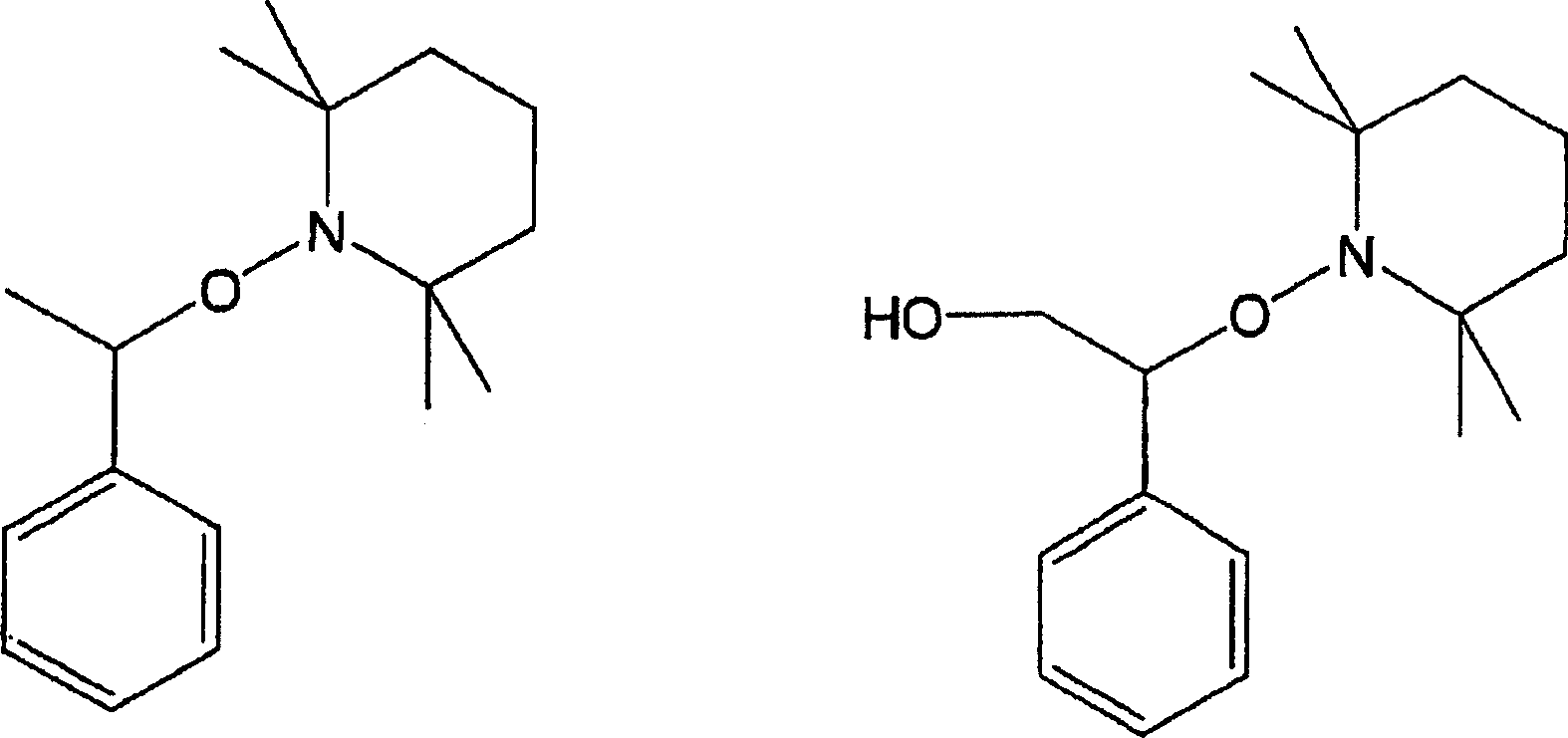

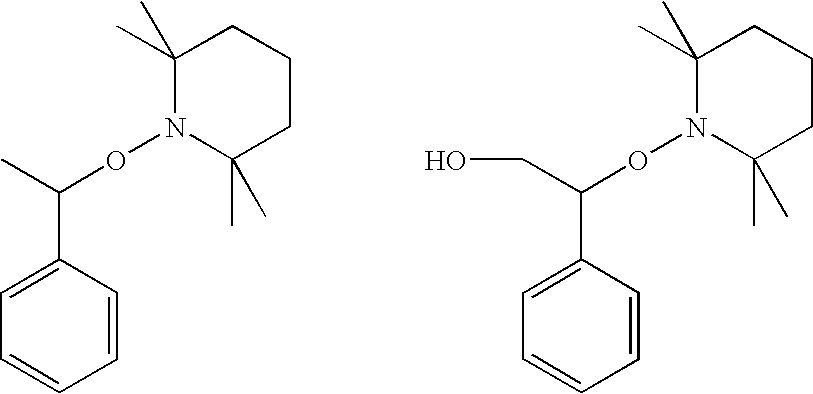

Photoresist polymer compositions

ActiveUS20060257781A1Overcomes drawbackPhotosensitive materialsPhotomechanical apparatusPolymer scienceEnd-group

The present invention is directed to the preparation of photoresist polymers via living free radical polymerization techniques. Sterically bulky ester monomers are utilized as the polymerization components. Use of chain transfer agents is included in polymerization processing conditions. Cleavage of polymer terminal end groups that include a heteroatom are described.

Owner:FREESLATE +1

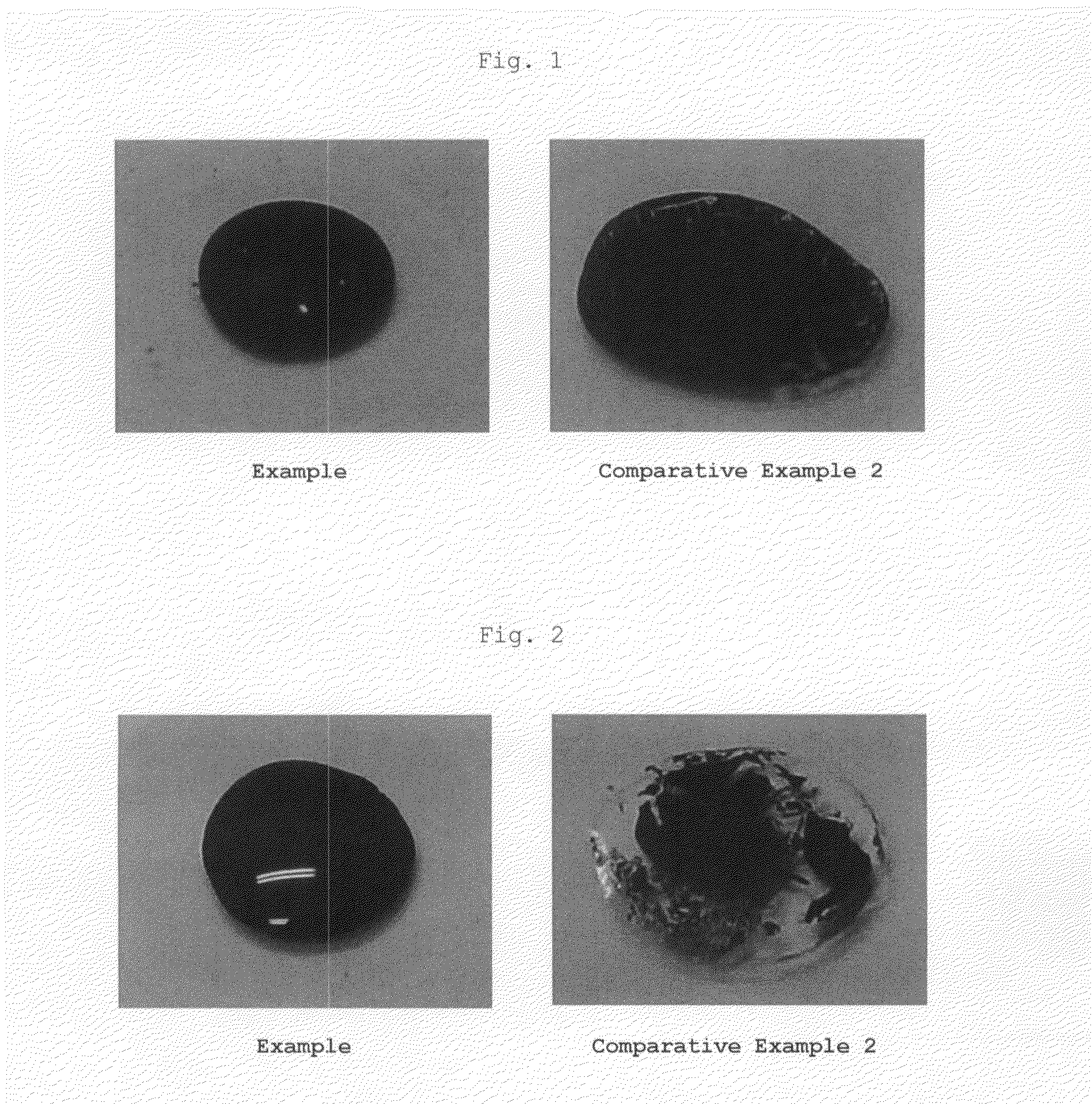

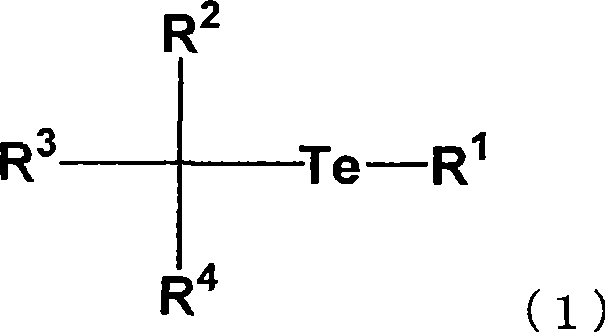

Aqueous pigment dispersion and applications thereof

InactiveUS20110223529A1Readily dissolved in waterGood dispersionTransportation and packagingInksPolymer sciencePigment dispersion

Disclosed are an aqueous pigment dispersion containing at least a pigment, water, a high-molecular dispersant, and an alkali. The high-molecular dispersant is a diblock polymer having a formula (1) of A-B or a triblock polymer having a formula (2) of A-B-C. The diblock or triblock polymer is a diblock or triblock polymer obtained by polymerizing addition-polymerizable monomers with a radical generator while using an organic iodide as a polymerization initiating compound and an organic phosphorus compound, organic nitrogen compound or organic oxygen compound as a catalyst. Also disclosed are a production method and use of the aqueous pigment dispersion. With the high-molecular dispersant obtained by a simple living radical polymerization process free of the problems of conventional living radical polymerization and having a precisely-controlled molecular structure, the aqueous pigment dispersion can be obtained with the pigment dispersed in it.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD +1

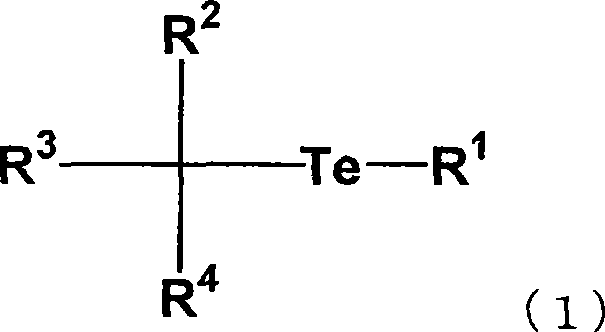

Resin composition and heat-resistant adhesive

Disclosed is a resin composition which is characterized in that the metal content in the composition is not more than 1000 ppm. The resin composition contains a copolymer which is obtained by copolymerizing 80-99.9 parts by weight of a vinyl monomer mainly containing a (meth)acrylic acid alkyl ester and 0.1-20 parts by weight of a vinyl monomer having a reactive functional group by living radical polymerization, while using, as a polymerization initiator, one of the following: (a) an organic tellurium compound represented by the formula (1) below; (b) a mixture of an organic tellurium compound represented by the formula (1) below and an azo polymerization initiator; (c) a mixture of an organic tellurium compound represented by the formula (1) below and an organic ditellurium compound represented by the formula (2) below; and (d) a mixture of an organic tellurium compound represented by the formula (1) below, an azo polymerization initiator and an organic ditellurium compound represented by the formula (2) below. (In the formula, R<1> represents a C1-C8 alkyl group, an aryl group, a substituted aryl group or an aromatic heterocyclic group; R<2> and R<3> respectively represent a hydrogen atom or a C1-C8 alkyl group; and R<4> represents an aryl group, a substituted aryl group, an aromatic heterocyclic group, an acyl group, an amide group, an oxycarbonyl group or a cyano group.) (R<1>Te)2 (2) (In the formula, R<1> is as defined above).

Owner:OTSUKA CHEM CO LTD

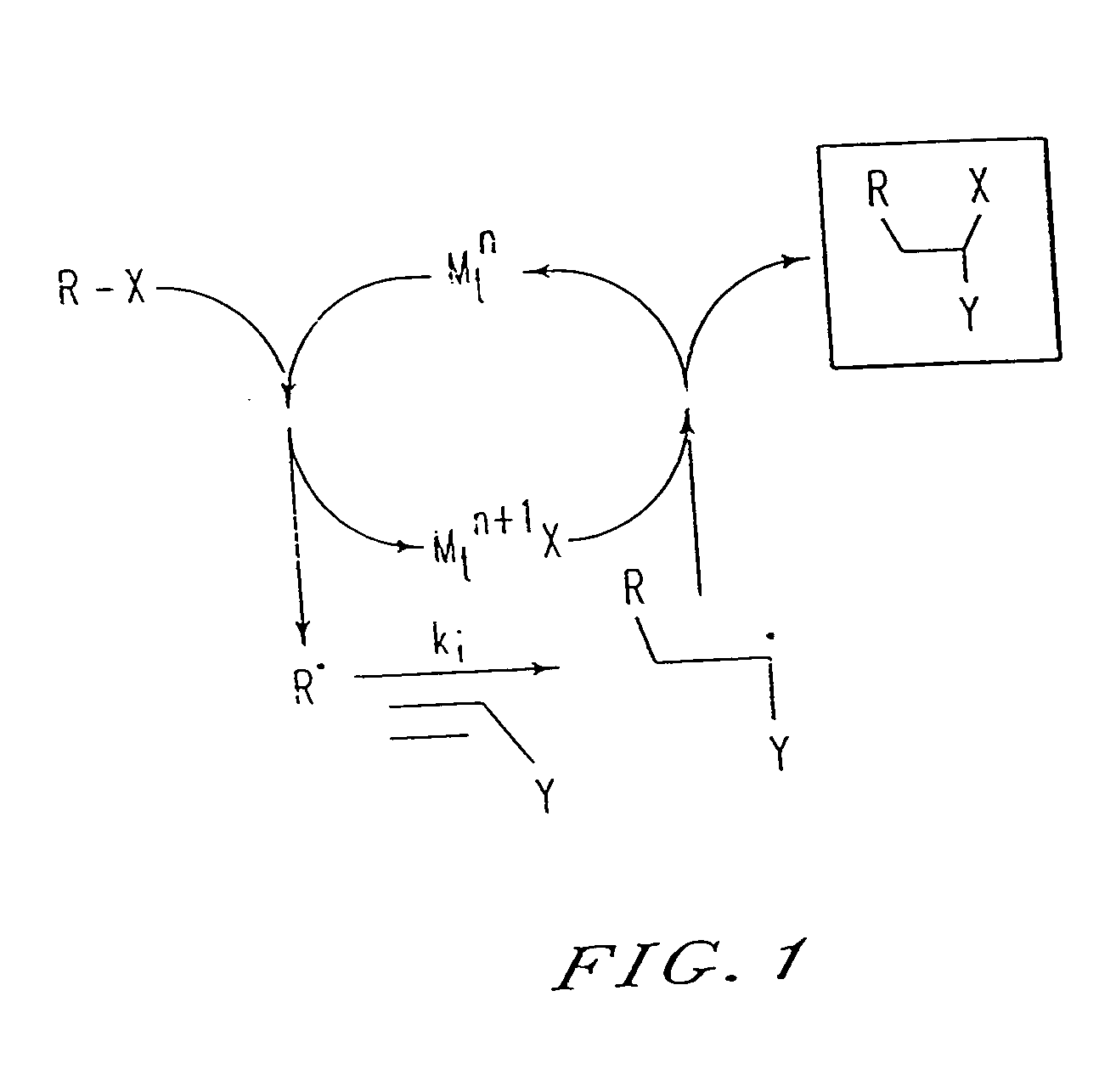

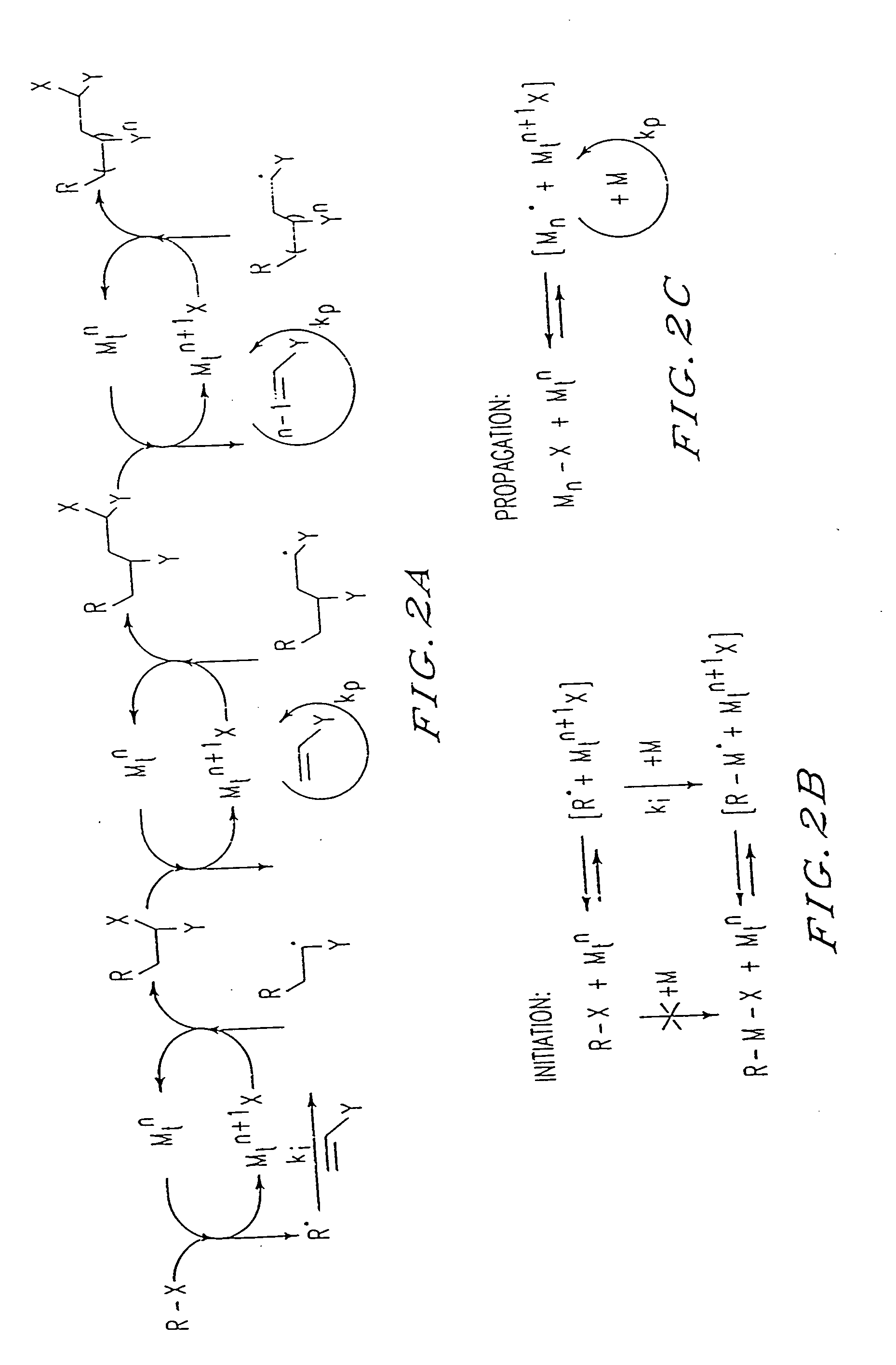

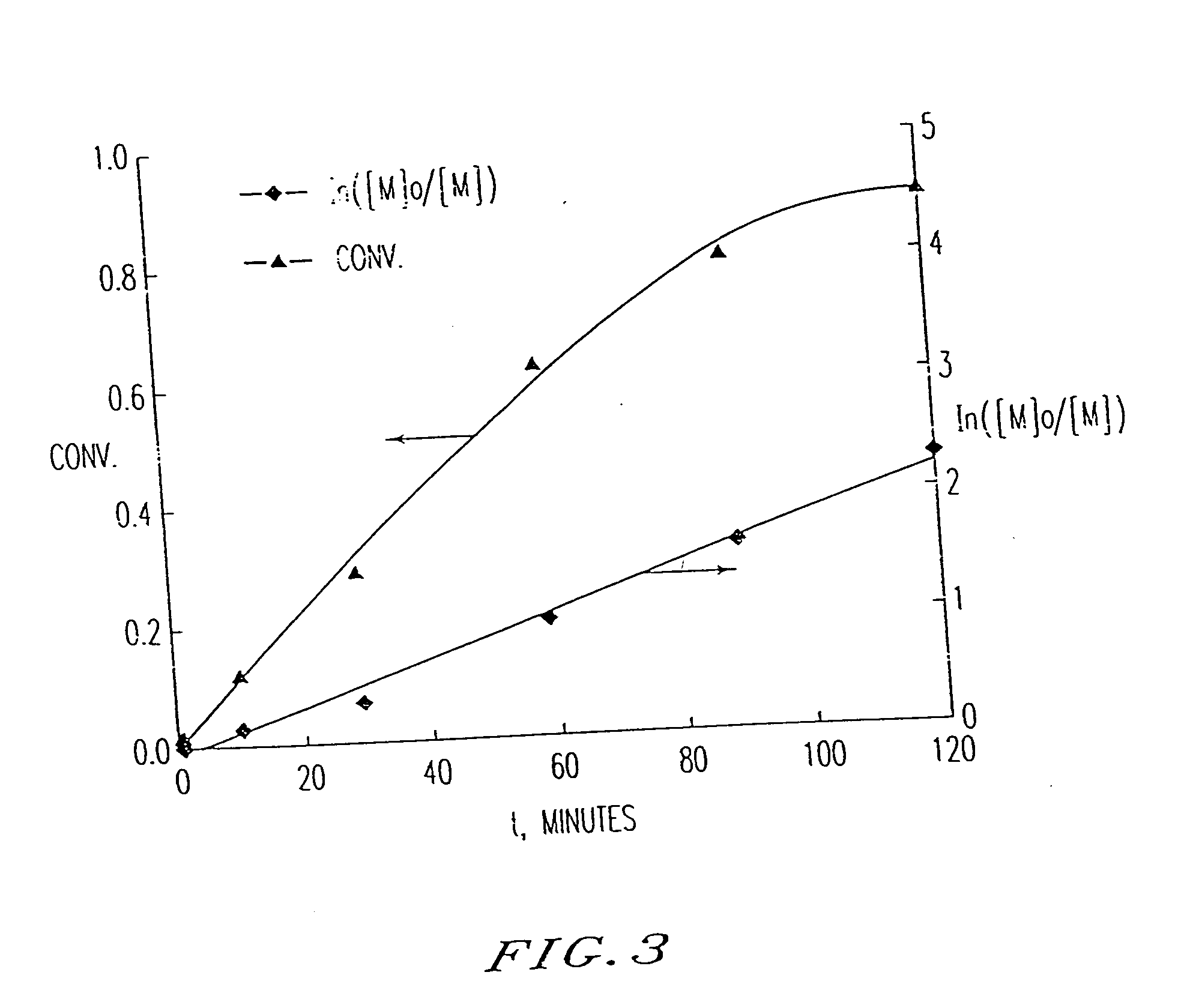

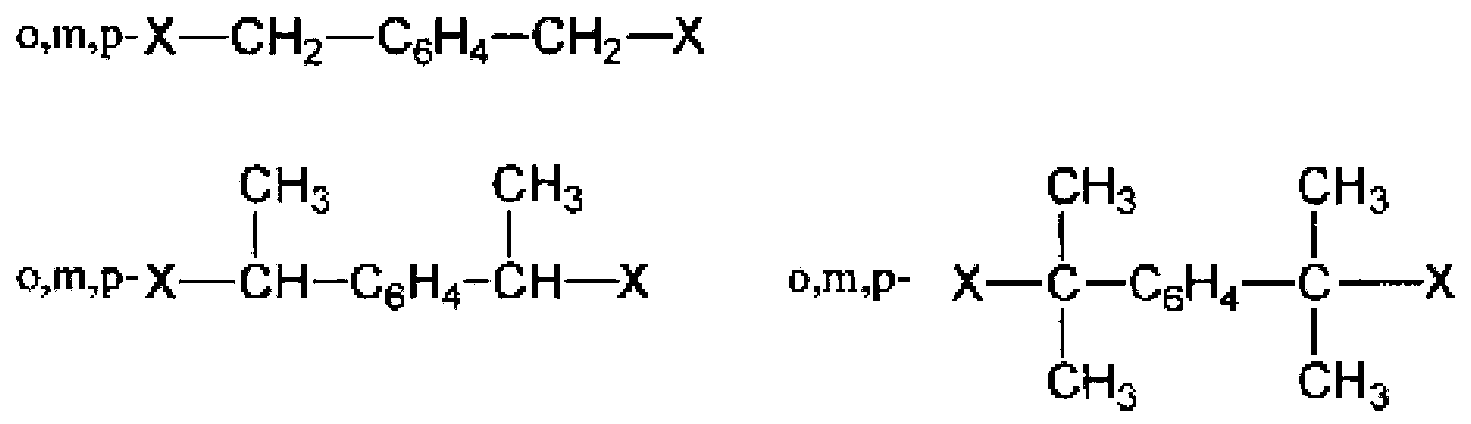

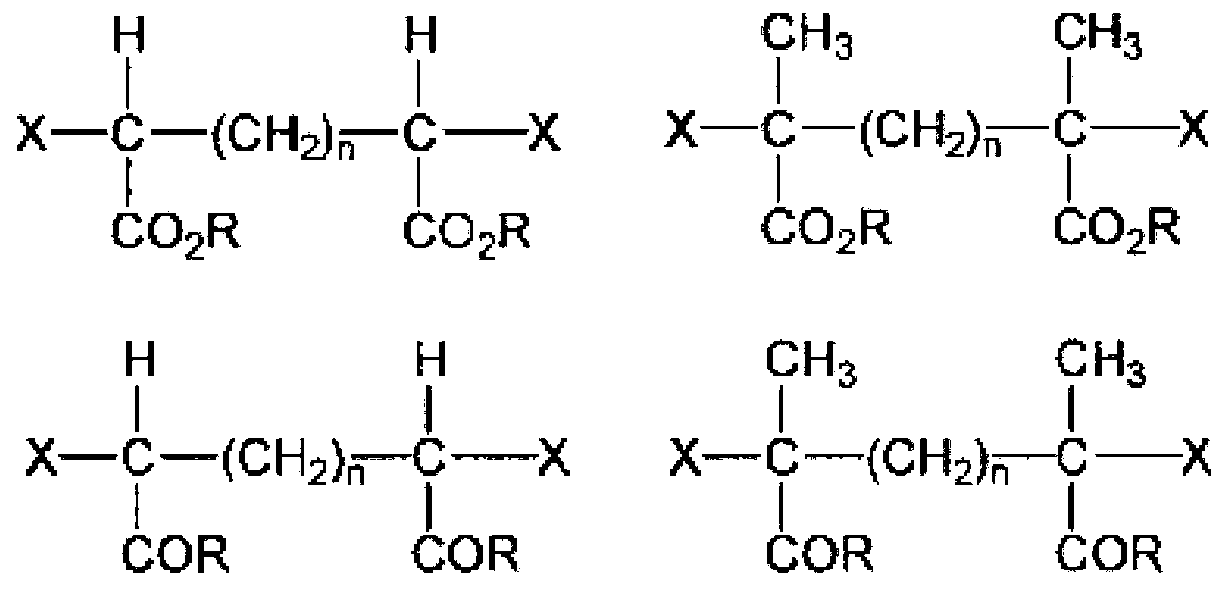

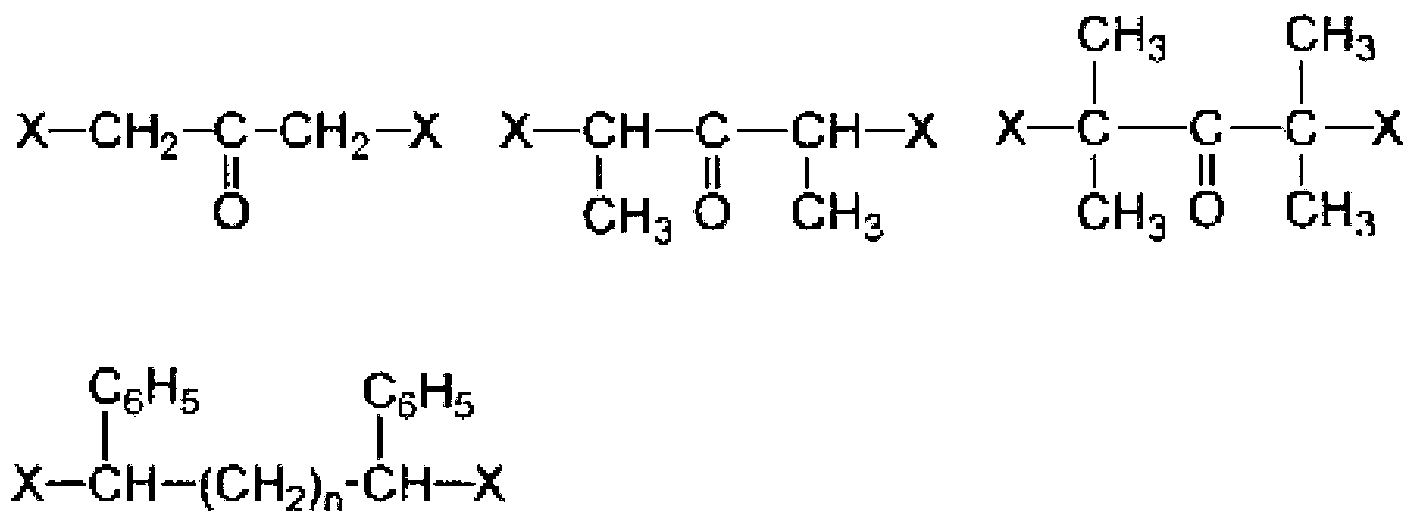

Noel (co) polymers and a novel polymerization process based on atom (or group) transfer radical polymerization

InactiveUS20050090632A1Increase in the rate of side reactionsReduce rateCoatingsGraft polymer adhesivesElastomerMeth-

A new polymerization process (atom transfer radical polymerization, or ATRP) based on a redox reaction between a transition metal (e.g., Cu(I) / Cu(II), provides “living” or controlled radical polymerization of styrene, (meth)acrylates, and other radically polymerizable monomers. Using various simple organic halides as model halogen atom transfer precursors (initiators) and transition metal complexes as a model halogen atom transfer promoters (catalysts), a “living” radical polymerization affords (co)polymers having the predetermined number average molecular weight by Δ[M] / [I]0 (up to Mn>105) and a surprisingly narrow molecular weight distribution (Mw / Mn), as low as 1.15. The participation of free radical intermediates in ATRP is supported by end-group analysis and stereochemistry of the polymerization. In addition, polymers with various topologies (e.g., block, random, star, end-functional and in-chain functional copolymers [for example, of styrene and methyl (meth)acrylate]) have been synthesized using the present process. The polymeric products encompassed by the present invention can be widely used as plastics, elastomers, adhesives, emulsifiers, thermoplastic elastomers, etc.

Owner:CARNEGIE MELLON UNIV

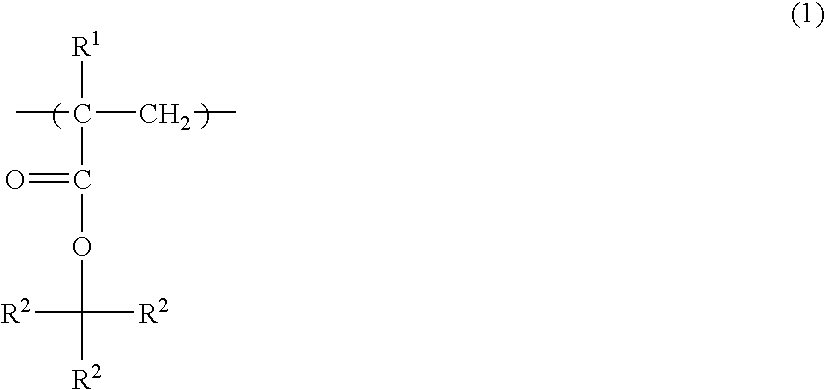

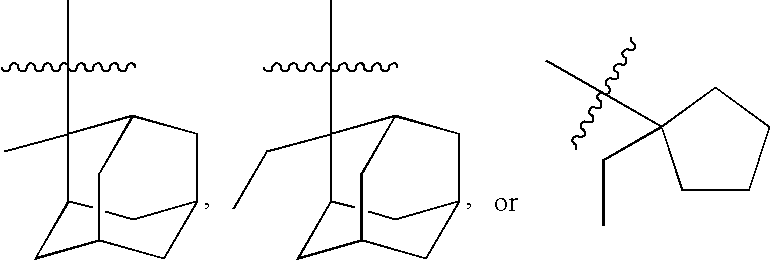

Radiation-sensitive resin composition

ActiveUS20060234154A1Molecular weight distribution can be decreasedReduce ratePhotosensitive materialsPhotosensitive materials for photomechanical apparatusPhotoacid generatorLiving free-radical polymerization

A radiation-sensitive resin composition comprising an acid-labile group-containing resin obtained by living radical polymerization having a specific structure which is insoluble or scarcely soluble in alkali, but becomes alkali soluble by the action of an acid, and a photoacid generator, wherein the ratio of weight average molecular weight to number average molecular weight (weight average molecular weight / number average molecular weight) of the acid-labile group-containing resin is smaller than 1.5.

Owner:JSR CORPORATIOON

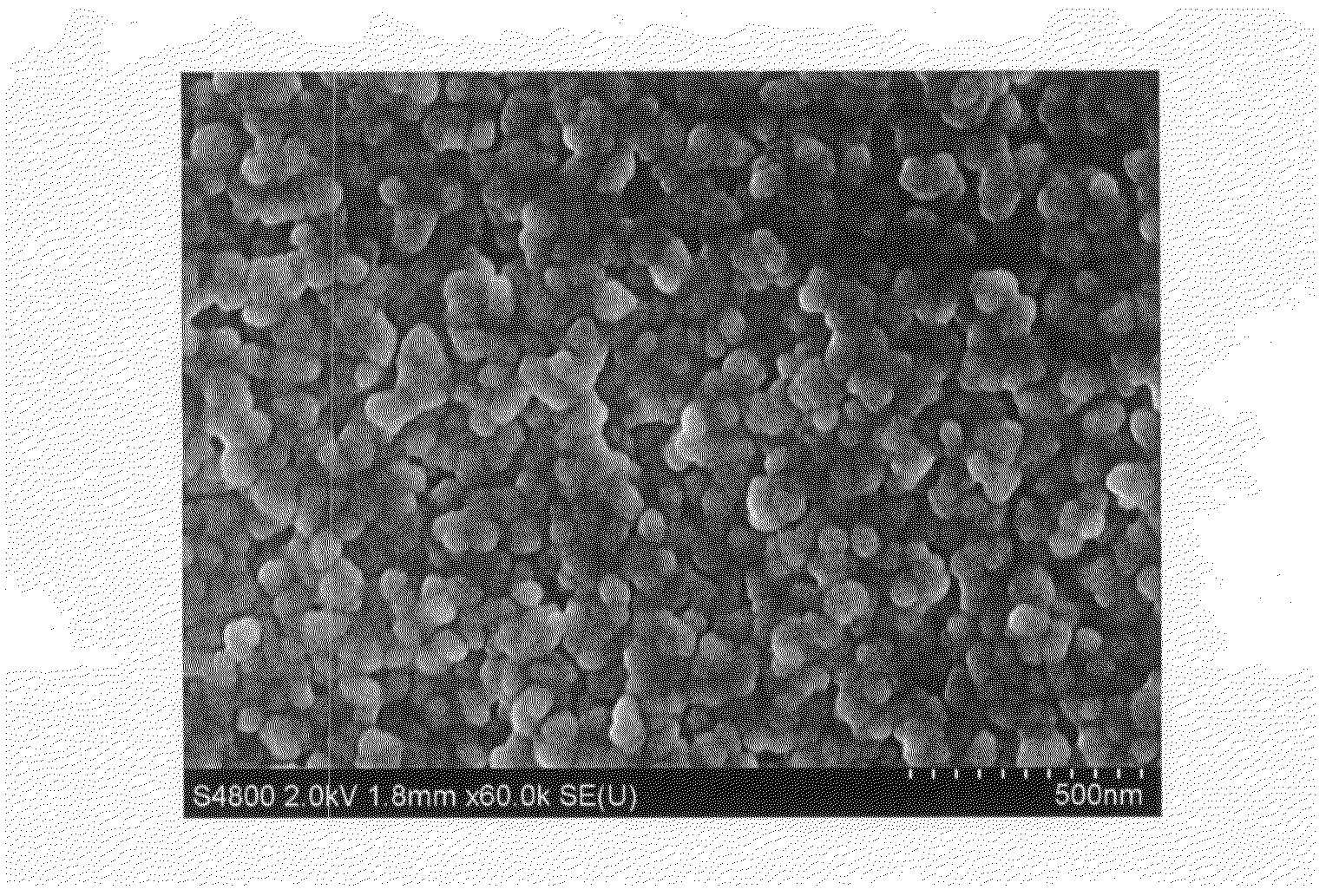

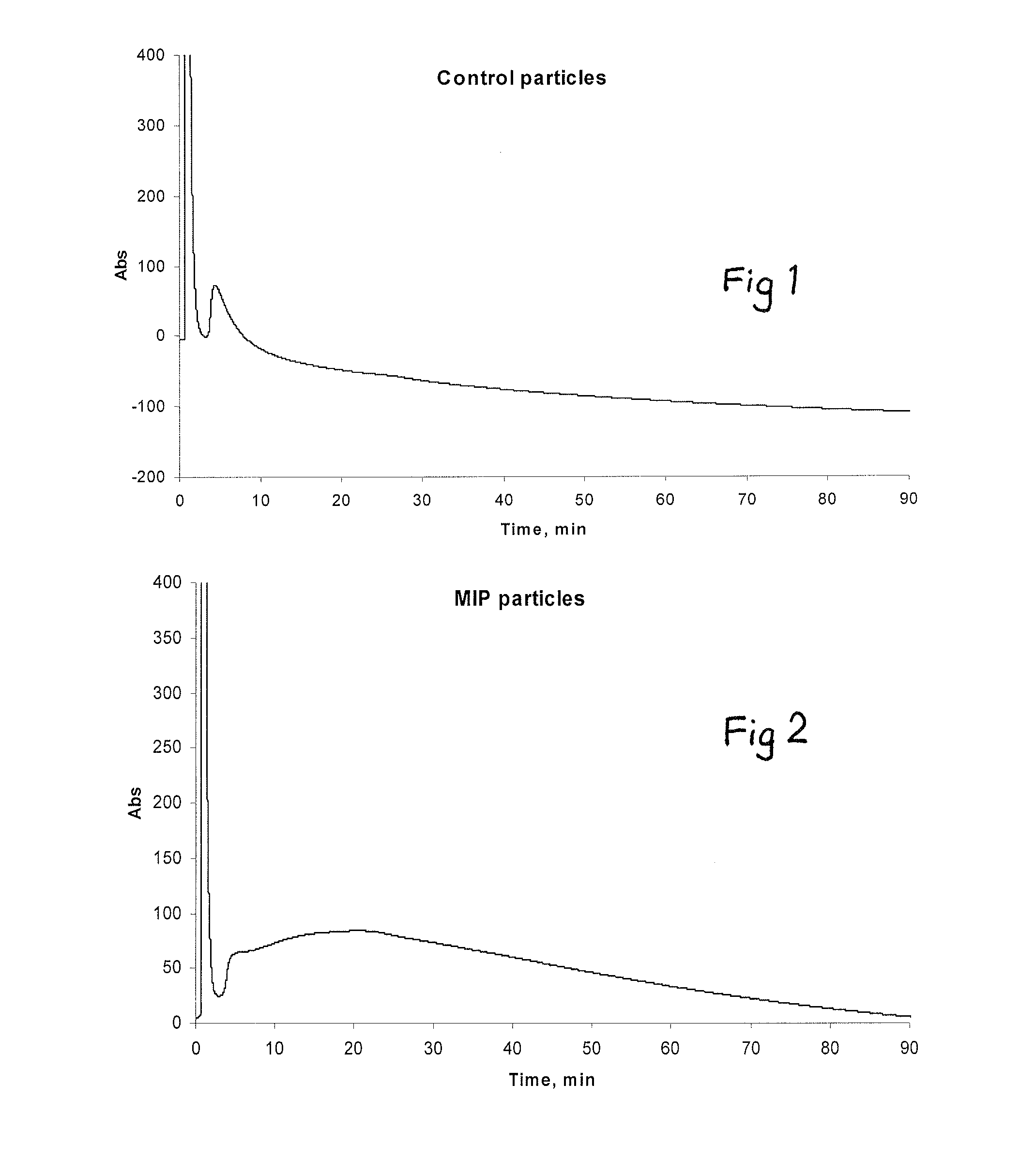

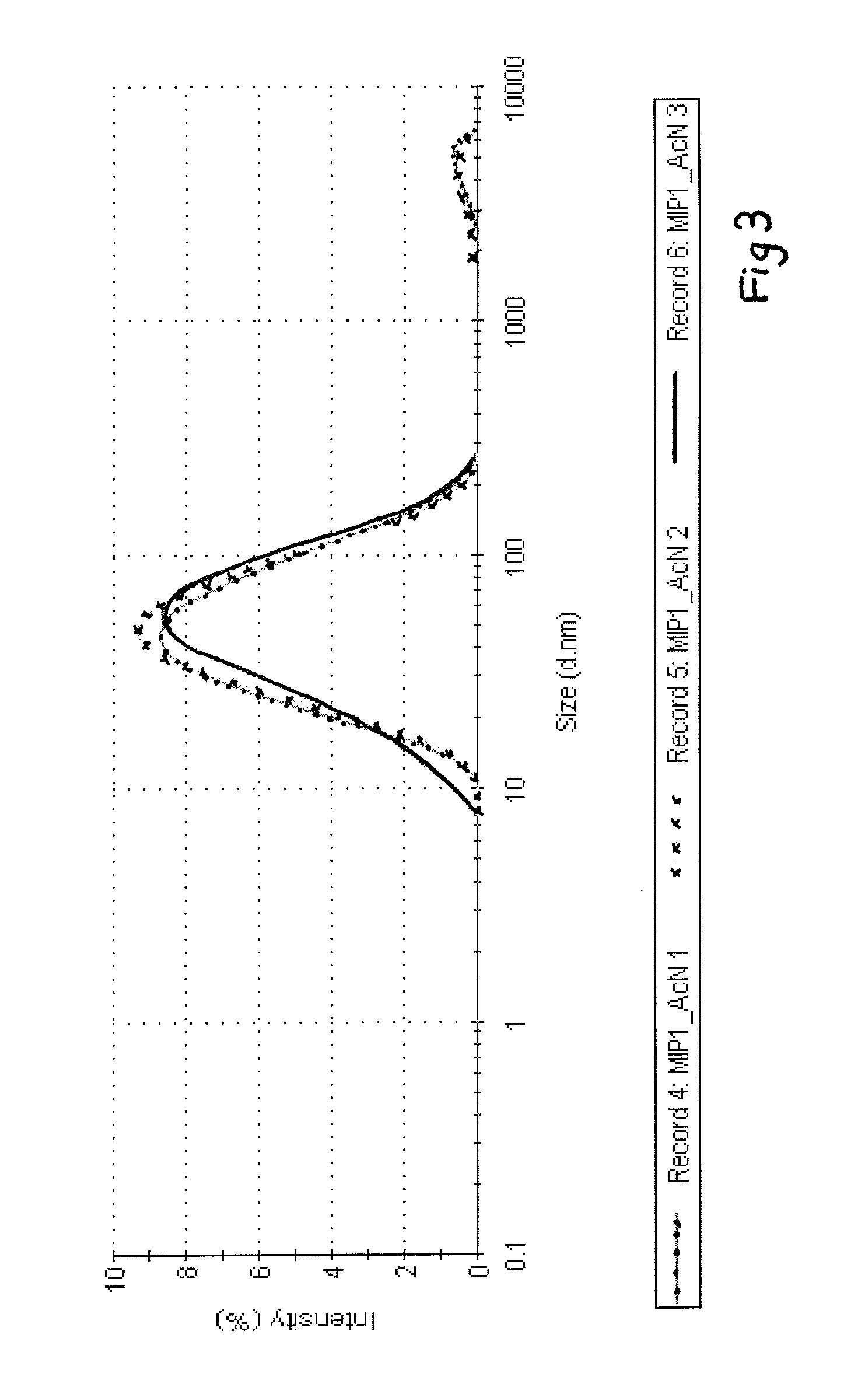

Preparation of molecularly imprinted polymers

ActiveUS20120270964A1Low costBiological material analysisPrintingCombinatorial chemistryLiving free-radical polymerization

A polymerization process, preferably a living radical polymerisation process, is carried out in the presence of a template substance, to produce s molecularly imprinted polymers (“MIPs”). It is controlled so that the products are quite small (500-106 Daltons) so that they are soluble or form colloidal suspensions. The template substances are immobilized templates, which can be re-used. Immobilized templates are also useful for purification of MIP solutions / suspensions by affinity chromatography.

Owner:MIP DIAGNOSTICS LTD

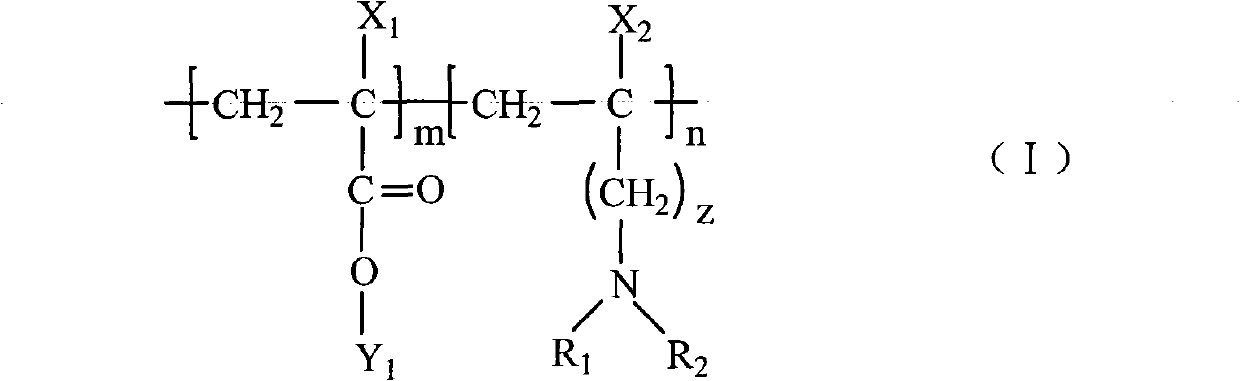

Block type polymer dispersant and preparation method thereof

InactiveCN101862619ALight colorThe synthesis process is simpleTransportation and packagingOrganic dyesChemistryLiving free-radical polymerization

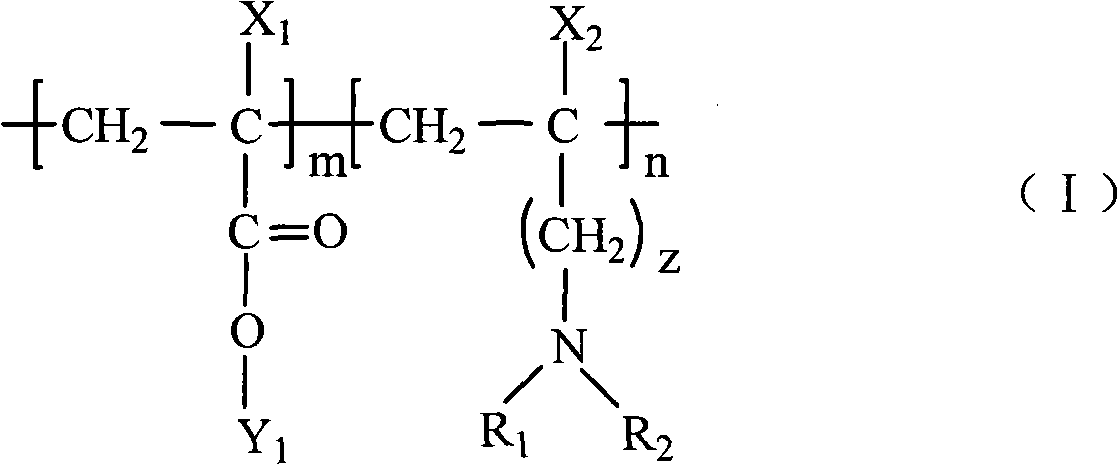

The invention discloses a block polymer dispersant and a preparation method thereof. The structure of the block polymer dispersant is shown in the following formula (I). The invention also discloses a synthesis method for preparing the block type polymer dispersant by single electron transfer / living radical polymerization. The invention has the following advantages: 1) the block type polymer dispersant prepared by the single electron transfer / living radical polymerization is light in color and nearly colorless, can be directly for use, and has a simple synthesis process; 2) the block type polymer dispersant can quickly humidify the pigment particles and shorten the milling time; 3) the steric effect of the polyitaconate deflocculates the pigment particles, and can prevent the pigment from flocculating and precipitating in the storage process; and 4) the deflocculated pigment particles are small, thereby achieving high glaze and color intensity, and increasing transparency and hiding power.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

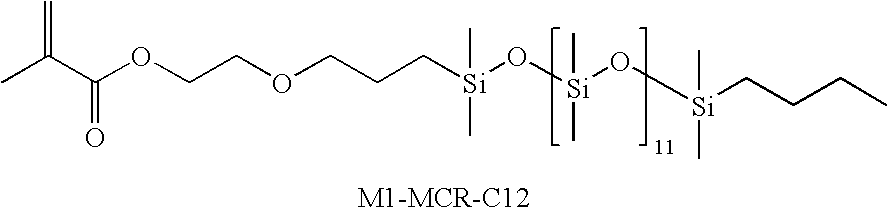

Biomedical devices

ActiveUS20100317816A1Clear processReduce polydispersityOptical partsOptical elementsHydrophilic monomerPolymer science

Biomedical devices such as contact lenses formed from a comprising a polymerization product of a mixture comprising an ethylenically unsaturated-containing non-amphiphilic macromonomer comprising hydrophilic units or hydrophobic units derived from a living radical polymerization of one or more ethylenically unsaturated hydrophilic monomers or one or more ethylenically unsaturated hydrophobic monomers are disclosed.

Owner:BAUSCH & LOMB INC

Cellulose absorbent with controllable structure and preparation method thereof

The invention discloses a cellulose absorbent with a controllable structure and a preparation method of the cellulose absorbent. The preparation method comprises the following steps of grafting polymerizing cellulose by adopting cotton fibers as raw materials and iminazole ion liquid as a solvent through the polymerization of active free radicals, introducing an epoxy basic group, and aminated ringopening the cellulose grafted polymer by utilizing an amination reagent to prepare the cellulose absorbent with the controllable structure. The cellulose absorbent is faint yellow or white particles, the weight-average molecular weight is 6000 to 69000, the molecular weight distribution is 1.02 to 1.2, the content of nitrogen is 10. 16 to 23.59 percent, the molecular weight is narrow in distribution, the structure is controllable, and a good absorption effect on cation and anion pollutants can be realized.

Owner:FUZHOU UNIV

Curable composition

InactiveUS20070167583A1Good storage stabilityNo surface tackEngine sealsOther chemical processesPolymer scienceLiving free-radical polymerization

Desirable properties required of curable compositions include: to have satisfactory storage stability; to give a cured product having a mat surface with almost no residual tack; to give a rubbery cured product having a low modulus and high elongation; and to give a cured product the surface of which is less apt to crack or discolor even in outdoor use. The present invention provides a curable composition which comprises: a vinyl polymer the main chain of which is a product of living radical polymerization and which contains at least one crosslinkable silyl group, and a primary and / or secondary amine having a melting point of not lower than 20° C. The curable composition of the present invention gives a cured product satisfying those properties.

Owner:KANEKA CORP

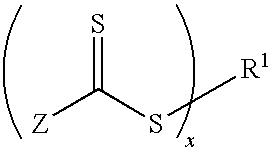

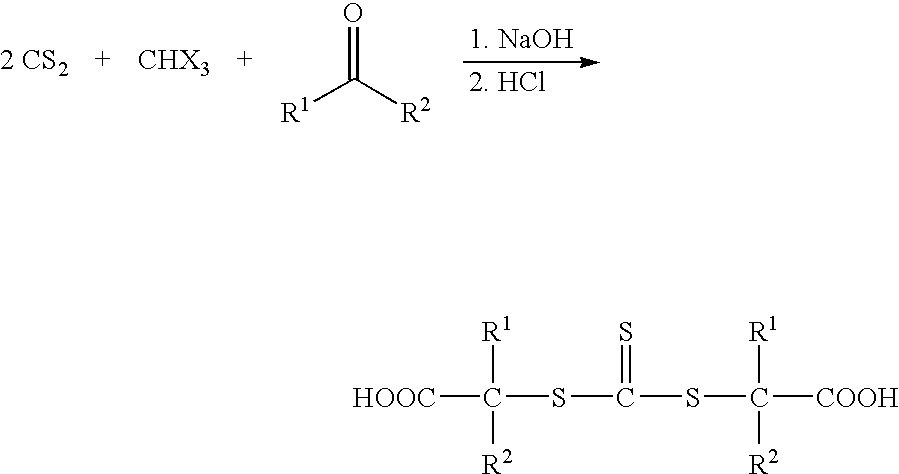

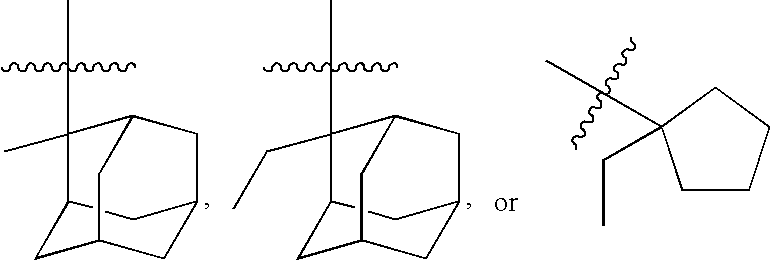

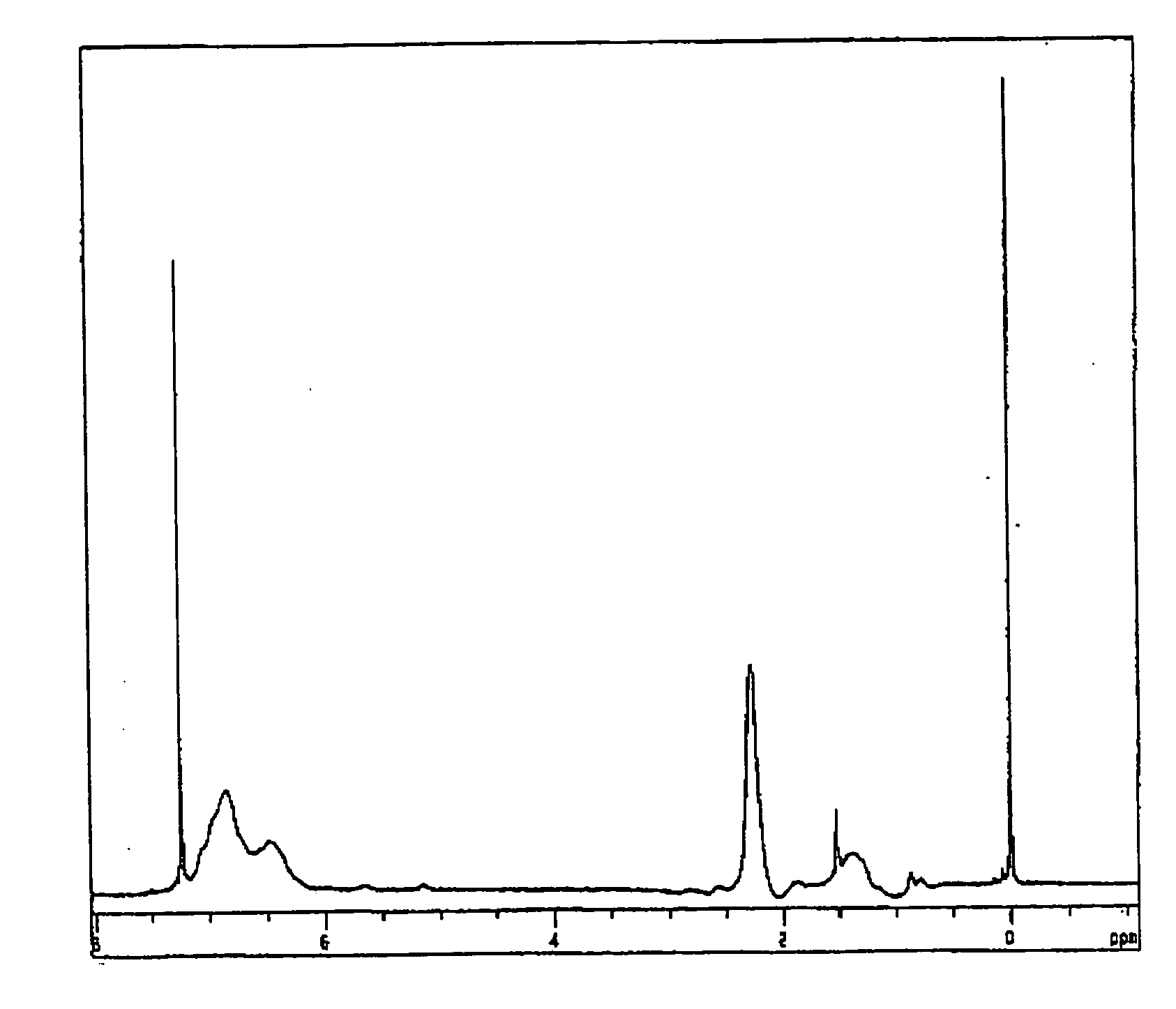

S,S'-BIS-(alpha, alpha'-DISUBSTITUTED-alpha-ACETIC ACID)-TRITHIOCARBONATES AND DERIVATIVES AS INITIATOR-CHAIN TRANSFER AGENT-TERMINATOR FOR CONTROLLED RADICAL POLYMERIZATIONS AND THE PROCESS FOR MAKING THE SAME

A s,s′-bis-(α, α′-disubstituted-α″-acetic acid)-trithiocarbonate and derivatives thereof can be used as an initiator, chain transfer agent, or terminator for polymerization of monomers such as free radical polymerizable monomers. Homopolymers, copolymers, and the like as well as block copolymers can be made utilizing the trithio carbonate compound such as in a living free radical polymerization as well as to form telechelic polymers.

Owner:LUBRIZOL ADVANCED MATERIALS INC

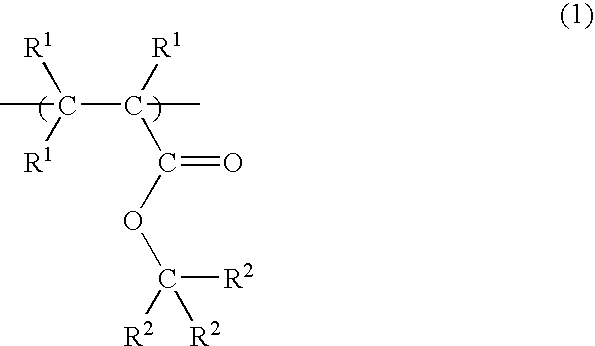

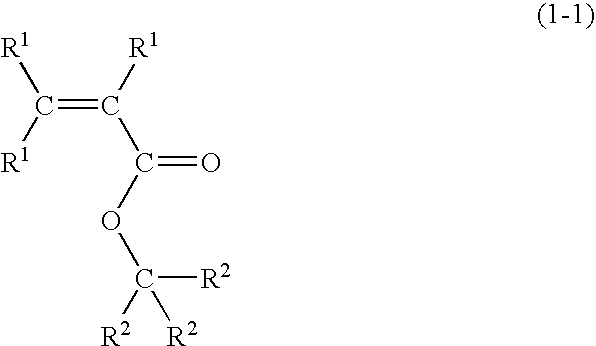

Process for production of living radical polymers and polymers

A process for producing a living radical polymer characterized in that a vinyl monomer is polymerized with use of a living radical polymerization initiator represented by the formula (1) and a compound represented by the formula (2), and the living radical polymer obtained by the processwherein R1 is C1-C8 alkyl, aryl, substituted aryl or an aromatic heterocyclic group, R2 and R3 are each a hydrogen atom or C1-C8 alkyl, and R4 is aryl, substituted aryl, an aromatic heterocyclic group, acyl, oxycarbonyl or cyano(R1Te)2 (2)wherein R1 is the same as above.

Owner:OTSUKA CHEM CO LTD

Photoresist polymer compositions

ActiveUS7510817B2Photosensitive materialsPhotosensitive materials for photomechanical apparatusResistPolymer science

The present invention is directed to the preparation of photoresist polymers via living free radical polymerization techniques. Sterically bulky ester monomers are utilized as the polymerization components. Use of chain transfer agents is included in polymerization processing conditions. Cleavage of polymer terminal end groups that include a heteroatom are described.

Owner:FREESLATE +1

Hyperbranched Polymer and Production Method Thereof

Owner:TOKYO INST OF TECH +1

Silicon compound

ActiveUS20050250925A1Good polymerizationExcellent living radical polymerization accelerating functionSilicon organic compoundsArylPolymer science

The present invention provides a novel silicon compound represented by Formula (1) having a living radical polymerization initiating ability for addition-polymerizable monomers and a polymer obtained using the same. The above polymer can provide an organic-inorganic composite material having a distinct structure. wherein R1 is hydrogen, alkyl, aryl or arylalkyl; R2 and R3 are alkyl, phenyl or cyclohexyl; and A is a group having an ability to initiate polymerization of a monomer.

Owner:JNC CORP

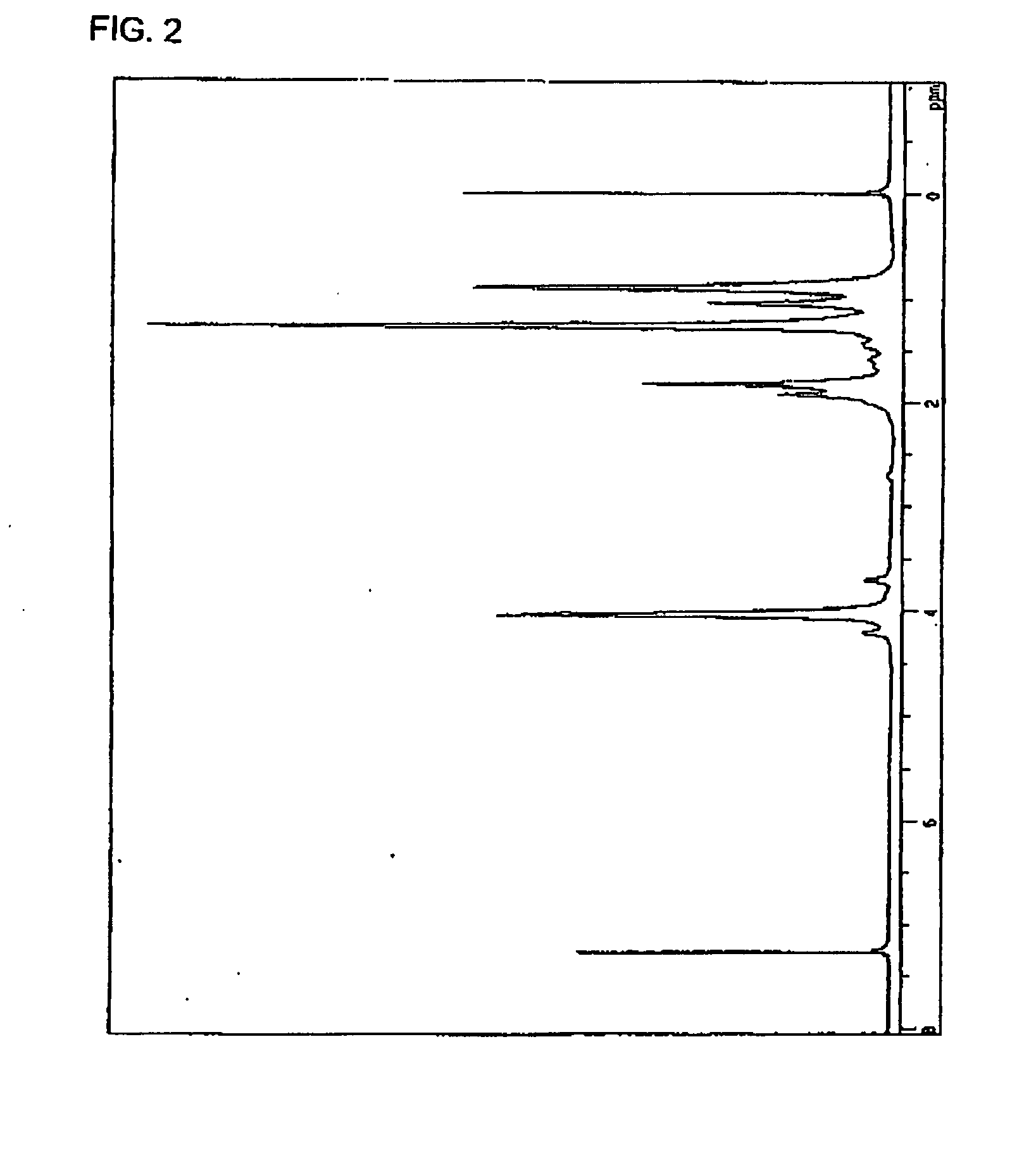

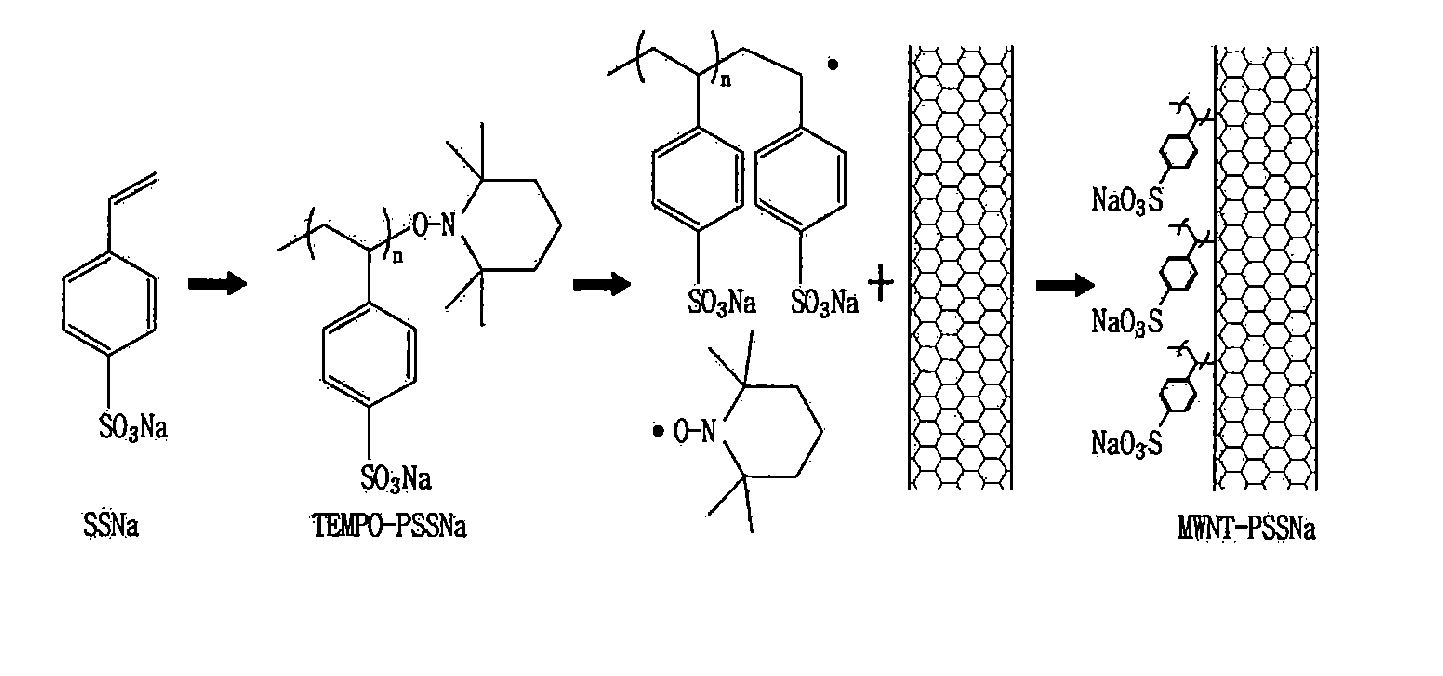

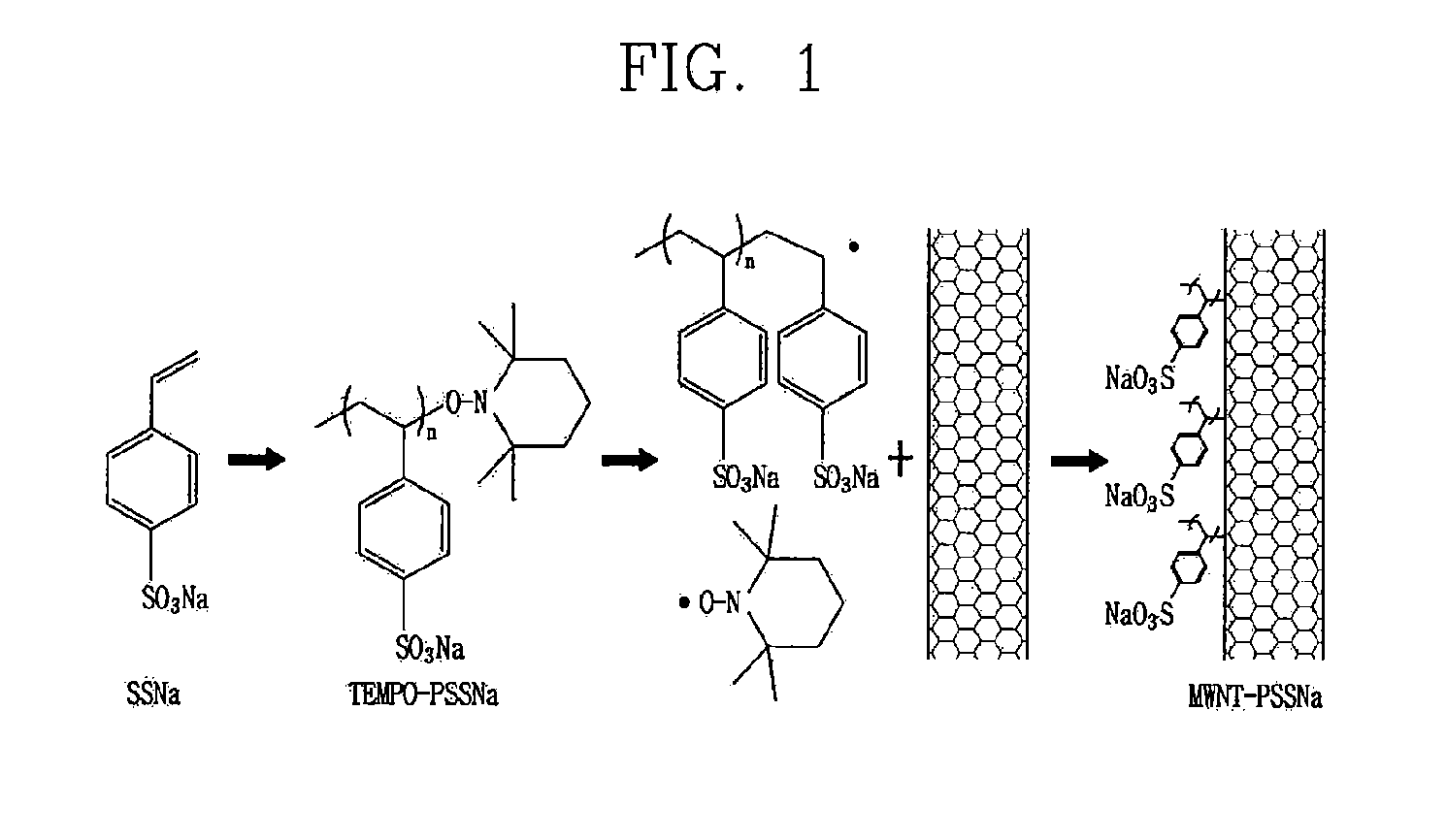

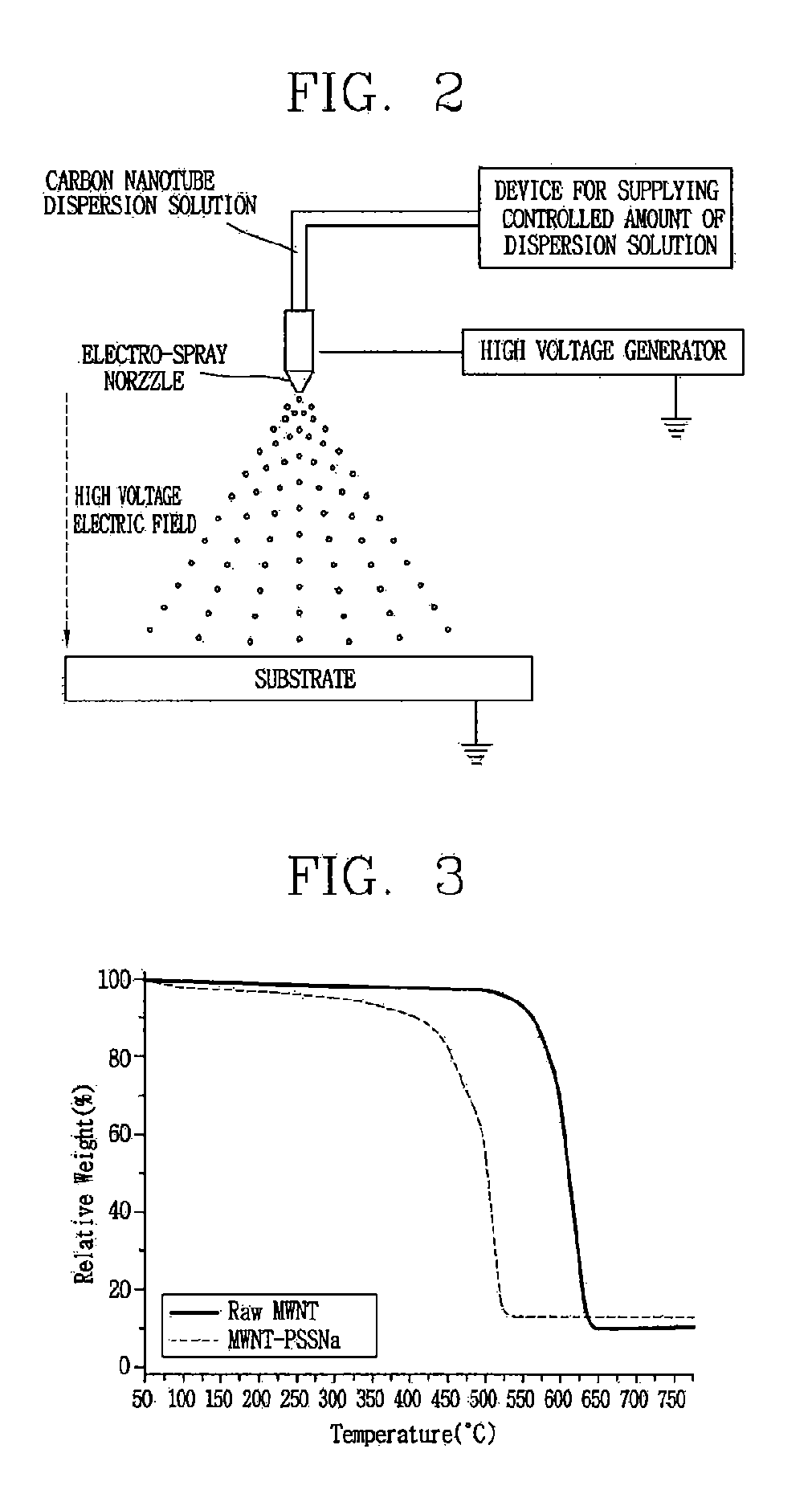

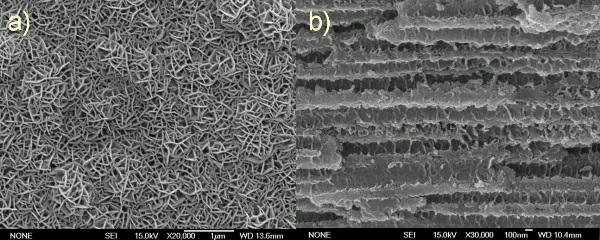

Modified carbon nanotube grafted by living polymer, carbon nanotube electrode and dye-sensitized solar cell using the same, and each preparation method thereof

InactiveUS20100084007A1Minimizing lowering of physical propertyGood dispersionMaterial nanotechnologyElectrolytic capacitorsEnd-groupElectro spray

Disclosed are to provide a modified carbon nanotube obtained by reacting a polymer to a carbon nanotube by a radical graft method, capable of minimizing lowering of a physical property of a carbon nanotube caused when being modified, and capable of enhancing dispersibility of the carbon nanotube and an adhesion strength between carbon nanotubes, the polymer having a molecular weight controlled by a living radical polymerization and still having a living radical end group.Also disclosed are to provide a carbon nanotube electrode and a dye-sensitized solar cell using the same, capable of forming a carbon nanotube film having a thickness thinner than that of the conventional electrode by directly spraying, on a substrate, by an electro-spray process, a uniform dispersion solution that the modified carbon nanotube is dispersed in a proper solvent without requiring an additional organic binder, capable of exhibiting an excellent catalytic characteristic owing to a close adhesion strength between carbon nanotubes and an increased relative density of the carbon nanotube film, and capable of implementing an excellent long-term stability owing to a strong bonding force between a carbon nanotube and a substrate.

Owner:KOREA INST OF SCI & TECH

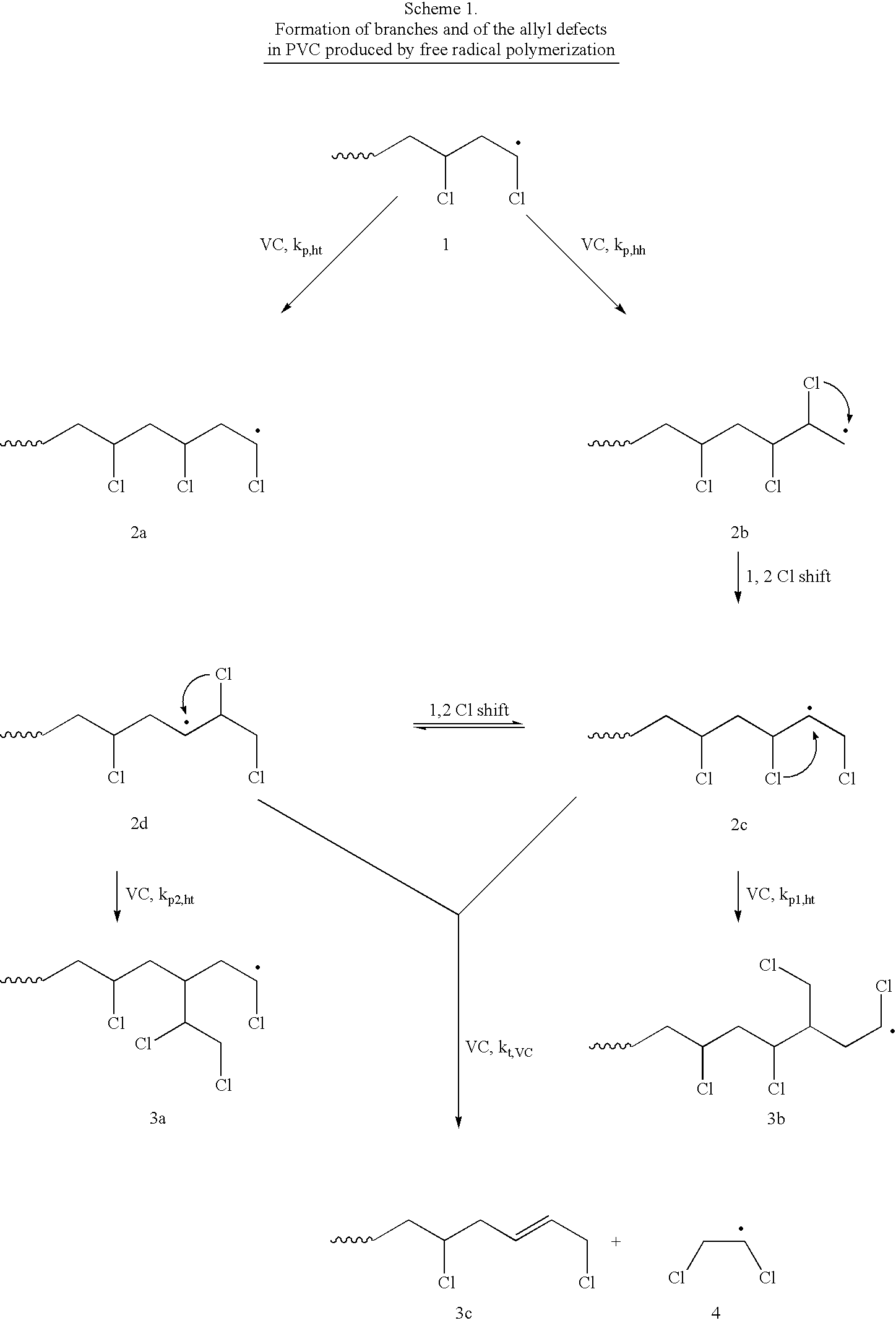

Process for the living radical polymerization of chlorine containing monomers

A process for the preparation of polyvinyl chloride (PVC) with controlled molecular weight and molecular weight distribution is disclosed. The polymerization reaction can be initiated by various organic halide initiators in conjunction with a metal catalyst and an optional ligand in organic solvents or water and in the presence of an optional comonomer. The polymerization process provides PVC with a controlled molecular weight and narrow molecular weight distribution. The chlorine containing polymers compositions are useful as, among others, viscosity modifiers, impact modifiers and compatibilizers.

Owner:PENNSYLVANIA UNIV OF

Multifunctional azo initiators for free radical polymerizations: uses thereof

ActiveUS8097687B2Chemical/physical/physico-chemical processesLiving free-radical polymerizationElectron

The invention provides compositions of matter, methods of their synthesis, and methods of their use in polymerization reactions. The compositions include polyfunctional initiators used to make star polymers when polymerized with monomers. The polyfunctional initiators are synthesized out of a multifunctional core with at least two functional groups and two or more initiator units bonded to the functional groups. The initiator units have two electron-withdrawing groups bonded to a central carbon atom and an azo group between the central carbon atom and the functional group. The polyfunctional initiators are particularly effective because when they decompose to form the radical core of a star polymer, the electron-withdrawing groups prevent the corresponding radical from forming any linear polymer contamination and only desired star polymers result. In addition when the desired star polymers are fed into a reaction vessel by streams with two different concentrations the star polymers produce superior properties.

Owner:ECOLAB USA INC

Material and process for precisely controlled polymeric coatings

ActiveUS7303821B1Suppresses electroosmotic flowReduces non-specific interactionCoatingsWater-setting substance layered productVinyl etherMethacrylate

This invention provides a chemically coated surface for the electrophoretic separation application. The surface comprises of block copolymers prepared from addition monomers selected from a group consisting of acrylates and its derivatives, metharylates and its derivatives, styrene and its derivatives, acrylamide, methacrylamide, dimethacrylamide, N-monosubstituted acrylamide, N-monosubstituted methacrylamide, N,N-bissubstituted acrylamide, N,N-bissubstituted methacrylamide, vinyl acetate, vinyl pyrolidone, vinyl ether, acrylic acid and methacrylic acid. This invention also provides a chemical process for making the chemically coated surface for the electrophoretic separation application. The process comprises:(a) contacting the support surface with a coupling agent solution, then(b) contacting the support surface with a first living radical polymerizing solution, and optionally(c) contacting the support surface with a second living radical polymerizing solution.

Owner:SEPAX TECH

Process for produciton of living radical polymers and polymers

A process for producing a living radical polymer characterized in that a vinyl monomer is polymerized with use of a living radical polymerization initiator represented by the formula (1) and a compound represented by the formula (2), and the living radical polymer obtained by the process wherein R1 is C1-C8 alkyl, aryl, substituted aryl or an aromatic heterocyclic group, R2 and R3 are each a hydrogen atom or C1-C8 alkyl, and R4 is aryl, substituted aryl, an aromatic heterocyclic group, acyl, oxycarbonyl or cyano (R1Te)2 (2) wherein R1 is the same as above.

Owner:OTSUKA CHEM CO LTD

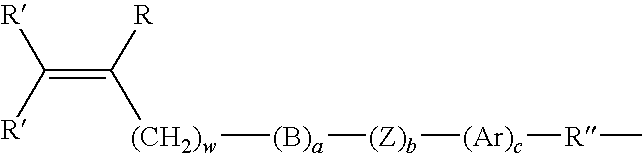

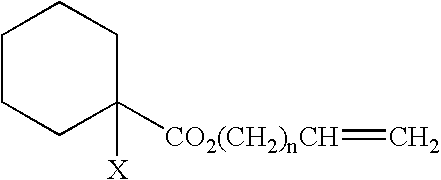

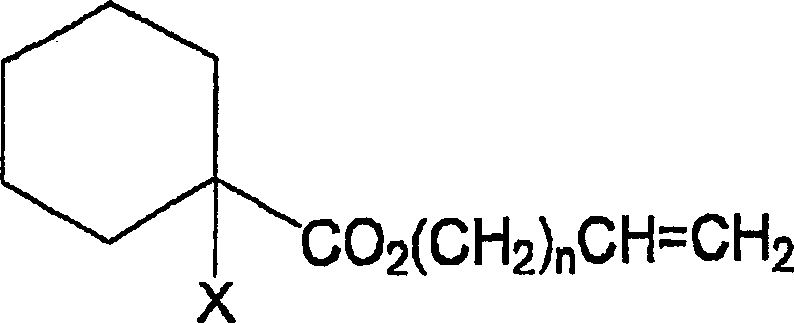

Process for producing branched polymer and polymer

This invention is related to a production method of a branched polymer which comprises polymerizing a macromonomer [I], said macromonomer [I] being a vinyl polymer obtainable by radical polymerization and terminally having one polymerizable carbon-carbon double bond-containing group per molecule. Furthermore, by producing the macromonomer by living radical polymerization, in particular atom transfer radical polymerization, it becomes possible to produce the above polymers or gels having a well controlled side chain molecular weights.

Owner:KANEKA CORP

Curing composition

InactiveCN1914281AExcellent weather resistance and adhesionReduce pollutionCovering/liningsOther chemical processesSilyleneWeather resistance

The present invention provides a curable composition capable of giving rubbery cured products having excellent adhesion properties against all-purpose substrates, improved in weather-resistant adhesion properties against photocatalyst-coated transparent substrates, low in modulus and high in elongation and, further, showing high weather resistance without undergoing surface cracking or discoloration even when used outdoors for a long period of time. In addition, the above-mentioned curable composition maintains the rate of curing after storage. The curable composition of the present invention comprises a vinyl polymer (I) the main chain of which is the product of living radical polymerization and which contains at least one crosslinkable silyl group, and an oxygen-curable substance (II).

Owner:KANEKA CORP

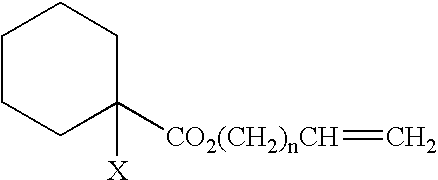

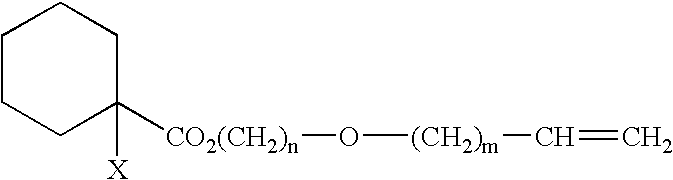

Active energy ray-curable composition for optical material, cured product, and production methods for active energy ray-curable composition and cured product

InactiveCN103237827AExcellent curability with active energy raysLow viscosity propertiesCoatingsOptical elementsCrack resistanceLow temperature curing

Provided are an active energy ray-curable composition for an optical material that has excellent low viscosity, shelf life, low foamability, low-temperature curability, low-warping performance, deep curability, heat-resistant and light-resistant transparency, rubber properties, cracking resistance, moisture permeation resistance and designability; a cured product; and production methods for obtaining the active energy ray-curable composition and the cured product. The active energy ray-curable composition for the optical material comprises (A) a vinyl polymer which has, per molecule, at least one methacryloyl group represented by the general formula (1) -OC(O)C(Ra)=CH2(1) (where Ra is a hydrogen atom or C1-C20 organic group) is produced by living radical polymerization, and has a color difference delta E* of 10 or less; (B) a light-induced radical polymerization initiator; and (C) at least one antioxidant selected from the group consisting of hindered phenol antioxidants, hindered amine antioxidants, and phosphorus antioxidants.

Owner:KANEKA CORP

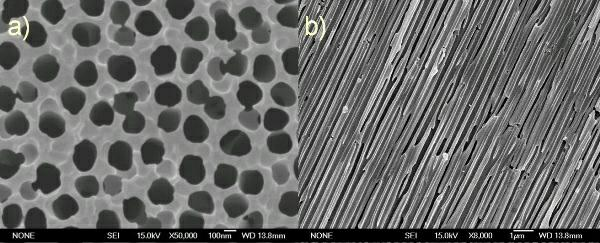

Preparation method of self-supporting molecularly imprinted polymer film

ActiveCN102432778ASolve the larger particlesSolve for uniformityOther chemical processesAlkali metal oxides/hydroxidesPolymer scienceCyanoacetic acid

The invention relates to a preparation method of a self-supporting molecularly imprinted polymer film. The preparation method comprises the following steps of: firstly, reacting divalent metal ions with a porous alumina film to obtain a porous alumina-based layered double hydroxide; secondly, carrying out further reaction to obtain an SBC (Sulpho-Benzoyl Cyanoacetic Acid) intercalated porous alumina-based layered double hydroxide; and finally, mixing the SBC intercalated porous alumina-based layered double hydroxide with a polymerizable monomer, a polymerized cross-linking agent, a molecularly imprinted template agent and an organic solvent, dispersing by using ultrasound wave, adding a free base polymerization initiator for polymerizing, washing a product obtained by reacting and then drying to obtain the self-supporting molecularly imprinted polymer film. According to the self-supporting molecularly imprinted polymer film disclosed by the invention, the advantages of high strength, corrosion resistance, high temperature resistance and great specific area of an inorganic material as well as high load information quantity and adjustable performance of an organic polymer material can be fully exerted; the active free base polymerization is assisted in controlling; and the controllable synthesis of an ultrathin nano self-supporting structure of a molecularly imprinted material can be realized by using the controllability of the growth process of an active chain.

Owner:SHANGHAI UNIV

Organosilicon compound

ActiveUS20060175684A1Solve the real problemSilicon organic compoundsSemiconductor/solid-state device detailsArylHydrogen

Since the majority of conventional organic / inorganic composite materials are obtained by mechanical blending of a silsesquioxane and an organic polymer or other means, it was extremely difficult to control the structure of the composite as a molecular agglomerate. In order to solve such a problem, the invention is to provide a silicon compound represented by Formula (1). This novel silicon compound has a living radical polymerization initiating ability for addition polymerizable monomers of a wide range. In Formula (1), R1 is hydrogen, an alkyl, an aryl, or an arylalkyl; R2 is an alkyl, phenyl, or cyclohexyl; and A is a group having a polymerization initiating ability for addition polymerizable monomers.

Owner:JNC PETROCHEM +1

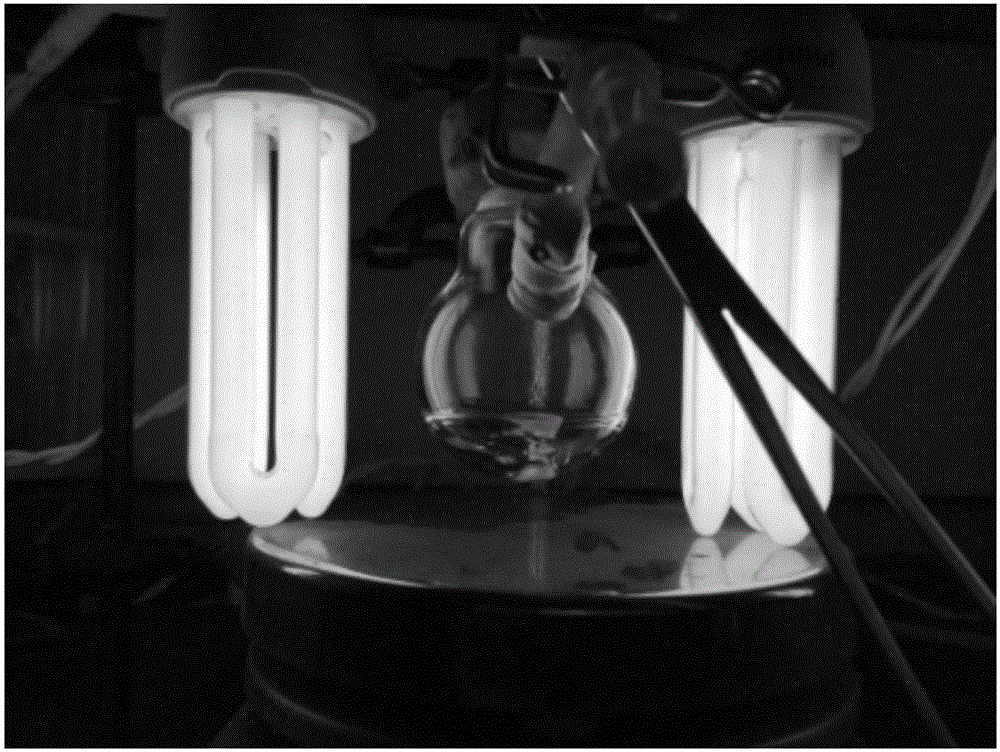

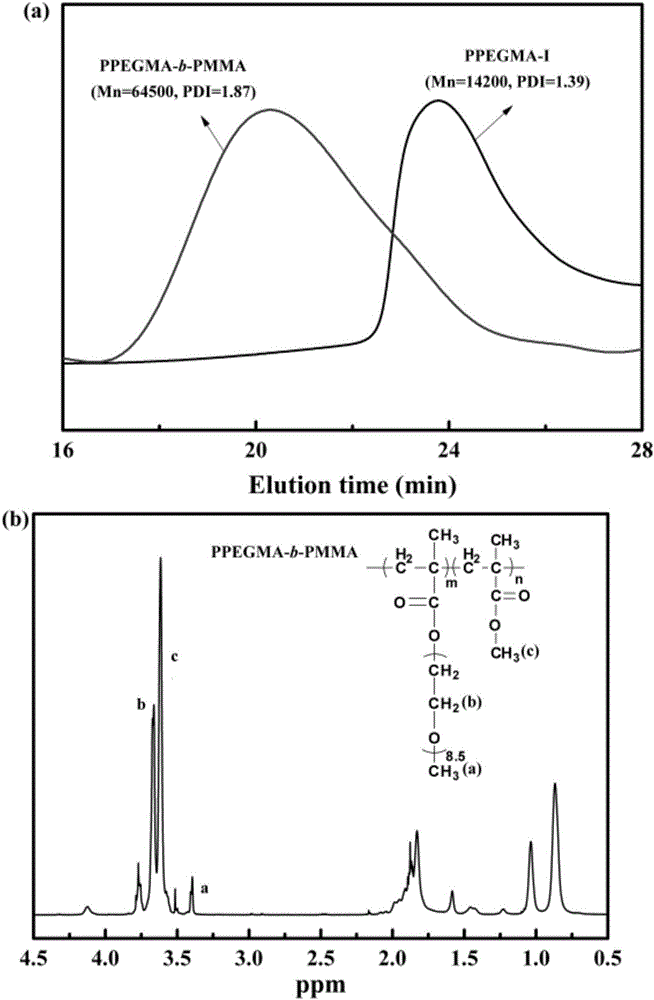

Initiation system for photo-polymerization of active free radicals of methacrylate monomers

The invention discloses an initiation system for photo-polymerization of active free radicals of methacrylate monomers. The initiation system comprises organic halide initiators, aromatic tertiary amine reducing agents and benzaldehyde photocatalysts with substituents. Visible light (such as a household 23W energy-saving lamp) can be used as a light source for the initiation system, and polymerization of the active free radicals of the methacrylate monomers can be initiated at the room temperature. The free radicals of methyl methacrylate (MMA), polyethylene glycol methacrylate (PEGMA) and methacrylic acid benzyl ester (BnMA) monomers and the like can be polymerized under preferred matching conditions. Polymers prepared by the aid of the initiation system are macromolecular initiators, chain extension reaction is successfully carried out, and accordingly block polymers can be obtained. The initiation system has the advantages that catalysts are low in toxicity, and polymerization reaction conditions are mild; the cost of polymerization reaction is lowered to a great extent owing to the usage of organic catalysts as compared with polymerization reaction catalyzed by transition metal complexes, and after-treatment working procedures can be reduced to a great extent.

Owner:BEIJING UNIV OF CHEM TECH

Process for producing branched polymer and polymer

This invention is related to a production method of a branched polymerwhich comprises polymerizing a macromonomer [I],said macromonomer [I] being a vinyl polymer obtainable by radical polymerization and terminally having one polymerizable carbon—carbon double bond-containing group per molecule. Furthermore, by producing the macromonomer by living radical polymerization, in particular atom transfer radical polymerization, it becomes possible to produce the above polymers or gels having well controlled side chain molecular weights.

Owner:KANEKA CORP

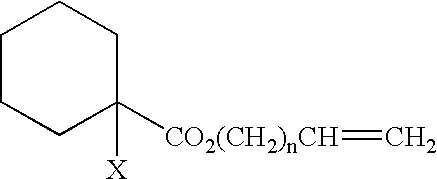

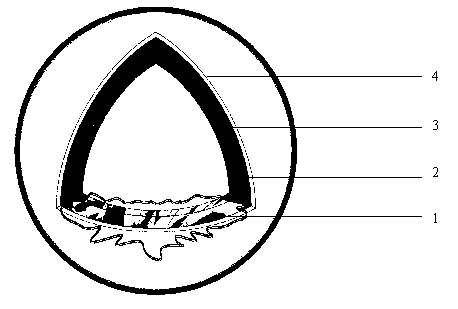

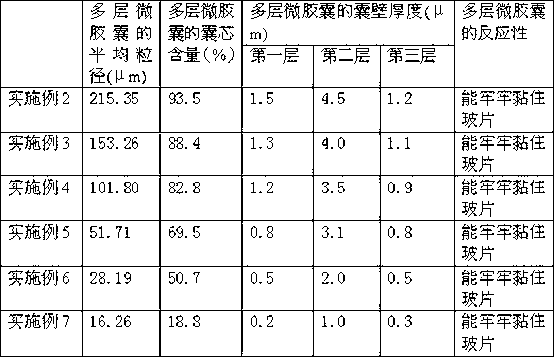

Multilayer microcapsule for self-repair polymer materials and its preparation method

InactiveCN103254372ASimple manufacturing processEliminate residueMicroballoon preparationMicrocapsule preparationMaterials preparationPolymer science

The invention discloses a multilayer microcapsule for self-repair polymer materials and its preparation method. The microcapsule is composed of a capsule core and three layers of capsule wall, wherein the second layer capsule wall material includes an atom transfer radical living polymerization macromolecular initiator and a catalyst, and the capsule core can undergo a room temperature living radical polymerization reaction under initiation of the second layer of capsule wall. Compared with traditional microcapsules, the multilayer microcapsule used for self-repair polymer materials is not only a storage container for reaction substances, but is also a multifunctional intelligent microcapsule integrating monomer and initiator storage, external crack perception, and polymerization reaction stimulation. The multilayer microcapsule disclosed in the invention can be widely applied to preparation of polymer composite materials with a self-repair function, and has the advantages of wide application range of a polymer matrix, strong adaptability of a composite material preparation process, and improvement of the repair efficiency of the composite material. With excellent storage stability, the multilayer microcapsule can realize mass production.

Owner:SUN YAT SEN UNIV

Polymethano-poly(methyl)acrylic ester two-block copolymer and preparation method thereof

The invention discloses a structurally controllable polymethylene / poly(methyl)acrylic esters block copolymer and a preparation method thereof. The preparation method comprises the following steps: using a structurally controllable polymethylene macromolecule initiator having the number average molecular weight capable of being regulated in a certain range(500-1*10<5>g / mol) and the narrow molecular weight distribution (PDI is equal to 1.01-1.49) to initiate the atom radical transfer active free radical polymerization (ATRP) of a (methyl)acrylic esters polymerization monomer; and further preparing the polymethylene / poly(methyl)acrylic esters block copolymer (Mn is equal to *10<3>-1*10<6>g / mol, PDI is equal to1.01-1.50) which enables the molecular weight regulation for both blocks and has the narrow molecular weight distribution. The two-block copolymer can be applied to the blending study of polyolefin and the preparation of a polymer porous membrane as a compatilizer.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com