Resin composition and heat-resistant adhesive

A resin composition, pressure-sensitive adhesive technology, applied in the direction of ester copolymer adhesives, adhesive types, film/sheet adhesives, etc., can solve difficult peeling, contaminated items, poor reactivity same problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

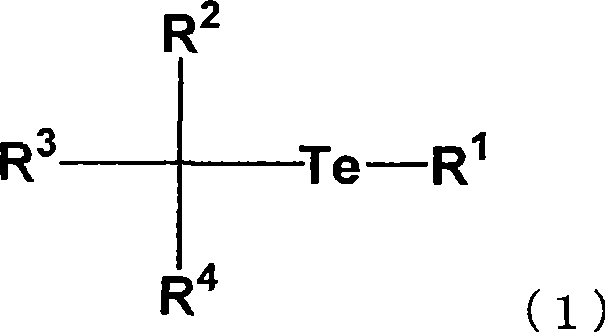

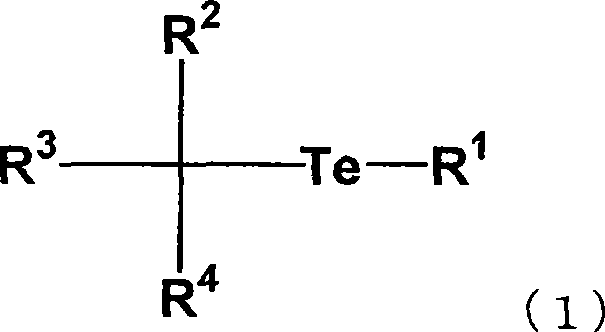

[0155] Synthesis example 1 (ethyl-2-methyl-2-n-butyl tellurium-propionate)

[0156] Metal tellurium [manufactured by Aldrich, trade name: Tellurium (-40 mesh)] 6.38 g (50 mmol) was suspended in THF 50 ml, and n-butyllithium (manufactured by Aldrich, 1.6 M hexyl) was slowly added dropwise (10 minutes) thereto at room temperature. alkane solution) 34.4ml (55mmol). The reaction solution was stirred until the tellurium metal disappeared completely (20 minutes). To this reaction solution was added 10.7 g (55 mmol) of ethyl-2-bromo-isobutyrate at room temperature, followed by stirring for 2 hours. After the reaction, the solvent was concentrated under reduced pressure, followed by distillation under reduced pressure to obtain 8.98 g of a yellow oily substance (59.5% yield).

[0157] pass 1 H-NMR confirmed ethyl-2-methyl-2-n-butyltellurium-propionate.

[0158] 1 H-NMR (500MHz, CDCl 3 )0.93(t, J=7.5Hz, 3H), 1.25(t, J=7.2Hz, 3H), 1.37(m, 2H), 1.74(s, 6H), 1.76(m, 2H), 2.90(t, J=...

Embodiment 1

[0159] Embodiment 1 (poly-n-butyl acrylate-copoly-polyhydroxyethyl methacrylate)

[0160] In a glove box replaced with argon, 63.8 μL (0.28 mmol) of ethyl-2-methyl-2-n-butyltellurium-propionate produced in Synthesis Example 1, n-butyl acrylate [Tokyo Chemical Co., Ltd. for distillation and purification] 154 mL (1.08 mol), 2-hydroxyethyl methacrylate [Sigma Aldrich Japan Co., Ltd.] 4 mL (32.9 mmol) and 2,2'-Azo 4.6 mg (0.03 mmol) of bis(isobutyronitrile) [manufactured by Otsuka Chemical Co., Ltd., trade name: AIBN] was reacted for 20 hours. According to NMR analysis, the polymerization rate was 94.4%.

[0161] After completion of the reaction, the reactor was taken out from the glove box, dissolved in 500 mL of ethyl acetate, and the polymer solution was passed through a column made of activated alumina (manufactured by Wako Pure Chemical Industries, Ltd.). Ethyl acetate was added to bring the viscosity of the polymer solution to 5000 mPa·S (25°C). The solid content of the o...

Embodiment 2

[0167] To 100 parts by weight of the polymer solution obtained in Example 1 in terms of solid content, 2 parts of Coronet L-55E (same as above) was added as a crosslinking agent in terms of solid content, and stirred to obtain a pressure-sensitive adhesive. combination.

[0168] This was applied on a PET film so that the thickness after drying would be 25 μm, and dried at 105° C. for 2 minutes to prepare an adhesive film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com