Styrene-acrylic waterproof latex and preparation method thereof

A waterproof emulsion, styrene-acrylic technology, applied in the coating and other directions, can solve the problems of difficulty in balancing tensile strength and elongation at break, poor affinity between polymers and cement, microstructure defects, etc., to achieve moderate consistency, The effect of stable product quality and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

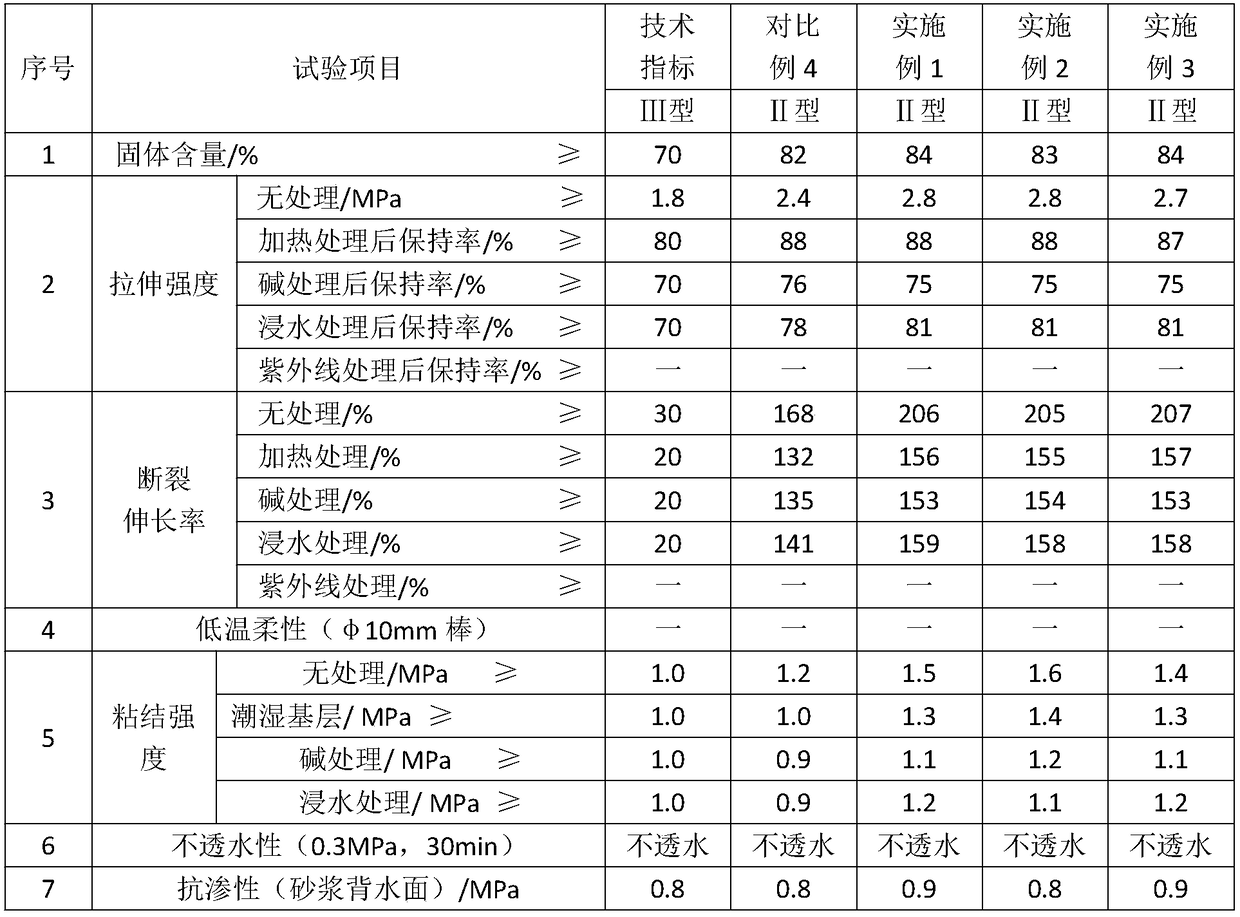

Examples

Embodiment 1

[0029] A styrene-acrylic waterproof emulsion comprises the following raw materials in parts by weight: 25 parts of styrene, 15 parts of methyl methacrylate, 15 parts of methyl acrylate, 45 parts of butyl acrylate, 0.6 part of acrylic acid, 1.5 parts of acrylamide, dodecane 2 parts of sodium base sulfate, 1.0 part of sodium persulfate, and 0.5 parts of buffering agent sodium bicarbonate.

[0030] The preparation method of described styrene-acrylic waterproof emulsion comprises the following steps:

[0031] (1) Stir and mix sodium lauryl sulfate and deionized water at room temperature (25°C) at a speed of 250rpm, and then add the above-mentioned parts by weight of styrene, methyl methacrylate, methyl acrylate, and butyl acrylate , acrylic acid, acrylamide with a total amount of 65%, and simultaneously open the agitator to stir at a speed of 250 rpm to obtain a pre-emulsion;

[0032] (2) Add buffer and deionized water to the reactor, stir and heat up to 80°C, then add 15% of the...

Embodiment 2

[0037] A styrene-acrylic waterproof emulsion comprises the following raw materials in parts by weight: 30 parts of styrene, 18 parts of methyl methacrylate, 20 parts of methyl acrylate, 50 parts of butyl acrylate, 0.8 part of acrylic acid, 2.0 parts of acrylamide, dodecane 3 parts of diphenyl ether disulfonic acid sodium salt, 1.5 parts of potassium persulfate, and 0.8 parts of buffering agent sodium bicarbonate.

[0038] The preparation method of described styrene-acrylic waterproof emulsion comprises the following steps:

[0039] (1) Stir and mix dodecyl diphenyl ether disulfonic acid sodium salt and deionized water at a speed of 260rpm at room temperature (25°C), and then add the above-mentioned parts by weight of styrene, methyl methacrylate, acrylic acid Methyl ester, butyl acrylate, acrylic acid, and acrylamide with a total amount of 70% are simultaneously turned on and stirred at a speed of 260 rpm to obtain a pre-emulsion;

[0040] (2) Add buffer and deionized water to ...

Embodiment 3

[0045] A styrene-acrylic waterproof emulsion comprises the following raw materials in parts by weight: 20 parts of styrene, 10 parts of methyl methacrylate, 12 parts of methyl acrylate, 40 parts of butyl acrylate, 0.2 part of acrylic acid, 1.0 part of acrylamide, alkylphenol 1.0 parts of polyoxyethylene ether, 0.5 parts of ammonium persulfate, and 0.2 parts of buffering agent sodium bicarbonate.

[0046] The preparation method of described styrene-acrylic waterproof emulsion comprises the following steps:

[0047] (1) At room temperature (25°C), stir and mix the alkylphenol polyoxyethylene ether and deionized water at a speed of 200rpm, and then add the above-mentioned parts by weight of styrene, methyl methacrylate, methyl acrylate, and butyl acrylate Ester, acrylic acid, acrylamide with a total amount of 60%, and simultaneously turn on the stirrer to stir at a speed of 200rpm to obtain a pre-emulsion;

[0048] (2) Add buffer and deionized water to the reaction kettle, stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com