Three-stage gasification device for producing synthesis gas through biomass pyrolysis and gasification

A technology of pyrolysis gasification and biomass, which is applied to the gasification of granular/powdered fuels, chemical industry, and the manufacture of combustible gases. It can solve the problems of complex gasification systems and devices, sensitive physical properties, and difficult operation control. Achieve the effects of simple structure, lower tar content, and convenient temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

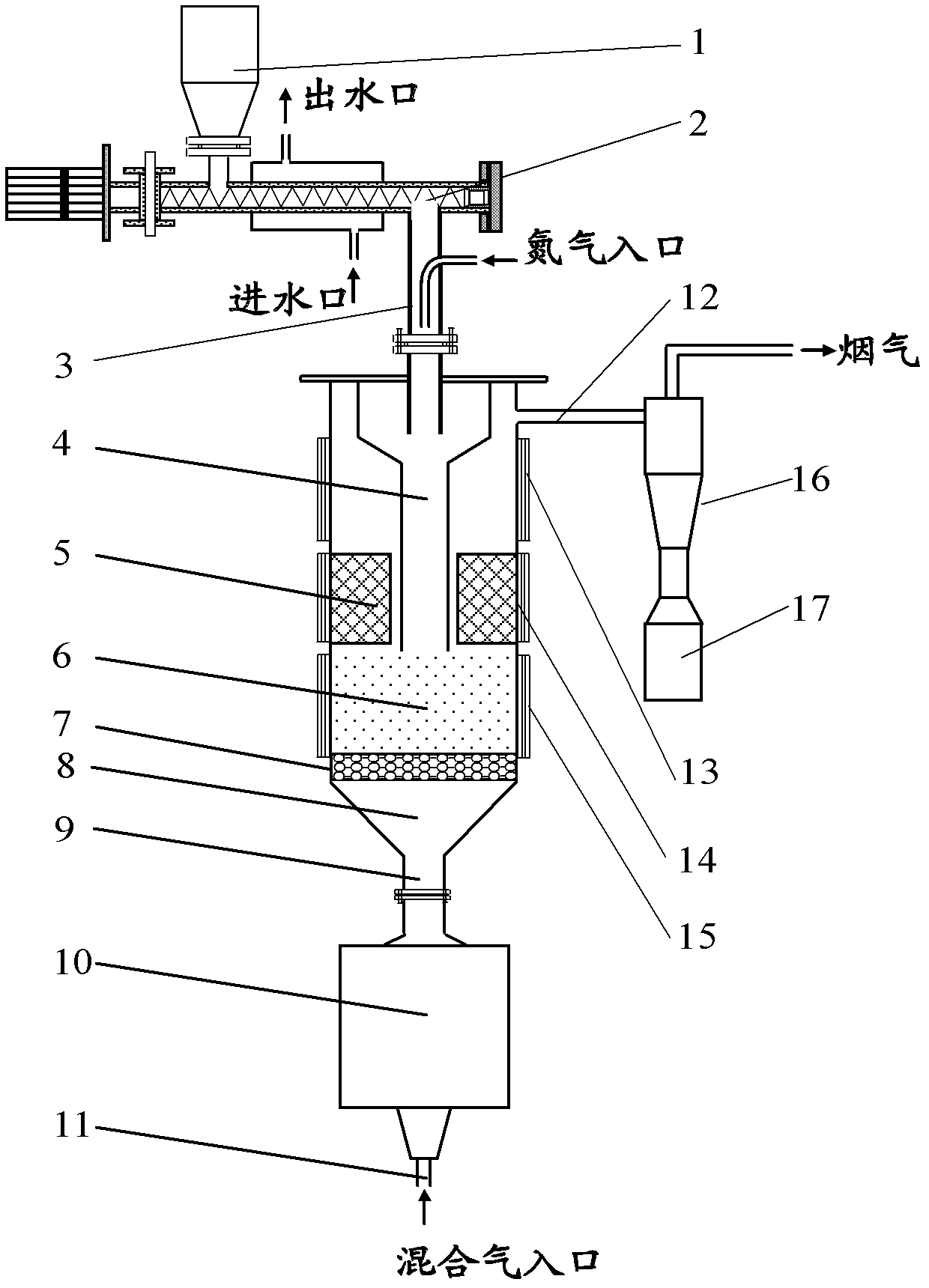

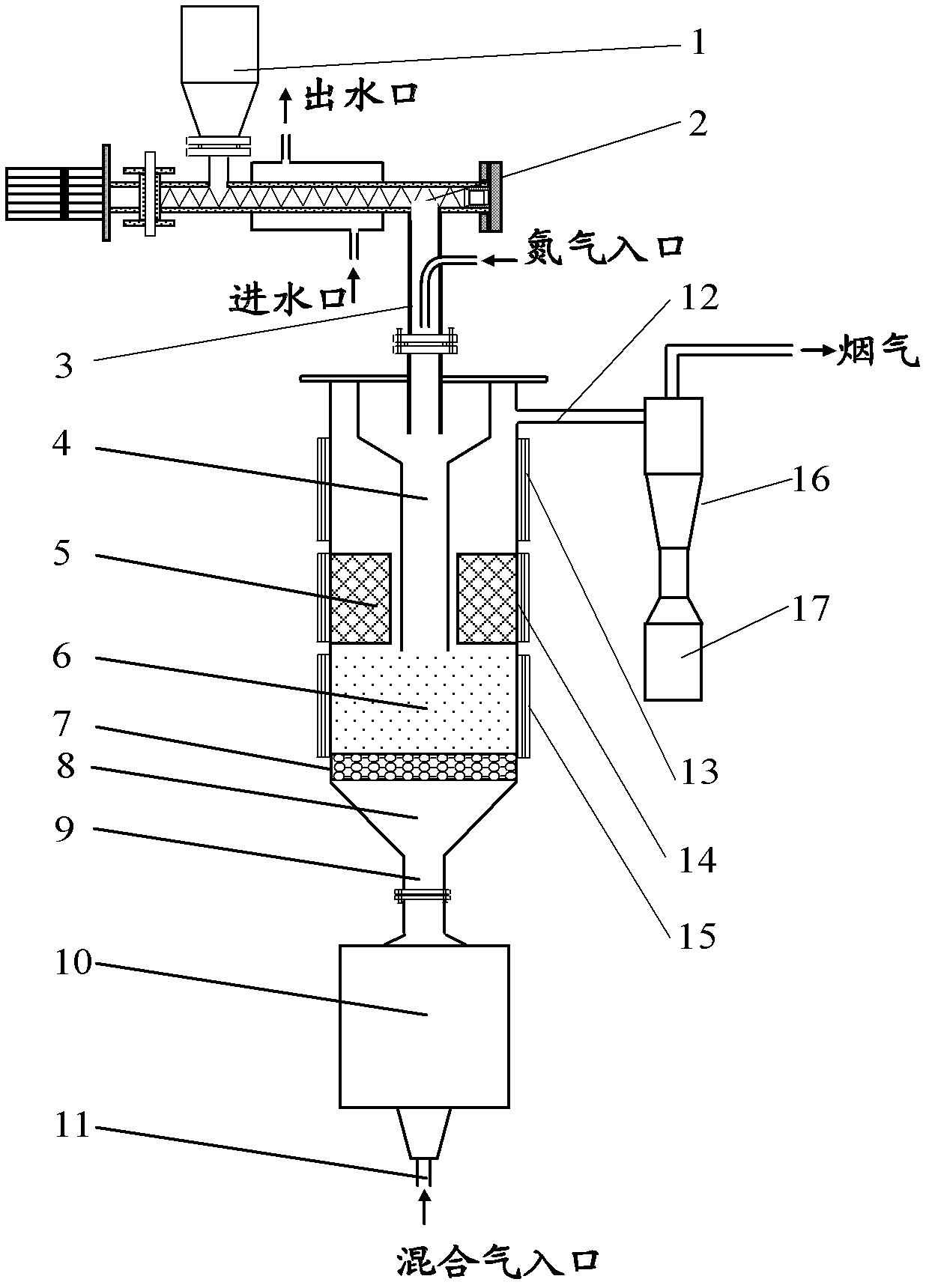

[0021] As shown in Figure 1, the novel three-stage pyrolysis gasification synthesis gas preparation device of the present invention includes a reaction furnace, the cylindrical lining of the reaction furnace is made of silicon carbide or corundum, and the reaction furnace includes an upper pyrolysis furnace [4], the gasification furnace in the lower section [6] and the inner annular catalyst bed in the middle section [5]. A screw feeding device is arranged on the upper part of the pyrolysis furnace [4], and the screw feeding device includes a biomass hopper [1], a screw feeder [2] and a feeding pipe [3] of the feeder, and the lower feeding pipe [3]. The feed pipe [3] is inserted into the upper pyrolysis furnace [4] of the pyrolysis gasification device, and the feed pipe [3] is provided with a nitrogen inlet. A tapered conical pipe section is set in the middle section of the upper pyrolysis furnace [4], and the angle formed with the upper pipe wall is 45° to ensure the smooth f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com