Method for gasifying pulverized coal step by step in double beds connected in series

A pulverized coal and coal gas technology, applied in the field of step-by-step gasification of pulverized coal in series twin beds, can solve the problems of high fine ash content, low carbon conversion rate, and pyrolysis products in crude gas, and avoid fly ash collection and oil content Effect of wastewater treatment process, content reduction, and improvement of coal type applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

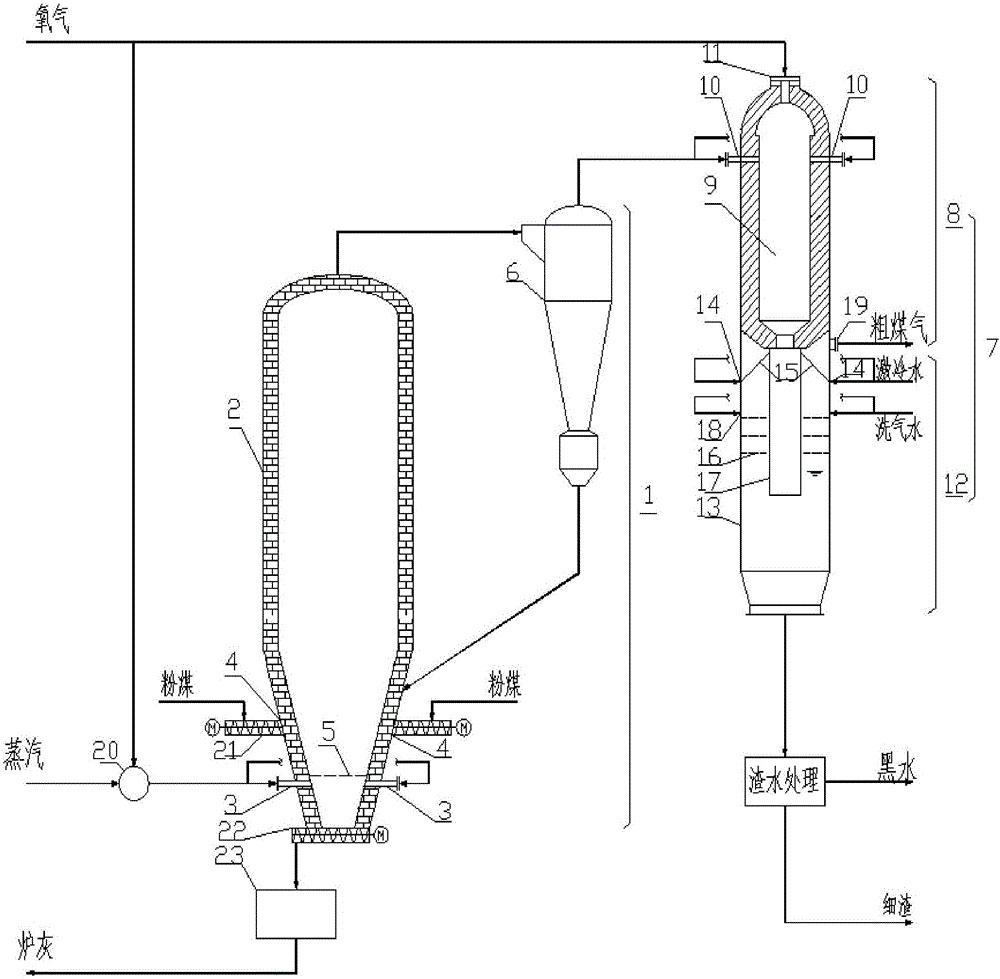

[0024] Such as figure 1 As shown, the circulating fluidized bed (1) is composed of a gasifier body (2), a gasification agent inlet (3), a pulverized coal inlet (4), an air distribution device (5), and a return cyclone separator (6). The gasifier body (2) is lined with refractory materials, the gasification agent inlet (3) is located at the lower part of the gasifier body (2), and the pulverized coal inlet (4) is located at the upper part of the gasification agent inlet (3). The gasifier body (2) is lined with a refractory material, and four gasification agent inlets are arranged around the gasifier at an angle of 90°.

[0025] The entrained bed (7) gasifier includes two parts, a combustion section (8) and a quenching section (12). The combustion section is composed of the gasifier hearth (9), the dusty gas inlet (10), and the oxygen nozzle (11), and the quenching section is composed of the gasifier shell (13), the quenching water inlet (14), the quenching water distributor (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com