Method for preparing naringin or hesperidin

A technology for hesperidin and naringin, which is applied in the field of preparation of naringin or hesperidin, can solve the problem of large solvent consumption, large and long loss in the operation process, reflux time of several hours to ten hours, and immersion The extraction time is at least half an hour, and it can take more than ten hours to achieve the effect of simple post-processing concentration, remarkable advancement, and simple purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

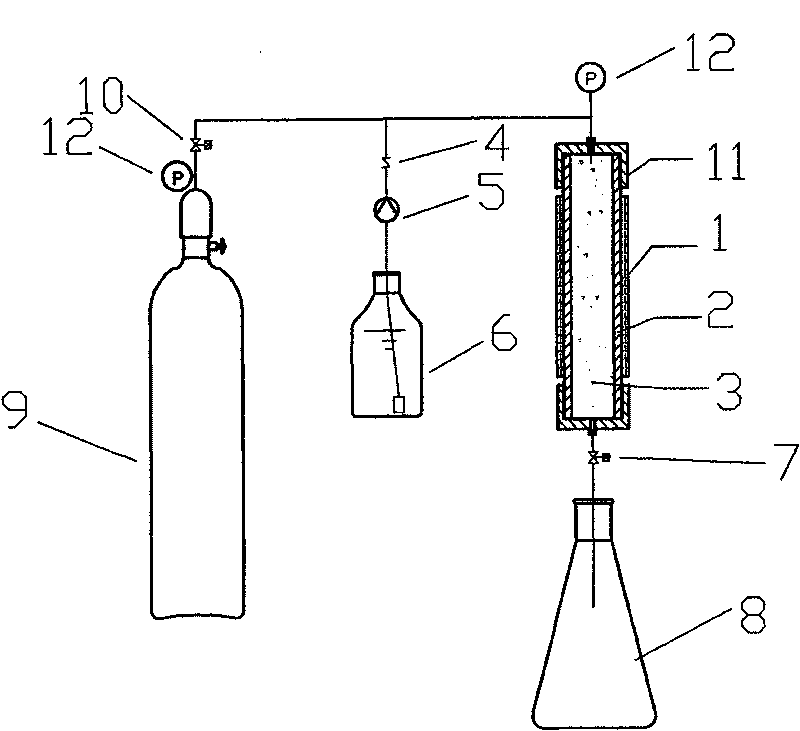

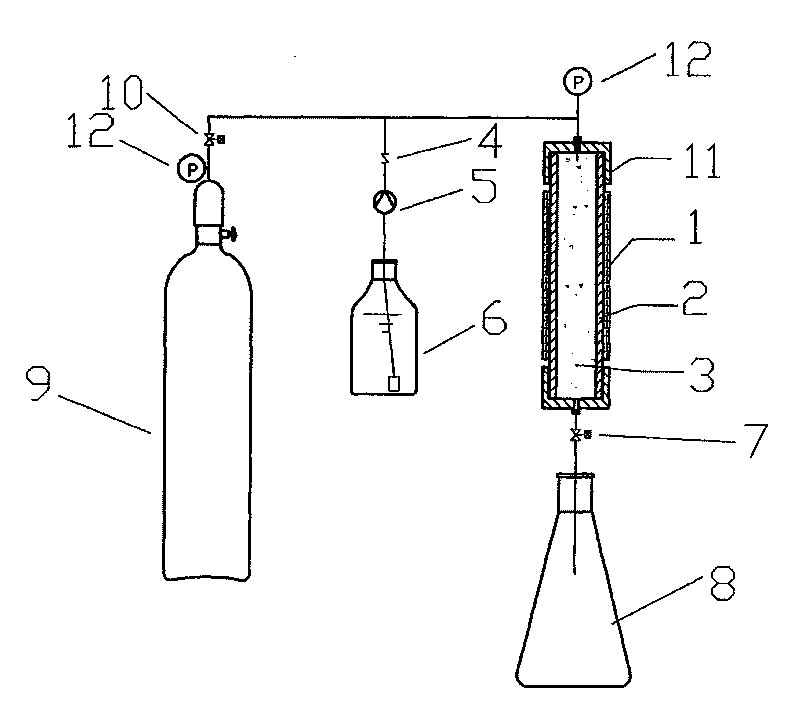

[0018] A kind of preparation method of naringin or hesperidin of the present invention, such as figure 1 As shown, the fruits or peels and pomace containing naringin or hesperidin are dried, pulverized, and sieved respectively, and the crushed and sieved extraction materials 3 are respectively loaded into a high-pressure extraction machine with a heating jacket 1. In the still 2; set the extraction pressure and extraction temperature, the heating jacket 1 starts to heat up, open the check valve 4, and use the high-pressure solvent pump 5 to pump the extraction solvent in the solvent tank 6 into the high-pressure extraction still 2. Open the electric valve 7 below the high-pressure extraction kettle 2, and collect the extract in the extract collection bottle 8. At the end of the extraction, open the electric valve 10 above the nitrogen bottle 9, and use the nitrogen in the nitrogen bottle 9 to blow out all the extract in the high-pressure extraction kettle 2 into the extract co...

Embodiment 1

[0021] Put 4.5 grams of pulverized pomelo peel powder into the extraction kettle, set the extraction pressure to 50 bar, the extraction temperature to 60°C, statically extract with absolute ethanol for 10 minutes, and extract continuously for 5 times. Combine the extracts, concentrate the extracts to one-fifth of the original volume in a vacuum concentrator, filter the insoluble matter with filter paper, adjust the pH of the filtered clear liquid to about 5 with acetic acid, cool and crystallize in a refrigerator, and filter the crystals to obtain Crude naringin. The crude naringin is recrystallized twice with 95% ethanol to obtain naringin with a purity greater than 91%.

Embodiment 2

[0023] Put 6 grams of pulverized pomelo peel powder into the extraction kettle, set the extraction pressure to 50 bar, the extraction temperature to 75° C., statically extract with 95% ethanol aqueous solution for 10 minutes, and extract continuously for 3 times. Combine the extracts, concentrate the extracts to one-fifth of the original volume in a decompression concentrator, remove insolubles by filtering through a 0.45 μ filter membrane, adjust the pH of the filtered clear liquid to about 5 with 10% hydrochloric acid solution, and place Cool and crystallize in the refrigerator, and filter the crystals to obtain crude naringin. Crude naringin is finely ground, washed with ethyl acetate until colorless, and recrystallized twice with 95% ethanol to obtain naringin with a purity greater than 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com