Device and method for polishing sapphire substrate material by ultrasound assisted chemical machinery

A sapphire substrate and chemical mechanical technology, applied in the field of polishing sapphire substrate materials, can solve the problems of lack of in-depth understanding of CMP mechanism, insufficient surface quality, low material removal rate, etc., to improve polishing efficiency and quality, reduce Polishing cost and time, simple effect of process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

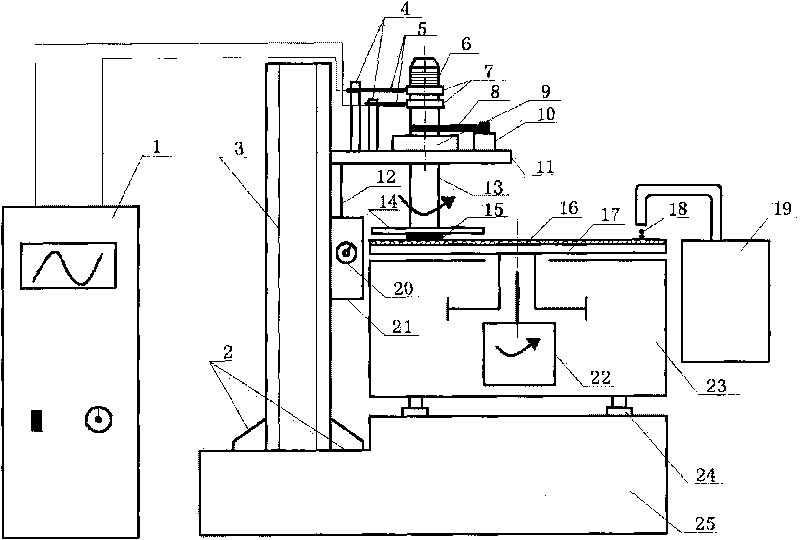

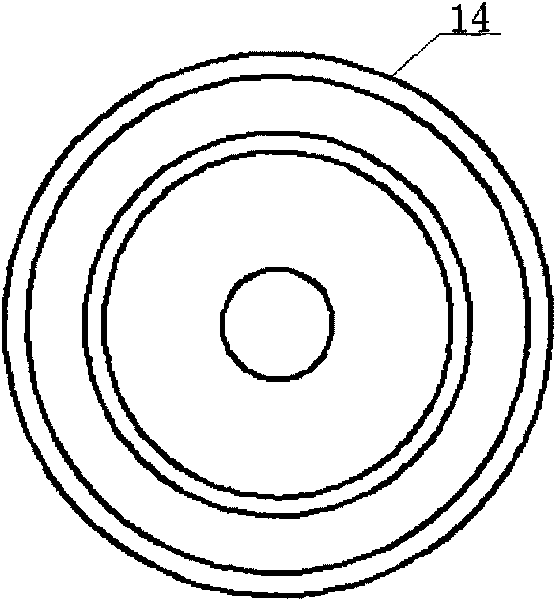

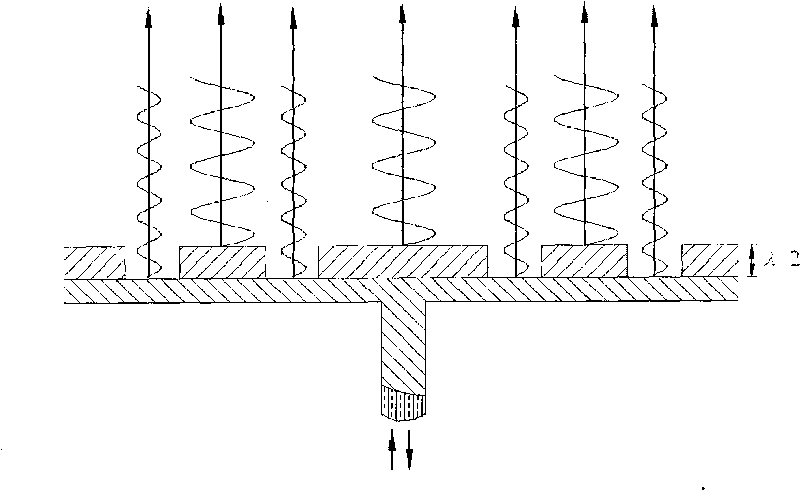

[0025] A device for ultrasonic-assisted chemical-mechanical polishing of sapphire substrate materials, the schematic diagram of which is shown in figure 1 As shown, the ultrasonic power supply control box 1 is connected to the carbon brush 5 installed on the carbon brush bracket 4 through wires, and the carbon brush 5 connects the positive and negative poles of the ultrasonic power supply to the positive and negative poles of the ultrasonic transducer 6 through a conductive copper slip ring 7 , the ultrasonic transducer 6 is made of a piezoelectric ceramic sheet and an insulating sheet, the ultrasonic transducer 6 is connected with the horn 13 by threads, the polishing head 14 is fixed on the lower end of the horn 13; the horn 13 passes through the rolling bearing 9 Through the support plate 11, the outer ring of the rolling bearing 9 is fixed on the support plate 11 by scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com