Dynamic demonomerization and defoaming method and device for carbon fiber spinning solution

A spinning liquid and carbon fiber technology, which is applied in the field of carbon fiber spinning liquid dynamic desingling and degassing method and its device, can solve the problems of large footprint, low desingling and degassing efficiency, high viscosity of spinning liquid, etc. Good foaming effect, improved defoaming effect, simple and practical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

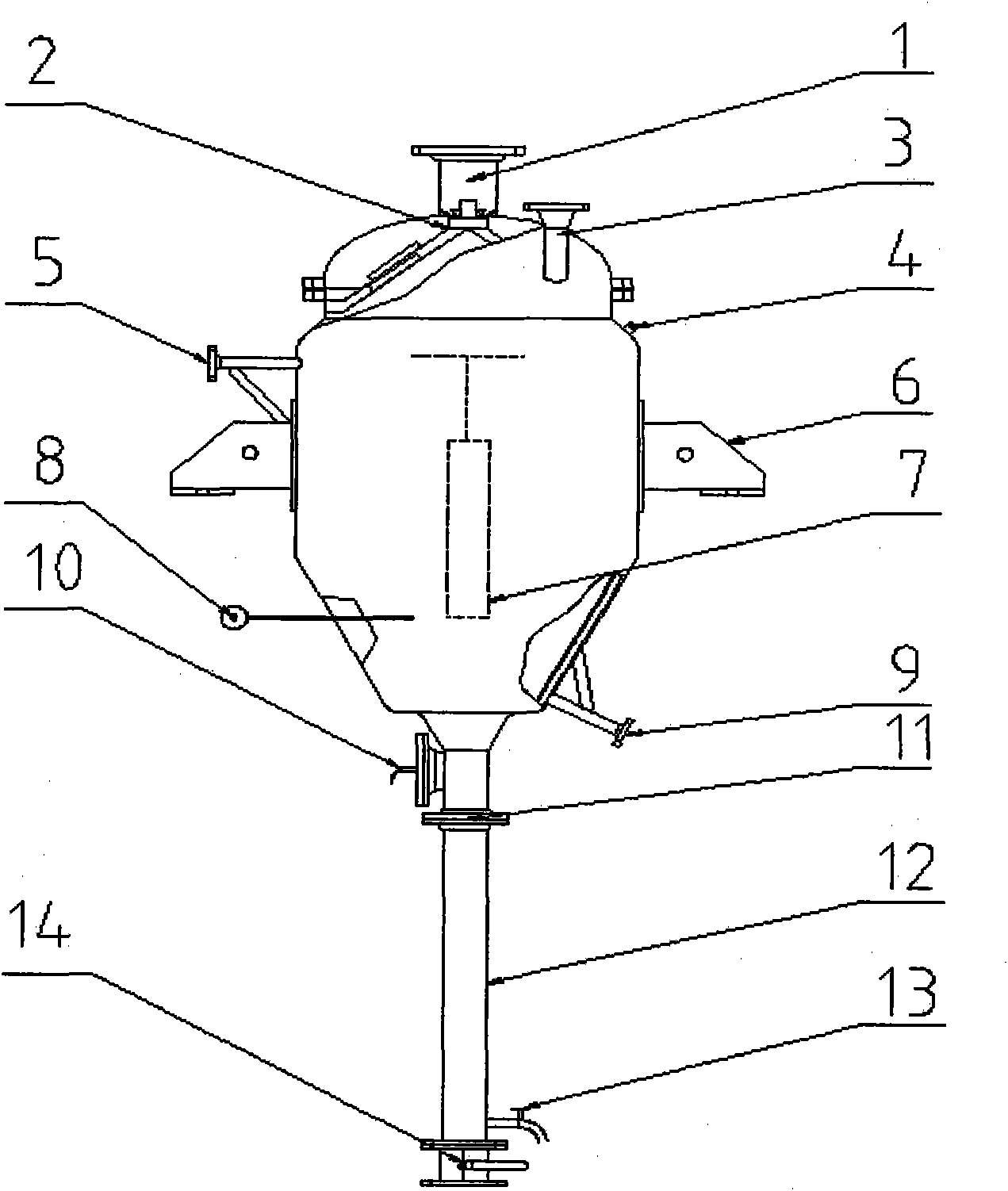

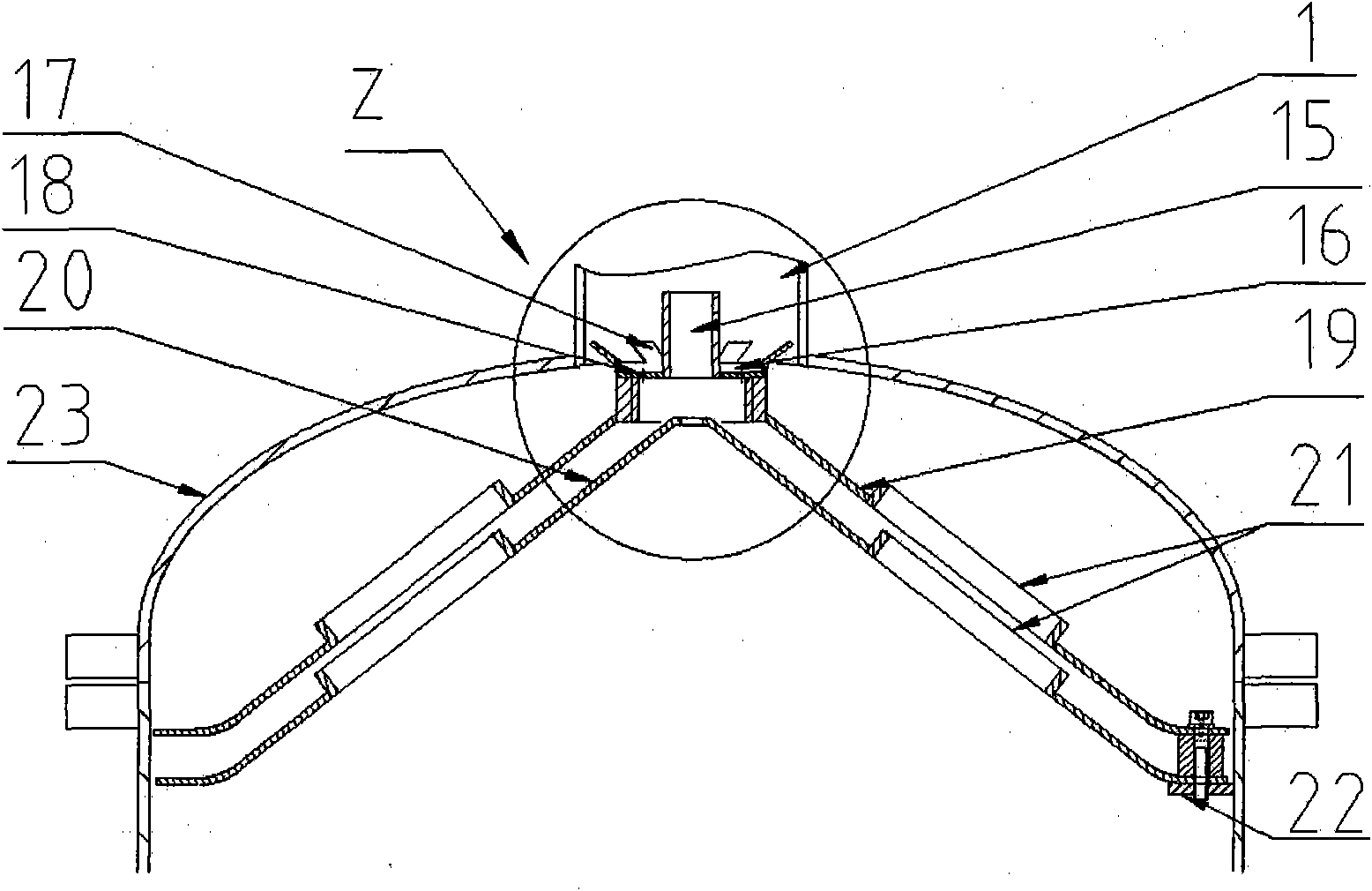

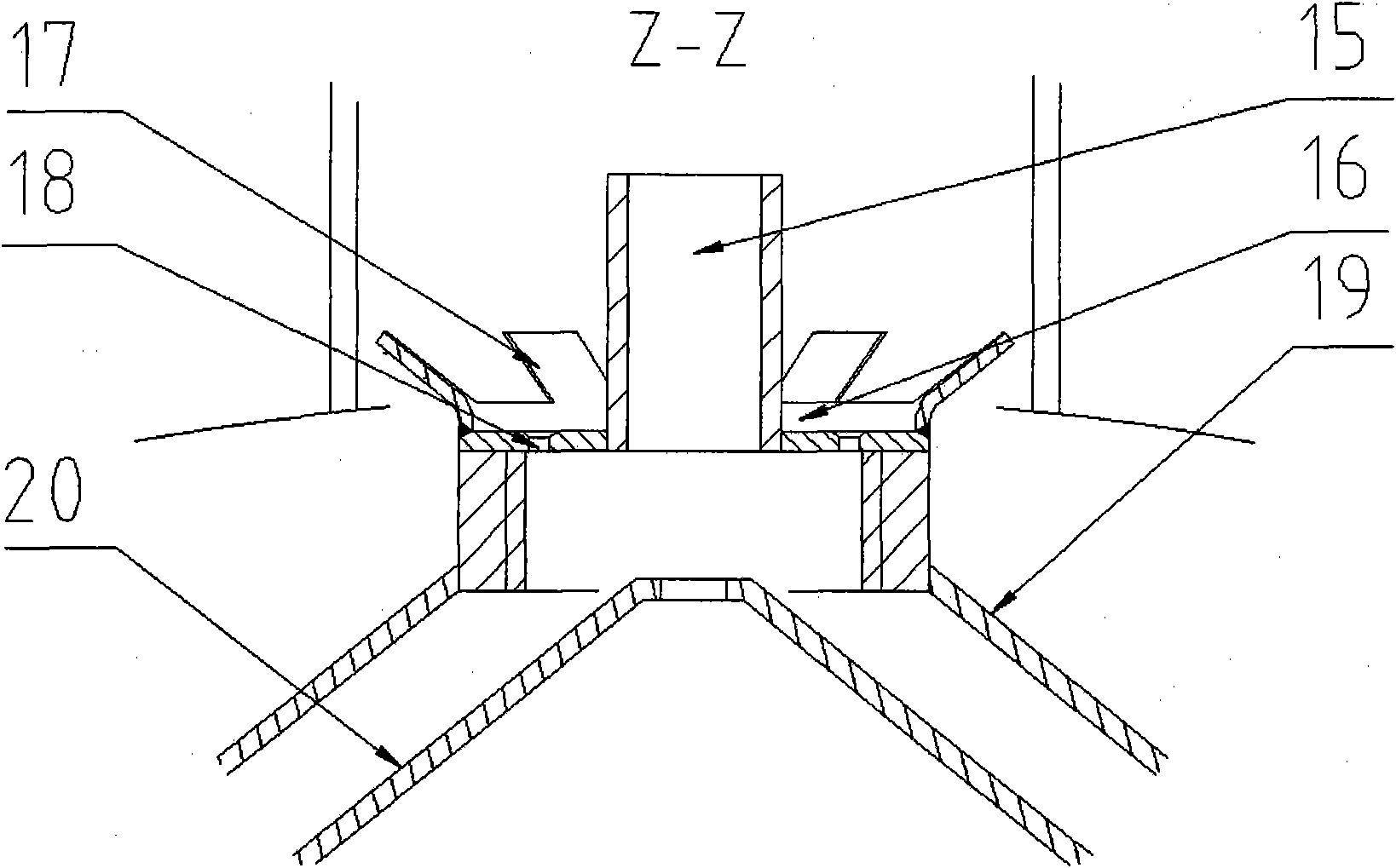

[0035] This embodiment is a method for dynamic desingling and degassing of carbon fiber spinning liquid, and its specific process includes the following steps:

[0036] Step 1: Heating the unit removal and degassing device; start the hot water circulation system and the vacuum system to heat the unit removal and degassing device to 45°C, the vacuum degree is -98kPa; the rotation speed of the unit removal tower is 750r / min.

[0037] Step 2, feeding; start the feeding pump and mass flow meter, and continuously feed the spinning solution into the single removal tower at a feeding rate of 36L / h.

[0038] Step 3: Gravity de-singulation and degassing; the spinning liquid is expanded and flows in the de-singulation tower at a temperature of 45°C, and is evenly flung onto the tower wall under the centrifugal force of the distribution plate of the de-singulation tower, and is slanted at the same time The scraper is scraped into a film with a thickness of 1.5mm to 2.0mm; the produced fi...

Embodiment 2

[0044] This embodiment is a method for dynamic desingling and degassing of carbon fiber spinning liquid, and its specific process includes the following steps:

[0045] Step 1: Heating the unit removal and degassing device; start the hot water circulation system and the vacuum system to heat the unit removal and degassing device to 50°C, the vacuum degree is -95kPa; the rotation speed of the unit removal tower is 500r / min.

[0046] Step 2, feeding; start the feeding pump and mass flow meter, and continuously feed the spinning solution into the single removal tower at a feeding rate of 35L / h.

[0047] Step 3, gravity de-singulation and degassing; the spinning liquid is expanded and flows in the de-singulation tower at a temperature of 50°C, and is evenly flung onto the tower wall under the centrifugal force of the distribution plate of the de-singulation tower, and is slanted at the same time The scraper is scraped into a film with a thickness of 1.5mm to 2.0mm; the produced film...

Embodiment 3

[0053] This embodiment is a method for dynamic desingling and degassing of carbon fiber spinning liquid, and its specific process includes the following steps:

[0054] Step 1: Heating the unit removal and degassing device; start the hot water circulation system and the vacuum system to heat the unit removal and degassing device to 55°C, the vacuum degree is -90kPa; the rotation speed of the unit removal tower is 340r / min.

[0055] Step 2, feeding; start the feeding pump and mass flow meter, and continuously feed the spinning solution into the single removal tower at a feeding rate of 34L / h.

[0056] Step 3: Gravity de-singulation and degassing; the spinning liquid is expanded and flows in the de-singulation tower at a temperature of 55°C, and is evenly flung onto the tower wall under the centrifugal force of the distribution plate of the de-singulation tower, and is slanted at the same time The scraper is scraped into a film with a thickness of 1.5mm to 2.0mm; the produced fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com