Device and method for decomposing rare earth ore through sulfuric acid low-temperature dynamic roasting

A rare earth ore and sulfuric acid technology, applied in the field of rare earth ore roasting and decomposition, can solve the problems of energy saving and emission reduction, environmental pollution, high investment in exhaust gas treatment equipment, and high sulfuric acid fumes content, so as to save auxiliary material consumption, less floor space, The effect of less investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Step 1, through the continuous quantitative feeder 2 and the sulfuric acid flow meter 7 to control the addition of rare earth ore and sulfuric acid, the rare earth ore to be decomposed and concentrated sulfuric acid with a mass concentration of more than 93% are added to the double helix at a mass ratio of 1:1 In the continuous mixer 3, fully mix to form a semi-dry bulk material;

[0046] Step 2: Add the material described in step 1 into the kiln body 4 through the feeding pipe 8, adjust the temperature in the kiln body to 200°C through the combustion chamber 5, and adjust the residence time of the material to 4 hours at the same time through the turning rate of the material turning system 10 , so that the material is fully decomposed, and the decomposed material is discharged into the immersion tank through the discharge pipe 11 for subsequent processing; the combustion chamber 5 uses gas as fuel;

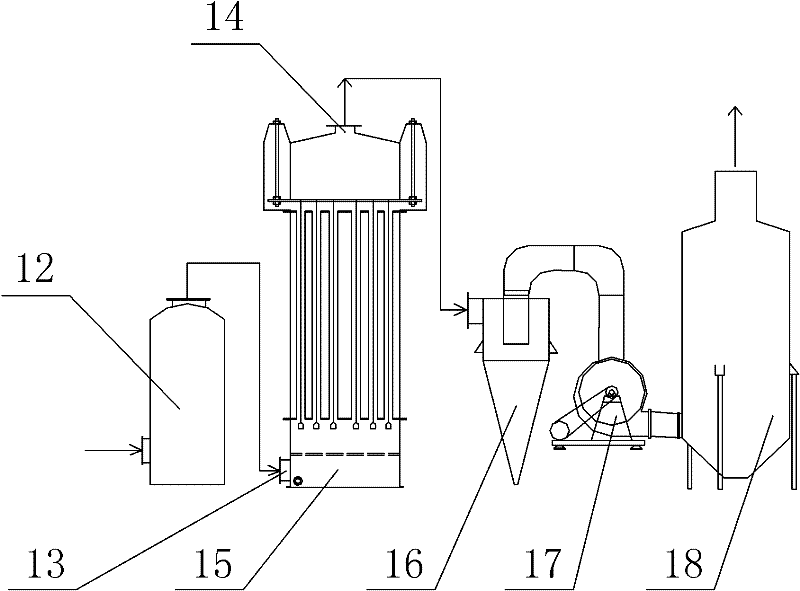

[0047] Step 3: The exhaust gas produced by roasting and decomposing ra...

Embodiment 2

[0050] Step 1, through the continuous quantitative feeder 2 and sulfuric acid flow meter 7 to control the addition of rare earth ore and sulfuric acid, the rare earth ore to be decomposed and concentrated sulfuric acid with a mass concentration of more than 93% are added to the double helix at a mass ratio of 1.5:1 In the continuous mixer 3, fully mix to form a semi-dry bulk material;

[0051] Step 2: Add the material described in step 1 into the kiln body 4 through the feeding pipe 8, adjust the temperature in the kiln body to 600°C through the combustion chamber 5, and adjust the residence time of the material to 2 hours at the same time through the turning rate of the material turning system 10 , so that the material is fully decomposed, and the decomposed material is discharged into the immersion tank through the discharge pipe 11 for subsequent processing; the combustion chamber 5 uses natural gas as fuel;

[0052] Step 3: The exhaust gas produced by roasting and decompos...

Embodiment 3

[0055] Step 1, through the continuous quantitative feeder 2 and the sulfuric acid flow meter 7 to control the addition of rare earth ore and sulfuric acid, the rare earth ore to be decomposed and concentrated sulfuric acid with a mass concentration of more than 93% are added to the double helix at a mass ratio of 1.2:1 In the continuous mixer 3, fully mix to form a semi-dry bulk material;

[0056] Step 2: Add the material described in step 1 into the kiln body 4 through the feeding pipe 8, adjust the temperature in the kiln body to 400°C through the combustion chamber 5, and adjust the residence time of the material to 3 hours at the same time through the turning rate of the material turning system 10 , so that the material is fully decomposed, and the decomposed material is discharged into the immersion tank through the discharge pipe 11 for subsequent processing; the combustion chamber 5 uses bituminous coal as fuel;

[0057] Step 3: The exhaust gas produced by roasting and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com