Incineration treatment device for nitrogen-containing organic wastes and incineration treatment process

An organic waste and treatment device technology, applied in incinerators, combustion methods, combustion types, etc., can solve the problem of uneven distribution of flow field and temperature field in the furnace, low nitrogen oxide emission concentration efficiency, thermal nitrogen oxides There are many problems, to achieve the effect of reducing the generation of thermal nitrogen oxides, reducing temperature, reducing investment costs and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

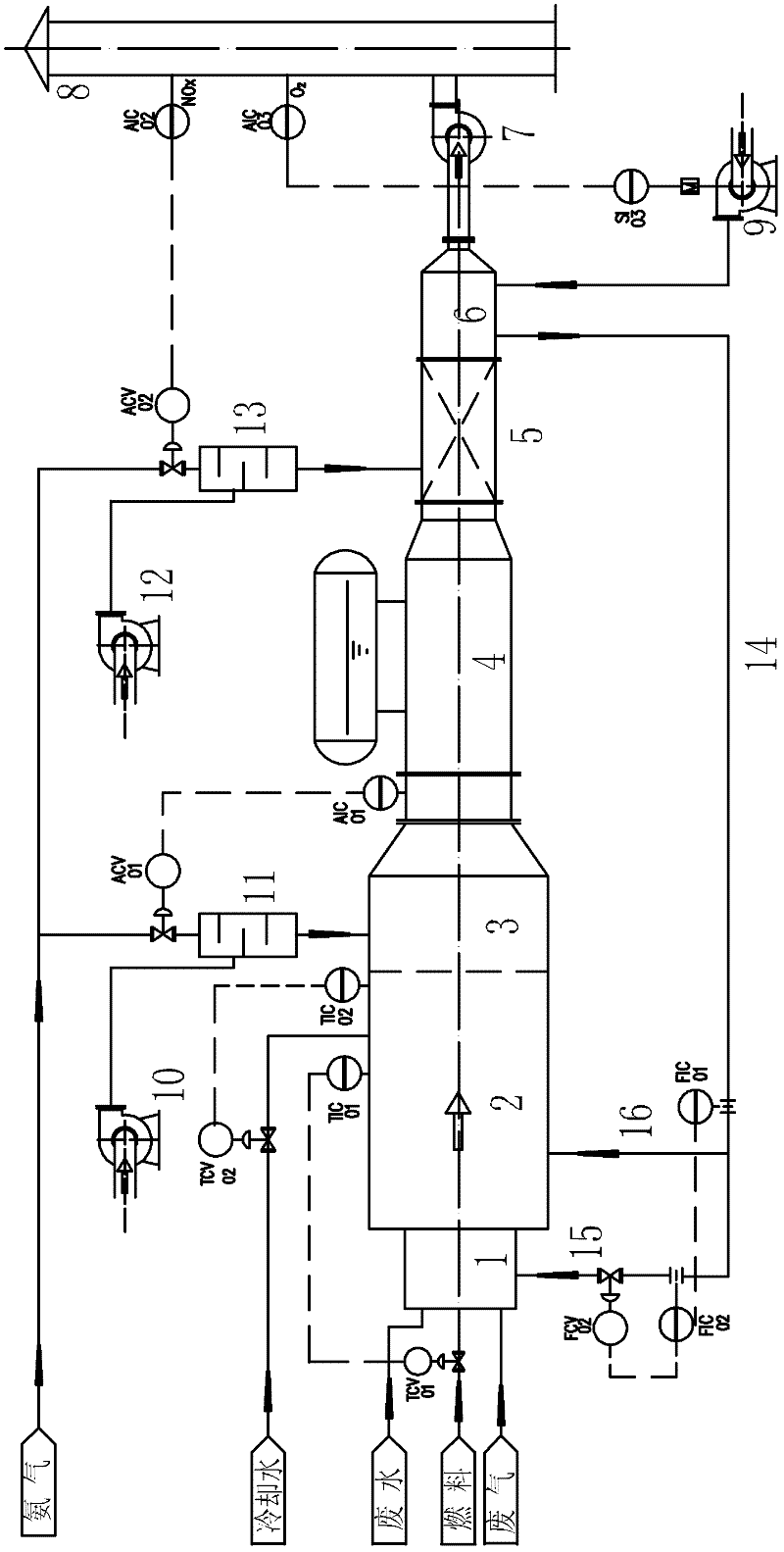

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

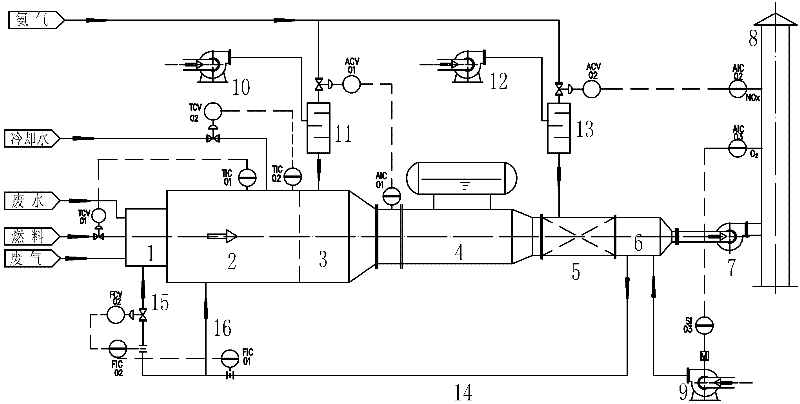

[0022] As shown in the accompanying drawings, the present invention is used for the incineration treatment device of nitrogen-containing organic waste, including a burner 1, a thermal oxidation furnace 2, a waste heat boiler 4, a selective catalytic reduction SCR processor 5, and an air preheater 6 connected in series. , an induced draft fan 7, a chimney 8 and a furnace pressure control circuit, the furnace pressure control circuit includes a pressure measuring point arranged at the front portion of the furnace of the thermal oxidation furnace 2 and a variable frequency motor connected with the induced draft fan 7 to form , adjust the frequency of the induced draft fan motor through this pressure measuring point, so as to ensure that the furnace has a certain negative pressure. The tail of the thermal oxidation furnace 2 is provided with a selective non-catal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com