Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Reduce nitrogen oxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

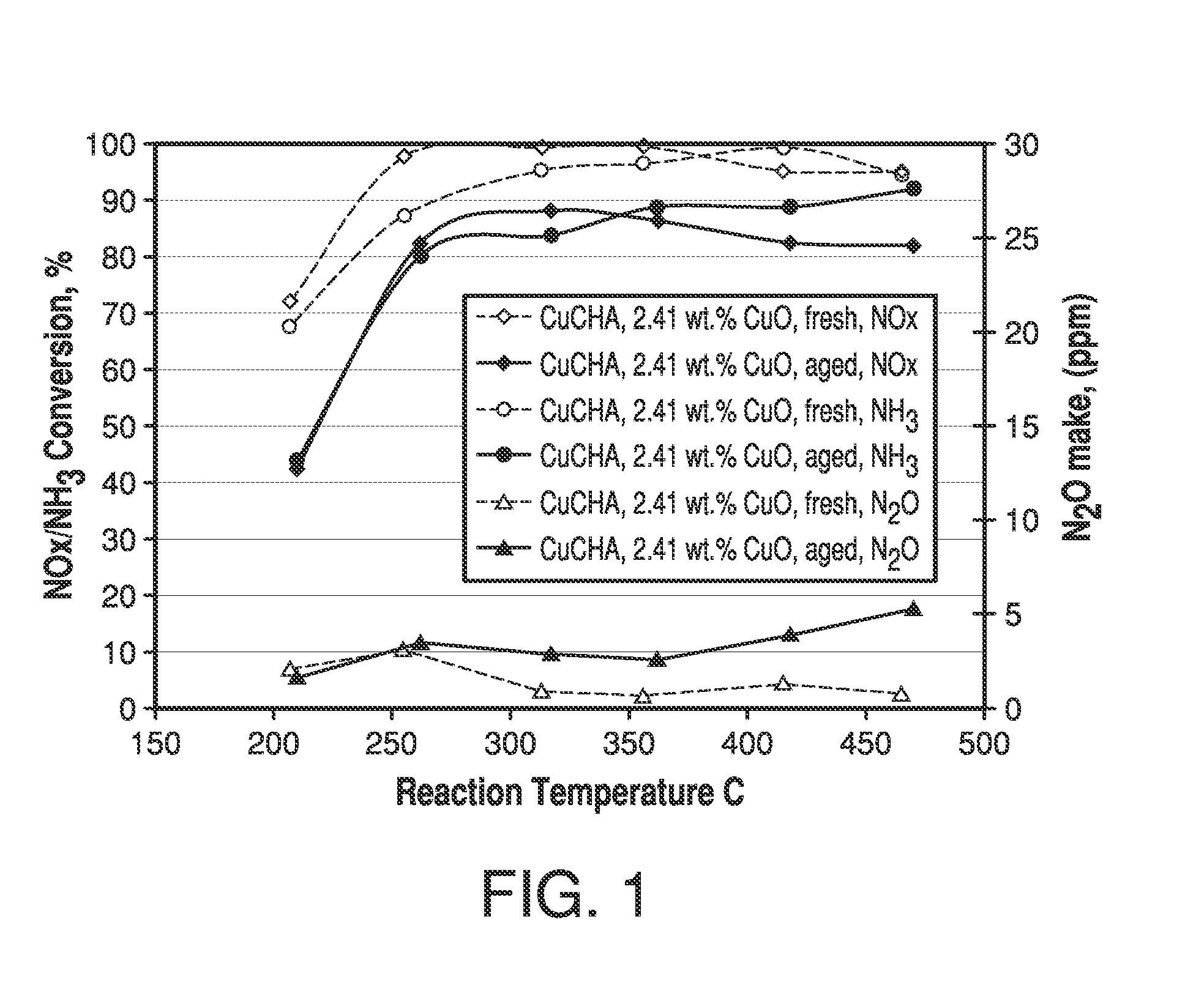

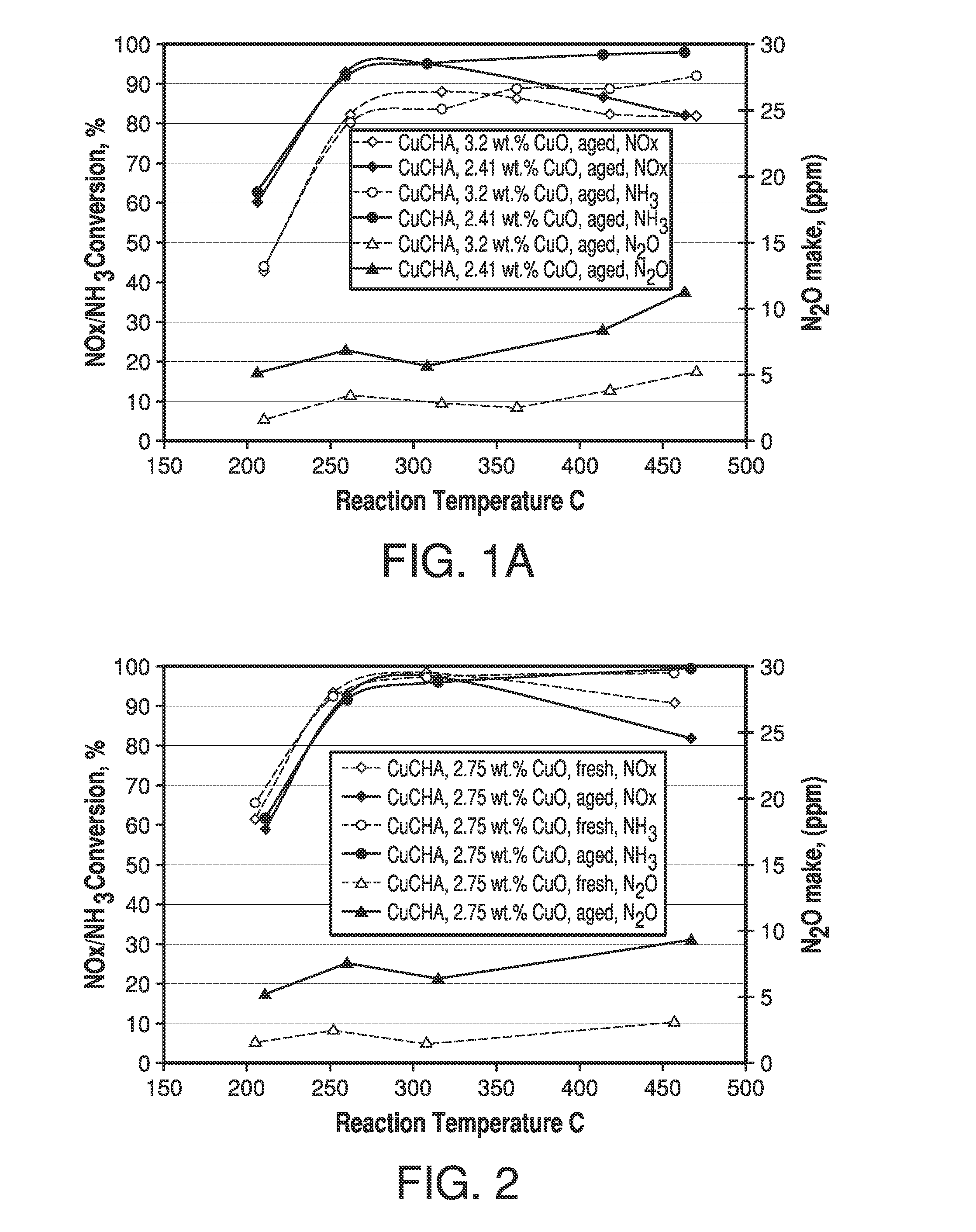

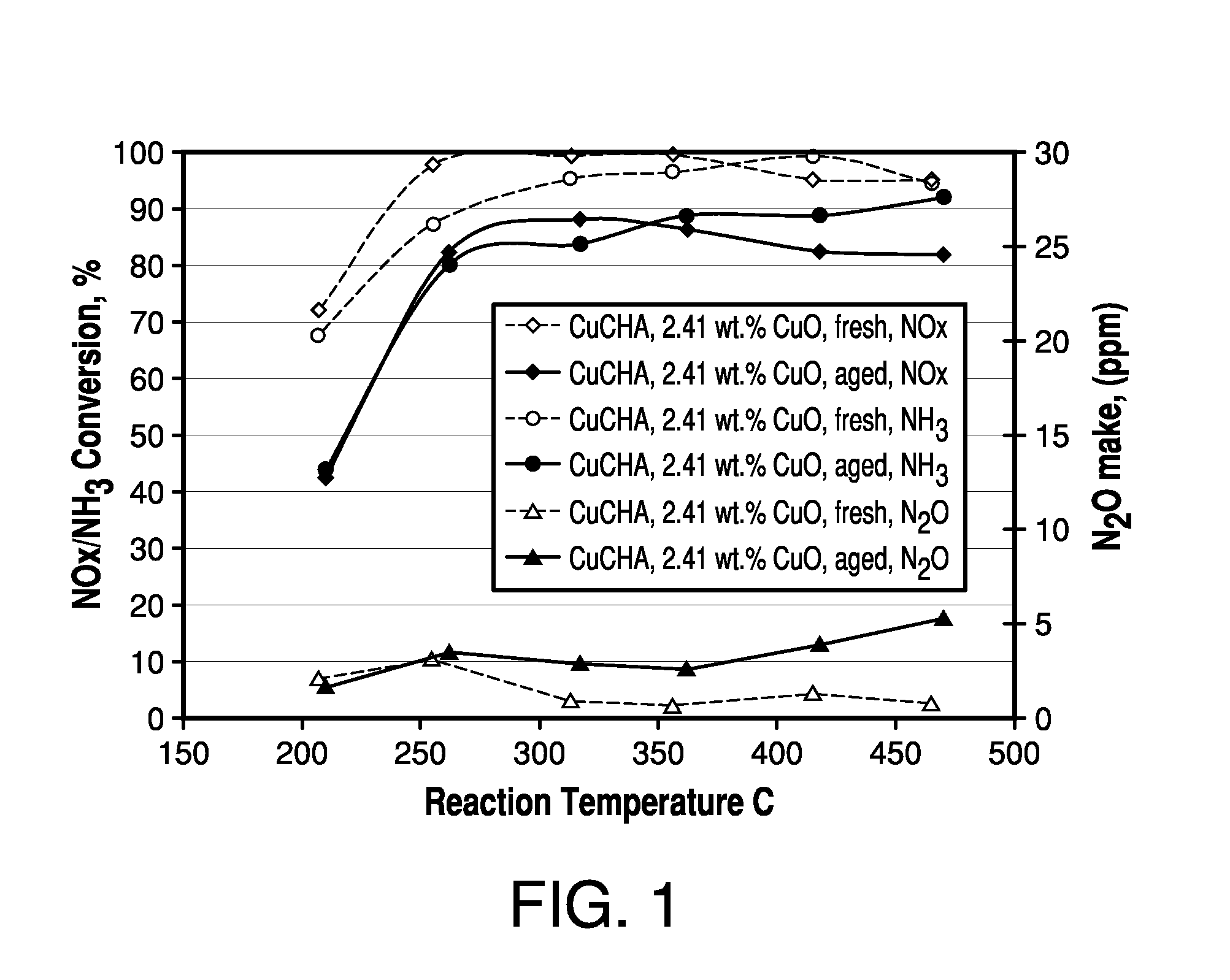

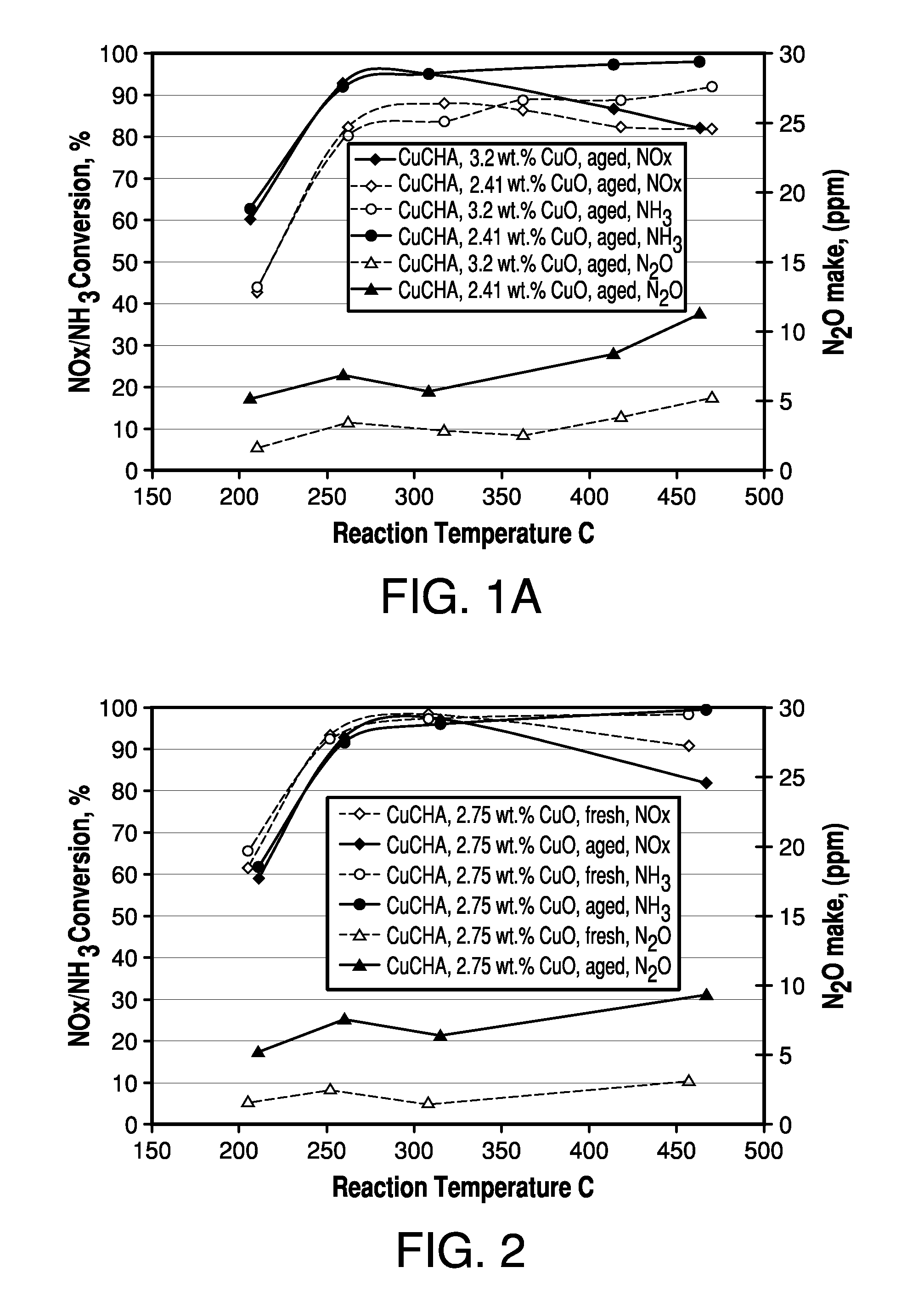

Copper CHA zeolite catalysts

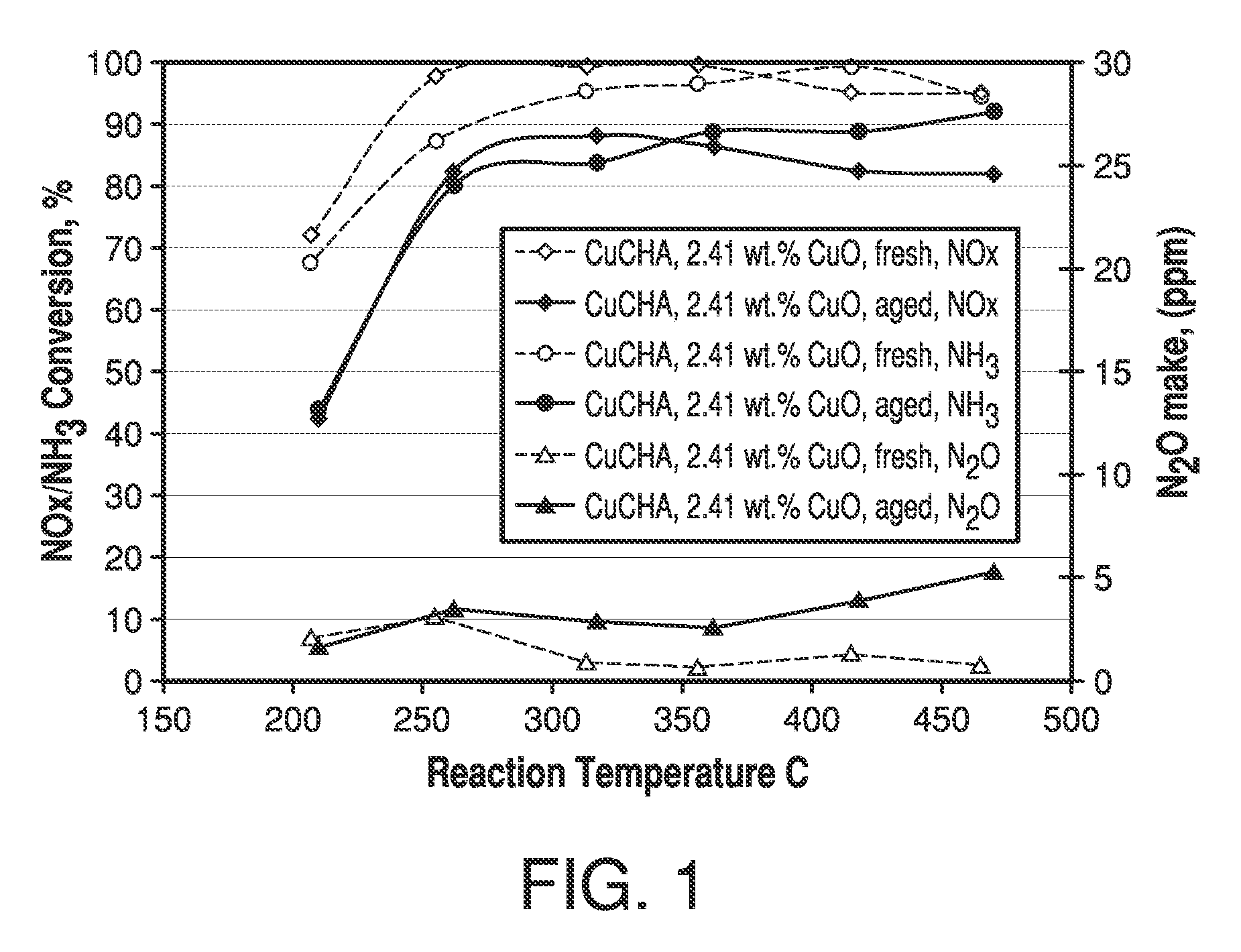

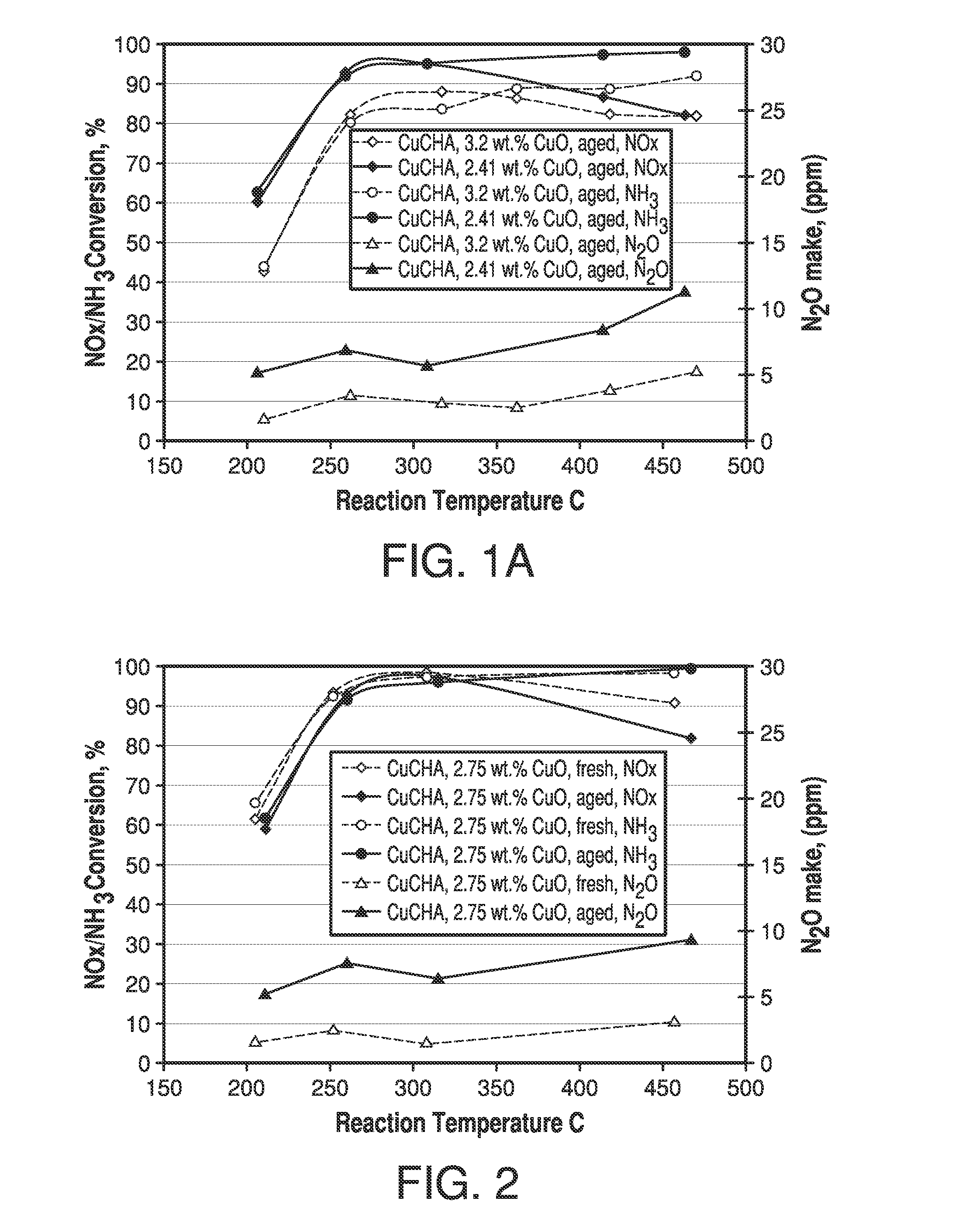

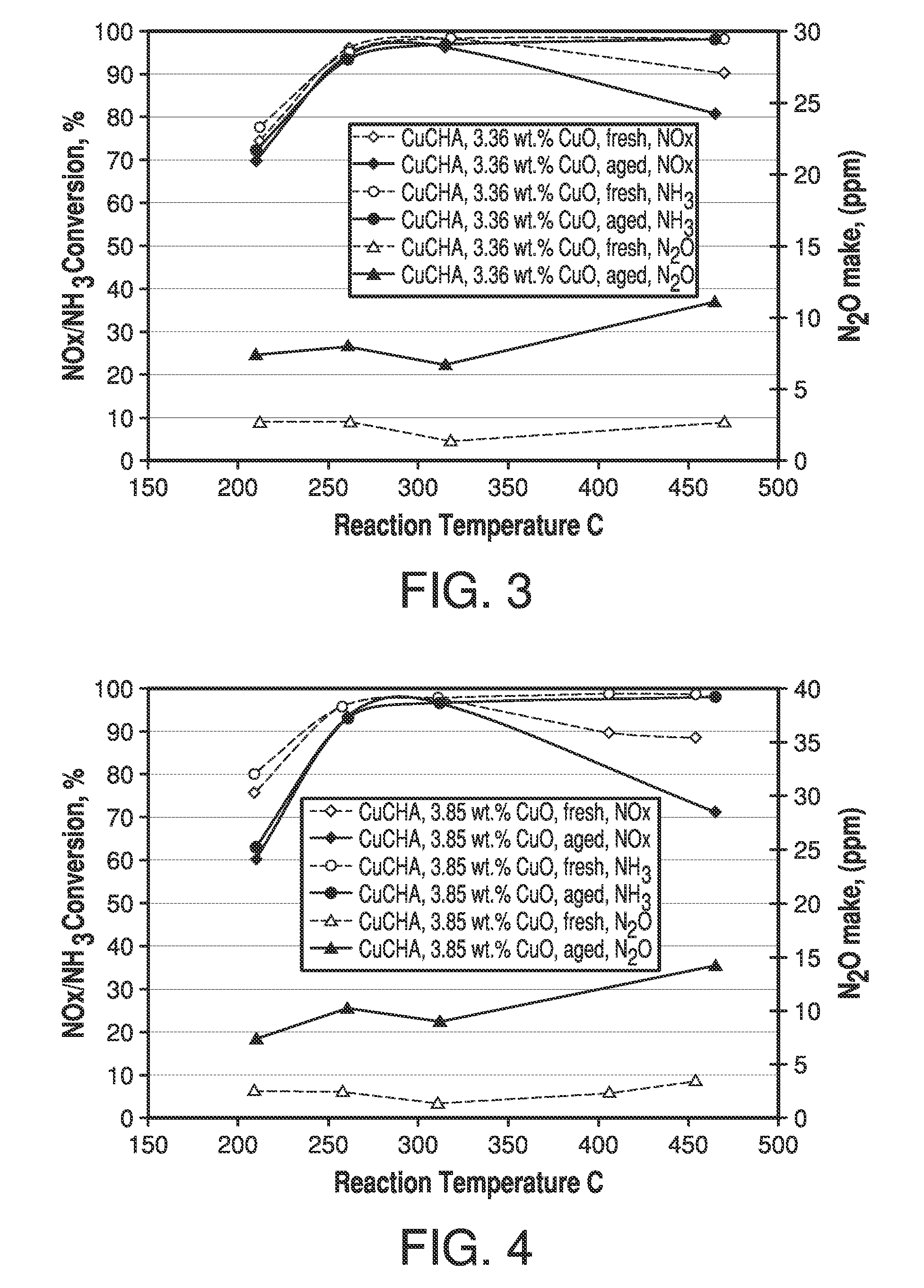

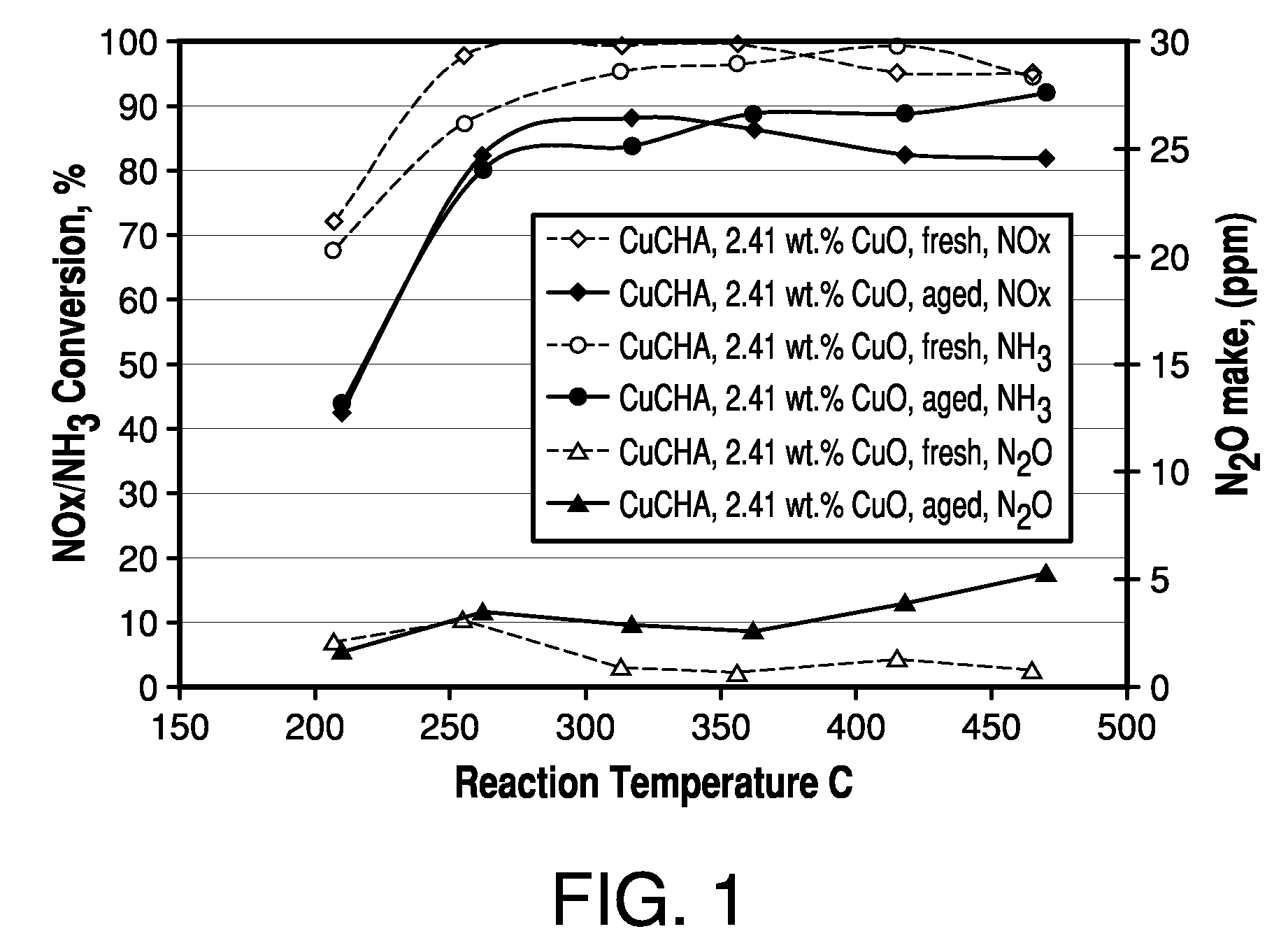

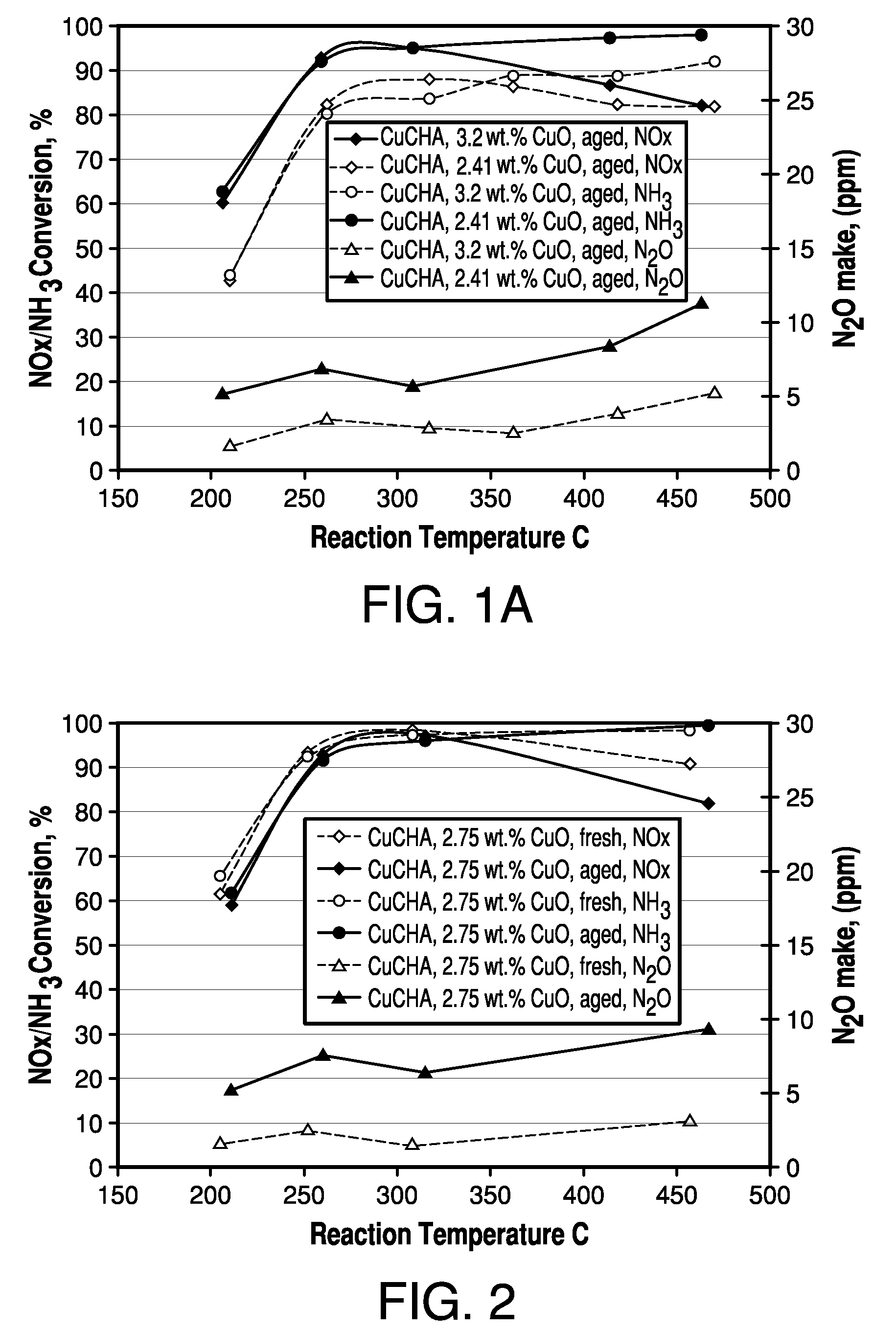

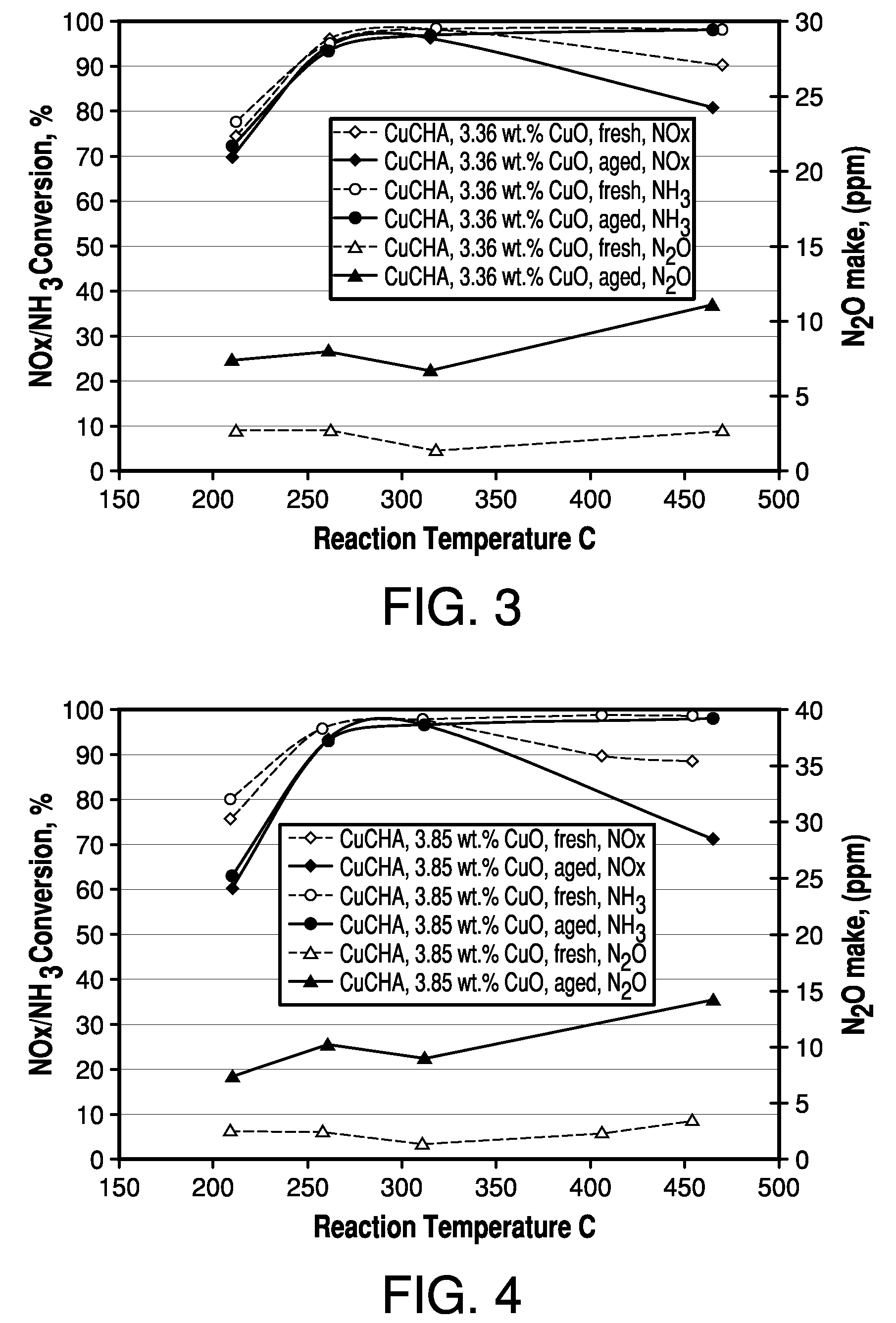

ActiveUS7601662B2Good hydrothermal stabilityHigh catalytic activityCombination devicesAluminium compoundsReaction temperatureCrystal structure

Zeolite catalysts and systems and methods for preparing and using zeolite catalysts having the CHA crystal structure are disclosed. The catalysts can be used to remove nitrogen oxides from a gaseous medium across a broad temperature range and exhibit hydrothermal stable at high reaction temperatures. The zeolite catalysts include a zeolite carrier having a silica to alumina ratio from about 15:1 to about 256:1 and a copper to alumina ratio from about 0.25:1 to about 1:1.

Owner:BASF CORP

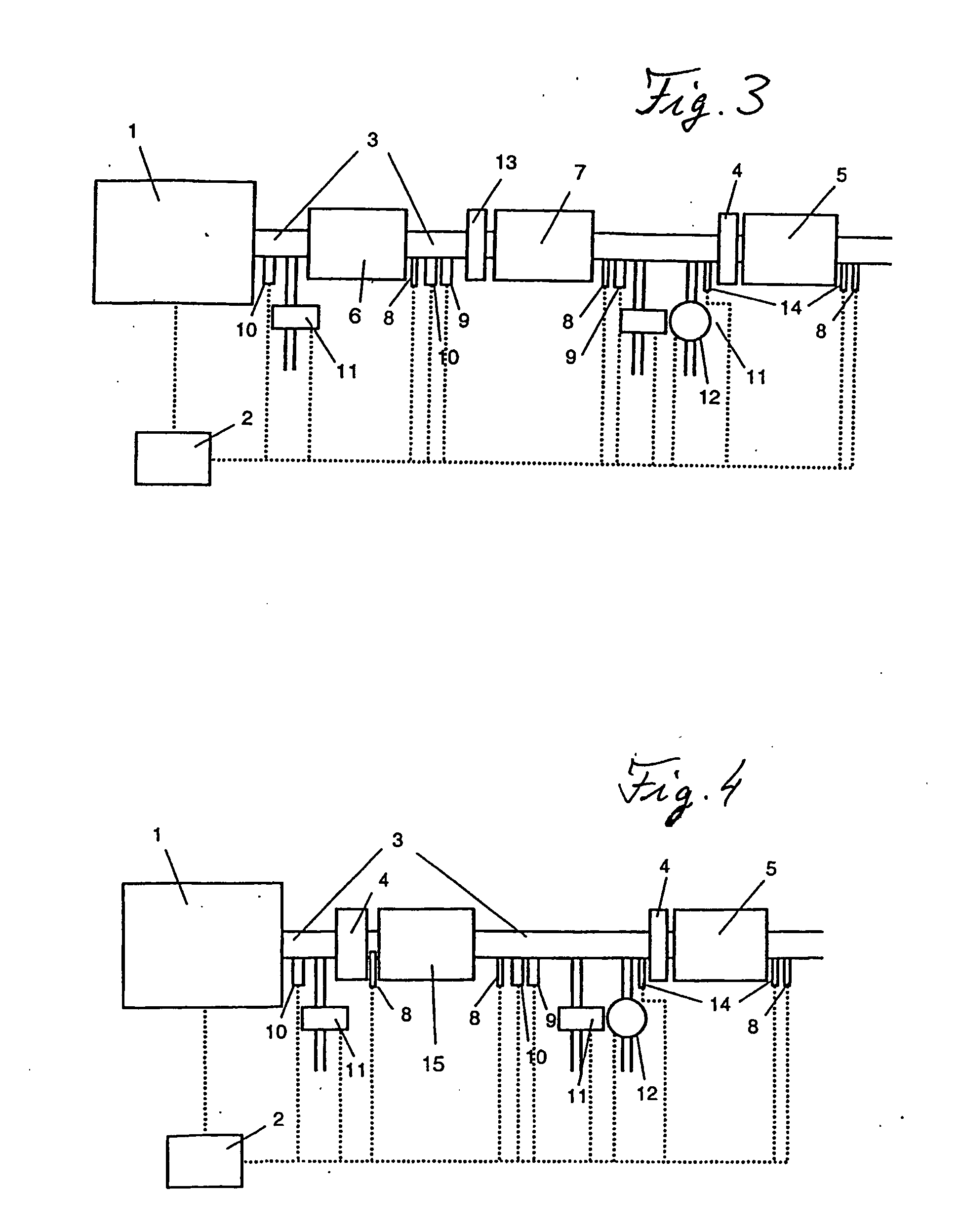

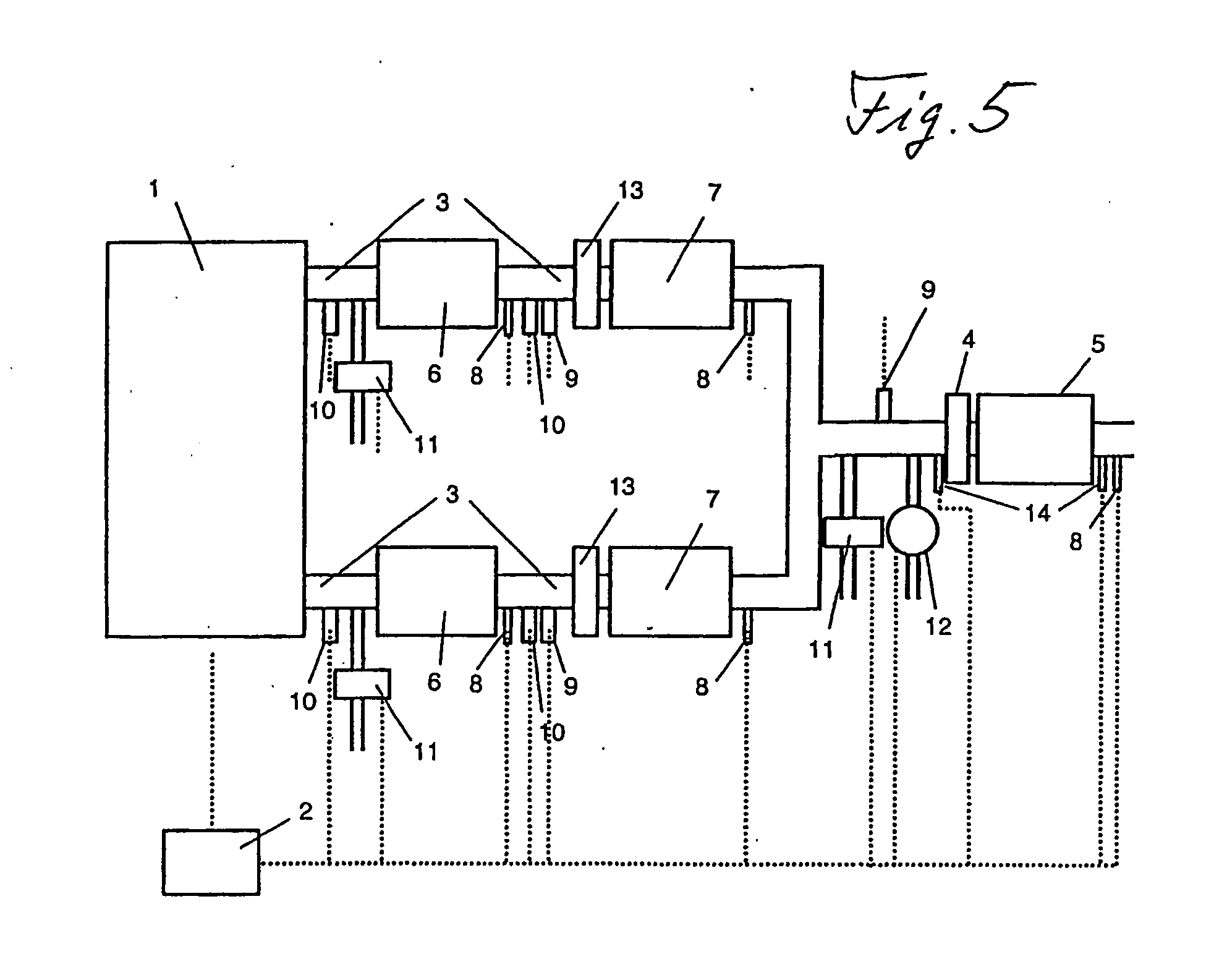

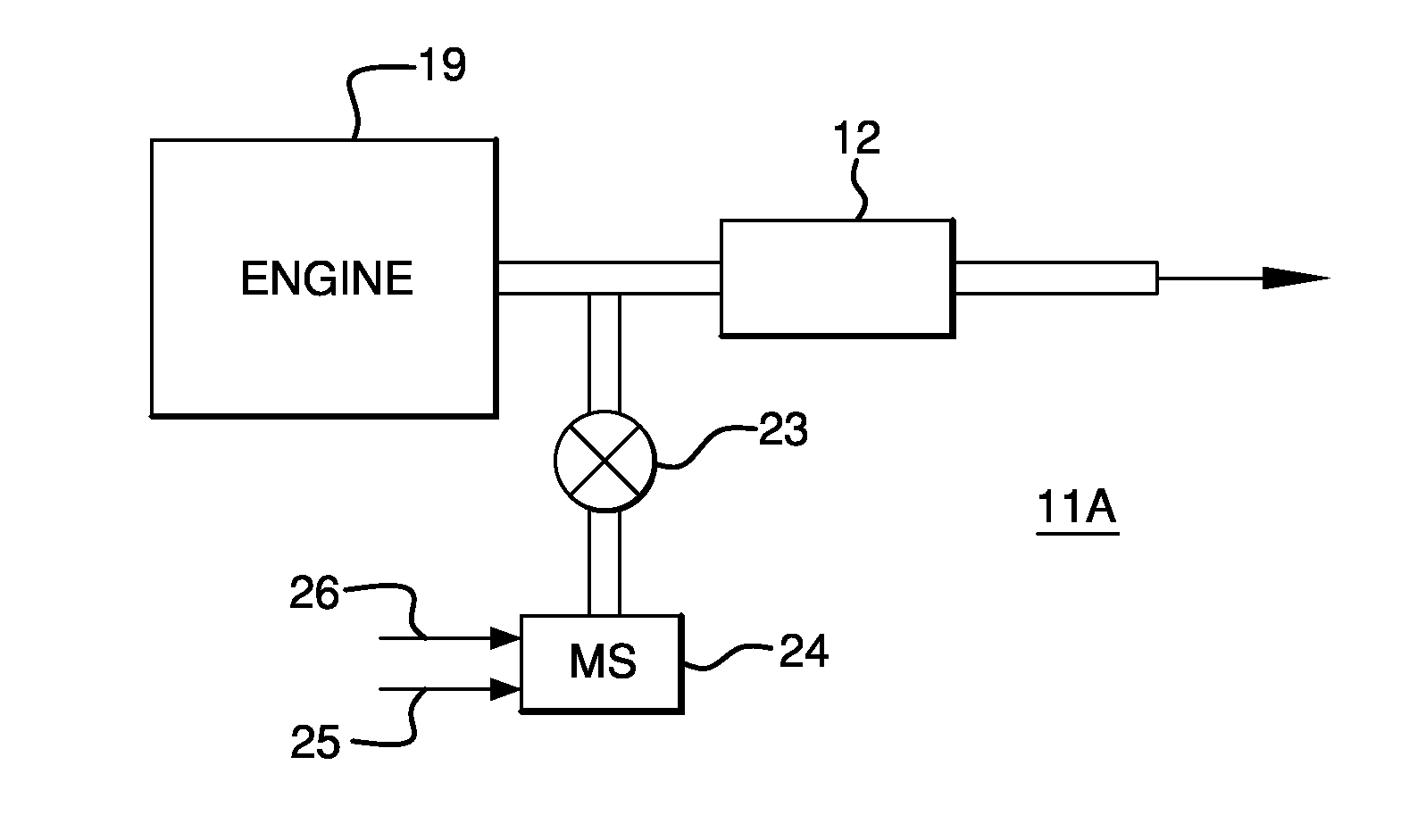

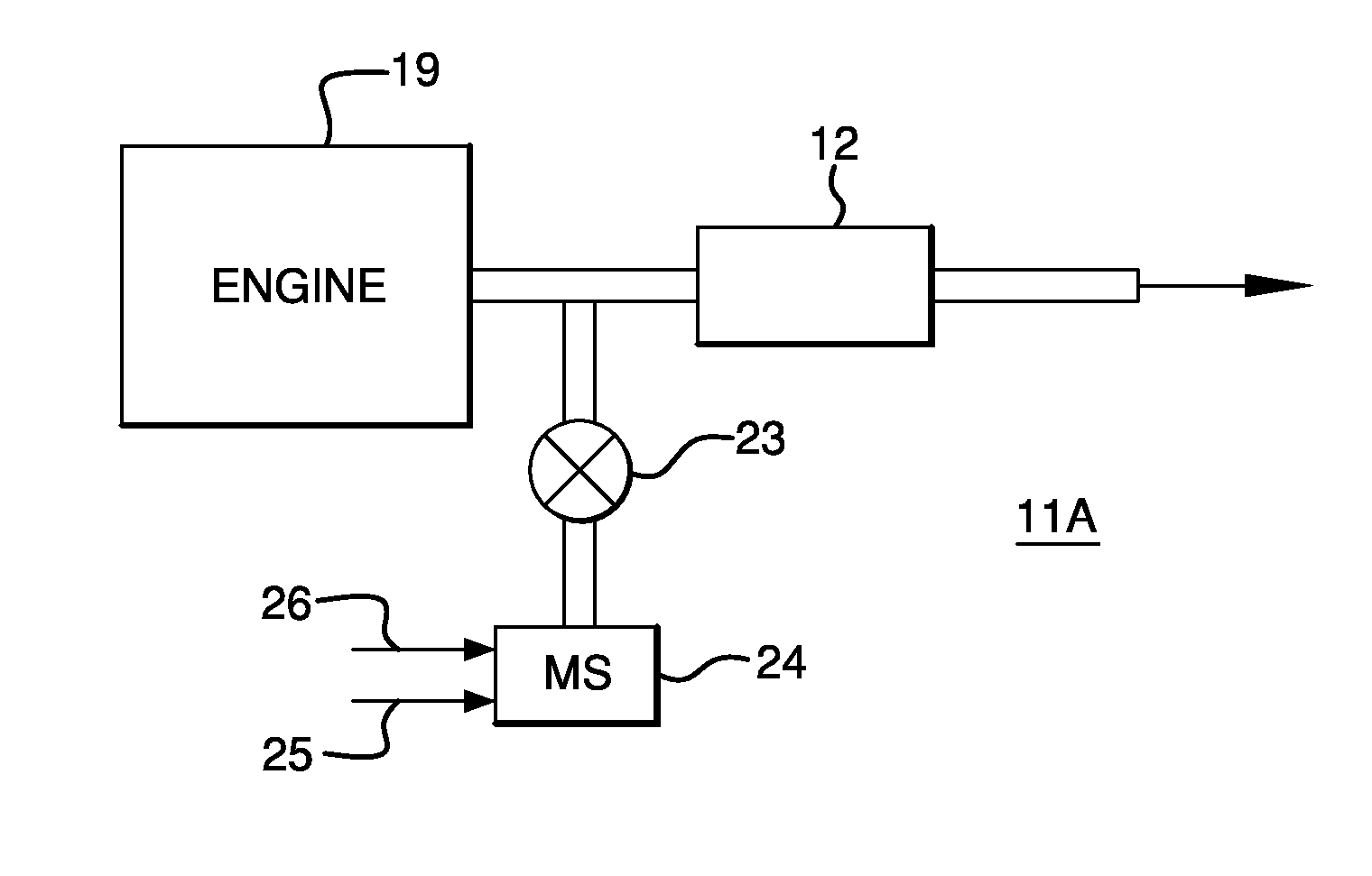

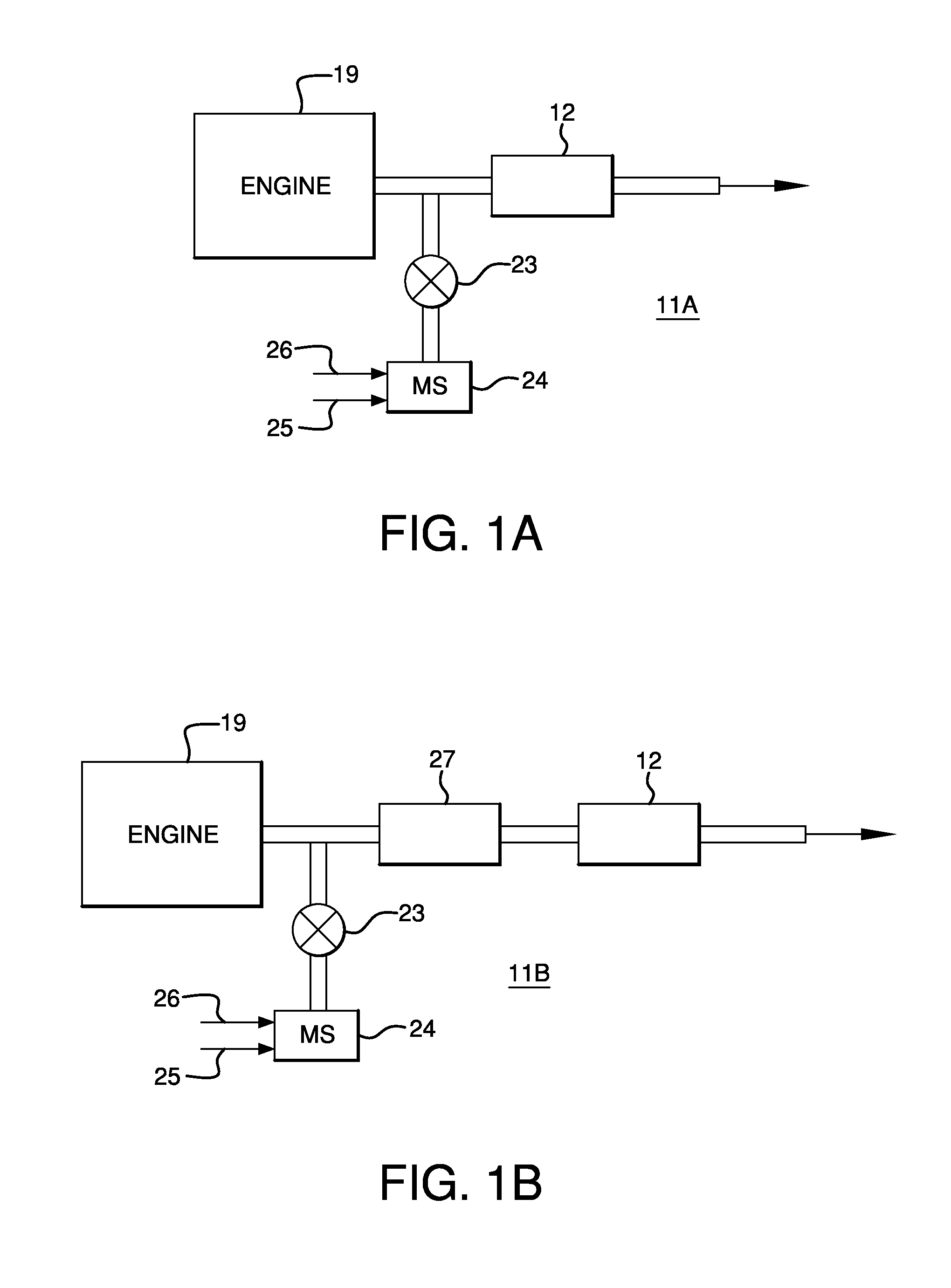

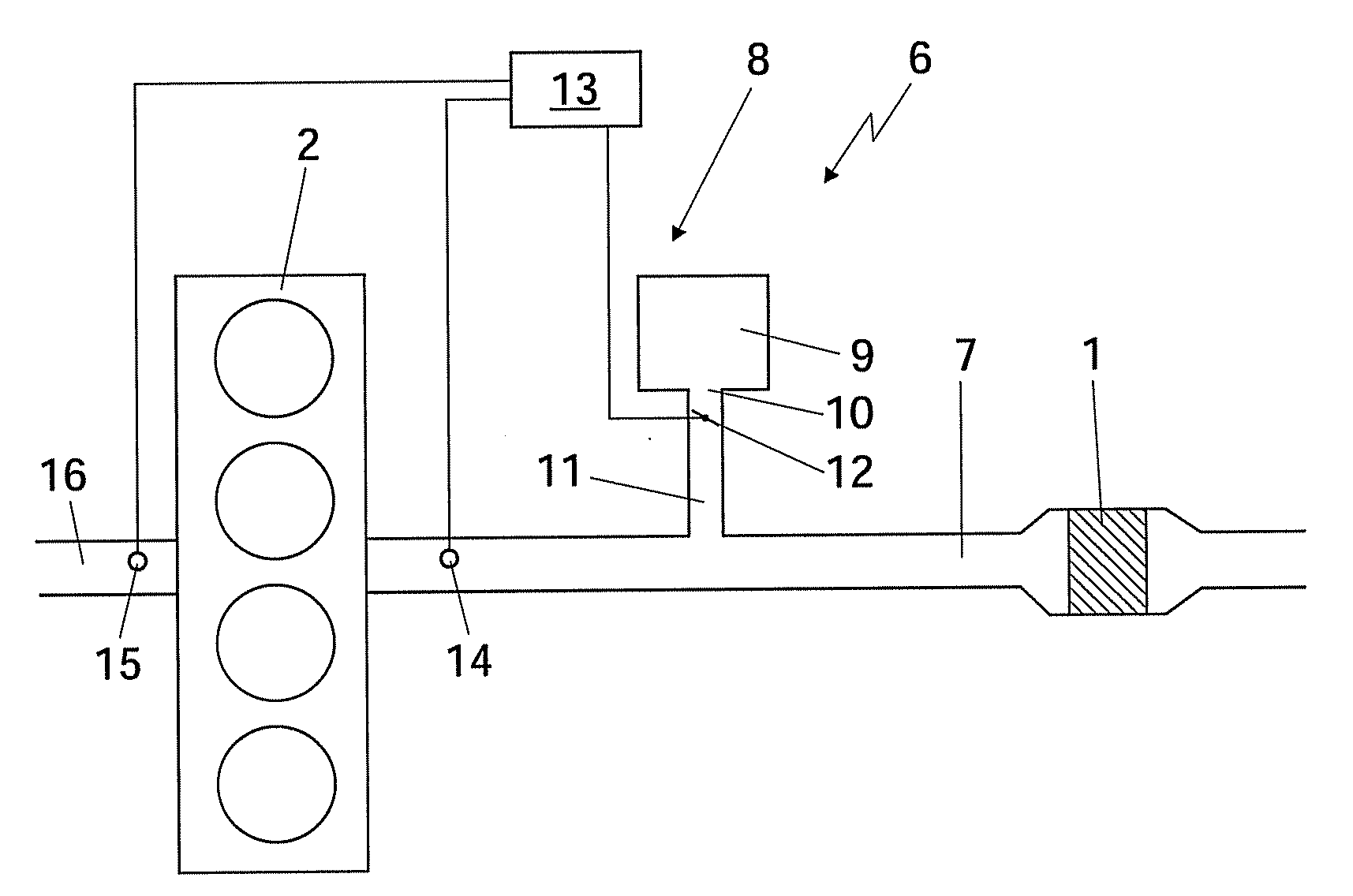

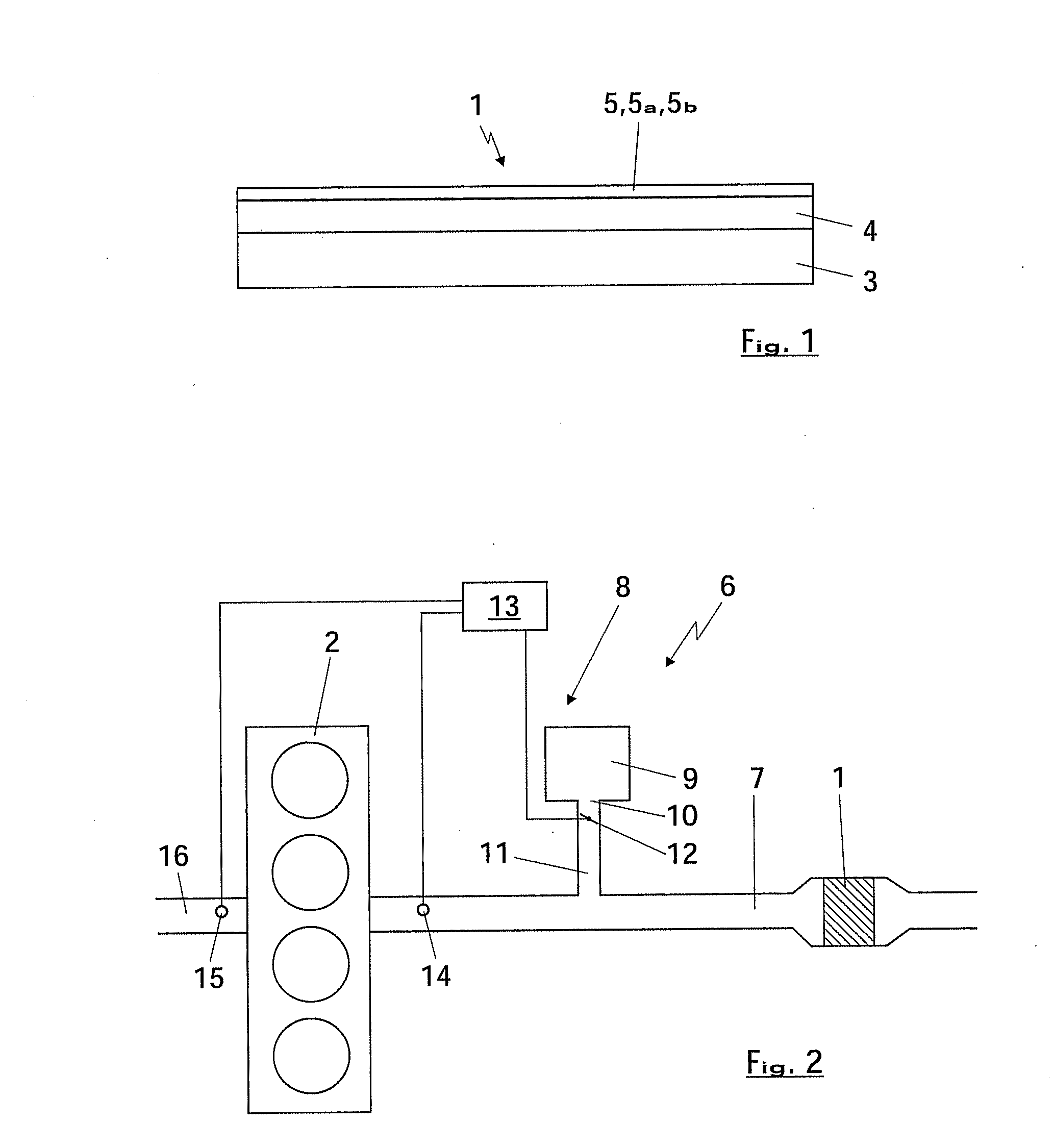

Exhaust gas aftertreatment installation and method

InactiveUS20060153761A1High NOx emissionReduce nitrogen oxidesCombination devicesNitrogen compoundsChemistryExhaust fumes

Owner:DAIMLER AG

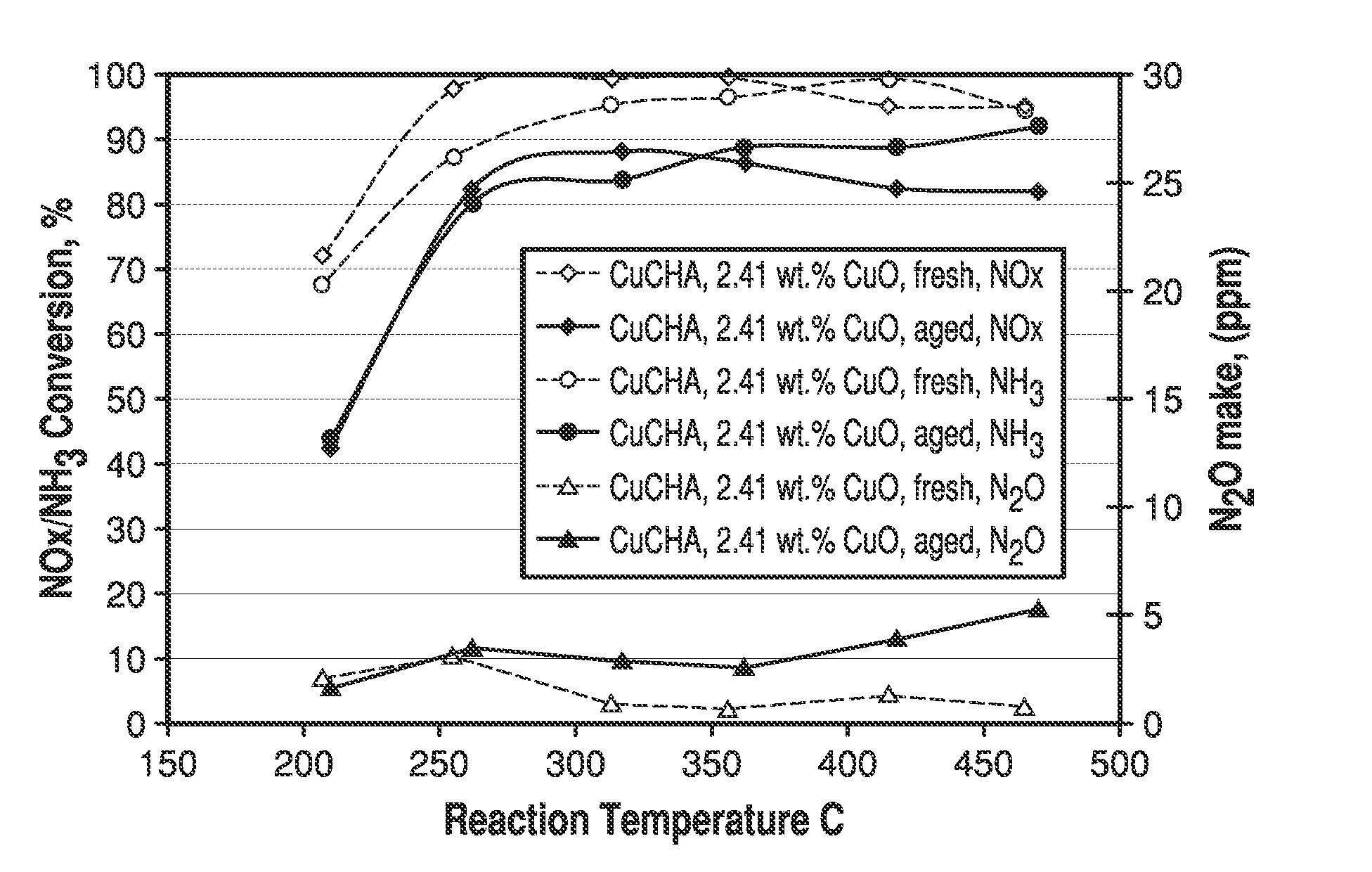

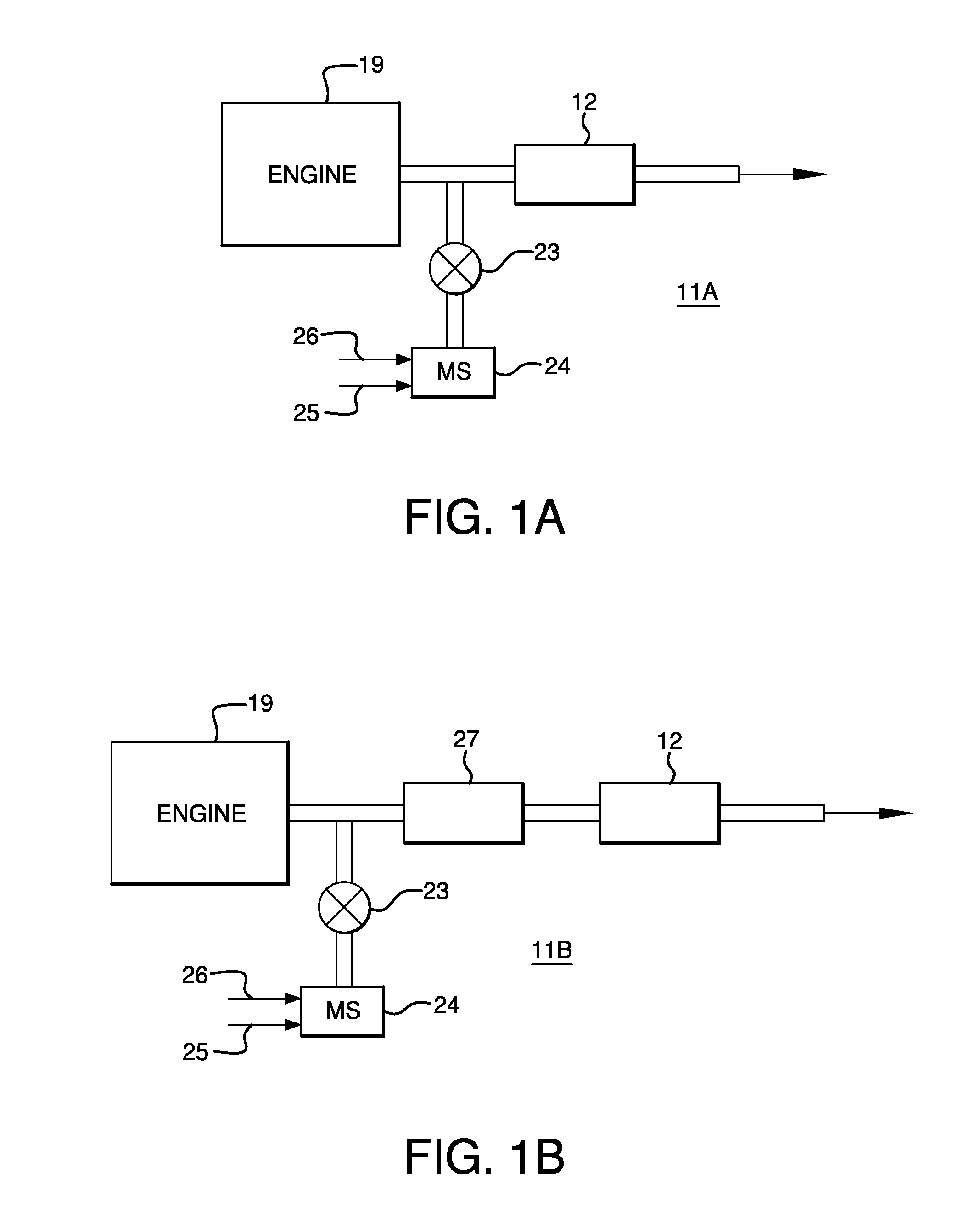

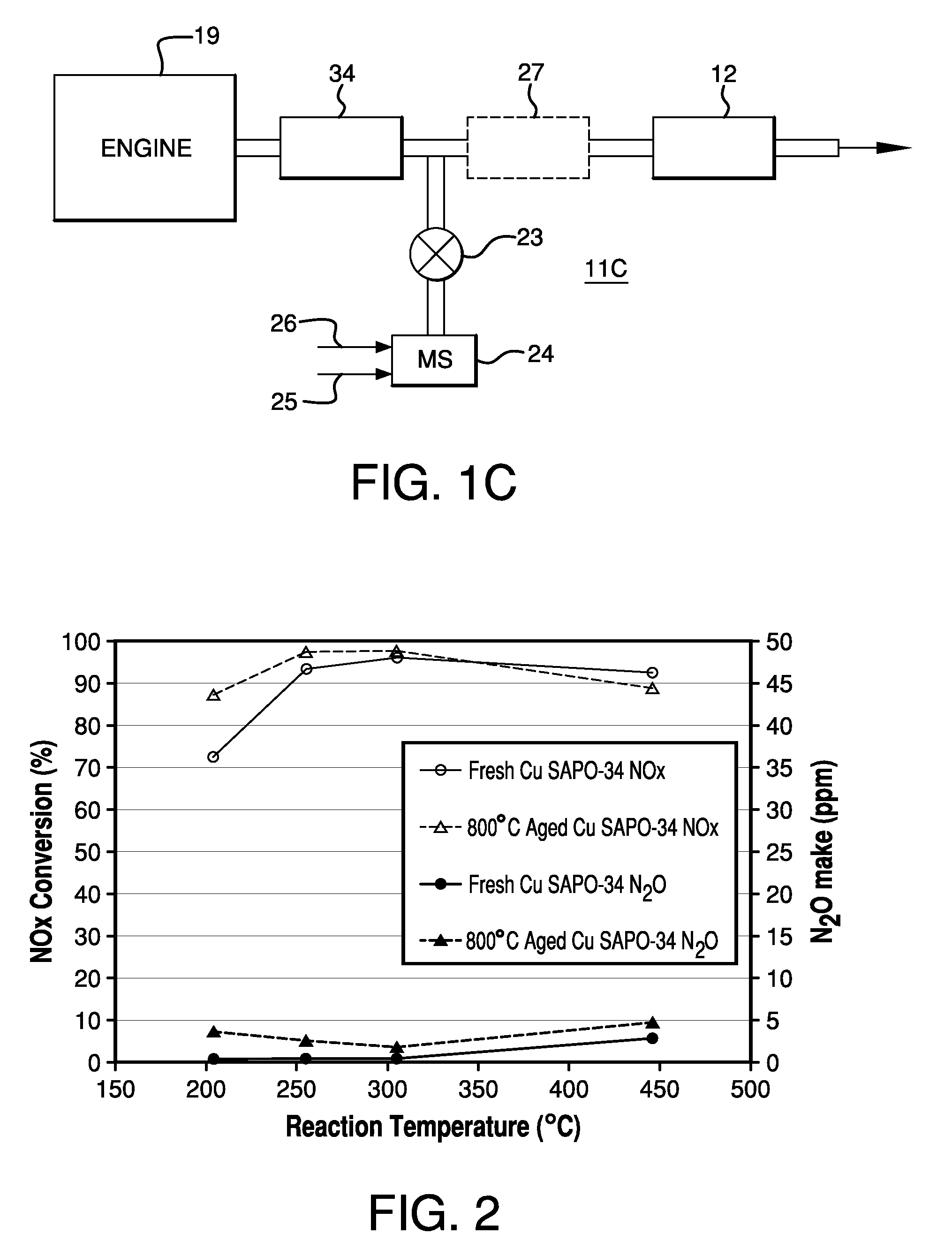

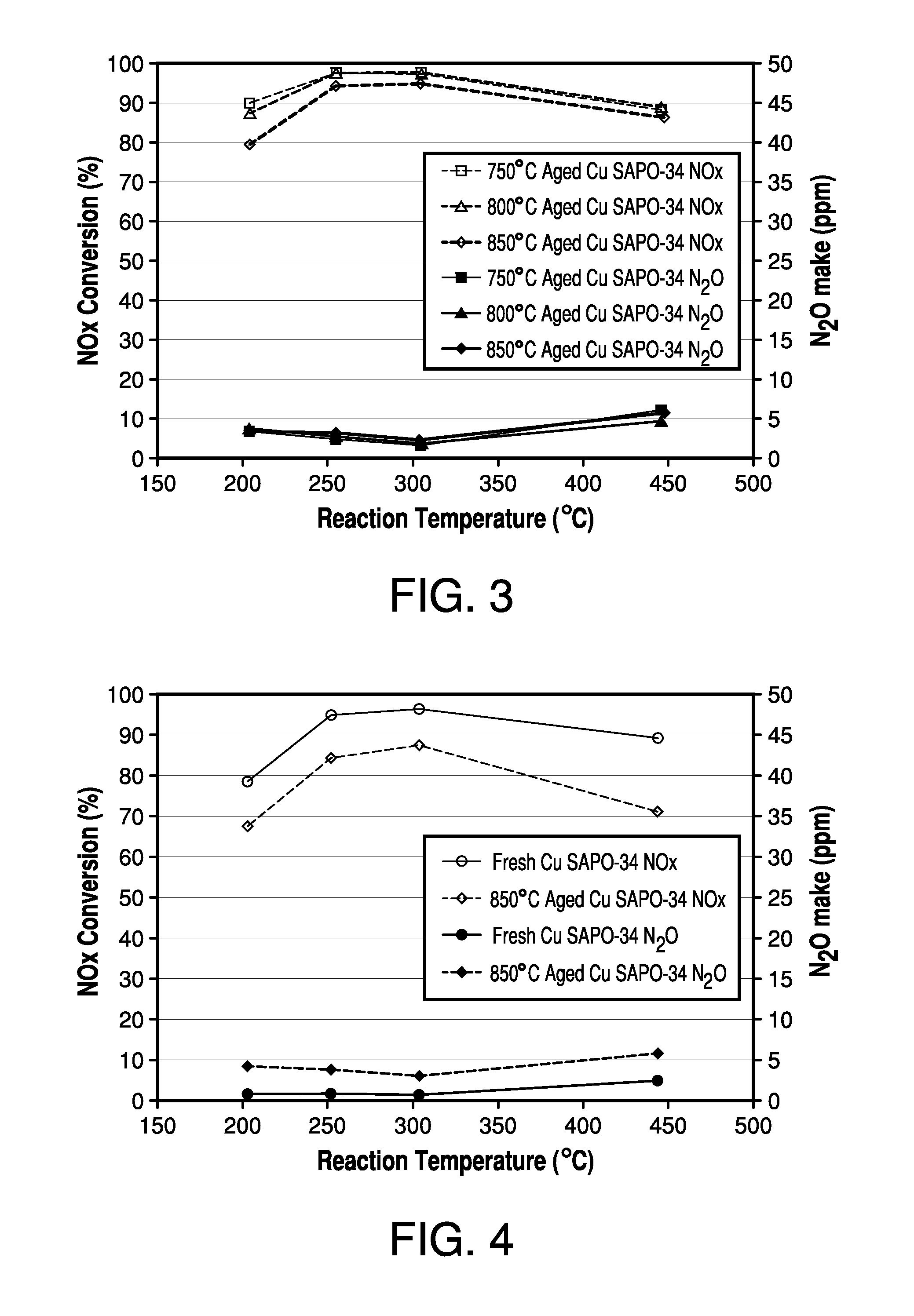

Catalysts, Systems and Methods Utilizing Non-Zeolitic Metal-Containing Molecular Sieves Having the CHA Crystal Structure

InactiveUS20090196812A1Improve nh3 scrExcellent hydrothermal stabilityNitrous oxide captureCombination devicesExhaust gasChemistry

Catalysts comprising metal-loaded non-zeolitic molecular sieves having the CHA crystal structure, including Cu-SAPO-34, methods for preparing such catalysts, and systems and methods for treating exhaust gas incorporating such catalysts are disclosed. The catalysts can be used to remove nitrogen oxides from a gaseous medium across a broad temperature range and exhibit hydrothermal stability at high reaction temperatures.

Owner:BASF CORP

Copper CHA Zeolinte Catalysts

ActiveUS20080226545A1Reduce decreaseImproved NH SCRCombination devicesAluminium compoundsCrystal structureReaction temperature

Zeolite catalysts and systems and methods for preparing and using zeolite catalysts having the CHA crystal structure are disclosed. The catalysts can be used to remove nitrogen oxides from a gaseous medium across a broad temperature range and exhibit hydrothermal stable at high reaction temperatures. The zeolite catalysts include a zeolite carrier having a silica to alumina ratio from about 15:1 to about 256:1 and a copper to alumina ratio from about 0.25:1 to about 1:1.

Owner:BASF CORP

Copper CHA zeolite catalysts

ActiveUS8735311B2Good hydrothermal stabilityHigh catalytic activityNitrous oxide captureAluminium compoundsReaction temperatureCrystal structure

Zeolite catalysts and systems and methods for preparing and using zeolite catalysts having the CHA crystal structure are disclosed. The catalysts can be used to remove nitrogen oxides from a gaseous medium across a broad temperature range and exhibit hydrothermal stable at high reaction temperatures. The zeolite catalysts include a zeolite carrier having a silica to alumina ratio from about 15:1 to about 256:1 and a copper to alumina ratio from about 0.25:1 to about 1:1.

Owner:BASF CORP

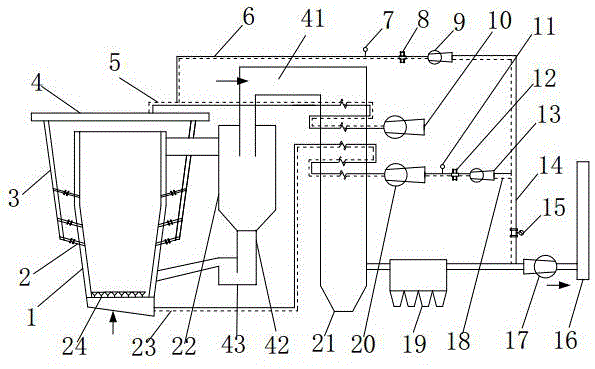

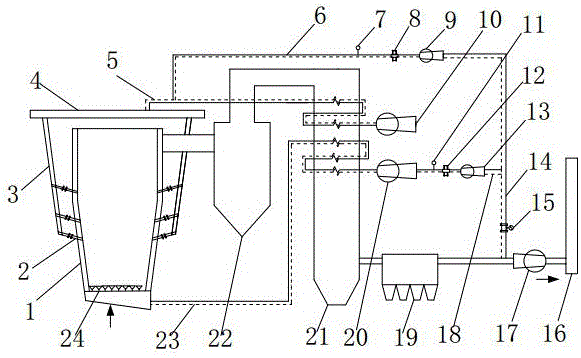

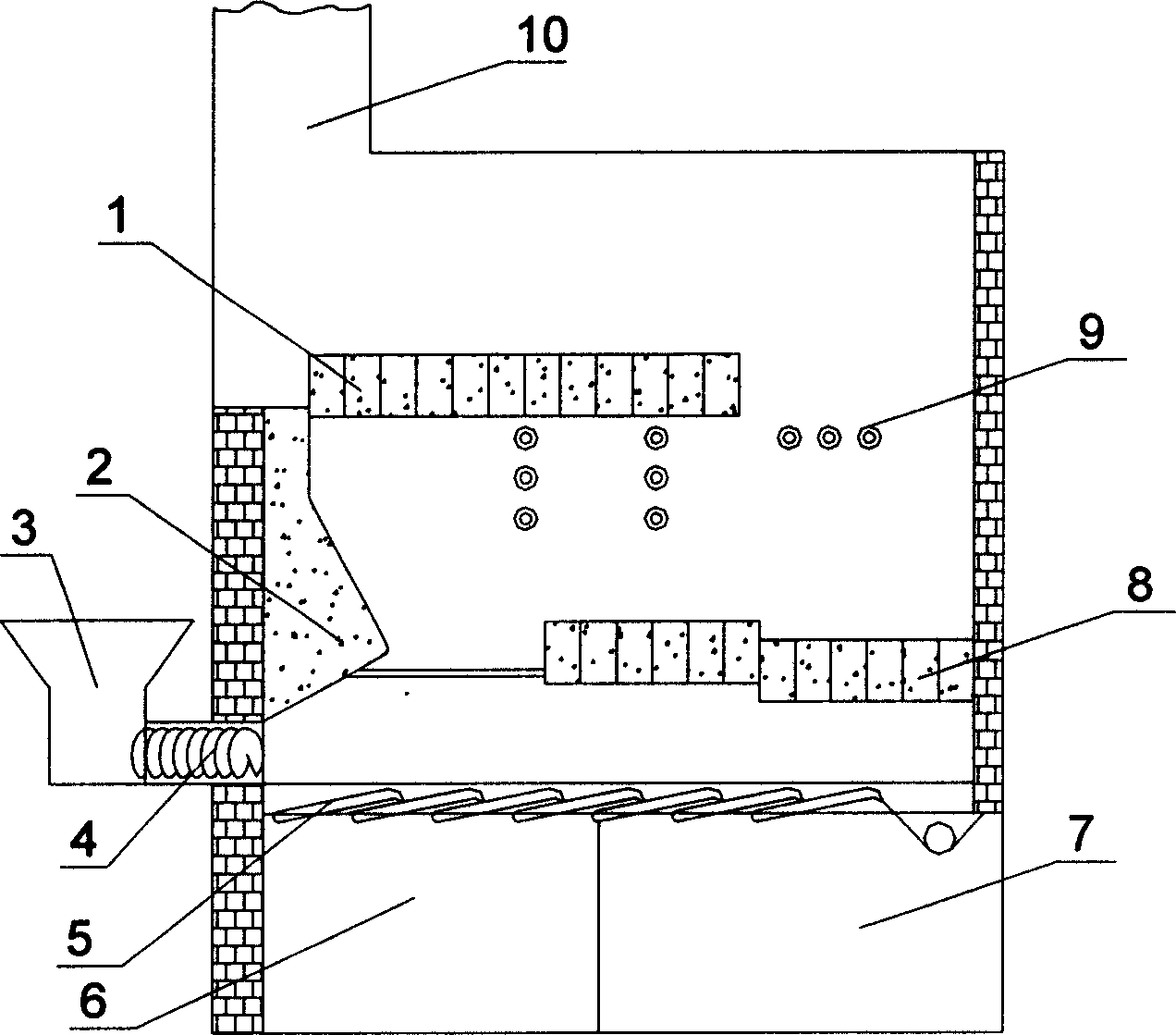

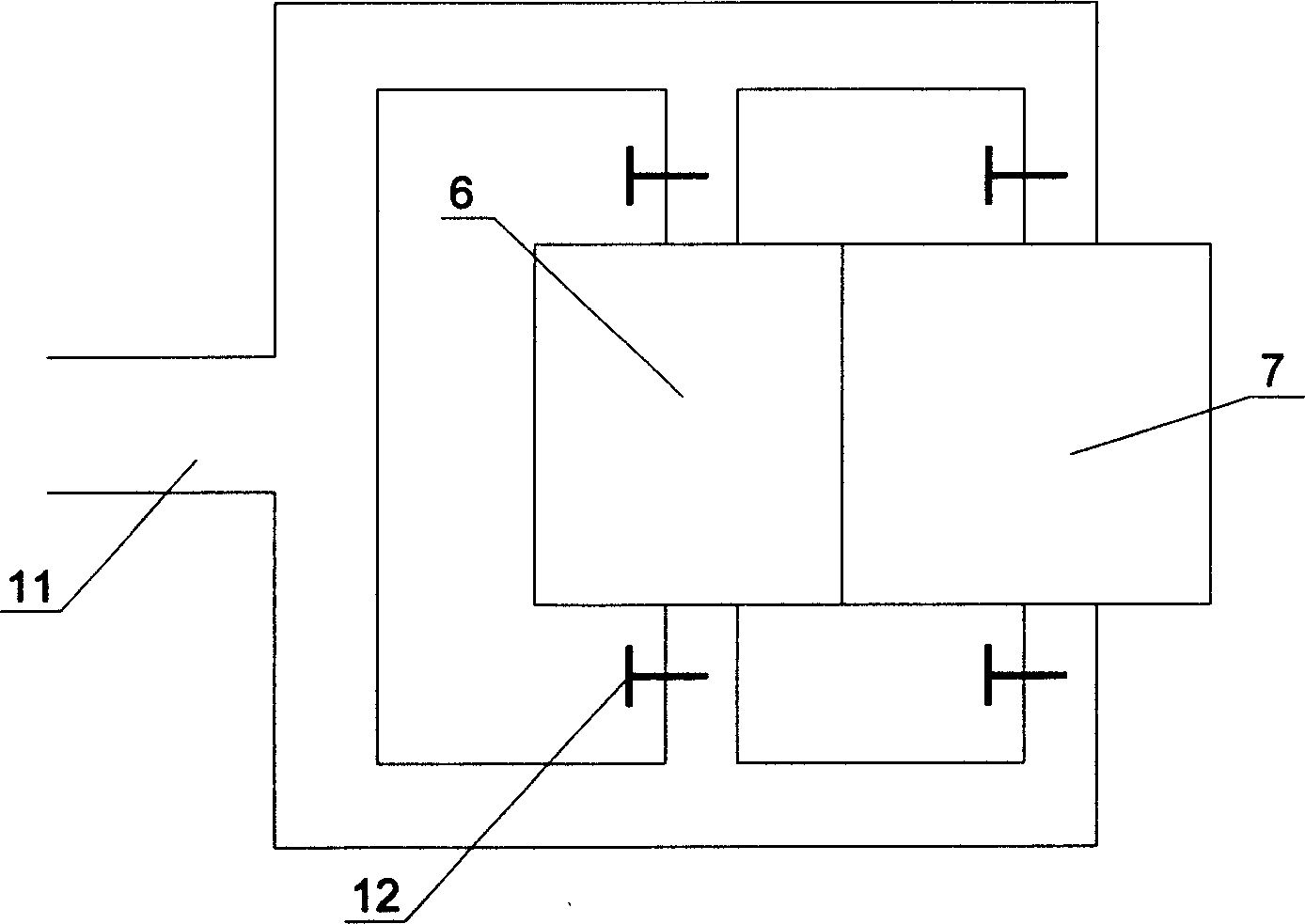

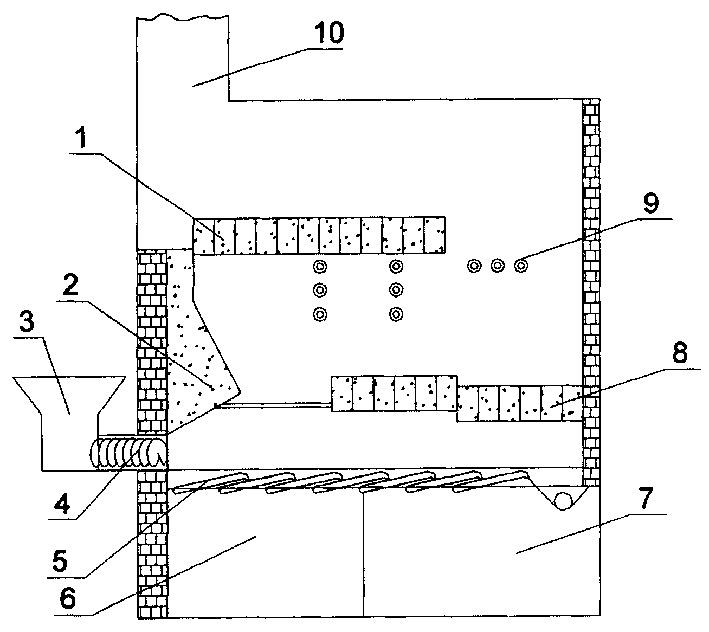

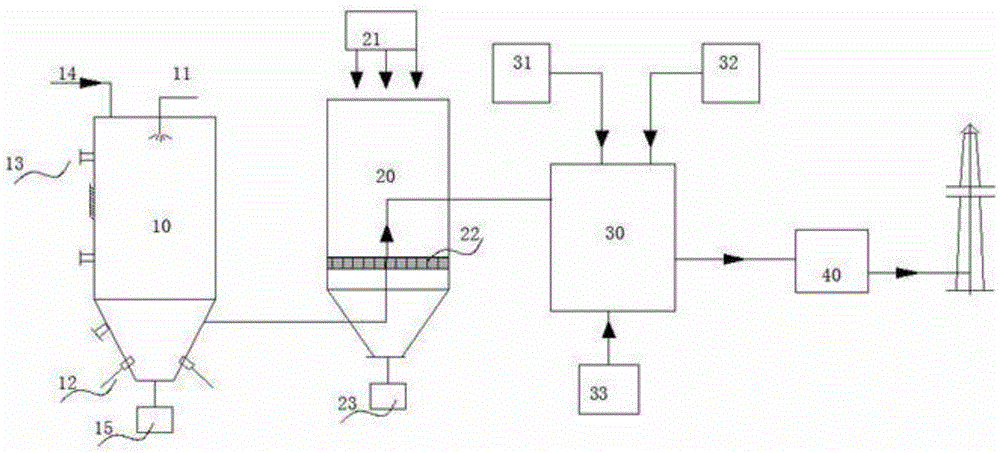

Storage-type super-low nitric oxide system in coal fired boiler coal mill

ActiveCN103216840ANot easy to explodeIncrease delivery temperatureLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationPowder mixtureNitric oxide

The invention relates to a storage-type super-low nitric oxide system in a coal fired boiler coal mill. On the basis of the existing low-nitrogen burning technology, the superfine coal powder preparation technology and the smoke circulating technology are adopted. The smoke circulating technology adopts cold furnace smoke to be mixed with primary air to be supercharged by a primary fan, the heating and powder feeding technology of an air preheater and the hot air and high-temperature furnace smoke drying technology of the powder production system are adopted, i.e. superfine coal powder can be prepared, the hot furnace smoke enters a primary air large air bellow, the hot furnace smoke is mixed with superfine coal powder prepared by a superfine coal powder preparation device in a coal powder blender and supplied by a powder supply machine from a coal powder cabin to be heated, and the air-powder mixture is fed into a low-nitrogen burner through a primary air pipe. In the main burning area of the boiler, since the air content of the furnace smoke is little, a lower residual air coefficient can be realized, the emission of the nitric oxide can be reduced.

Owner:南京佛莱斯特环保科技有限公司

Copper CHA Zeolite Catalysts

ActiveUS20130195731A1Reduce decreaseImproved NH SCRNitrous oxide captureCombination devicesCrystal structureReaction temperature

Zeolite catalysts and systems and methods for preparing and using zeolite catalysts having the CHA crystal structure are disclosed. The catalysts can be used to remove nitrogen oxides from a gaseous medium across a broad temperature range and exhibit hydrothermal stable at high reaction temperatures. The zeolite catalysts include a zeolite carrier having a silica to alumina ratio from about 15:1 to about 256:1 and a copper to alumina ratio from about 0.25: 1 to about 1:1.

Owner:BASF CORP

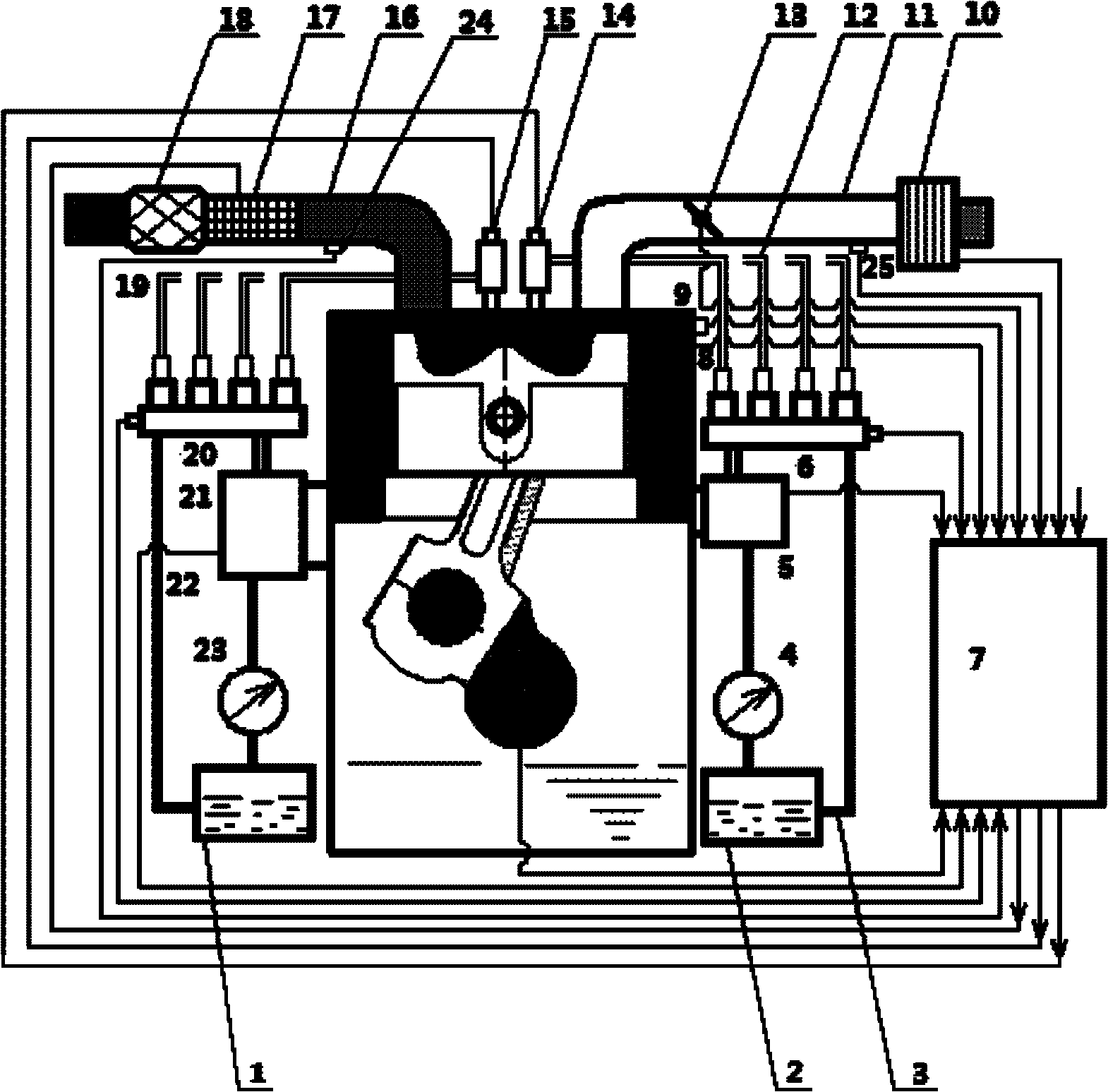

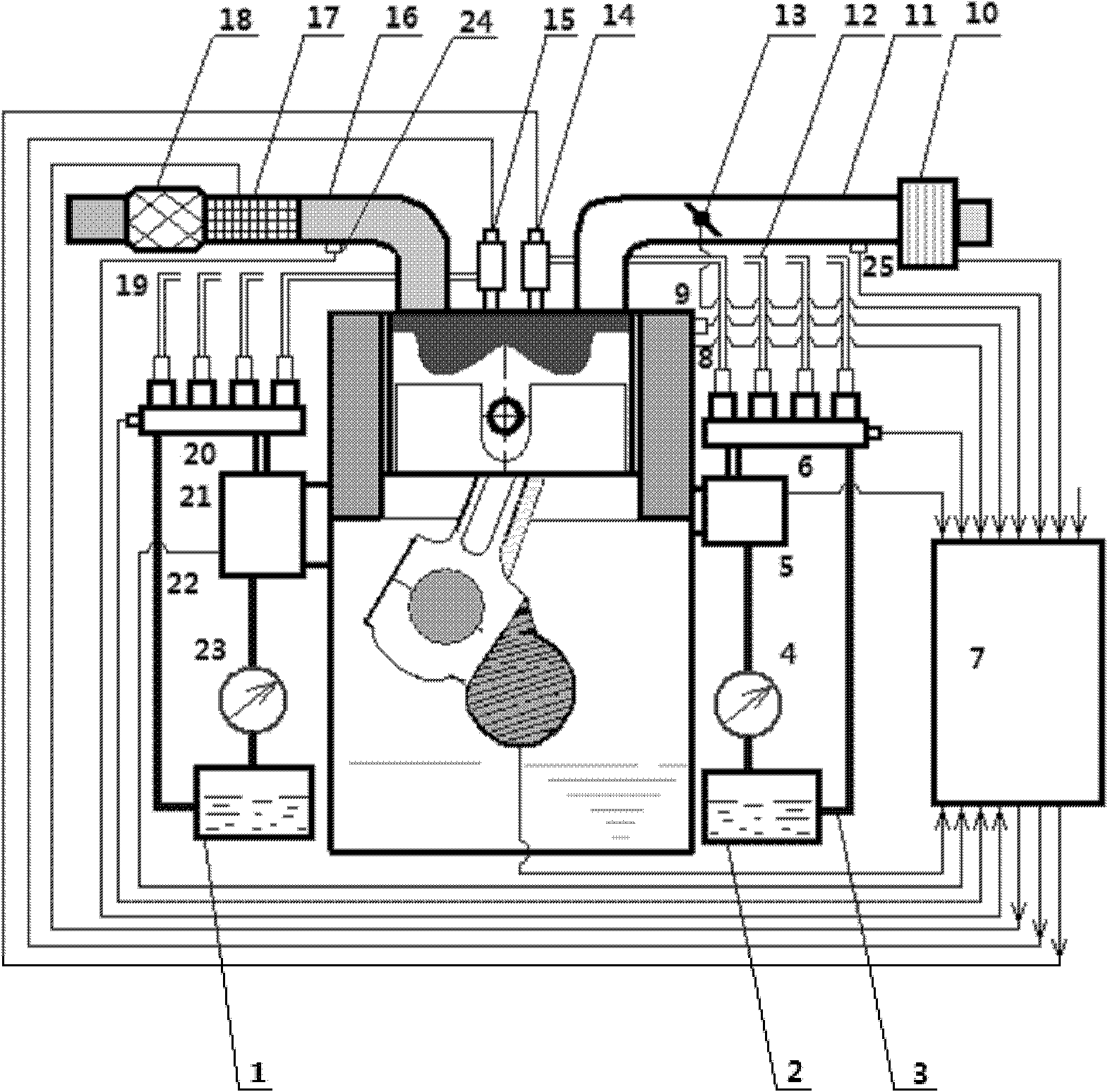

Diesel-gasoline dual fuel sequential combustion direct injection engine

ActiveCN102278189AReduce nitrogen oxidesGood hydrocarbon and carbon monoxide emissionsInternal combustion piston enginesExhaust apparatusThermal efficiencyInternal combustion engine

The invention discloses a direct injection engine with diesel-gasoline dual-fuel sequence combustion, belonging to the technical field of engines. On the one hand, the engine can simultaneously make use of diesel and gasoline, and the two fuels can be sequentially and directly injected in one cycle; on the other hand, according to the engine, a high-compression-rate and three-way catalysis aftertreatment device, so that the engine can realize the purposes of high thermal efficiency and low emission simultaneously.

Owner:SHANGHAI JIAO TONG UNIV

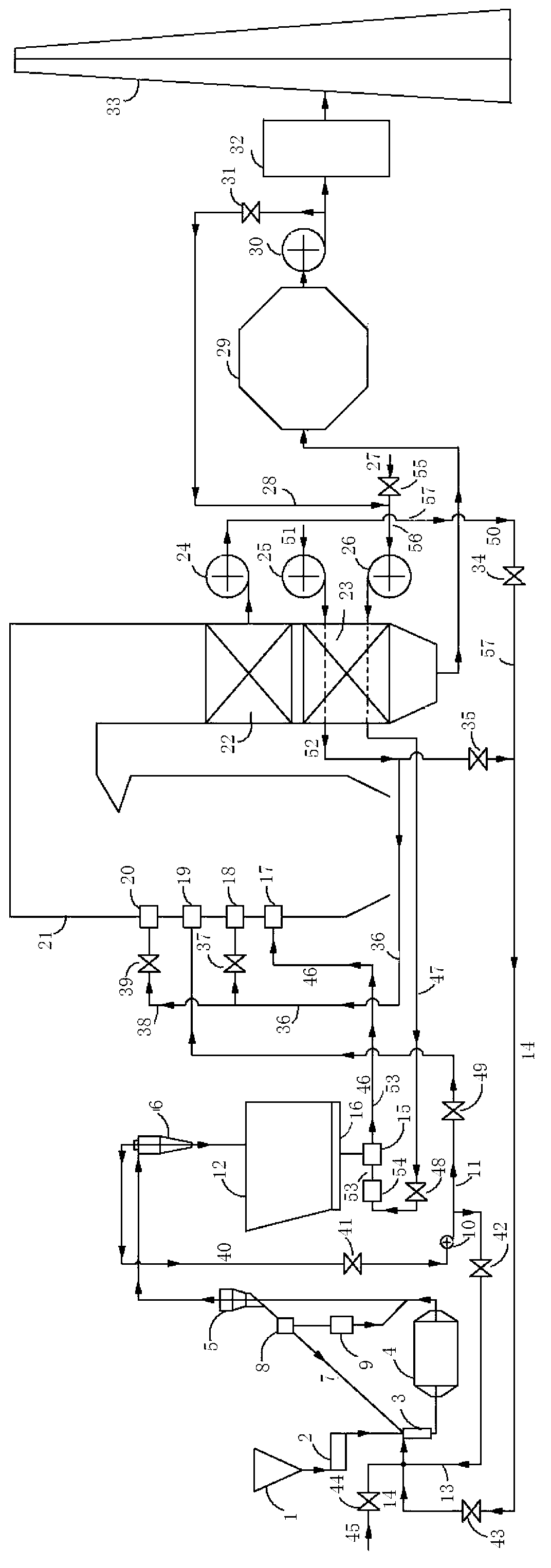

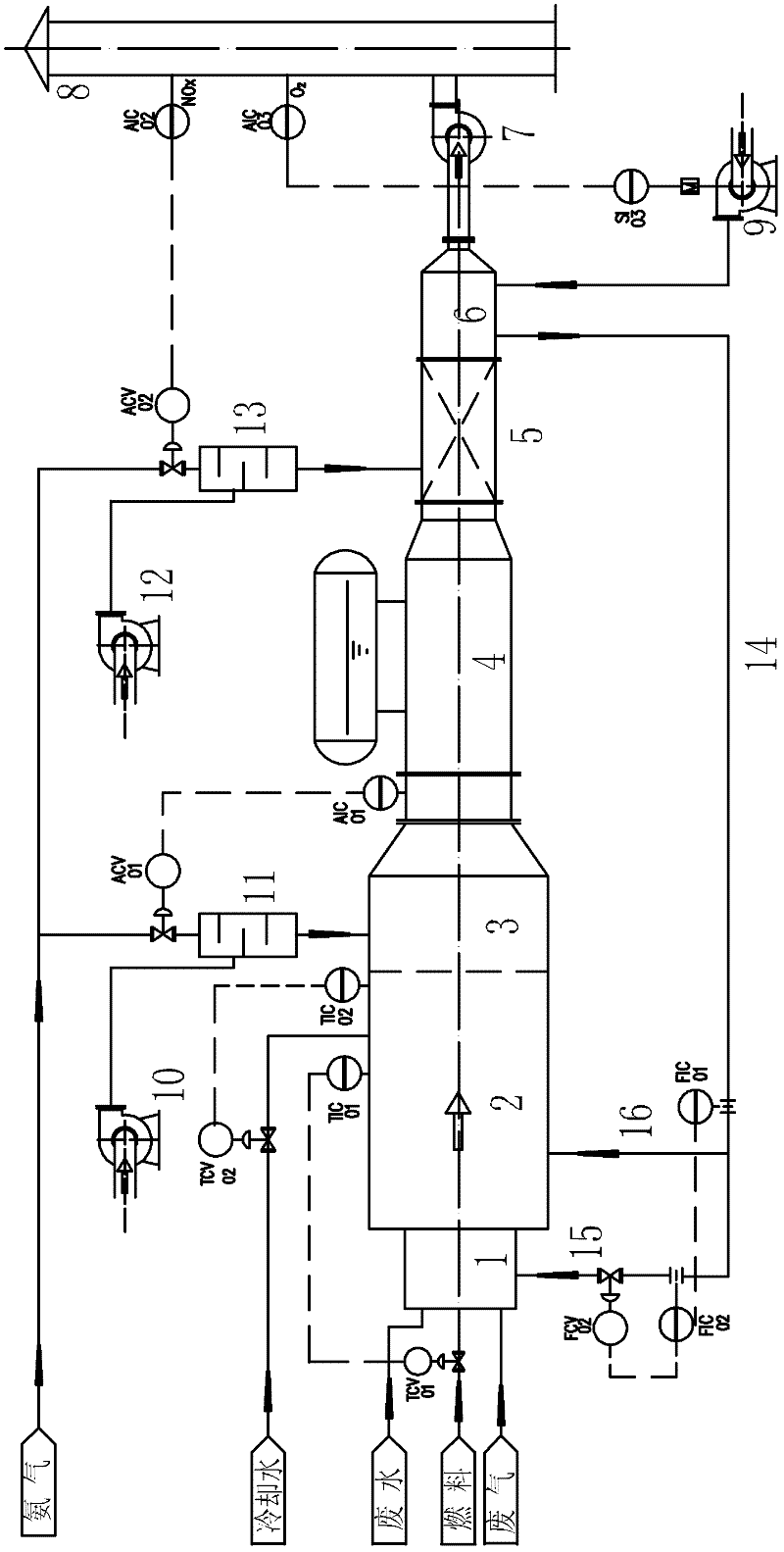

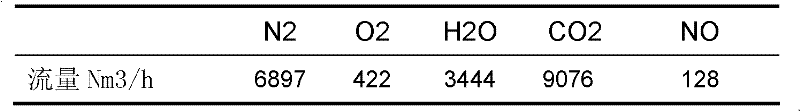

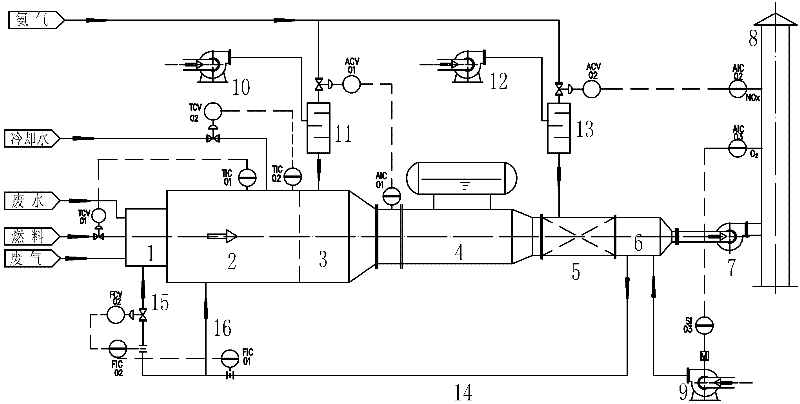

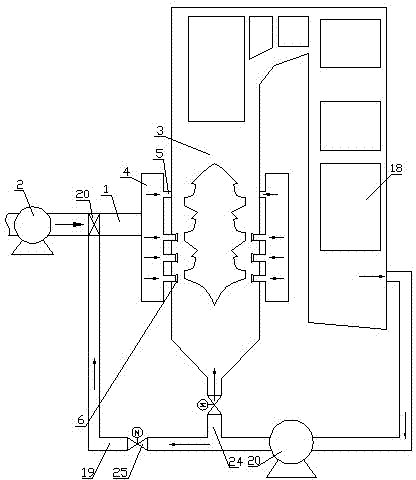

Incineration treatment device for nitrogen-containing organic wastes and incineration treatment process

ActiveCN102644922AEvenly distributedReduce the temperatureIncinerator apparatusChemical industryFlue gas

The invention discloses an incineration treatment process for nitrogen-containing organic wastes, which includes: a, sending wastes into an incinerator to incinerate at a high temperature and maintaining the incineration temperature by injecting after-burning fuel; b, injecting combustion-supporting air which is divided into primary air and secondary air according to a certain proportion into a fire chamber for supporting combustion; c, injecting reducing agents to the tail of a hot oxidation furnace and reducing part of NOx in flue gas by the SNCR (selective non-catalytic reduction) method; d, leading high-temperature flue gas from the hot oxidation furnace into a waste heat boiler to recover part of heat; e, leading the flue gas from the waste heat boiler into an SCR(selective catalytic reduction) treater to reduce content of NOx in flue gas further; and f, further recovering afterheat of flue gas by the aid of an air preheater arranged at the downstream of the SCR treater and then discharging flue gas through a chimney. The incineration treatment process is simple and low in cost for incineration of organic wastes, denitration efficiency can be guaranteed by a two-stage denitration process, emission standards can be met, afterheat of flue gas can be recovered, and accordingly the incineration treatment process can be applied to the similar organic waste treatment projections in the chemical industry.

Owner:天津辰创环境工程科技有限责任公司

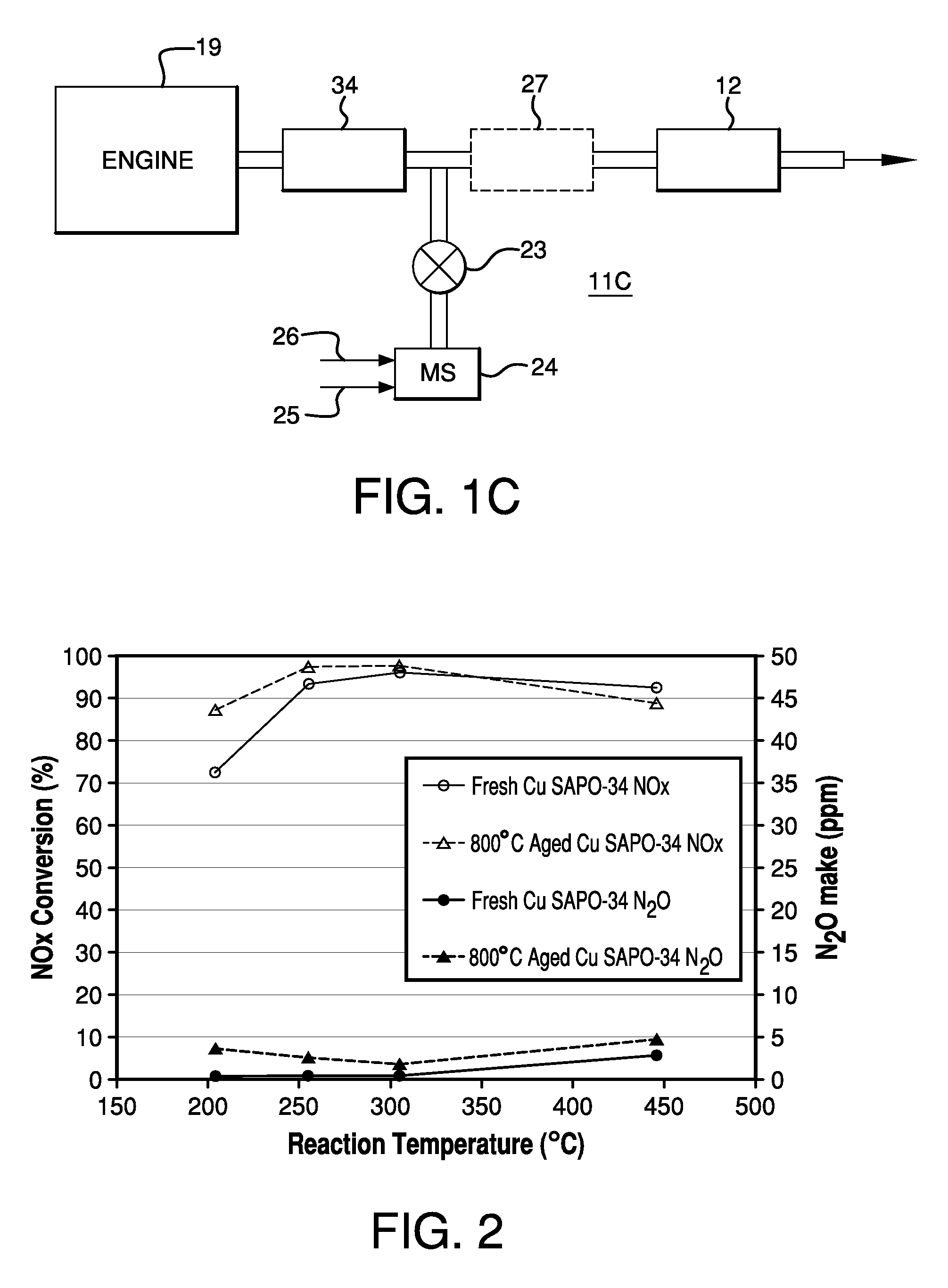

Systems Utilizing Non-Zeolitic Metal-Containing Molecular Sieves Having The CHA Crystal Structure

ActiveUS20110300028A1Good hydrothermal stabilityImprove catalytic performanceNitrous oxide captureCombination devicesMolecular sieveCrystal structure

Systems for treating exhaust gas incorporating catalysts comprising metal-loaded non-zeolitic molecular sieves having the CHA crystal structure, including Cu-SAPO-34, and methods for preparing such catalysts are disclosed. The catalysts can be used to remove nitrogen oxides from a gaseous medium across a broad temperature range and exhibit hydrothermal stability at high reaction temperatures.

Owner:BASF CORP

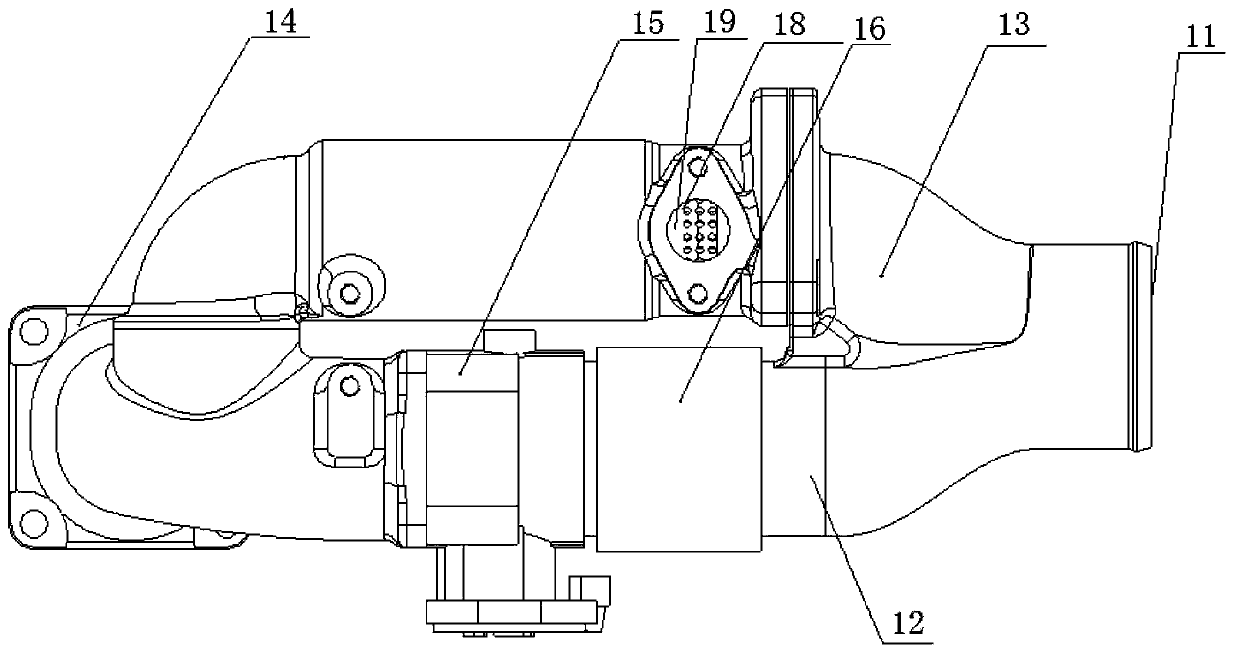

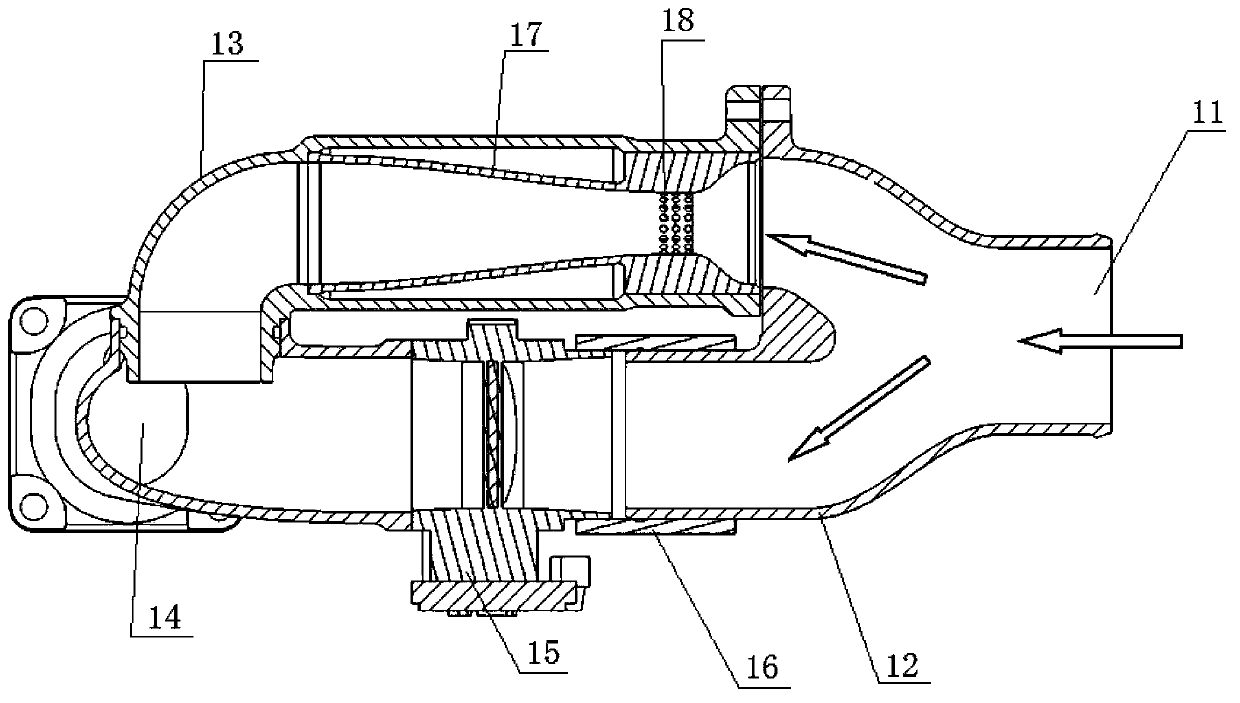

Air inlet connecting pipe of EGR engine

InactiveCN103397959AImprove mixing uniformityIncrease consumption rateNon-fuel substance addition to fuelInternal combustion piston enginesElectronic throttleEngineering

The invention discloses an air inlet connecting pipe of an EGR engine. The air inlet connecting pipe comprises a fresh air inlet single pipe and an exhaust gas mixing tube. The two ends of the fresh air inlet single pipe are provided with a sharing air inlet and a sharing air outlet respectively. The sharing air inlet is connected with a device used for providing fresh air, the sharing air outlet is connected with an air inlet pipe, and an electronic throttle valve which is in control connection with an engine ECU is connected between the sharing air inlet and the sharing air outlet in series. The exhaust gas mixing tube uses the sharing air inlet together with the fresh air inlet single pipe, and an air outlet of the exhaust gas mixing tube is connected into the fresh air inlet single pipe on the upstream portion of the sharing air outlet. A Venturi tube is additionally arranged in the exhaust gas mixing tube, an exhaust gas channel hole which is led to the inside of the Venturi tube is formed in the throat portion of the equal diameter of the Venturi tube, and an exhaust gas air inlet is formed in the side wall of the exhaust gas mixing tube corresponding to the exhaust gas channel hole. According to the air inlet connecting pipe of the EGR engine, a double-channel air inlet mode is adopted, the mixing uniformity of exhaust gas and the fresh air is improved, and nitric oxide in the exhaust gas can be effectively lowered.

Owner:GUANGXI YUCHAI MASCH CO LTD

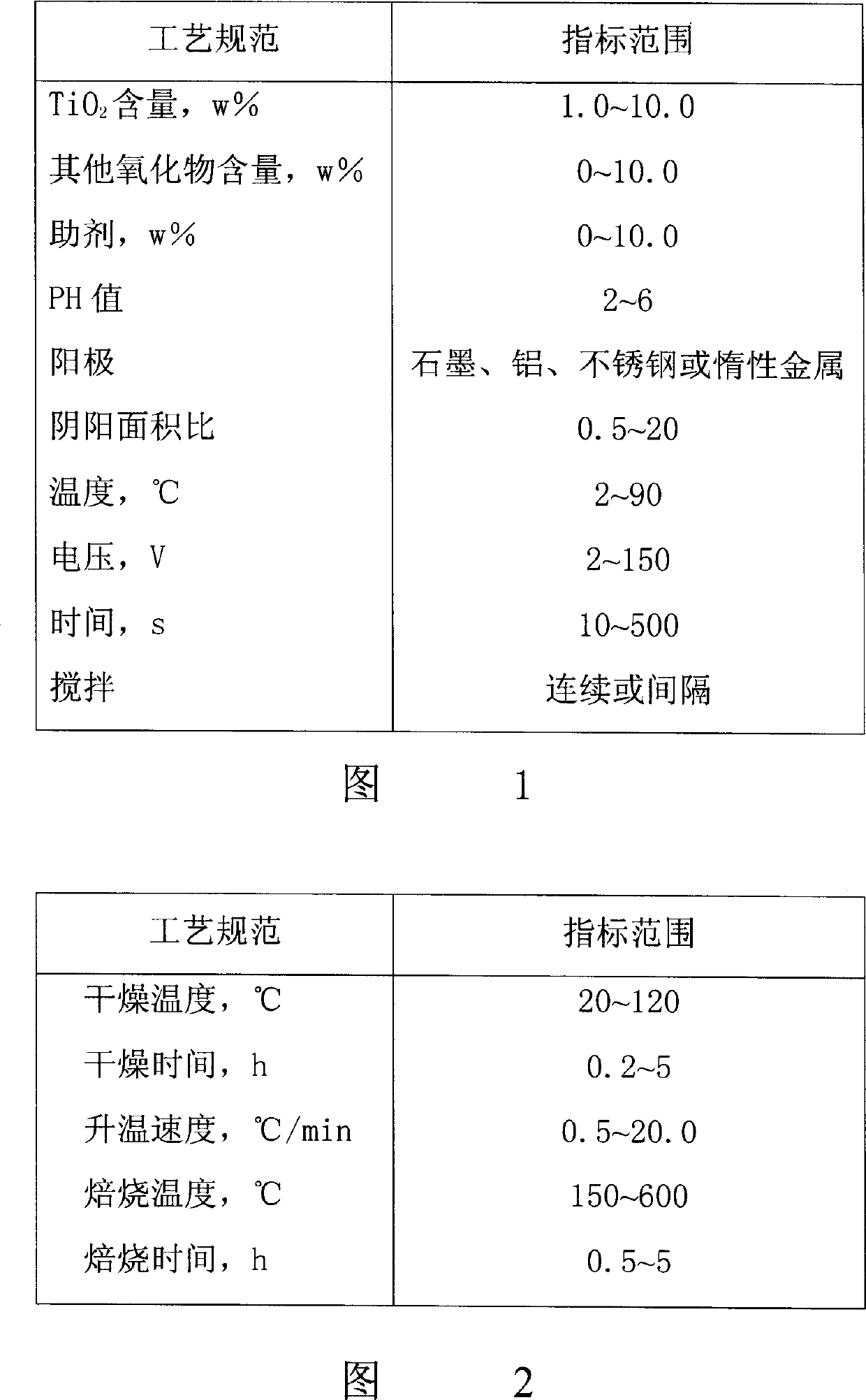

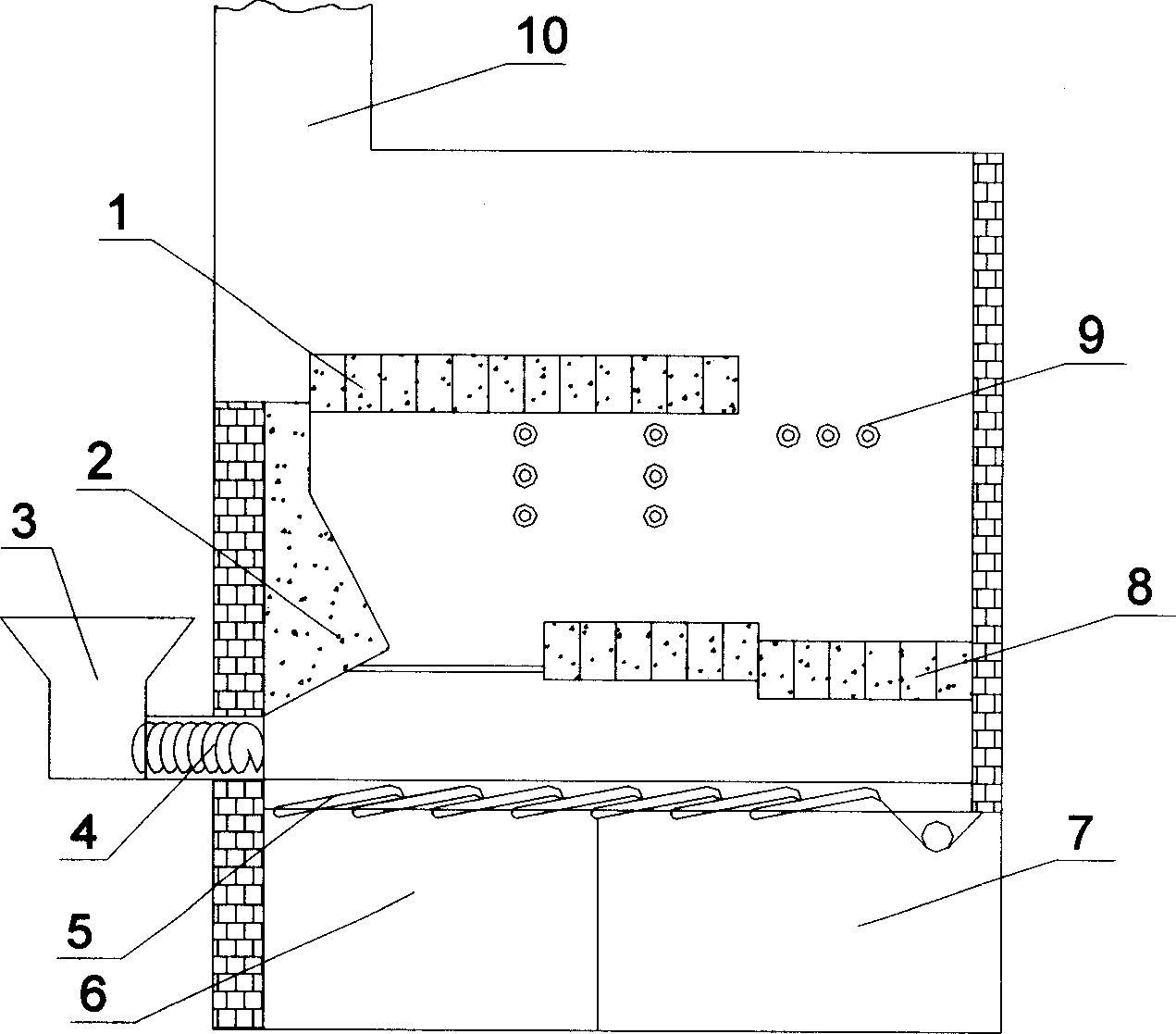

Electrophoresis preparation method for surface optical catalytic film of metal substrate

InactiveCN1438069AImprove adhesion strengthThickness is easy to controlWater/sewage treatment by irradiationCatalyst activation/preparationMetallic materialsMetallic substrate

The present invention discloses a preparation method of titanium dioxide photocatalytic membrane loaged on metal surface, its main technological process includes: in the electrophoretic solution containing a certain content of titanium dioxide sol or containing binary or multi-component compounded oxide sol of titanium dioxide using the pretreated metal base body as cathode, using graphite, aluminium, stainless steel and inert metal as anode, utilizing electrophoretic mode to form a layer of titanium dioxide membrane on the metal surface under the condition of a certain voltage, drying and calcining to make the titanium dioxide membrane be fixed on the metal surface. Said membrane is high in adhesive strength, and has high photocatalytic activity.

Owner:FUZHOU UNIV

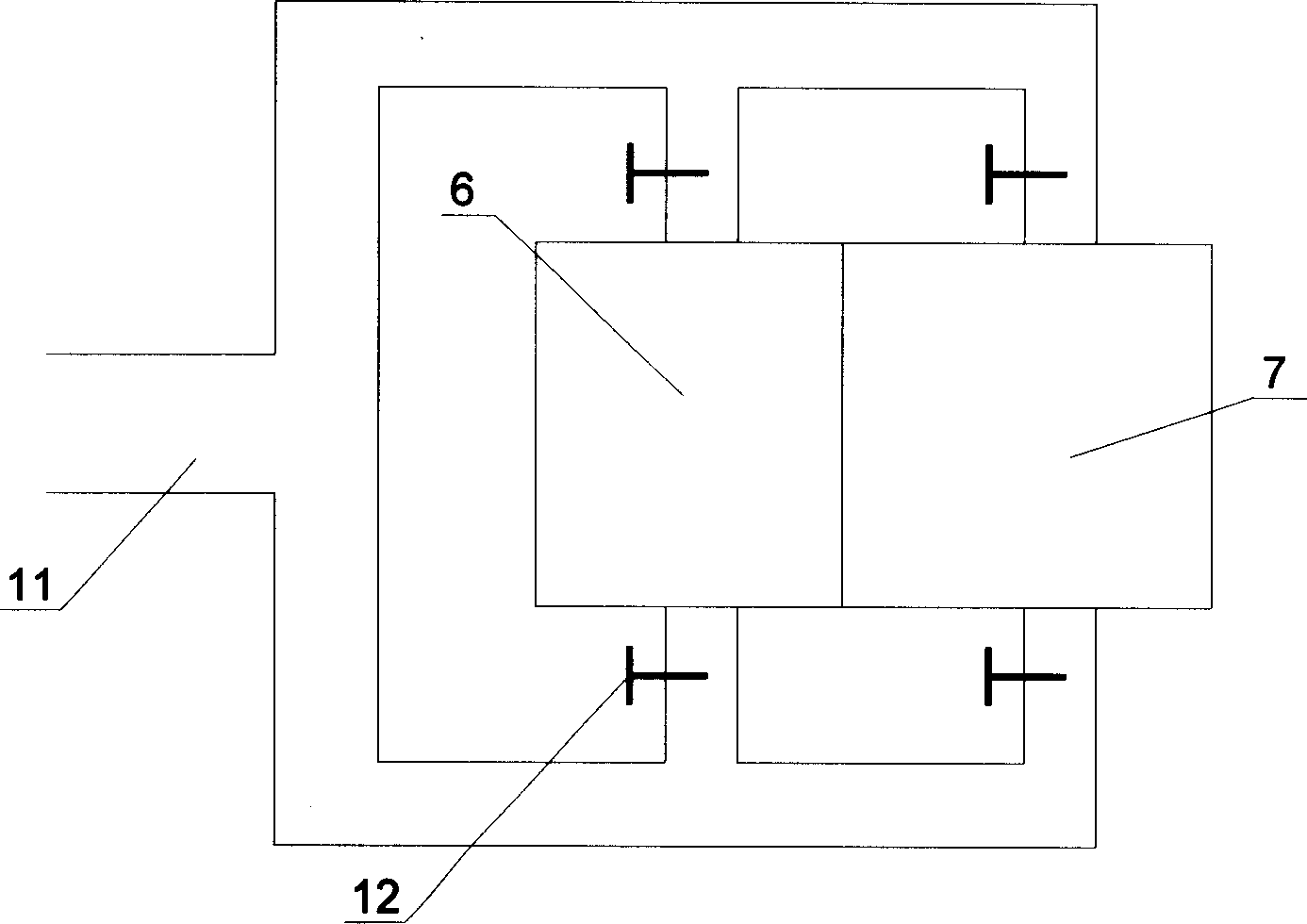

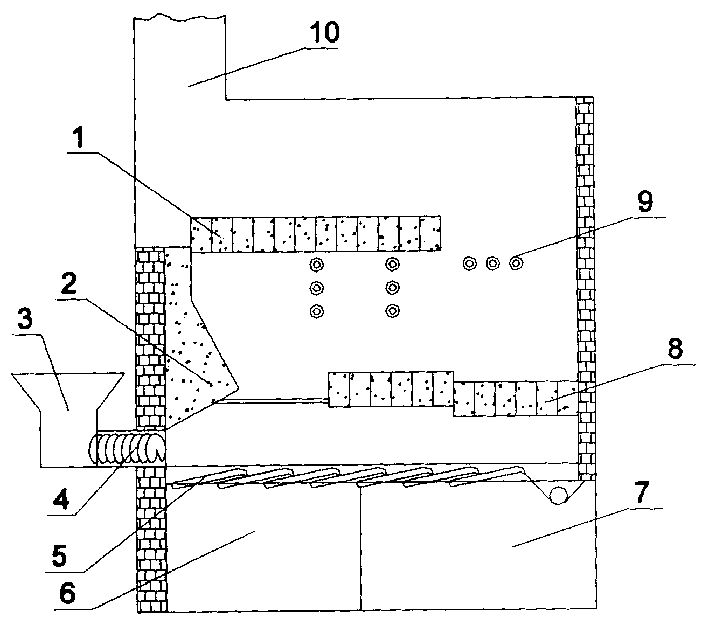

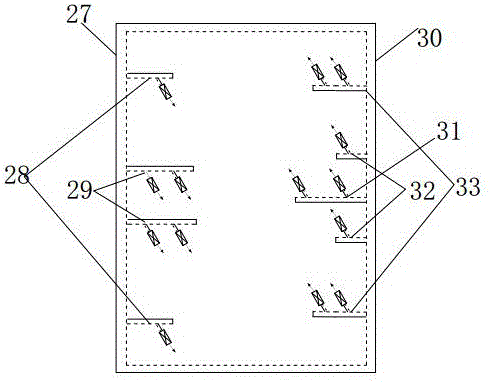

Low nitrogen oxide biomass boiler with variable furnace arch structure

InactiveCN1488889ARich varietyAdapt to many types of biomassIncinerator apparatusFirebridgesLow nitrogenEngineering

The present invention relates to a low-nitrogen oxide biomass boiler with variable furnace arch structure, including front and rear zoned-air chambers, reciprocating grate, combined arch formed from front arch, rear arch and upper arch and zoned-air nozzles. The bottom portion of the boiler is equipped with front zone air chamber and rear zone air chamber to implement zoned-air distribution, and the reciprocating grate is arranged over the front and rear zound-air chambers, and in the interior of furnace cavity wall between upper arch and rear arch air inlaid several zoned-air nozzles whose inlets are connected with main air channel. Said boiler can extensively utilize biomass fuel, and can obtain good combustion effect.

Owner:SHANGHAI JIAO TONG UNIV

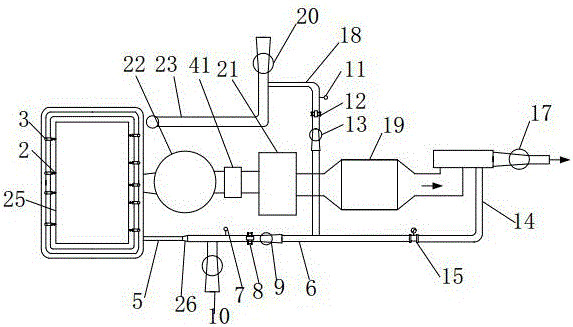

Low-nitrogen combustion technique based on circulating fluidized bed boiler

ActiveCN106051749ASolve the reduction of NOx emissionsSolve the high carbon content of fly ashFluidized bed combustionFluegas recirculationBurning outCirculating fluidized bed boiler

The invention discloses a low-nitrogen combustion technique based on circulating fluidized bed boiler. The circulating fluidized bed boiler comprises a boiler body, a cyclone separator, a deduster, an induced draft fan, a primary air supply system and a secondary air supply system which are connected in sequence. A smoke recirculation pipe is drawn out behind the induced draft fan. The primary air supply system and the secondary air supply system are connected to the smoke recirculation pipe in parallel. A burn-out chamber is arranged at an outlet of the cyclone separator. The low-nitrogen combustion technique based on the circulating fluidized bed boiler comprises the following steps that pulverized coal enters the boiler body under the action of primary air, specifically, the amount of smoke recirculation air in the primary air accounts for 8-10% the total air amount of the primary amount, and the amount of the primary air accounts for 40-45% of the total air amount; secondary air is introduced into the boiler body through the secondary air supply system, specifically, the amount of smoke recirculation air in the secondary air accounts for 12-14% the total air amount of the secondary air; fine flying ash enters the burn-out chamber; and over fire air is introduced into the burn-out chamber. According to the low-nitrogen combustion technique based on the circulating fluidized bed boiler, the burn-out chamber is arranged at the outlet of the separator, and part of smoke is mixed into the primary air and the secondary air, so that generation of NOx is reduced.

Owner:QINGDAO JINTIAN THERMAL POWER CO LTD

Burning system of heavy oil boiler and method thereof

ActiveCN102927561AReduce nitrogen oxidesMeet environmental protection requirementsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelNitrogen oxidesFlue gas

The invention discloses a burning system of a heavy oil boiler and a method thereof. The burning system comprises an air inlet pipe, an air fan, more than one air box placed on the outer side of a hearth, burnout air spouts formed in each air box, a plurality of burners and igniters, wherein each burner comprises an atomized oil gun, a primary air pipe and a secondary air pipe which are arranged in a sleeving way from interior to exterior, the atomized oil gun comprises an oil pipe and a nozzle which are connected, and the front end of the primary air pipe is provided with a combustion stabilizer; the secondary air pipe is internally provided with a rotational flow device, the front end surface of the nozzle is concentricalally provided with two circles of nozzle holes, each circle of nozzle holes comprises a plurality of nozzle holes which are formed in an equidistant manner, the two circles of nozzle holes are formed in the periphery at intervals, and the hole diameters and spray angles of the outer circle of nozzle holes are larger than those of the inner circle of nozzle holes; and an economizer outlet of the boiler is also connected with an air inlet pipe through a flue gas recirculation pipe, and the flue gas recirculation pipe is provided with a circulating fan. As the burning system and the method are used, the generation amount of nitrogen oxide is greatly reduced, more and more environmental requirements are met, and the burning system of the heavy oil boiler and the method thereof respectively have a relatively wide market prospect.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Process for producing an scr catalyst

InactiveUS20070173404A1Reduce nitrogen oxidesMaintain good propertiesCombination devicesNitrogen compoundsCombustionIron salts

In a process for producing an SCR catalyst for the selective reduction of NOx in NOx-containing exhaust gases of internal combustion engines, a support layer is applied to a substrate body. An iron salt dissolved in a liquid is applied to the support layer in such an amount that no excess of iron salt is present.

Owner:KARLSRUHER INST FUR TECH

Methods Utilizing Non-Zeolitic Metal-Containing Molecular Sieves Having The CHA Crystal Structure

ActiveUS20110300042A1Good hydrothermal stabilityImprove catalytic performanceNitrous oxide captureNitrogen compoundsMolecular sieveReaction temperature

Catalysts comprising metal-loaded non-zeolitic molecular sieves having the CHA crystal structure, including Cu-SAPO-34, and methods for treating exhaust gas incorporating such catalysts are disclosed. The catalysts can be used to remove nitrogen oxides from a gaseous medium across a broad temperature range and exhibit hydrothermal stability at high reaction temperatures.

Owner:BASF CORP

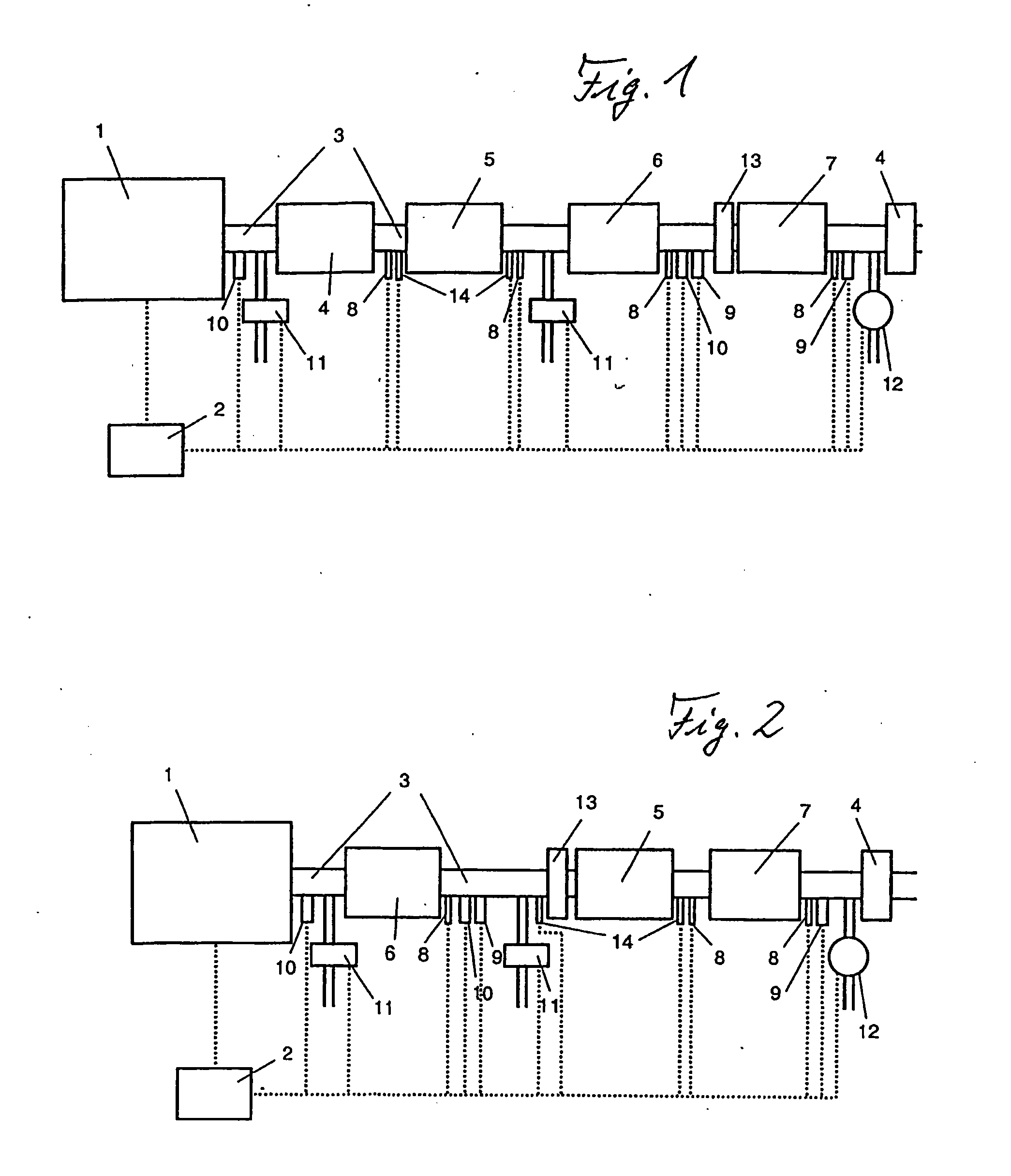

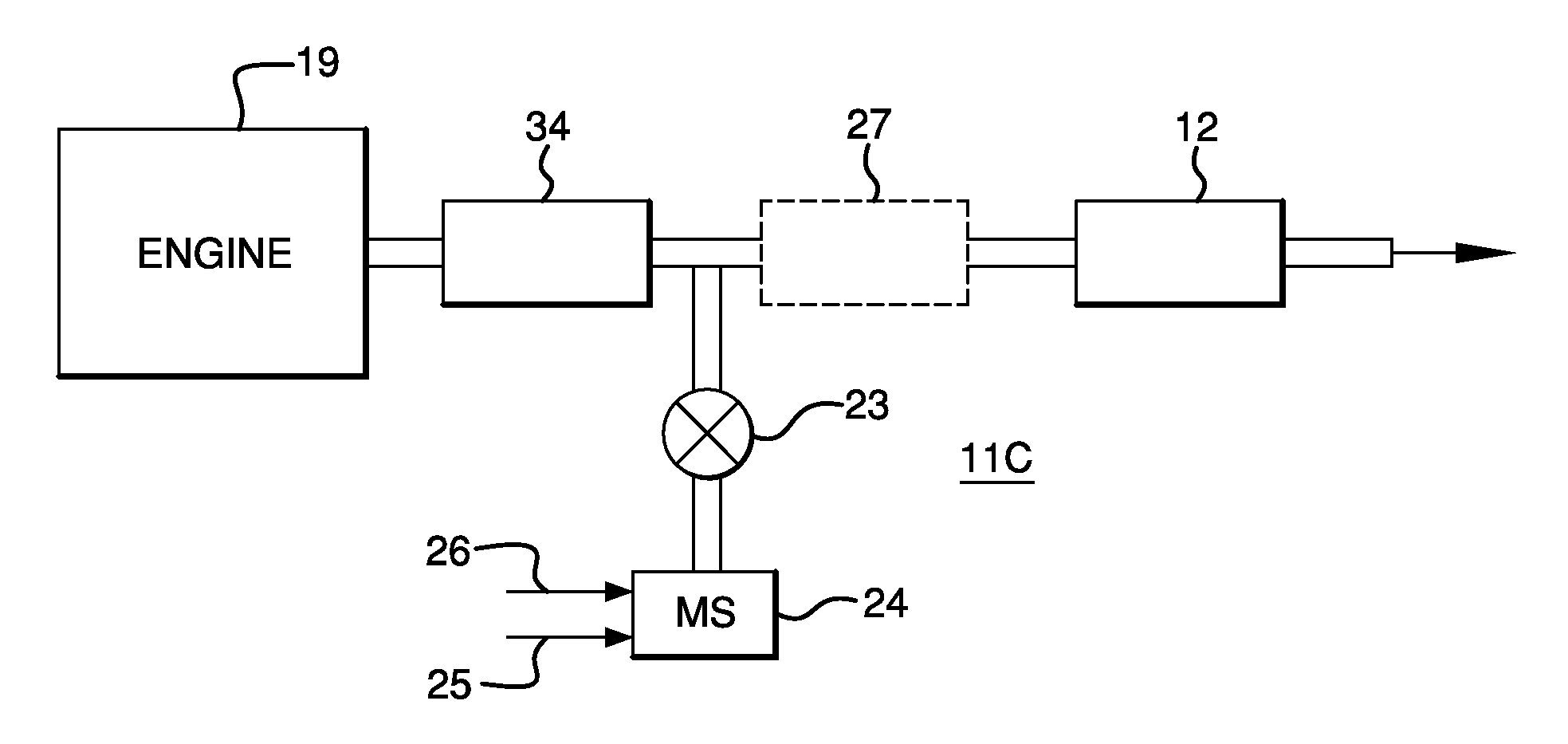

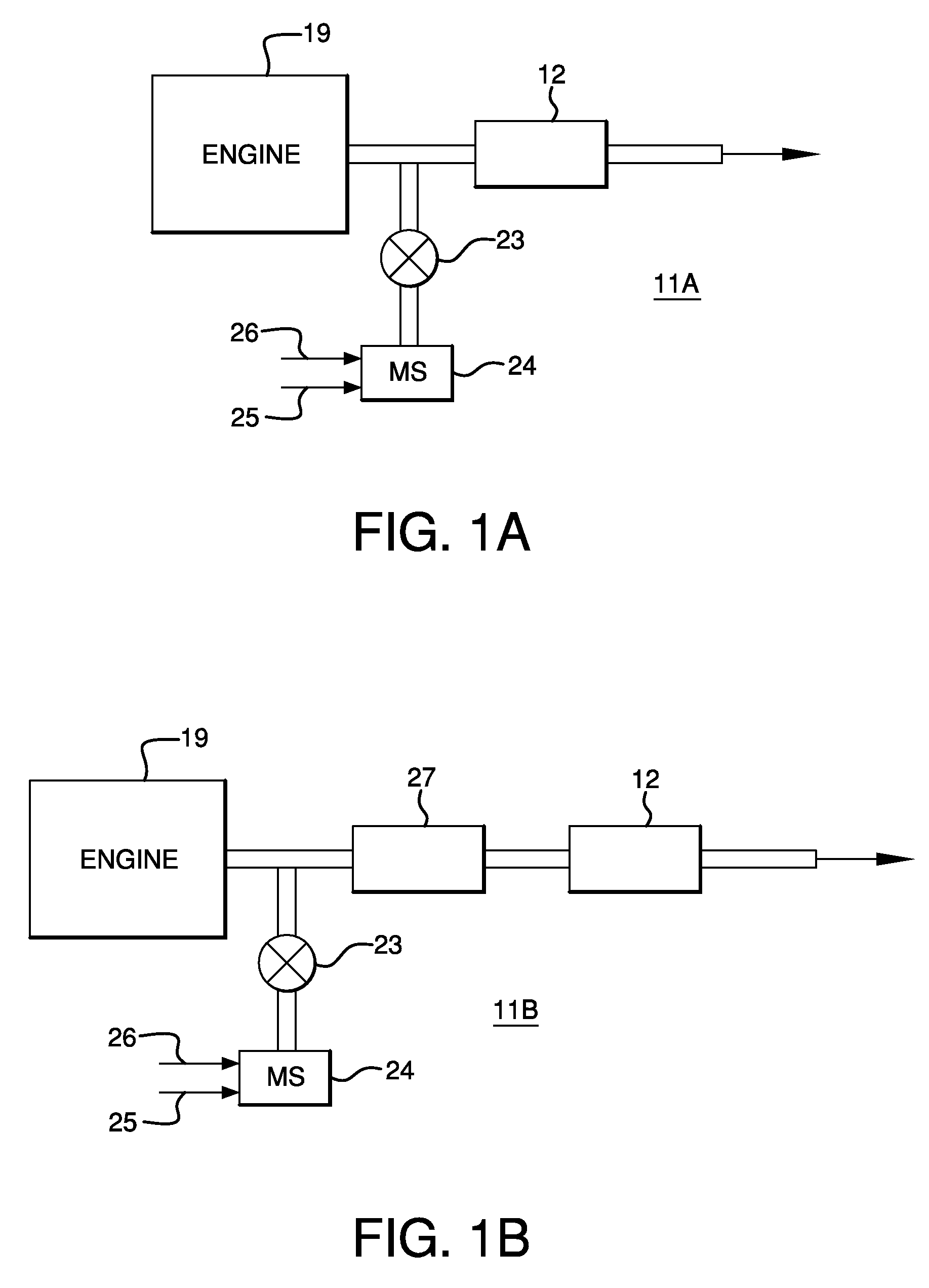

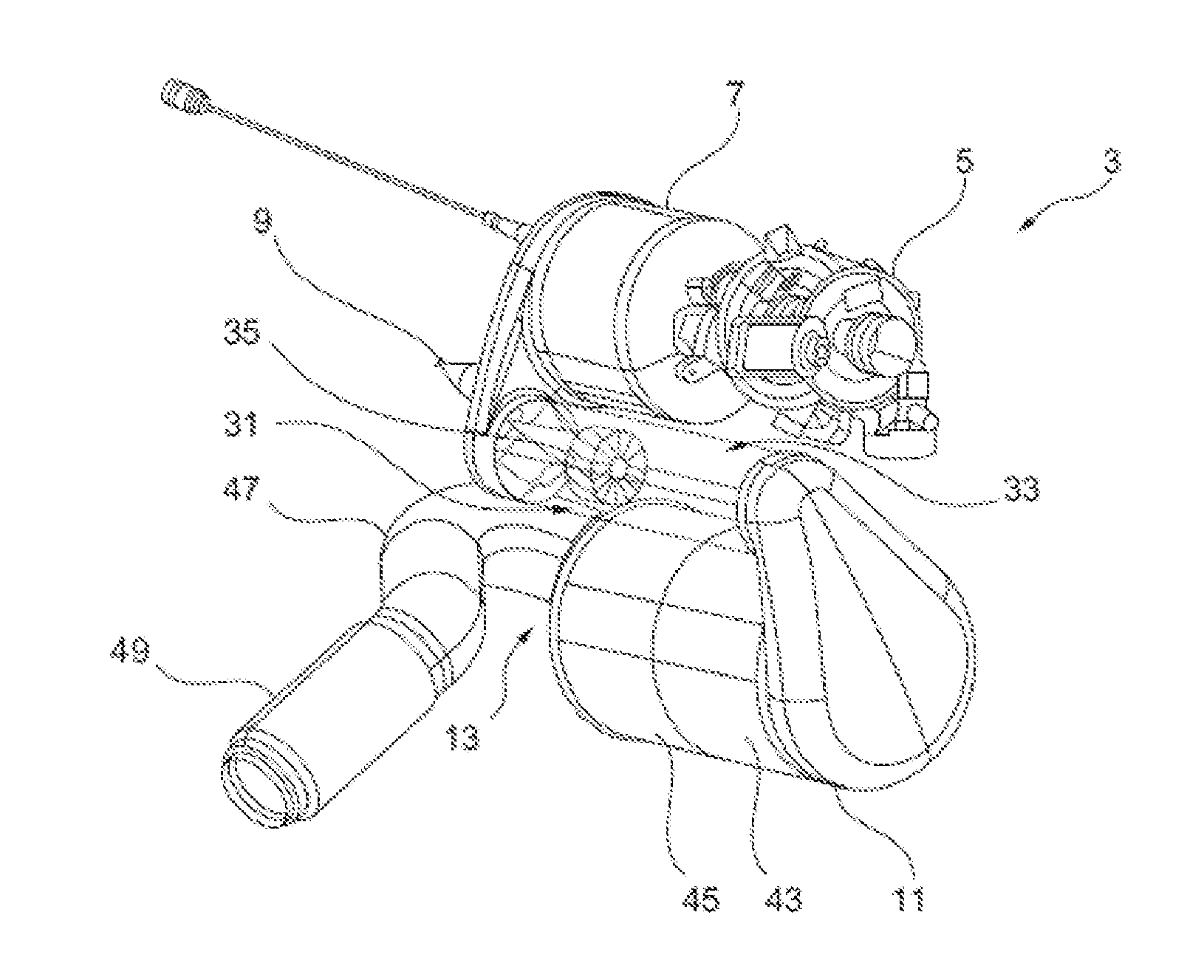

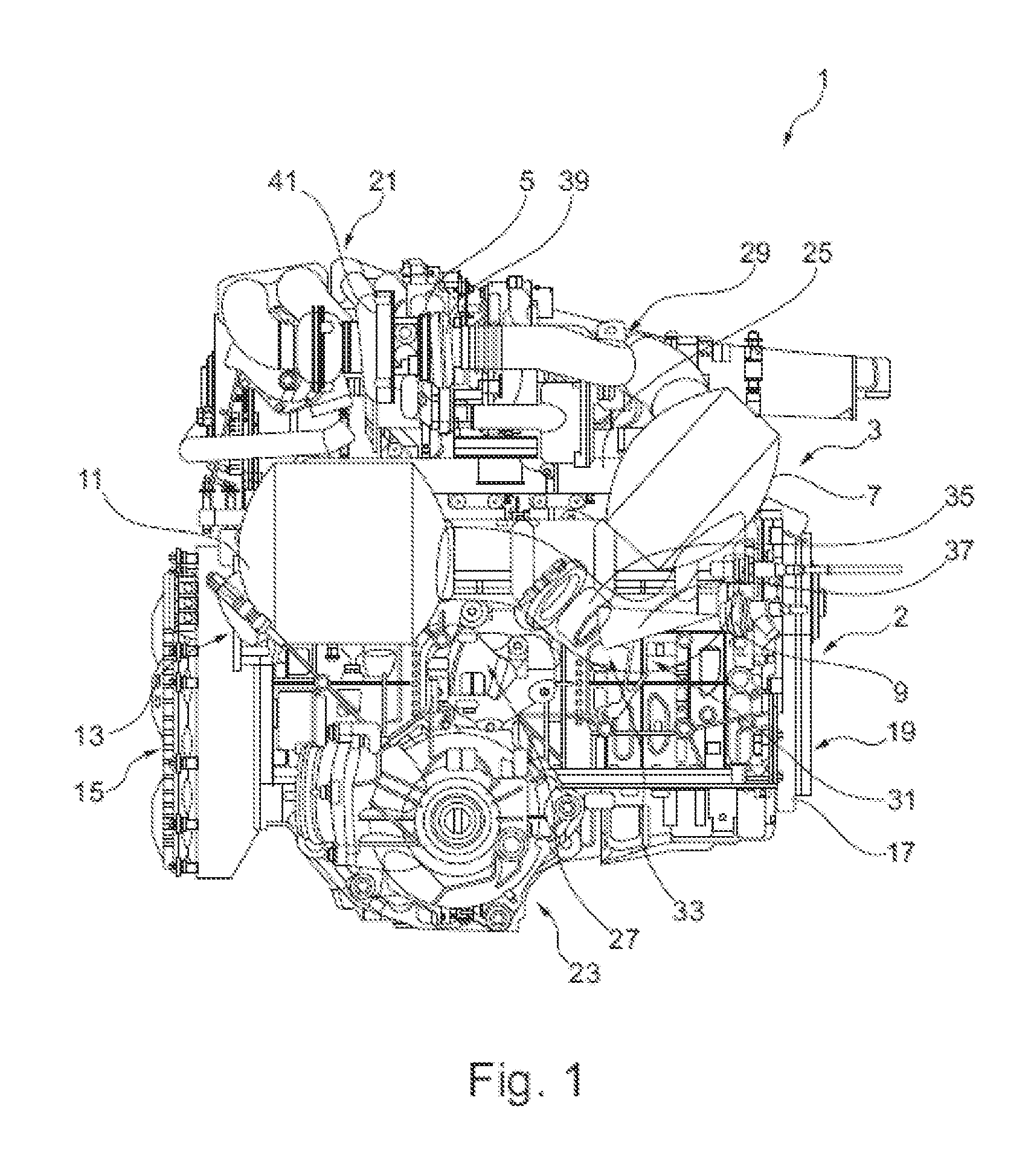

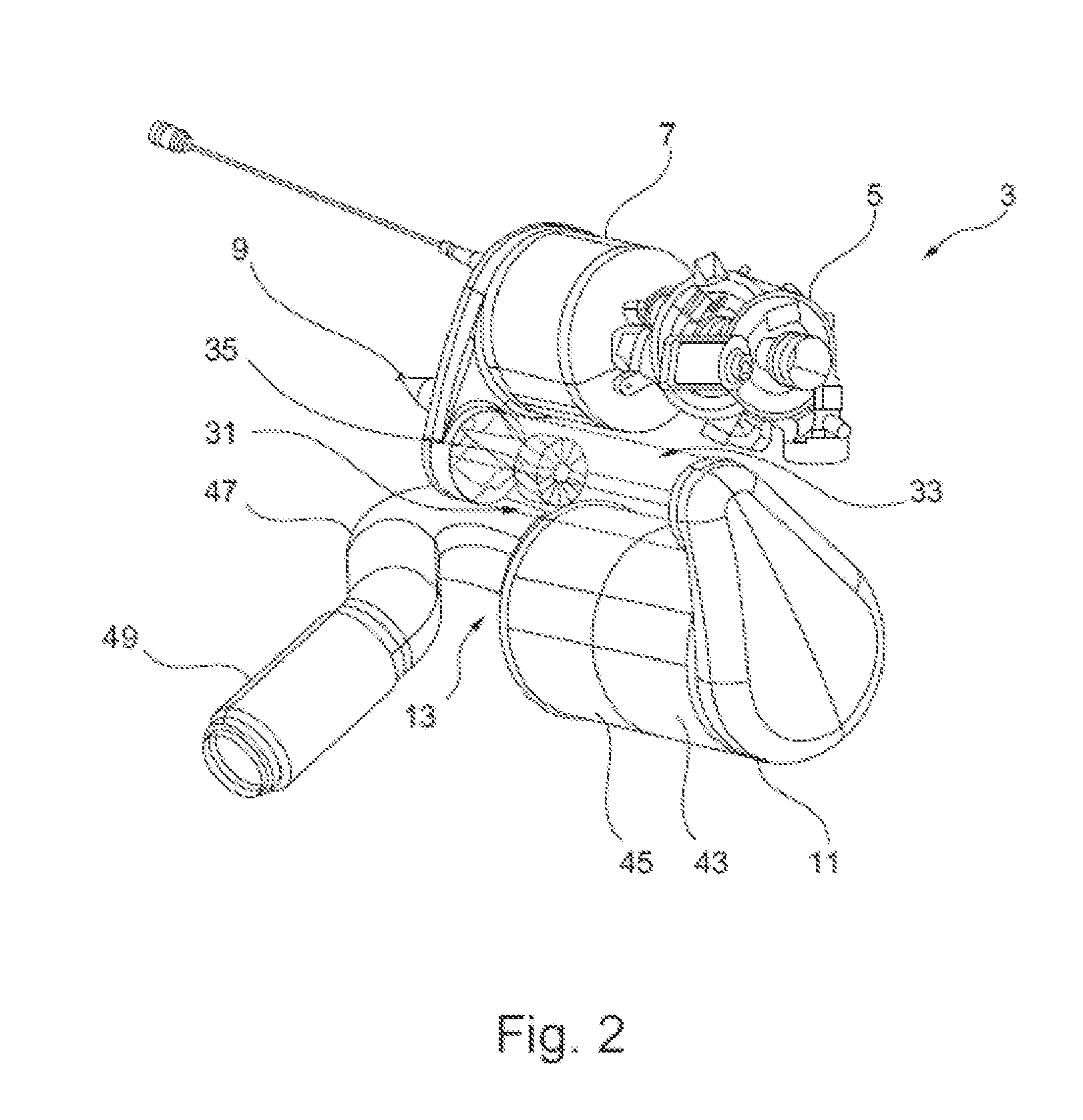

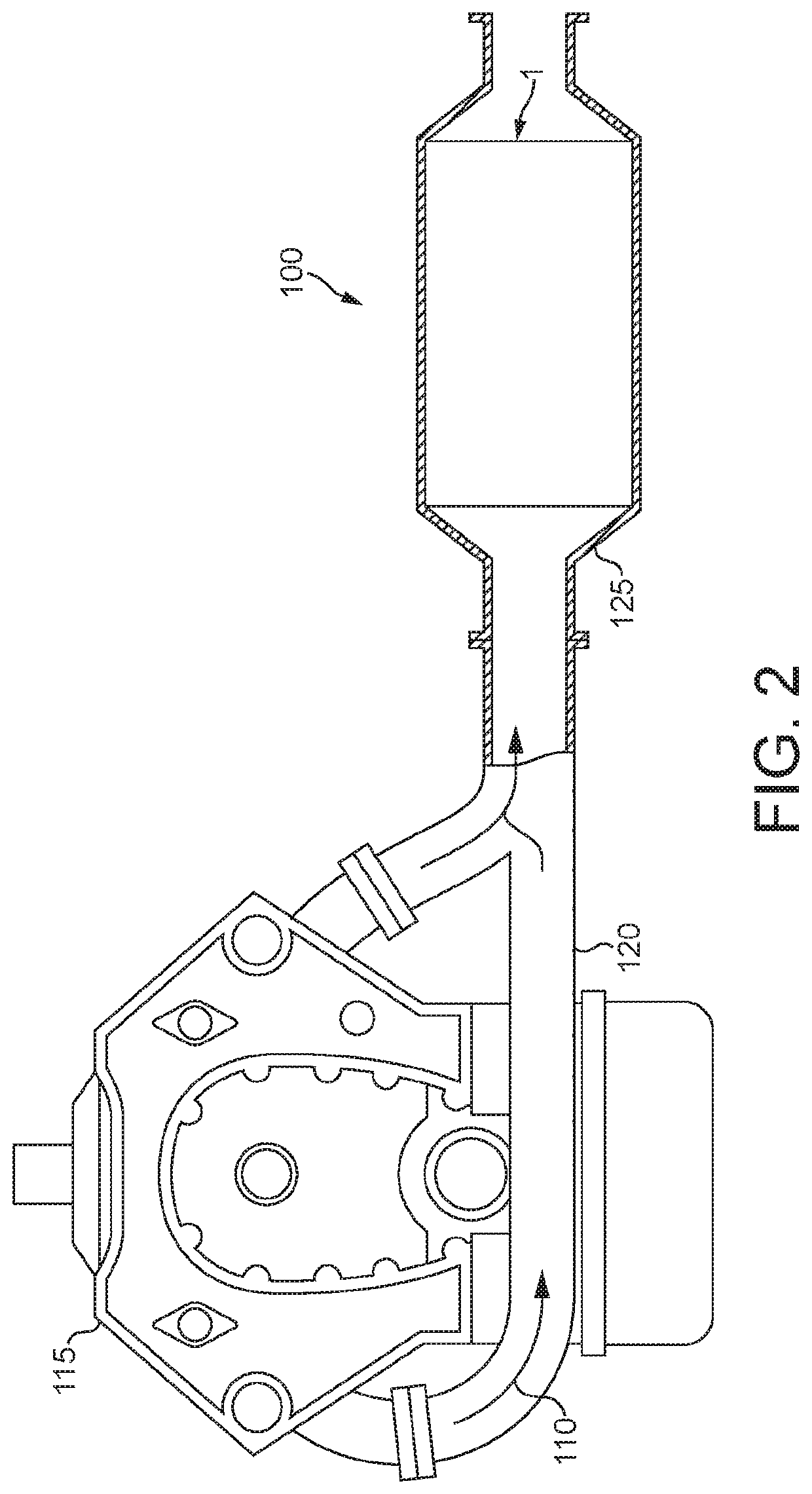

Cylinder Block Arrangement with an Exhaust Gas System

ActiveUS20140352297A1Minimized pressure lossMinimize temperatureInternal combustion piston enginesExhaust apparatusTurbochargerProcess engineering

An engine block arrangement includes an engine block and an exhaust gas system. The exhaust gas system, viewed in the flow direction of an exhaust gas flow, includes an exhaust gas turbocharger, an oxidation catalytic converter, a feed device for a urea-water solution, a particle filter, and an SCR catalytic converter arranged one behind the other. The exhaust gas turbocharger, the oxidation catalytic converter, the feed device for the urea-water solution, the particle filter, and the SCR catalytic converter are situated together on the engine block along one side thereof, the side being oriented essentially perpendicularly with respect to an output side of the engine block.

Owner:DAIMLER AG

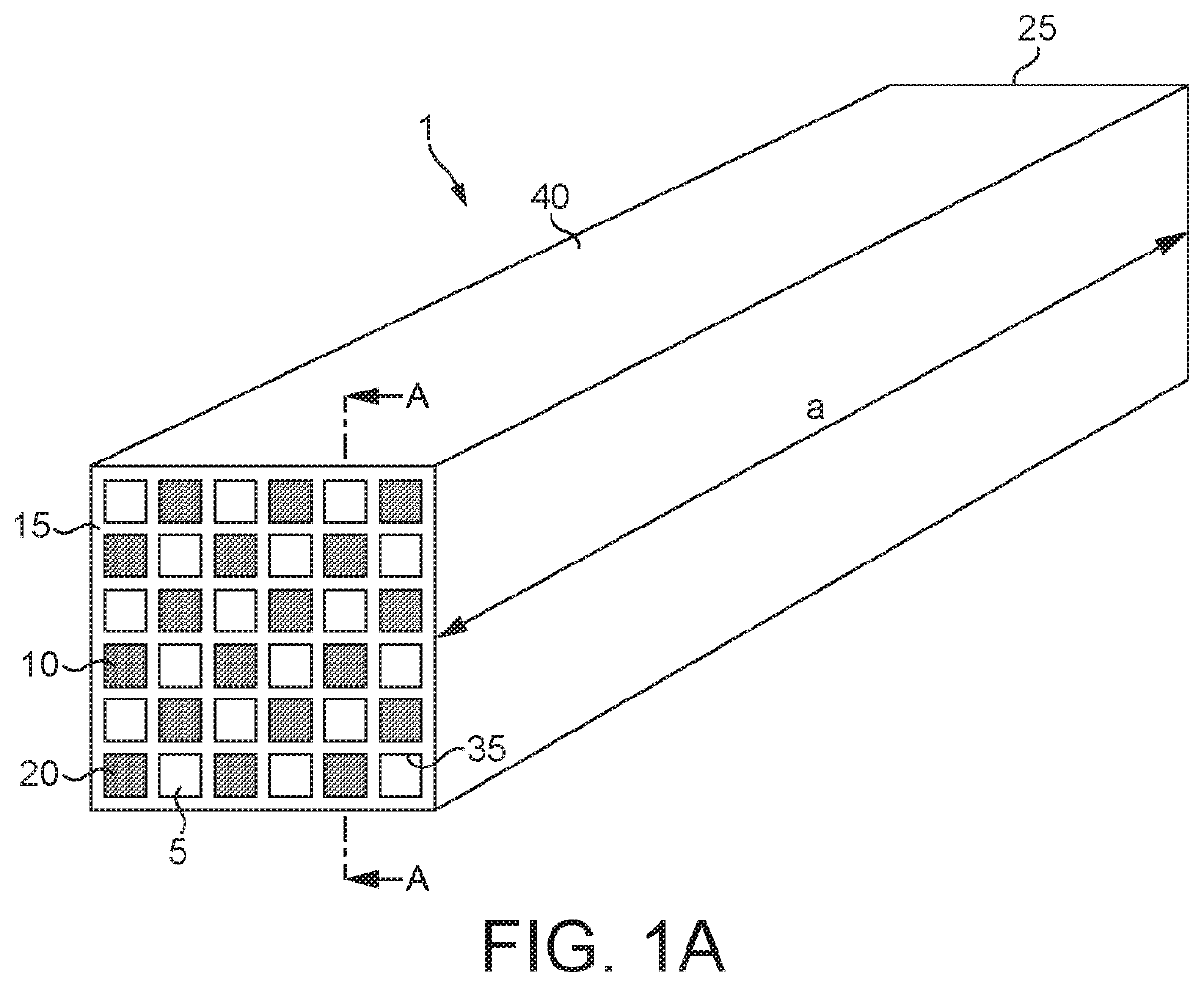

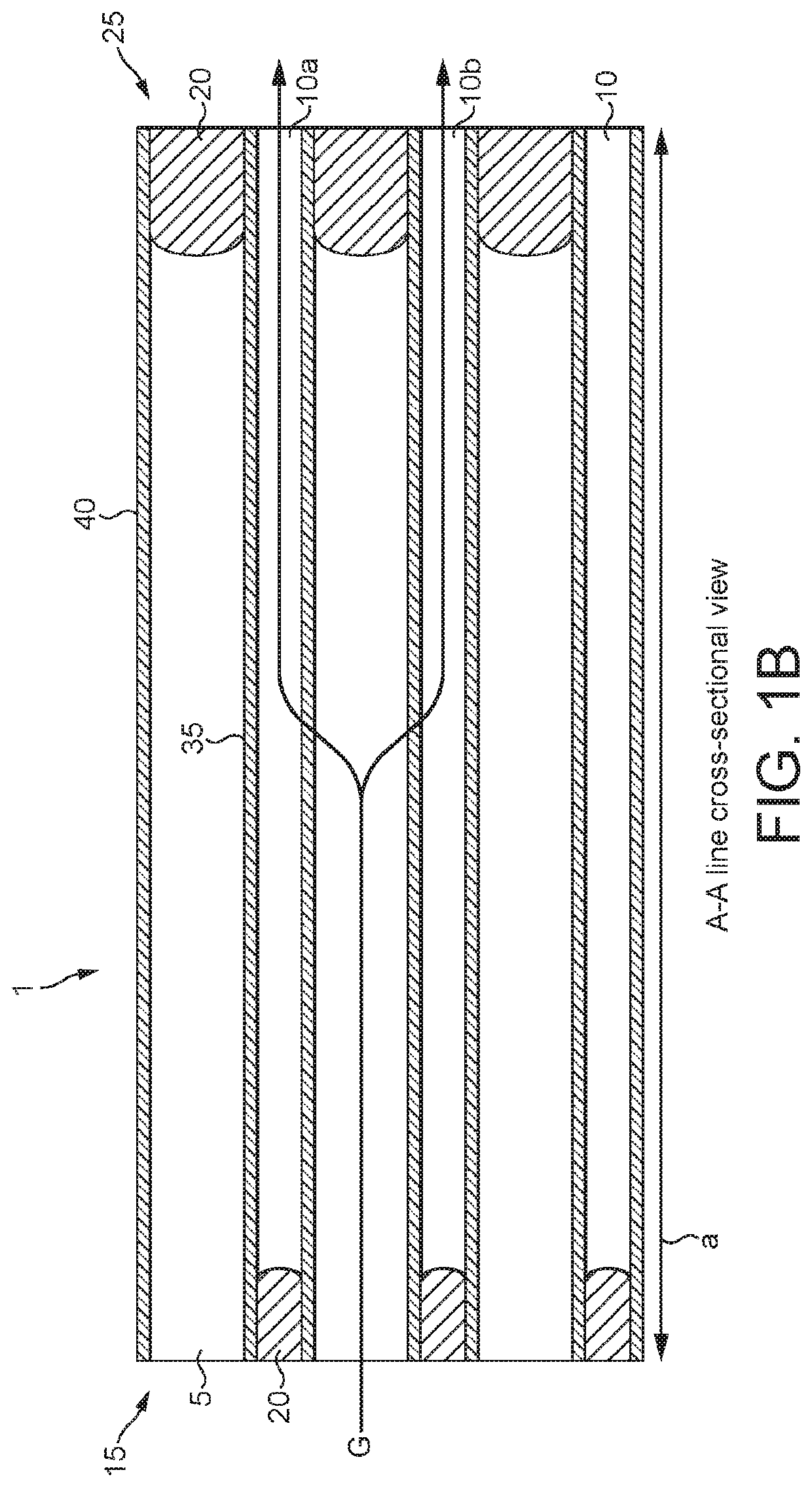

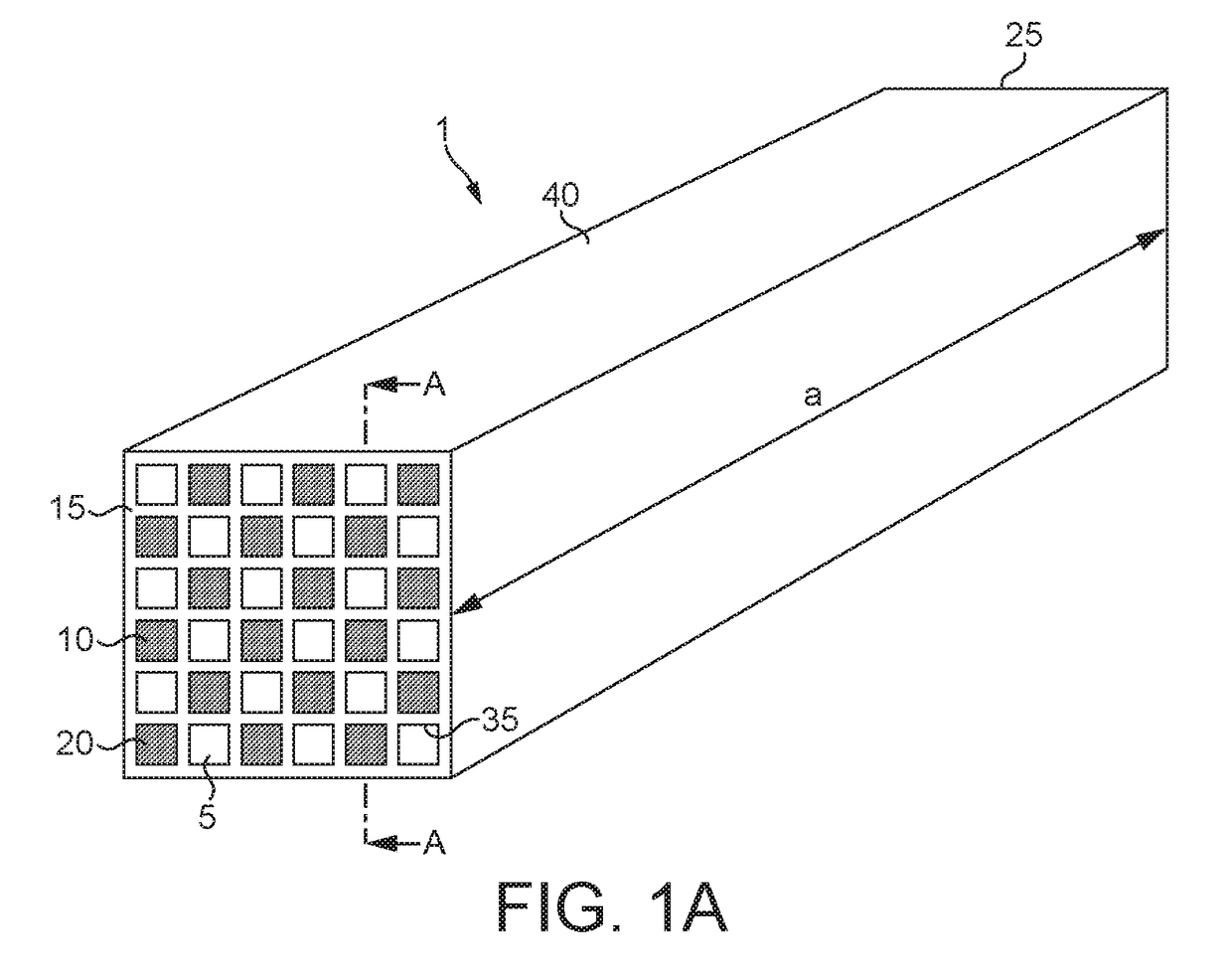

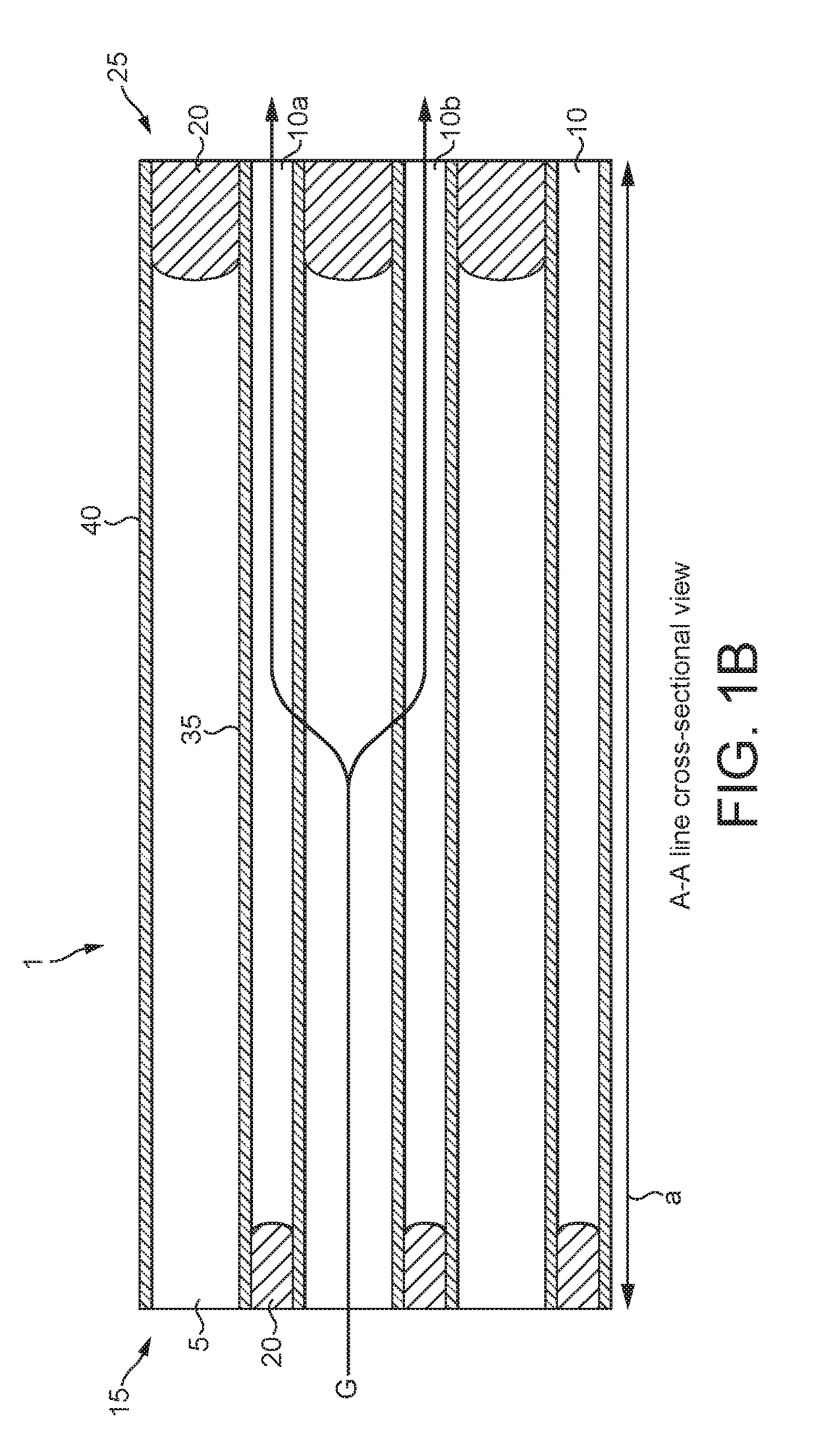

Gasoline particulate filter

ActiveUS10625243B2Solve the lack of activityReduce nitrogen oxidesInternal combustion piston enginesDispersed particle separationPorous substratePtru catalyst

A catalytic wall-flow monolith for use in an emission treatment system comprises a porous substrate and a three-way catalyst (TWC), wherein the TWC is distributed substantially throughout the porous substrate and wherein the TWC comprises:(i) alumina;(ii) one or more platinum group metals; and(iii) an oxygen storage component (OSC),wherein the OSC comprises ceria or one or more mixed oxides comprising cerium and is present in a ratio by weight of OSC to alumina of from 65:35 to 85:15.

Owner:JOHNSON MATTHEY PLC

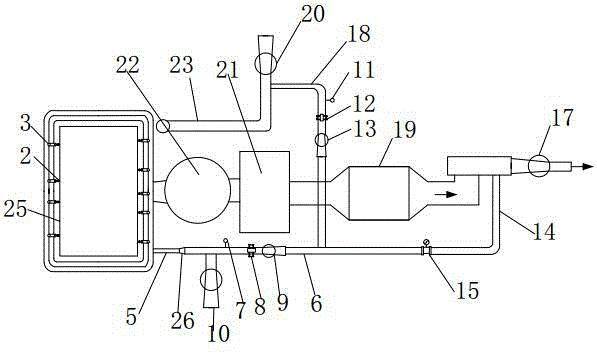

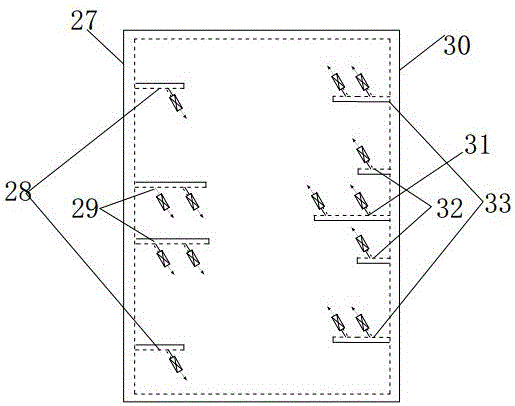

Circulating fluidized bed boiler system for achieving low nitrogen oxide discharge

InactiveCN105805730AImprove fluidization characteristicsWell mixedFluidized bed combustionStaged combustionFlue gasEngineering

The invention discloses a circulating fluidized bed boiler system for achieving low nitrogen oxide discharge. The circulating fluidized bed boiler system comprises a boiler, a cyclone separator, a dust remover and an induced draft fan which are sequentially connected. The circulating fluidized bed boiler system further comprises a primary air supply system and a secondary air supply system. A flue gas recirculation pipe is guided out of the rear portion of the induced draft fan and connected with the primary air supply system and the secondary air supply system in parallel. The secondary air supply system comprises a secondary air fan, a secondary air pipe, a plurality of secondary air vertical pipes arranged on the outer sides of a front wall and a rear wall of the boiler and secondary air nozzles, wherein the secondary air nozzles are arranged on a water cooling wall, connected with the secondary air vertical pipes and arranged in a dilute phase area of the boiler in a layered manner. According to the circulating fluidized bed boiler system, part of flue gas is mixed into primary air, the fluidization characteristic of a dense phase area during low-load running is improved, part of flue gas is mixed into secondary air, the air speed of the secondary air nozzles can be increased easily, a local high-temperature area is avoided, and generated NOx is reduced. By means of the secondary air arrangement manner of the system, the disturbance function of the flue gas in a hearth is increased, fuel is combusted fully, and the generated NOx is reduced.

Owner:QINGDAO JINTIAN THERMAL POWER CO LTD

Automotive Catalysts With Palladium Supported In An Alumina-Free Layer

InactiveUS20180071679A1Reduce nitrogen oxidesInternal combustion piston enginesExhaust apparatusNitrogen oxideInternal combustion engine

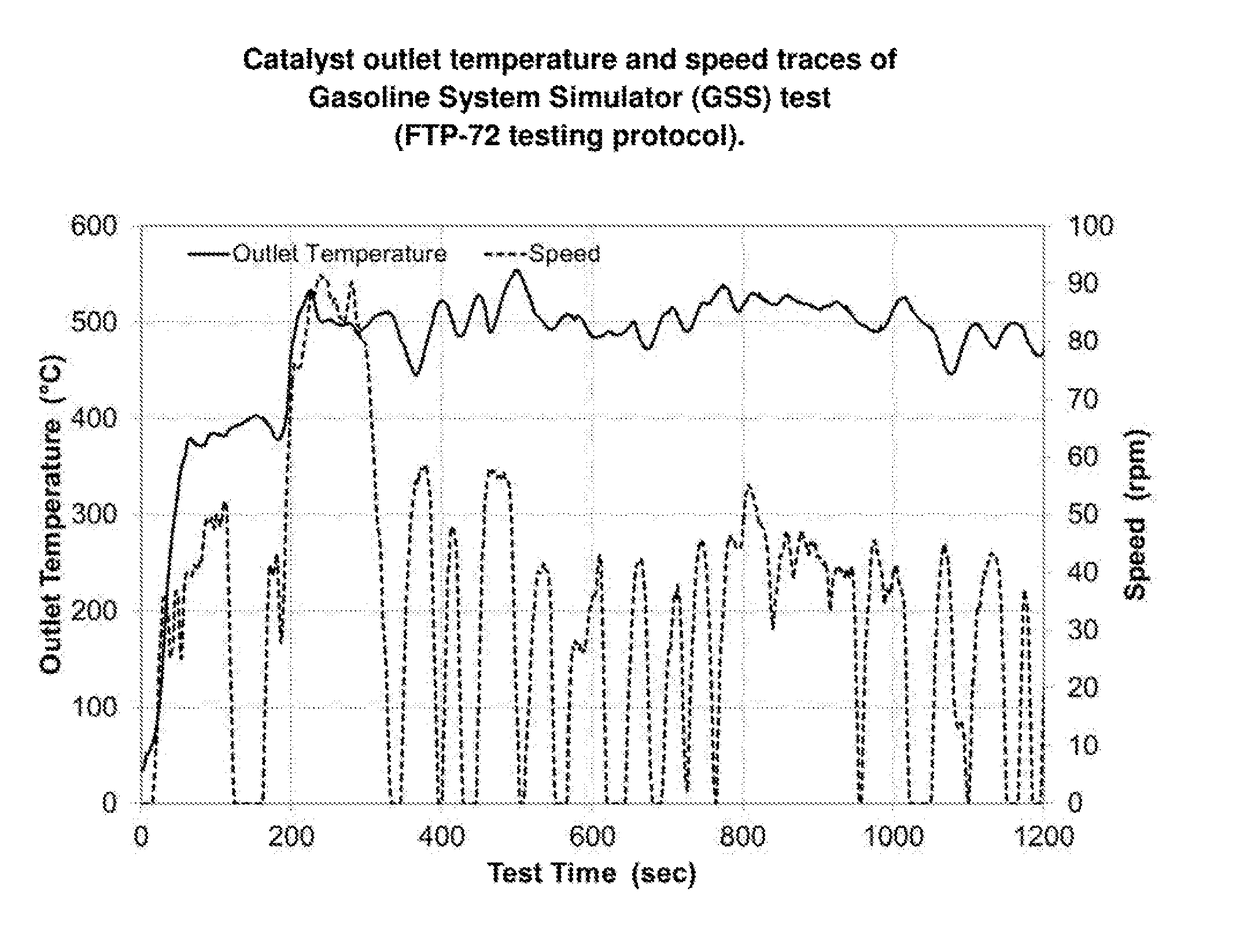

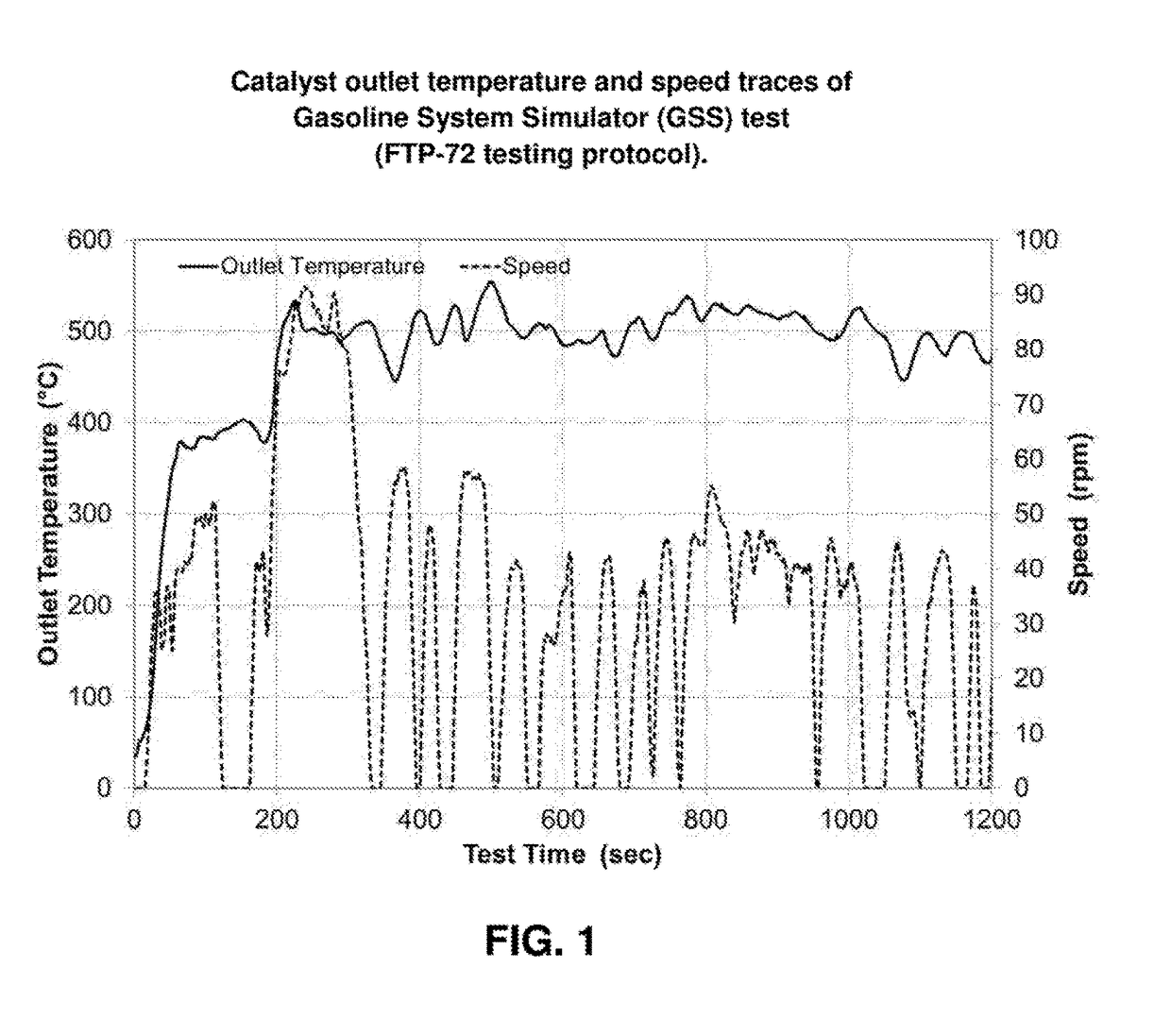

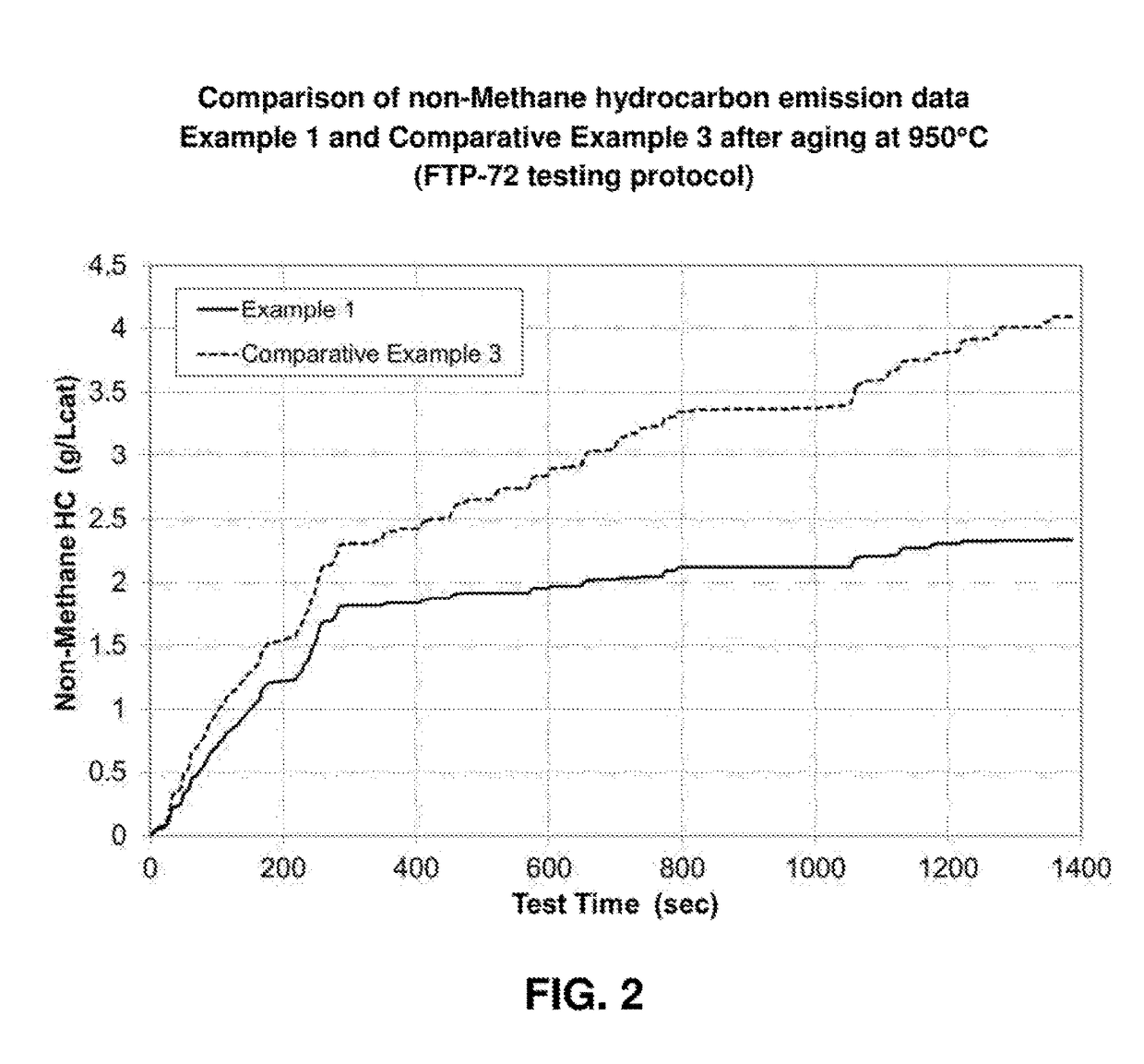

Catalysts that improve carbon monoxide (CO), hydrocarbon (HC), Catalyst outlet temperature and speed traces of and nitrogen oxides (NOx) light-off performance are provided. A catalyst composite for combustion engines, as provided herein, comprises a carrier and a first layer comprising a catalytic material on the carrier, the catalytic material comprising a palladium component supported on both a ceria-praseodymia-based oxygen storage component and a ceria-zirconia-based oxygen storage component, wherein the first layer is essentially free of alumina. The catalytic material is effective to substantially simultaneously oxidize carbon monoxide and hydrocarbons and reduce nitrogen oxides.

Owner:BASF CORP

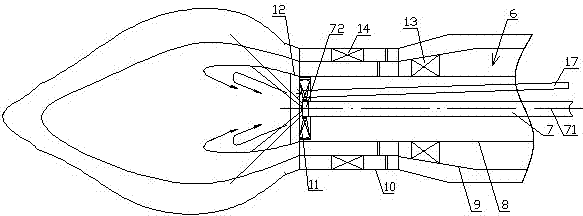

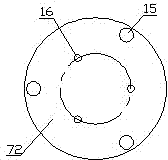

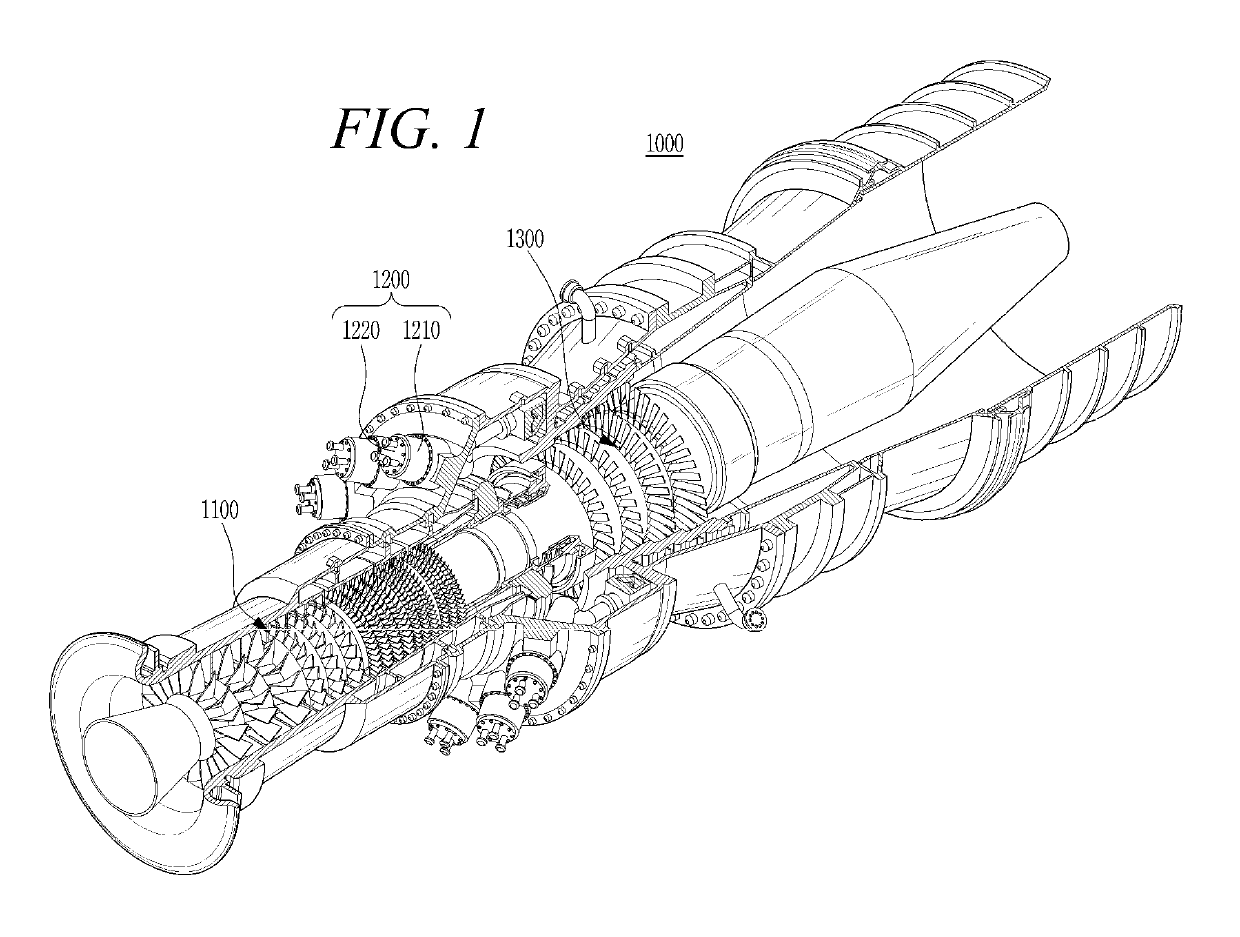

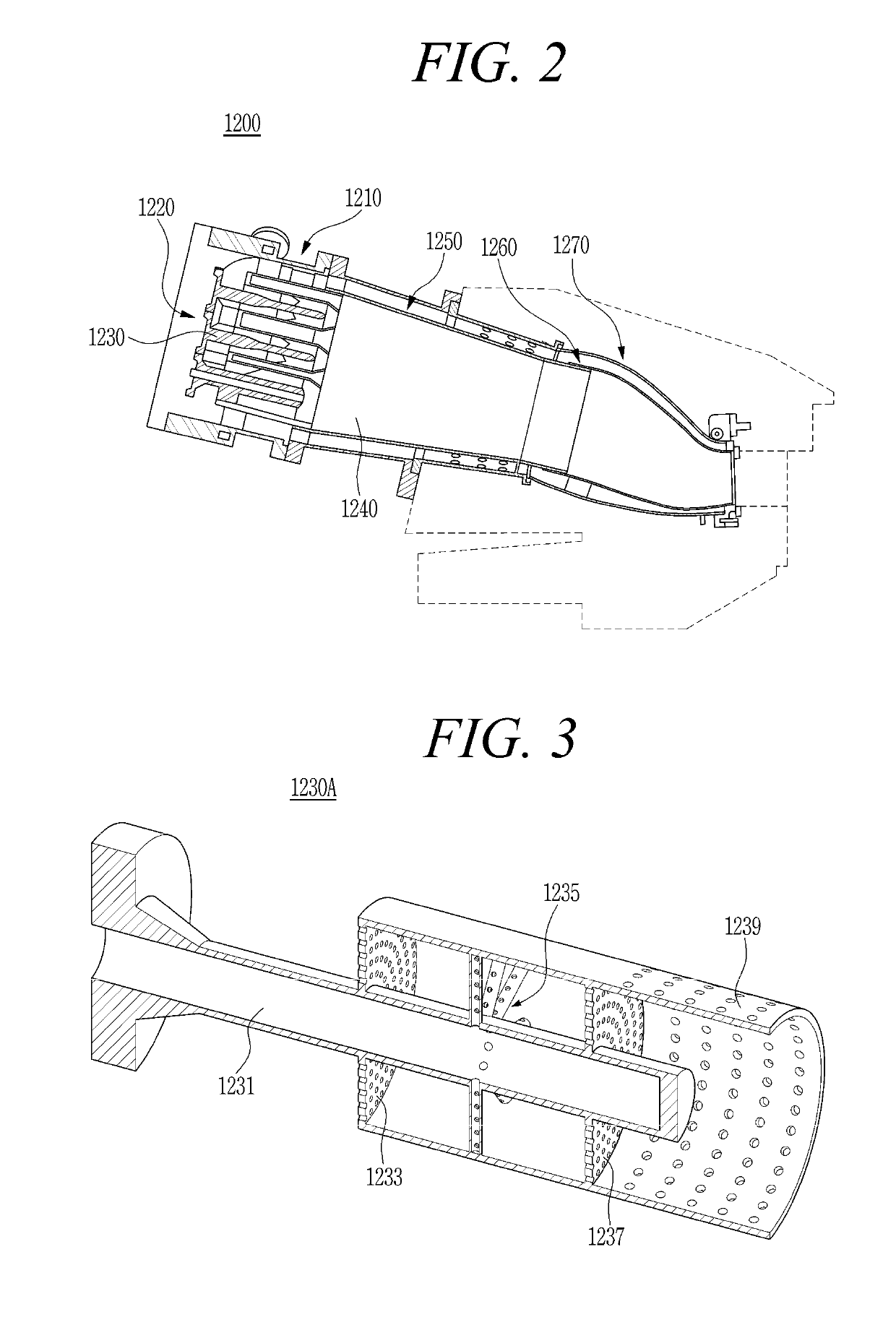

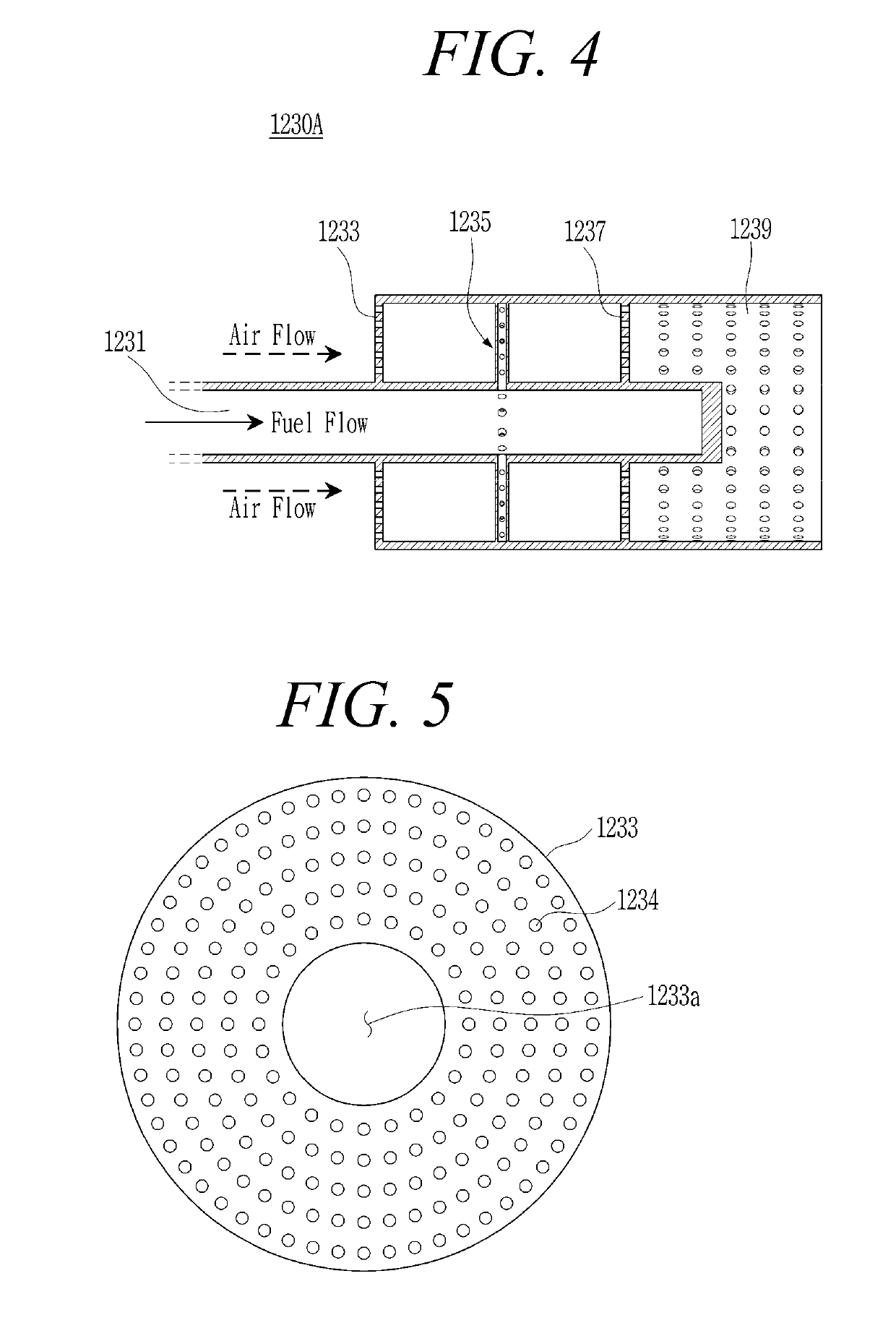

Fuel supply device for gas turbines and fuel nozzle and gas turbine having the same

ActiveUS20190285278A1Stable combustionReduce nitrogen oxidesContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustion chamberNitrogen oxide

The present disclosure relates to a fuel supply device for gas turbines, and a fuel nozzle and gas turbine having the same. The fuel supply device of present disclosure is mounted to the fuel nozzle for a uniform flow of air introduced thereinto and for allowing uniform mixing with fuel. The present disclosure allows a uniform fuel-air mixture to be supplied to a combustion chamber. According to the present disclosure, it is possible to uniformly supply a fuel-air mixture to a combustion chamber by arranging a plurality of perforated plates in a fuel supply device for gas turbines, to suppress generation of nitrogen oxides, and to prevent flame from stagnating or flowing backward.

Owner:DOOSAN HEAVY IND & CONSTR CO LTD

Low nitrogen oxide biomass boiler with variable furnace arch structure

InactiveCN1195173CRich varietyAdapt to many types of biomassSolid fuel combustionIncinerator apparatusLow nitrogenEngineering

The present invention relates to a low-nitrogen oxide biomass boiler with variable furnace arch structure, including front and rear zoned-air chambers, reciprocating grate, combined arch formed from front arch, rear arch and upper arch and zoned-air nozzles. The bottom portion of the boiler is equipped with front zone air chamber and rear zone air chamber to implement zoned-air distribution, and the reciprocating grate is arranged over the front and rear zound-air chambers, and in the interior of furnace cavity wall between upper arch and rear arch air inlaid several zoned-air nozzles whose inlets are connected with main air channel. Said boiler can extensively utilize biomass fuel, and can obtain good combustion effect.

Owner:SHANGHAI JIAOTONG UNIV

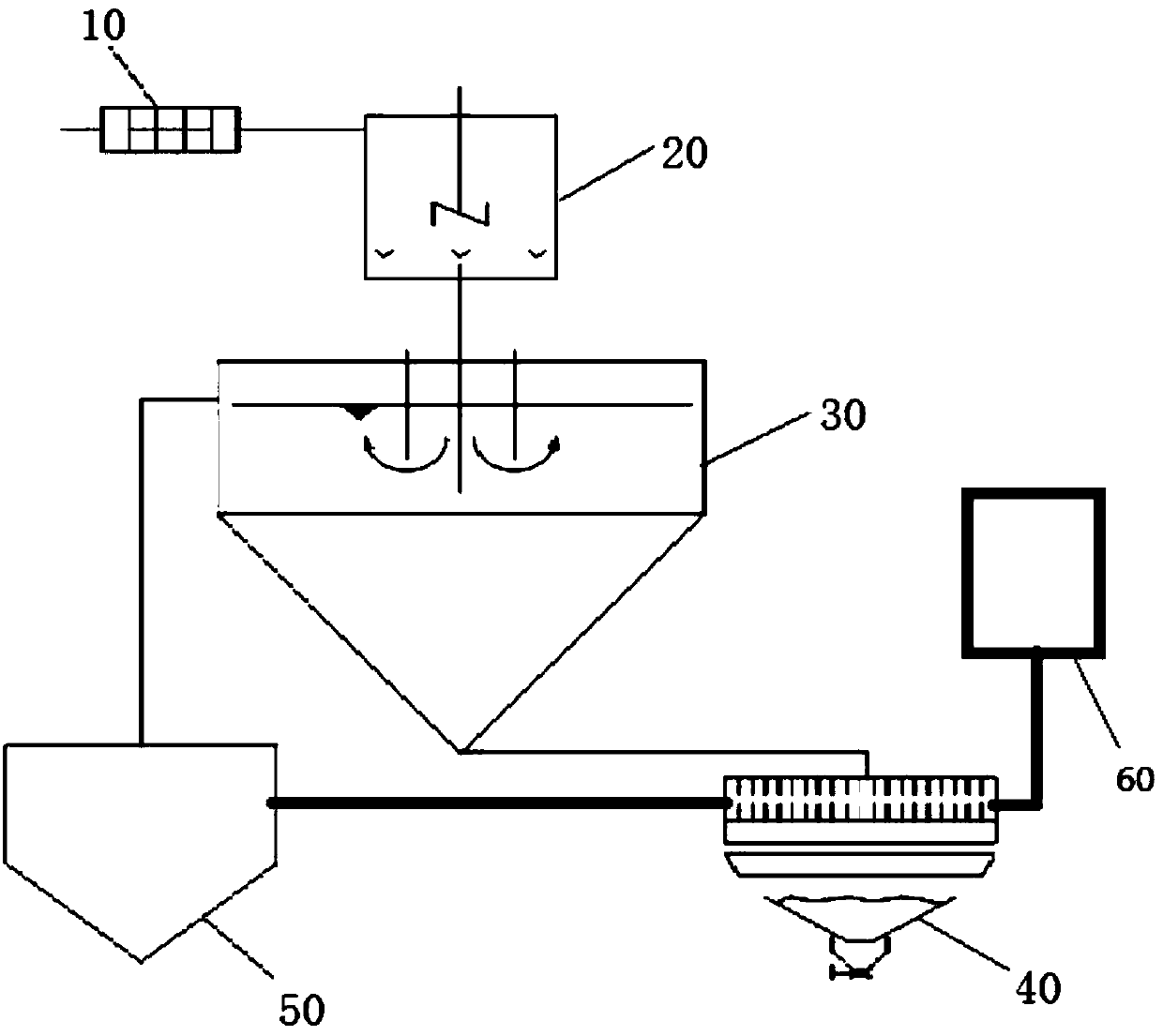

Stainless steel pickling mixed waste acid liquid pretreatment system and technology

InactiveCN107585912ARealize solid-liquid separationHigh recovery rateSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processSludge cakeHigh pressure

The invention discloses a stainless steel pickling mixed waste acid liquid pretreatment system. The stainless steel pickling mixed waste acid liquid pretreatment system comprises a graphite cooler, amixing tank, a settling tank, a press filter, a pretreated acid collecting tank and a high-pressure rinsing device, wherein the graphite cooler is used for cooling waste acid liquid; the mixing tank is provided with a stirring device, and an inlet of the mixing tank is connected with an outlet of the graphite cooler so as to flocculate the cooled waste acid liquid; an inlet of the settling tank isconnected with an outlet of the mixing tank so as to perform solid-liquid separation on the waste acid liquid; an inlet of the press filter is connected with a sludge outlet of the settling tank so as to filter sludge for further solid-liquid separation; an inlet of the pretreated acid collecting tank is connected with a waste acid liquid outlet of the settling tank and a waste acid liquid outletof the press filter so as to collect the pretreated waste acid liquid; and an inlet of the high-pressure rinsing device is connected with industrial water, and an outlet of the high-pressure rinsingdevice is connected with the inlet of the press filter to rinse a filtered sludge cake so as to reduce the acid content of the sludge cake. The stainless steel pickling mixed waste acid liquid pretreatment system provided by the invention increases the recycling rate of free acid in the waste acid liquid, and facilitates recycling of metal oxide.

Owner:WISDRI ENG & RES INC LTD

Gasoline particulate filter

ActiveUS20190009254A1Avoid deactivationAvoid complex processInternal combustion piston enginesDispersed particle separationParticulatesPorous substrate

A catalytic wall-flow monolith for use in an emission treatment system comprises a porous substrate and a three-way catalyst (TWC), wherein the TWC is distributed substantially throughout the porous substrate and wherein the TWC comprises:(i) alumina;(ii) one or more platinum group metals; and(iii) an oxygen storage component (OSC),wherein the OSC comprises ceria or one or more mixed oxides comprising cerium and is present in a ratio by weight of OSC to alumina of from 65:35 to 85:15

Owner:JOHNSON MATTHEY PLC

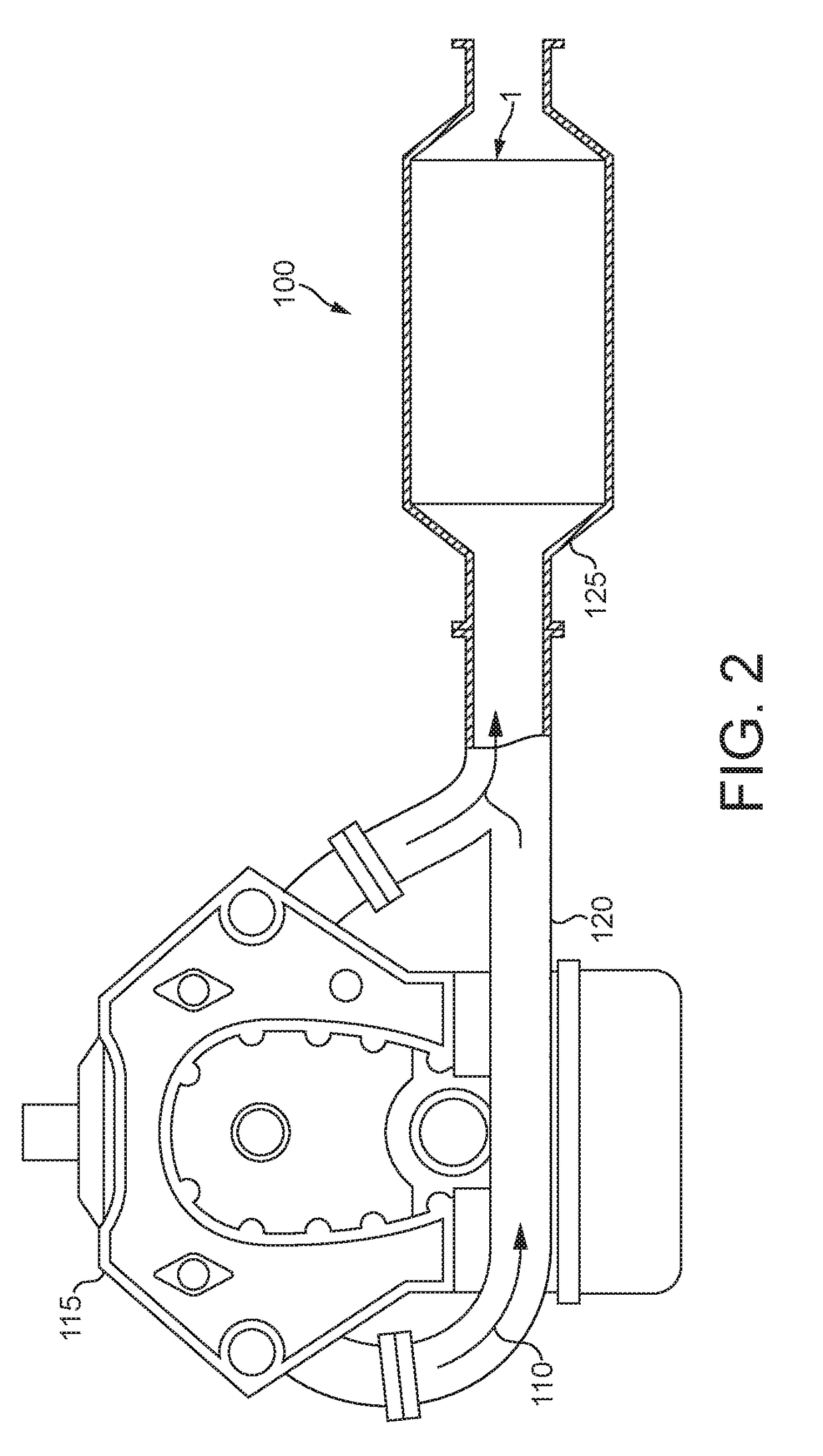

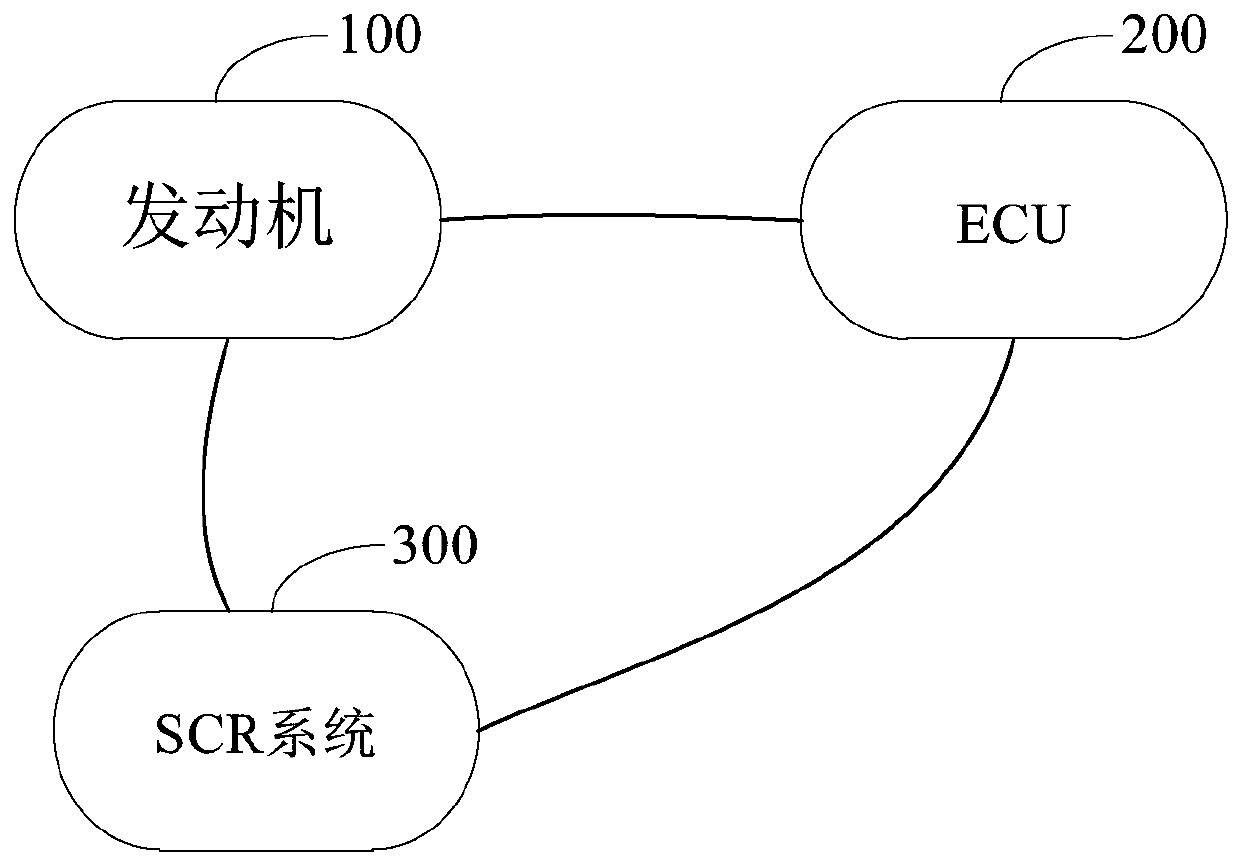

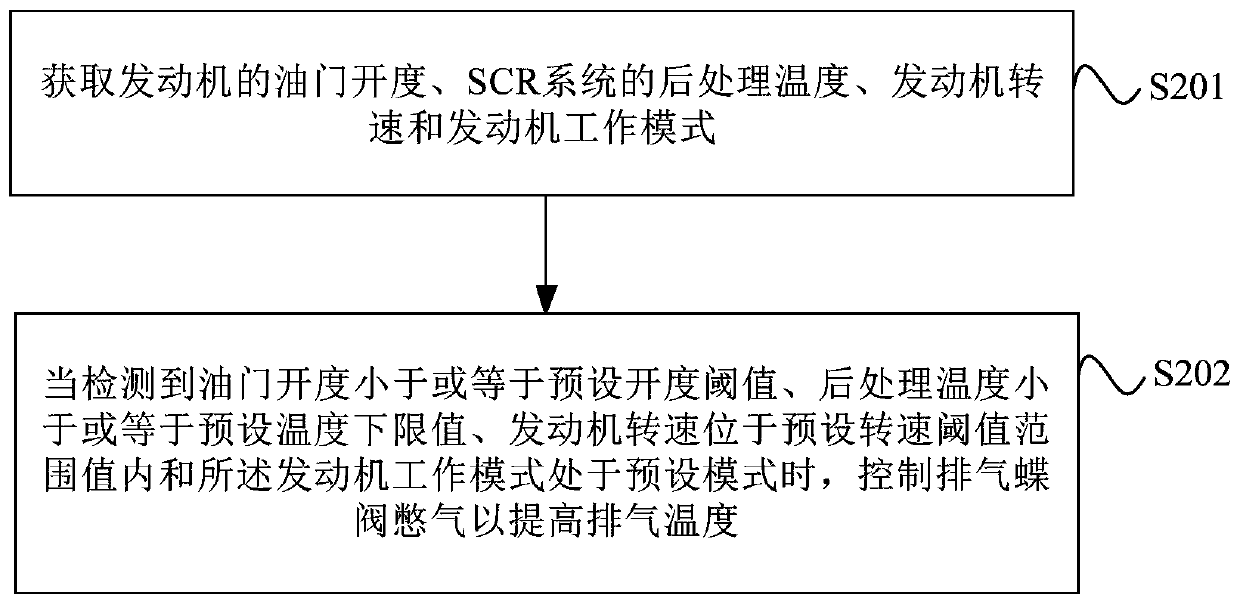

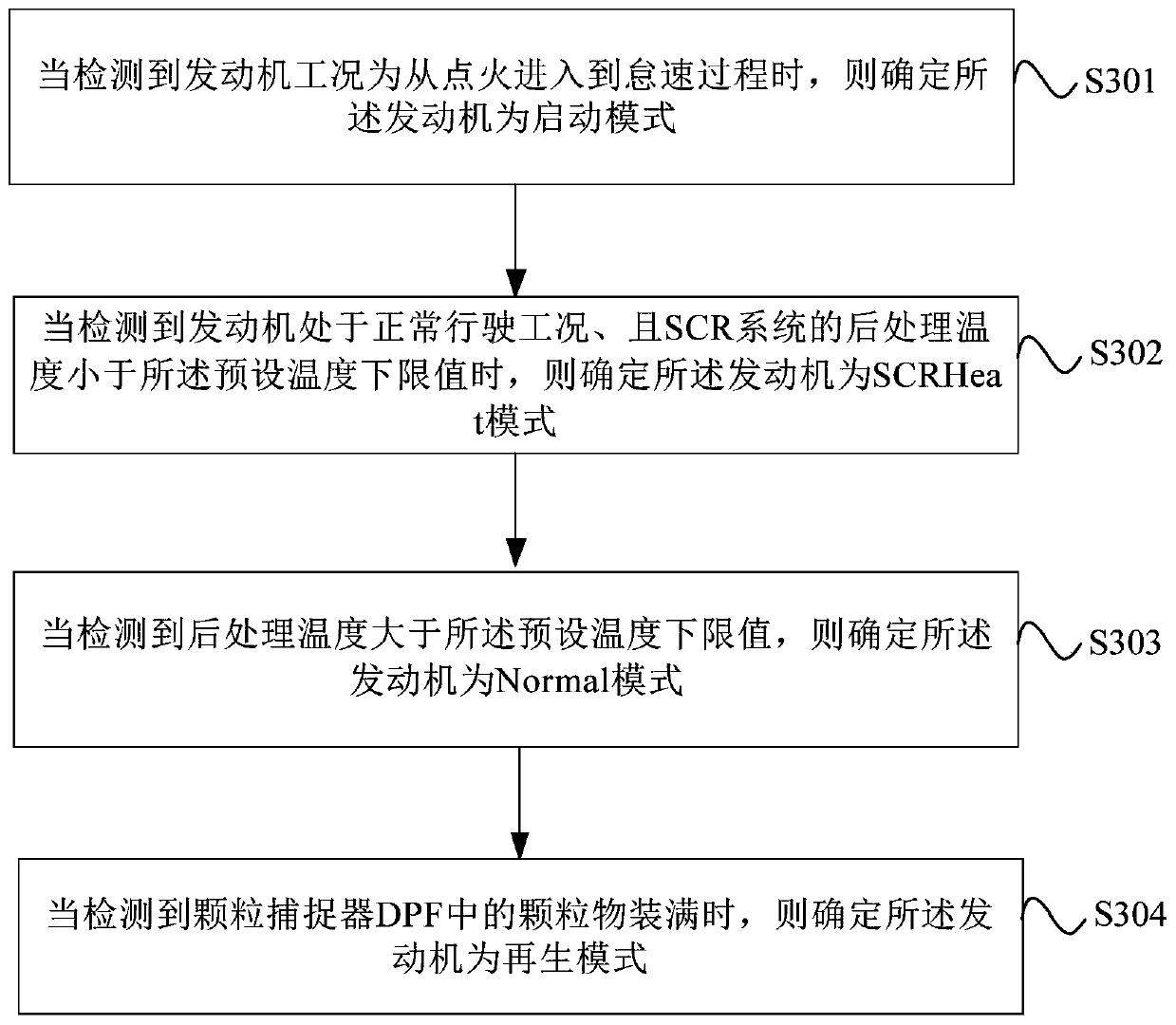

Exhaust temperature heat management method and equipment

InactiveCN110578607AGood oxidationReduce nitrogen oxidesElectrical controlMachines/enginesExhaust gasNitrogen oxides

The embodiment of the invention provides an exhaust temperature heat management method and equipment. The method includes the steps that the opening of an accelerator of an engine, the aftertreatmenttemperature of an SCR system, the rotating speed of the engine and the working manner of the engine are acquired; and when it is detected that the opening of the accelerator is smaller than or equal to a preset opening threshold value, the aftertreatment temperature is smaller than or equal to a preset temperature lower limiting value, the rotating speed of the engine is located within a preset rotating speed threshold value range value and the working manner of the engine is in a preset manner, an exhaust butterfly valve is controlled to hold breath in order to increase the exhaust temperature, it can still be guaranteed that the exhaust temperature is located in the temperature needed by aftertreatment when the vehicle speed is low, the accelerator is low, the engine returns to an idlingstate and the load of the engine is low, the temperature of an aftertreatment carrier is increased, a good oxidizing effect is achieved, nitrogen oxides in tail gas are effectively reduced, generation of carbon particles is reduced, and the DPF carbon deposition amount is reduced.

Owner:WEICHAI POWER CO LTD

Process for producing an SCR catalyst

InactiveUS7662744B2Reduce nitrogen oxidesMaintain good propertiesCombination devicesNitrogen compoundsIron saltsCombustion

In a process for producing an SCR catalyst for the selective reduction of NOx in NOx-containing exhaust gases of internal combustion engines, a support layer is applied to a substrate body. An iron salt dissolved in a liquid is applied to the support layer in such an amount that no excess of iron salt is present.

Owner:KARLSRUHER INST FUR TECH

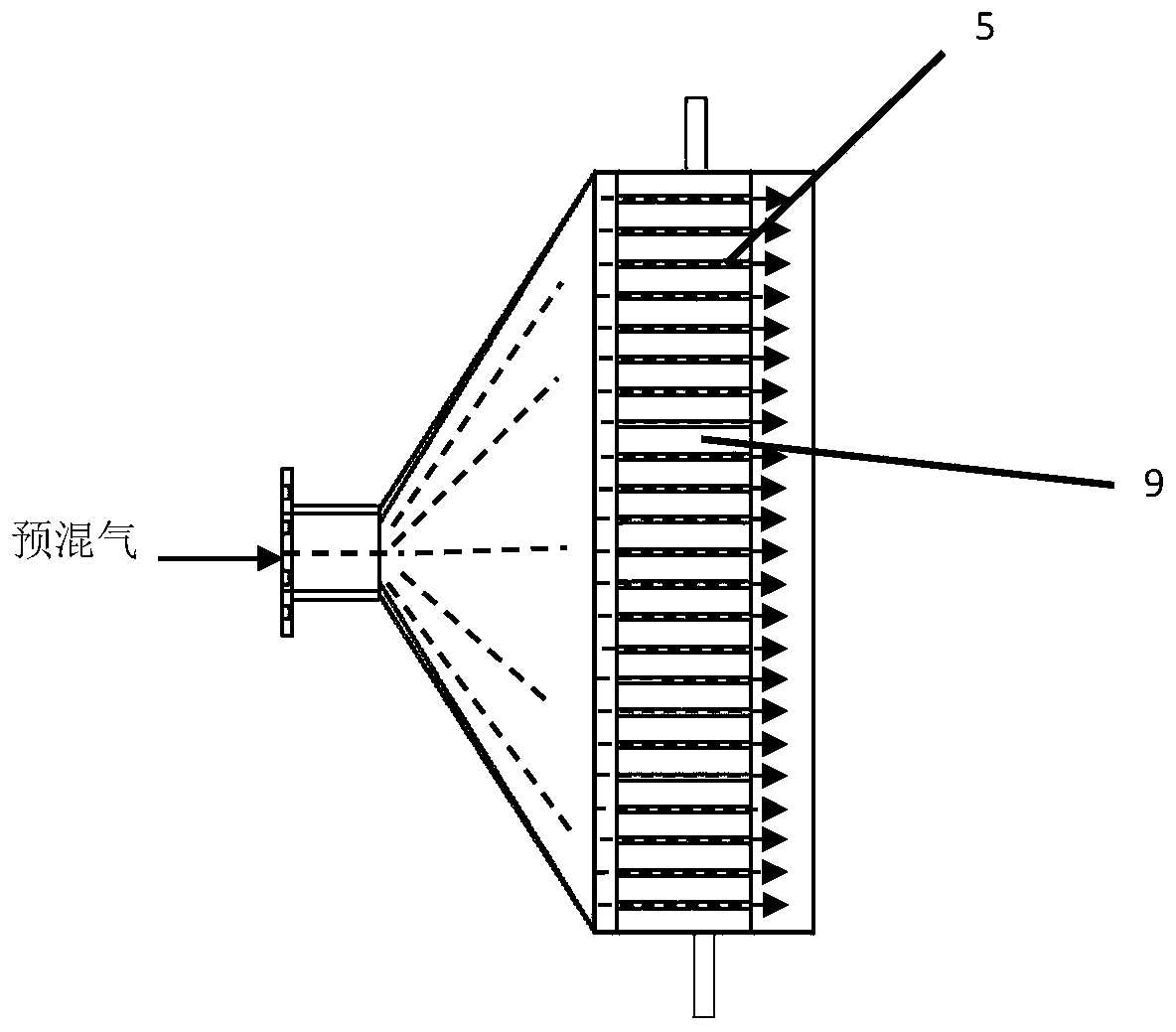

Low-nitrogen combustion device and method

InactiveCN110360568AAvoid concentrationLarge burning flame areaBurner coolingCombustion technology mitigationCombustion chamberNitrogen oxides

The invention relates to a low-nitrogen combustion device and an application method thereof. The device comprises an outer shell, a gas distribution chamber, a plurality of gas mixing pipes, an anti-backfire cavity, a combustion chamber, an ignition needle, a heat exchange tube bank, a first water inlet pipe, a first water outlet pipe, a second water inlet pipe and a second water outlet pipe, wherein the anti-backfire cavity is arranged on the rear side of the gas distribution chamber; the plurality of gas mixing pipes are transversely and uniformly distributed in the anti-backfire cavity; theignition needle is arranged in the combustion chamber and is closely attached to the wall of the anti-backfire cavity; the heat exchange tube bank is arranged on the rear side of the anti-backfire cavity, and the distance between the heat exchange tube bank and the anti-backfire cavity is 40-80 mm; and the anti-backfire cavity is connected with the first water inlet pipe and the first water outlet pipe, and the heat exchange tube bank is connected with the second water inlet pipe and the second water outlet pipe. The low-nitrogen combustion device comprehensively utilizes a water cooling technology, a premixing technology and an anti-backfire technology, effectively reduces the emission of nitrogen oxides by reducing the temperature of a flame surface, solves the problems of high emissionof nitrogen oxides and carbon monoxide or premixed backfire and the like of a full premixed condensing boiler in the current market, and can be widely suitable for a commercial or domestic distributed heating system.

Owner:BEIJING LONGTAO ENVIRONMENTAL TECH CO LTD

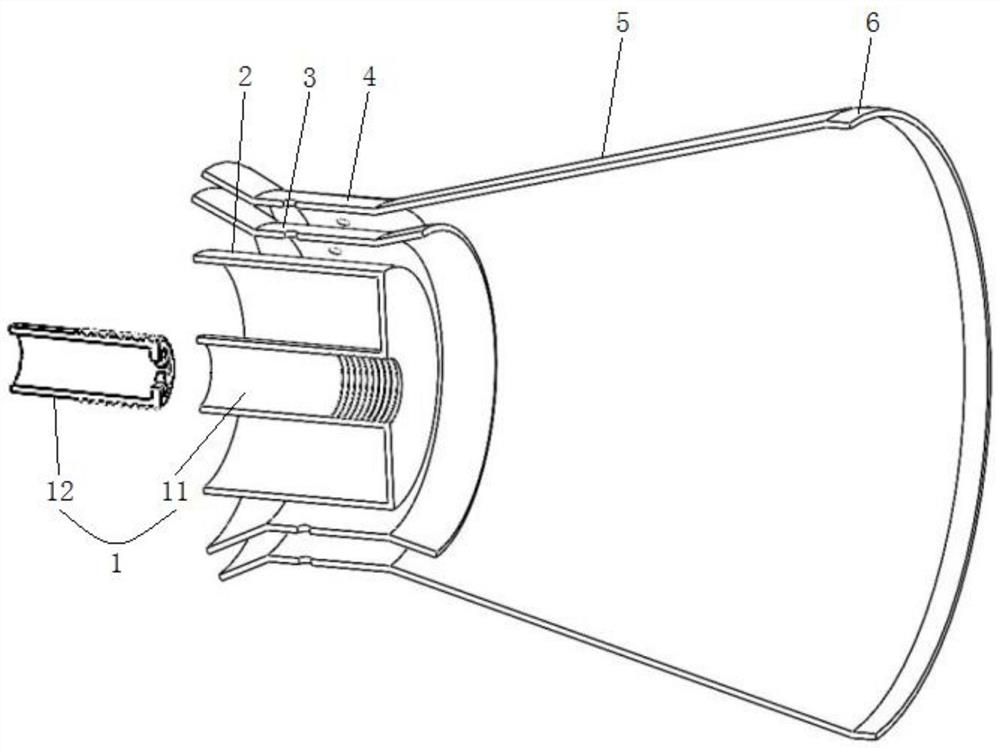

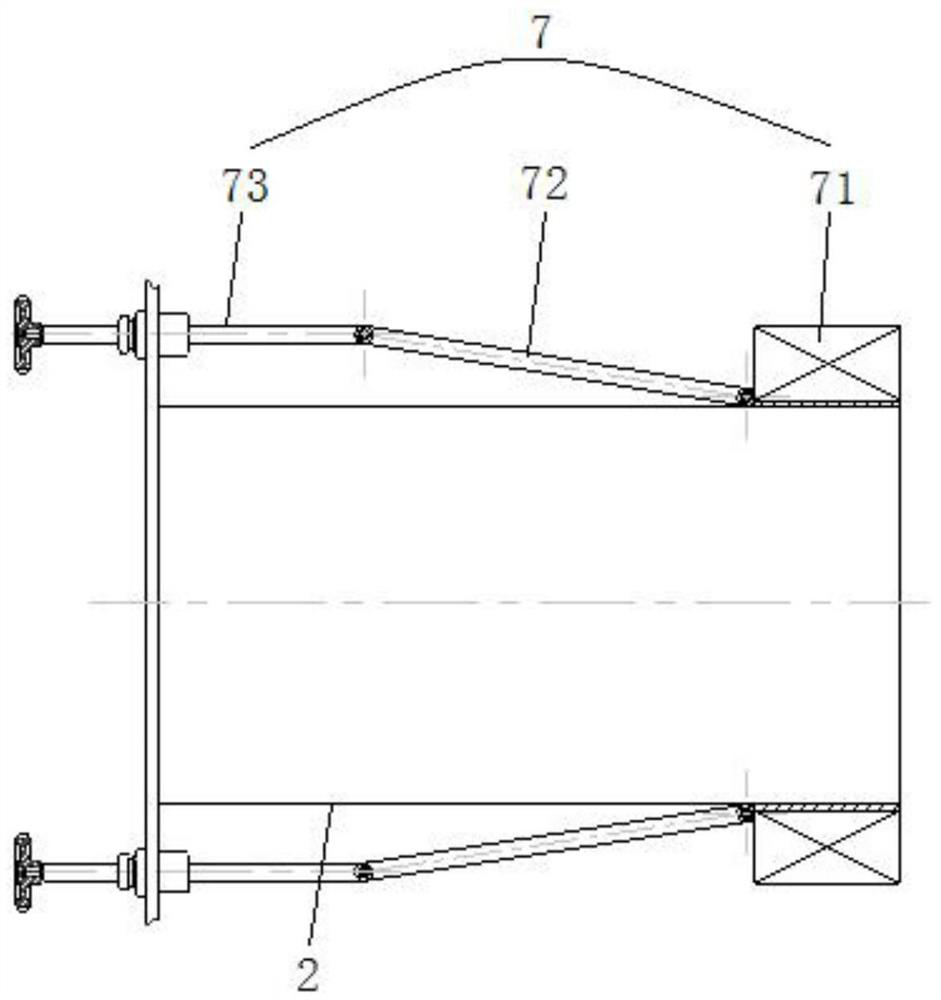

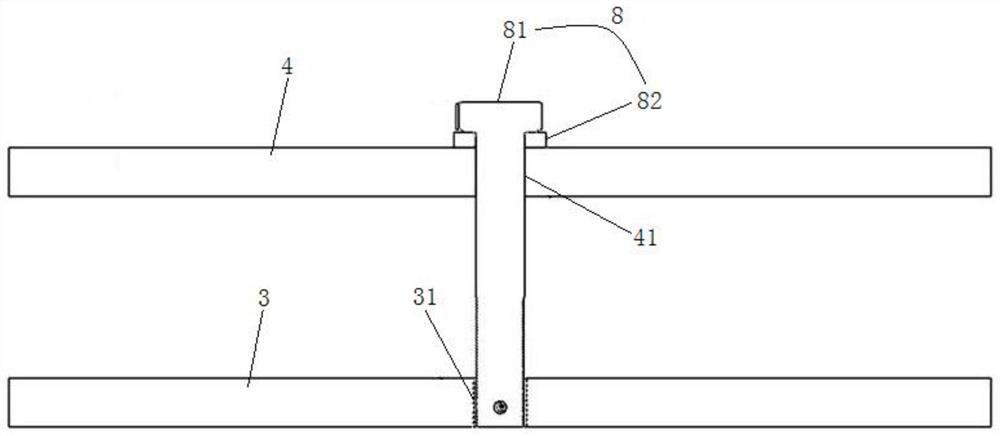

Double-channel combustor with thick pulverized coal and thin pulverized coal being separated and use method thereof

PendingCN111895397AReduce maintenance frequencyExtended service lifePulverulent fuel combustion burnersIndirect carbon-dioxide mitigationThermodynamicsCombustor

The invention relates to a double-channel combustor with thick pulverized coal and thin pulverized coal being separated and a use method thereof. The double-channel combustor with the thick pulverizedcoal and the thin pulverized coal being separated comprises a pulverized coal supplying mechanism, a transition channel, an internal secondary air guide duct, an external secondary air guide duct, acombustion stabilizing cavity and a rectifying cavity. The external secondary air guide duct, the combustion stabilizing cavity and the rectifying cavity are sequentially connected. The pulverized coal supplying mechanism comprises an air-pulverized coal pipe and a thick and thin pulverized coal separating device. The air-pulverized coal pipe communicates with the combustion stabilizing cavity. The thick and thin pulverized coal separating device is detachably connected to the air-pulverized coal pipe. The internal secondary air guide duct is coaxially arranged in the outer secondary air guideduct in a spaced manner. The transition channel is coaxially arranged in the internal secondary air guide duct in a spaced manner. The outlet end of the internal secondary air guide duct forms an expanded opening. The angle of the expanded opening is identical with the angle of the combustion stabilizing cavity. By the adoption of the double-channel combustor with the thick pulverized coal and the thin pulverized coal being separated, air can be divided into internal secondary air and external secondary air to respectively enter the combustor, the internal secondary air is combined with the transition channel to sufficiently mix pulverized coal and air, the external secondary air can form a cooling air layer flowing along the wall face of the combustion stabilizing cavity in the combustion stabilizing cavity, and the wall face of the combustion stabilizing cavity is protected against ash accumulation and coking.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD

Method and device for treating waste gas of TFT glass substrate kiln

InactiveCN105674756AReduce nitrogen oxidesSimple structureGas treatmentDispersed particle filtrationNitric oxideCombustion chamber

The invention relates to a method and device for treating waste gas of a TFT glass substrate kiln. The device comprises a cooling tank, a dust removal box, a combustion chamber and an SCR reaction unit which are sequentially communicated; a first discharging opening for discharging mixtures and boric oxides is formed in the bottom of the cooling tank; a first waste gas inlet, a first waste gas outlet and a cooling medium inlet are formed in the cooling tank, and the first waste gas outlet is communicated with the dust removal box; a dust removal device is arranged in the dust removal box; and an air inlet, a natural gas inlet and a reducing agent inlet are formed in the combustion chamber. The method comprises the steps of firstly, removing the boric oxides in the waste gas, secondly, removing particle matter in the waste gas, thirdly, adopting a combustion manner to remove parts of the nitric oxides, and fourthly, adopting a catalytic deoxidizing reaction to remove the nitric oxides, completing treatment of the waste gas of the TFT glass substrate kiln, and performing discharging after the environment-friendly standard is achieved. The operation steps are simple, and various forms of boron and nitrogen oxides in the waste gas of the kiln can be effectively removed.

Owner:IRICO DISPLAY DEVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com