Electrophoresis preparation method for surface optical catalytic film of metal substrate

A metal substrate, photocatalytic technology, applied in catalyst activation/preparation, chemical instruments and methods, electrophoretic plating, etc., can solve problems such as high cost and complex process, and achieve low cost, uniform film layer, and high photocatalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

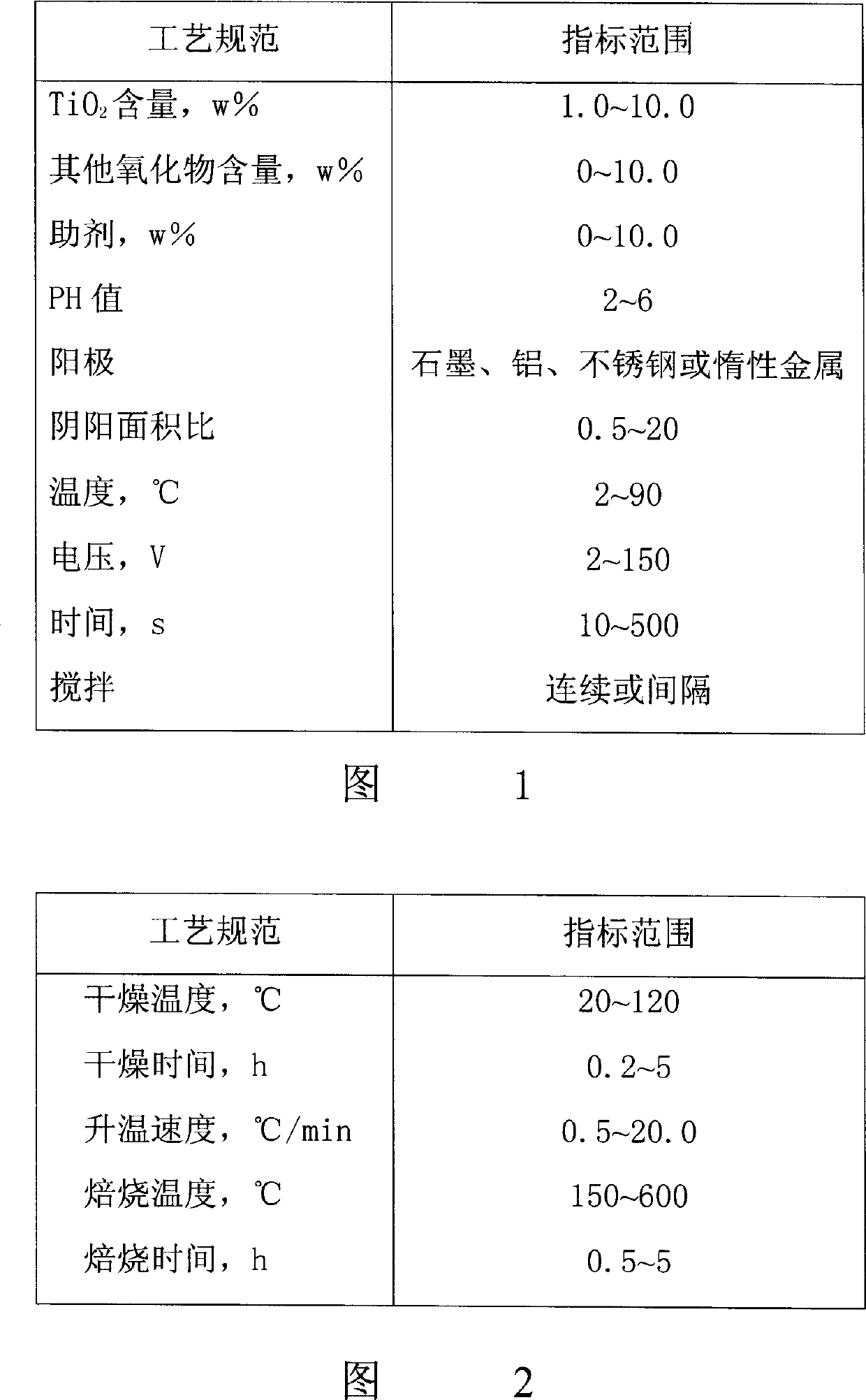

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1: the preparation of pure titanium dioxide sol electrophoresis liquid

[0012] In 1 liter of 2.5% titanium dioxide sol (PH=3.2) prepared in the method of patent 98115808.0, add 10 grams of polyethylene glycol and stir evenly under electromagnetic stirring to prepare titanium dioxide sol electrophoretic liquid.

Embodiment 2

[0013] Embodiment 2: the preparation of titania-silica sol electrophoretic liquid

[0014] Under vigorous stirring, 50 ml of ethyl orthosilicate was slowly dropped into a solution prepared by 0.25 ml of concentrated nitric acid (68%) and 100 ml of deionized water, and the stirring was continued until a uniform transparent silica sol was formed. 100 milliliters of this sol was mixed with 1000 milliliters of titanium dioxide sol prepared according to Example 1, and 50 grams of polyethylene glycol was added, and stirred evenly under electromagnetic stirring to prepare titanium dioxide sol electrophoretic liquid. In the electrophoretic liquid, the content of titanium dioxide is 2.3%, the content of silicon dioxide is 1.1%, the content of polyethylene glycol is 4.5%, and the pH value is 2.8.

Embodiment 3

[0015] Embodiment 3: the preparation of titania-zirconia sol electrophoretic liquid

[0016] Under vigorous stirring, 15.7 milliliters of tetrapropyl zirconate was slowly dropped into a solution prepared by 4.3 milliliters of concentrated nitric acid (68%) and 215 milliliters of deionized water, and the stirring was continued until a uniform and transparent zirconia sol was formed. 250 milliliters of this sol was mixed with 1000 milliliters of titanium dioxide sol prepared according to Example 1 and stirred evenly, and 25 grams of polyethylene glycol was added, and stirred evenly under electromagnetic stirring to prepare titanium dioxide sol electrophoretic liquid. In the electrophoretic liquid, the content of titanium dioxide is 2.0%, the content of zirconium dioxide is 0.5%, the content of polyethylene glycol is 2.0%, and the pH value is 2.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com