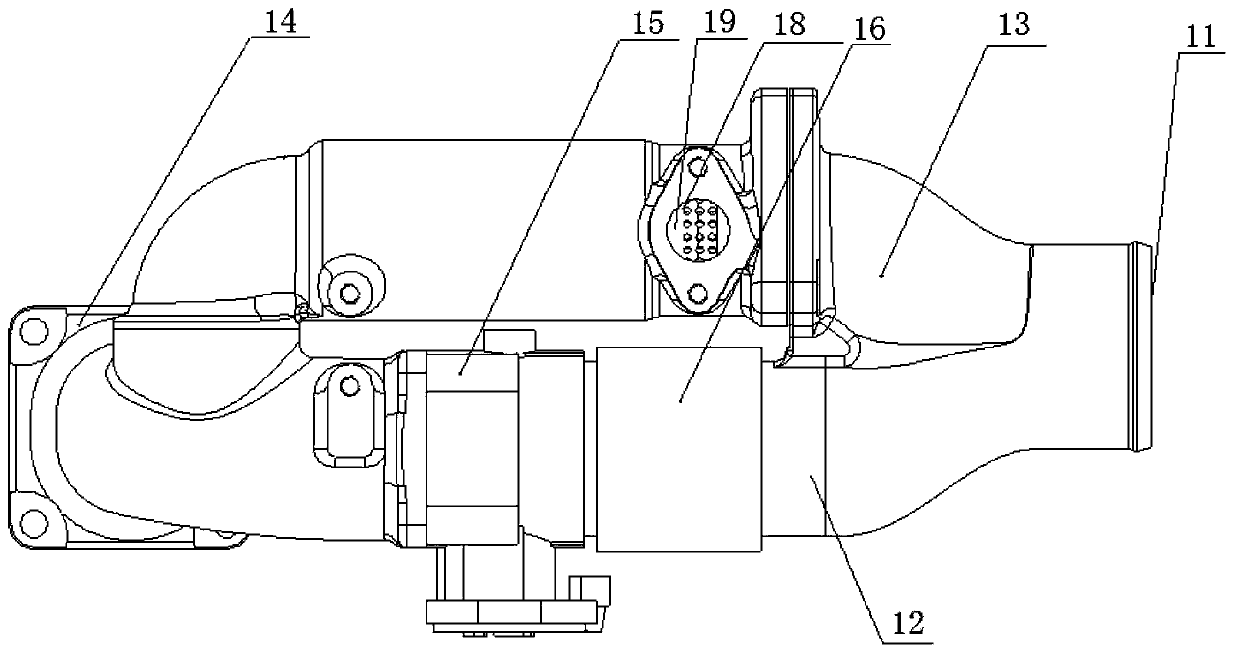

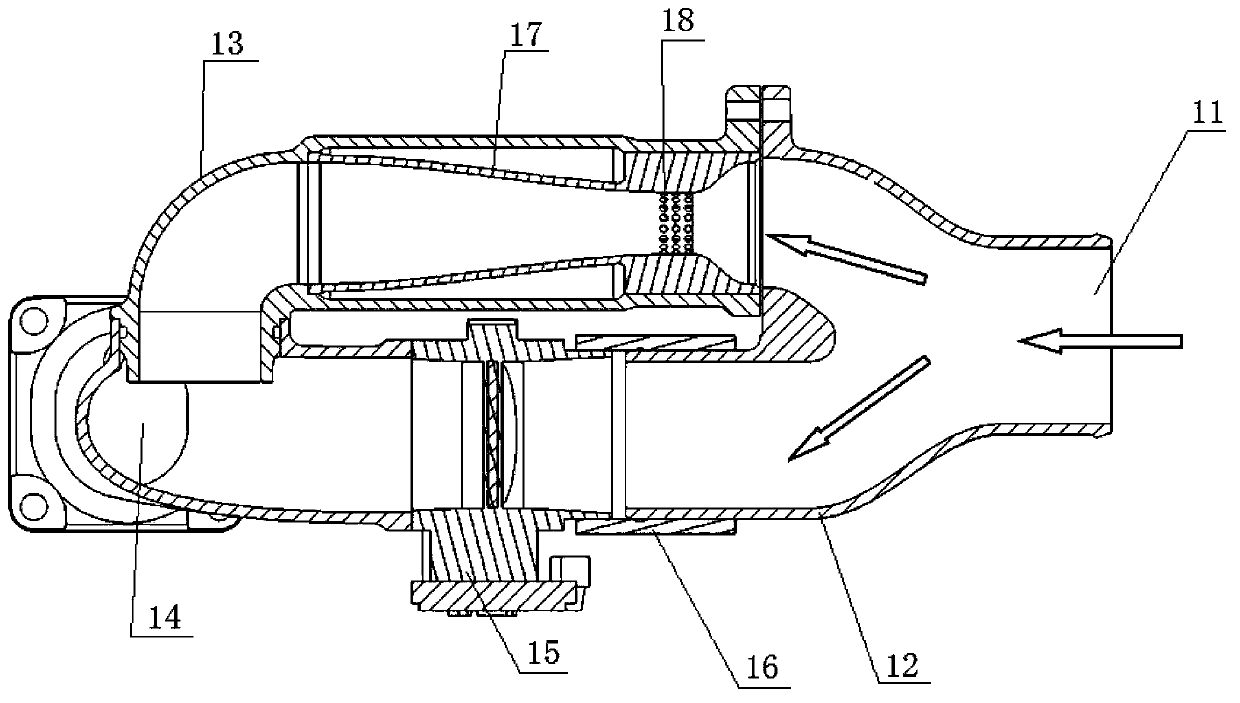

Air inlet connecting pipe of EGR engine

A technology for intake pipes and engines, which is applied to engine components, engine control, combustion engines, etc., can solve problems such as poor fuel consumption rate improvement, inability to realize engine dynamic control, poor nitrogen oxide reduction effect, etc., to achieve improved mixing uniformity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment. It should be understood that the "upper", "lower", "left", "right", "front" and "reverse" mentioned in the following embodiments of the present invention are all based on the directions shown in the figures, These words used to limit the direction are only for convenience of description, and do not mean to limit the specific technical solution of the present invention.

[0020] The EGR engine intake pipe of the present invention adopts a dual-channel air intake method, wherein the first circuit is connected in series with the electronic throttle to control the amount of fresh air intake, and the second circuit has a built-in Venturi tube, and the exhaust gas passes through the throat of the Venturi tube to meet with the fresh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com