Dynamic demonomerization and defoaming method and device for carbon fiber spinning solution

A spinning solution and carbon fiber technology, which is applied in the field of the carbon fiber spinning solution dynamic de-singling and defoaming method and the device thereof, can solve the problems of high viscosity of the spinning solution, large area, low de-singling and de-foaming efficiency, etc. The process is simple and practical, the defoaming effect is good, and the effect of improving the defoaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

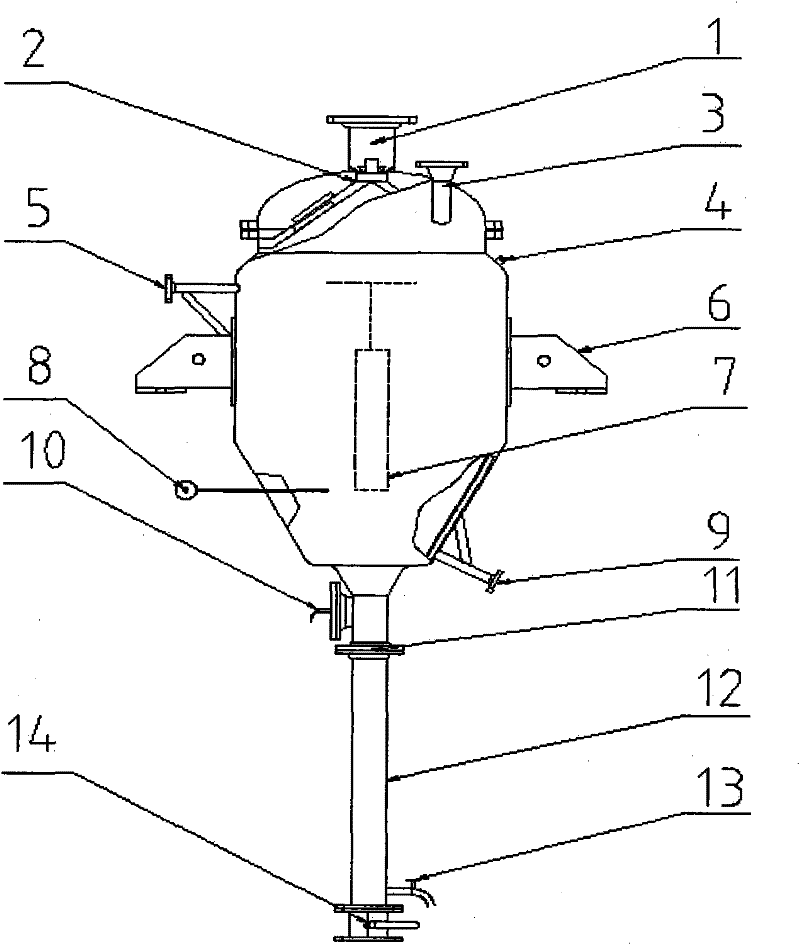

[0036] This embodiment is a method for dynamic desingling and degassing of carbon fiber spinning liquid, and its specific process includes the following steps:

[0037] Step 1: Heating the unit removal and degassing device; start the hot water circulation system and the vacuum system to heat the unit removal and degassing device to 45°C, the vacuum degree is -98kPa; the rotation speed of the unit removal tower is 750r / min.

[0038] Step 2, feeding; start the feeding pump and mass flow meter, and continuously feed the spinning solution into the single removal tower at a feeding rate of 36L / h.

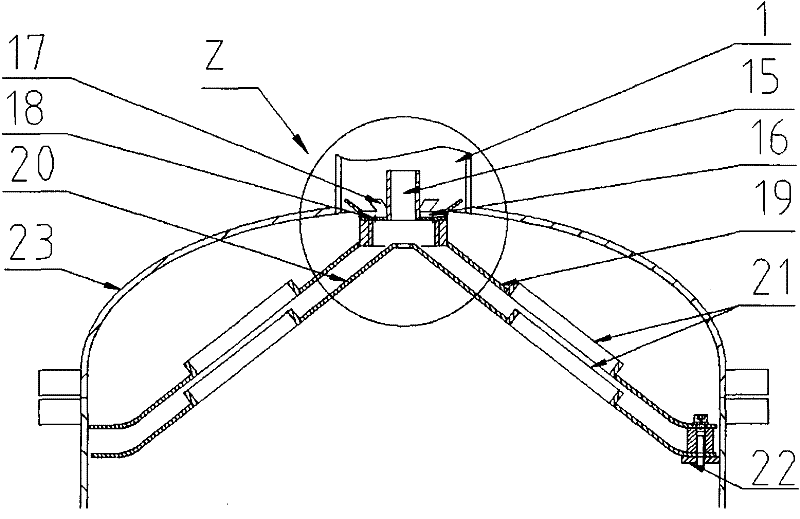

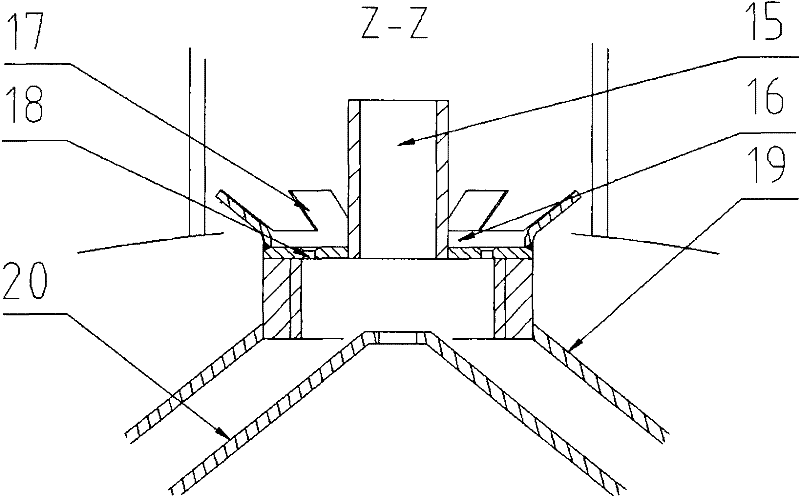

[0039] Step 3: Gravity de-singulation and degassing; the spinning liquid is expanded and flows in the de-singulation tower at a temperature of 45°C, and is evenly flung onto the tower wall under the centrifugal force of the distribution plate of the de-singulation tower, and is slanted at the same time The scraper is scraped into a film with a thickness of 1.5mm to 2.0mm; the produced fi...

Embodiment 2

[0045] This embodiment is a method for dynamic desingling and degassing of carbon fiber spinning liquid, and its specific process includes the following steps:

[0046] Step 1: Heating the unit removal and degassing device; start the hot water circulation system and the vacuum system to heat the unit removal and degassing device to 50°C, the vacuum degree is -95kPa; the rotation speed of the unit removal tower is 500r / min.

[0047] Step 2, feeding; start the feeding pump and mass flow meter, and continuously feed the spinning solution into the single removal tower at a feeding rate of 35L / h.

[0048] Step 3, gravity de-singulation and degassing; the spinning liquid is expanded and flows in the de-singulation tower at a temperature of 50°C, and is evenly flung onto the tower wall under the centrifugal force of the distribution plate of the de-singulation tower, and is slanted at the same time The scraper is scraped into a film with a thickness of 1.5mm to 2.0mm; the produced fi...

Embodiment 3

[0054] This embodiment is a method for dynamic desingling and degassing of carbon fiber spinning liquid, and its specific process includes the following steps:

[0055] Step 1: Heating the unit removal and degassing device; start the hot water circulation system and the vacuum system to heat the unit removal and degassing device to 55°C, the vacuum degree is -90kPa; the rotation speed of the unit removal tower is 340r / min.

[0056] Step 2, feeding; start the feeding pump and mass flow meter, and continuously feed the spinning solution into the single removal tower at a feeding rate of 34L / h.

[0057] Step 3: Gravity de-singulation and degassing; the spinning liquid is expanded and flows in the de-singulation tower at a temperature of 55°C, and is evenly flung onto the tower wall under the centrifugal force of the distribution plate of the de-singulation tower, and is slanted at the same time The scraper is scraped into a film with a thickness of 1.5mm to 2.0mm; the produced fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com