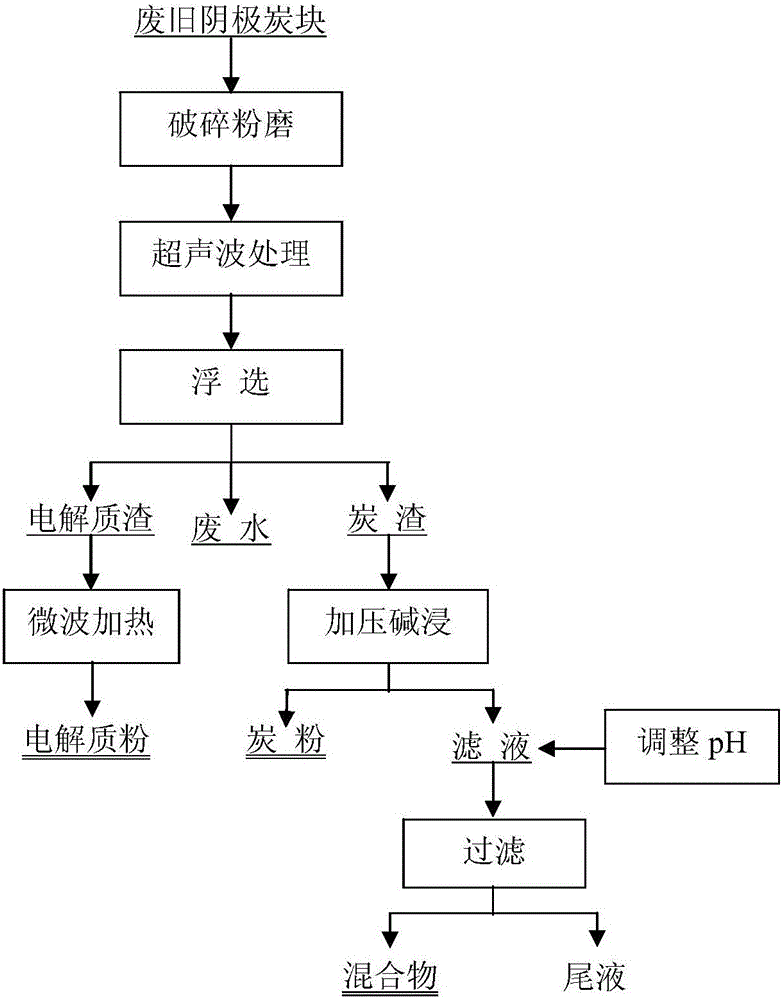

Method for comprehensively recovering aluminum electrolysis waste cathode carbon blocks through ultrasonic-assisted floatation and pressure alkali leaching

A technology of waste cathode carbon block and pressurized alkali leaching, which is applied in the direction of solid waste removal, etc., can solve the problems of ineffective recovery of valuable substances, restricting process promotion, and long process cycle, and achieves low raw material prices and good economic benefits. , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Take 100g of waste cathode carbon blocks from an aluminum electrolytic cell in a domestic factory, and the main element contents are (wt%): C 70.9, Al8.23, O 7.55, F 5.38, Na 4.57.

[0050] The waste cathode carbon blocks are crushed and ground to -200 mesh, accounting for 90%, and mixed with water at a liquid-solid ratio of 2:1 for ultrasonic pretreatment. The ultrasonic frequency is 40KHz, the ultrasonic treatment time is 20min, and the power is 200W.

[0051] The slurry after ultrasonic pretreatment is mixed with water at a mass concentration of 25% to form a slurry, which is roughed by a single-cell flotation machine. The flotation inhibitor is water glass, the dosage is 320g / t waste cathode; the collector is kerosene, the dosage is 400g / t waste cathode; the foaming agent is No. 2 oil, the dosage is 40g / t waste cathode. The flotation foam and underflow were washed with water, dried and weighed to obtain 77.23g and 22.61g of carbon residue and electrolyte residue res...

Embodiment 2

[0072] Take 300g of waste cathode carbon blocks from an aluminum electrolytic cell in a domestic factory, and the main element contents are (wt%): C 70.9, Al8.23, O 7.55, F 5.38, Na 4.57.

[0073] The waste cathode carbon blocks are crushed and ground to -200 mesh, accounting for 100%, and mixed with water at a liquid-solid ratio of 3:1 for ultrasonic pretreatment. The ultrasonic frequency is 40KHz, the ultrasonic treatment time is 5min, and the power is 600W.

[0074] The slurry after ultrasonic pretreatment is mixed with water at a mass concentration of 10% to form a slurry, which is roughed by a single-cell flotation machine. The flotation inhibitor is water glass, the dosage is 200g / t waste cathode; the collector is kerosene, the dosage is 600g / t waste cathode; the foaming agent is No. 2 oil, the dosage is 20g / t waste cathode. The flotation foam and underflow were washed with water, dried and weighed to obtain 227.07g and 66.73g of carbon residue and electrolyte residue re...

Embodiment 3

[0080] Take 1000g of waste cathode carbon blocks from an aluminum electrolytic cell in a domestic factory, and the main element contents are (wt%): C 70.9, Al8.23, O7.55, F 5.38, Na 4.57.

[0081] The waste cathode carbon blocks are crushed and ground to -200 mesh, accounting for 50%, and mixed with water at a liquid-solid ratio of 1:1 for ultrasonic pretreatment. The ultrasonic frequency is 25KHz, the ultrasonic treatment time is 40min, and the power is 400W.

[0082] The slurry after ultrasonic pretreatment is mixed with water at a mass concentration of 30% to form a slurry, which is roughed by a single-cell flotation machine. The flotation inhibitor is water glass, the dosage is 320g / t waste cathode; the collector is kerosene, the dosage is 200g / t waste cathode; the foaming agent is No. 2 oil, the dosage is 100g / t waste cathode. The flotation foam and underflow were washed with water, dried and weighed to obtain 765.93 g of carbon residue and 213.37 g of electrolyte residue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com