A solid vacuum insulated ring network cabinet and its manufacturing method

A technology of vacuum insulation and ring main unit, which is applied in the setting of switchgear, electrical components, substation/distribution device shell, etc., can solve the problems of no arc extinguishing ability, easy aging, easy cadmium brittleness and zinc brittleness, etc. Insulation and arc extinguishing performance, guaranteed stability, moderate viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

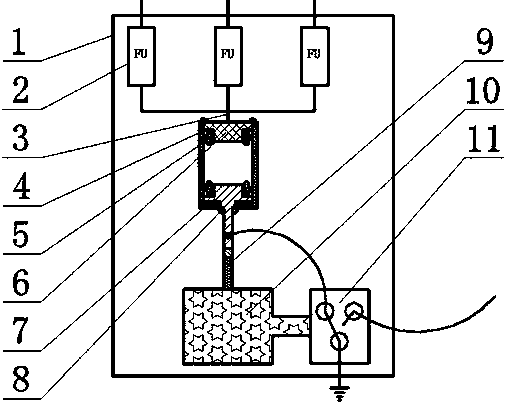

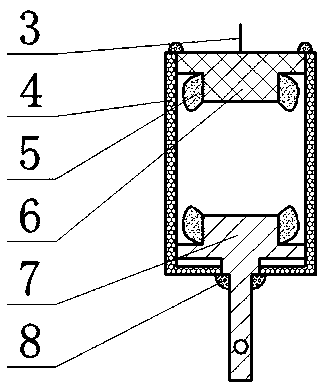

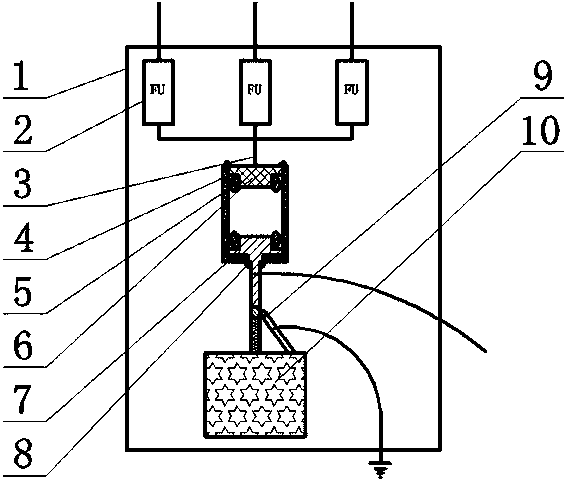

[0029] like image 3A solid vacuum insulated ring network cabinet is shown, which includes a casing 1, a vacuum arc extinguishing load switch 4, an isolator 11, three sets of fuses 2, a grounding device, and a device connected to the vacuum arc extinguishing load switch 4 and the isolator 11. The mechanical transmission device 10, the bus bar 3 connecting both ends of all fuses 2, the two ends of the vacuum arc extinguishing load switch 4 and two of the three joints of the isolator 11; the vacuum arc extinguishing load switch 4 is made of arc extinguishing flame retardant ceramics The outer casing made, the fixed power connection unit 6 fixed at one end inside the casing, the mobile power connection unit 7 arranged at the other end inside the casing to match the inner diameter of the casing and connected with the insulating elastic member 9, the mobile power connection unit 7 and the fixed power connection unit The power connection unit 6 is composed of vulcanized silicone rub...

Embodiment 2

[0045] Whole is the same as embodiment 1, and its difference is:

[0046] like figure 1 A solid vacuum insulated ring network cabinet is shown:

[0047] The casing 1 is not additionally sealed.

[0048] The isolator 11 and the vacuum arc extinguishing load switch 4 are set separately. The isolator 11 has a three-joint structure, two joints are connected to the bus bar 3, and the third joint is connected to the grounding device. There is a switch inside it. When the switch is closed, it is connected to the bus bar 3 The two joints of the busbar are connected, and the busbar 3 incoming line joint is connected with the grounding device when it is disconnected.

[0049] A method for manufacturing a ceramic shell of a vacuum arc-extinguishing load switch 4 for a solid vacuum insulated ring network cabinet, comprising the following steps:

[0050] 1) Preparation of nano-alumina fibers

[0051] ① Mix aluminum chloride hexahydrate with an appropriate amount of pure water, stir and...

Embodiment 3

[0060] Whole is the same as embodiment 1, and its difference is:

[0061] A method for manufacturing a ceramic shell of a vacuum arc-extinguishing load switch 4 for a solid vacuum insulated ring network cabinet, comprising the following steps:

[0062] 1) Preparation of nano-alumina fibers

[0063] ① Mix aluminum chloride hexahydrate with an appropriate amount of pure water, stir and filter impurities, and prepare to obtain an aluminum chloride solution with a mass percentage of 65%;

[0064] ③ After step ② is completed, continue to vibrate at high frequency for 40 minutes, then place the solution to be treated obtained in step ② in a constant temperature environment of 30°C, and mechanically stir for 40 minutes to obtain a prefabricated solution;

[0065] ④ Slowly add dilute hydrochloric acid solution dropwise in the prefabricated solution obtained in step ③ and stir until the pH value of the solution is 5.2 to obtain the original sol solution;

[0066] ⑤ Place the original...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com