Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Suitable for filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

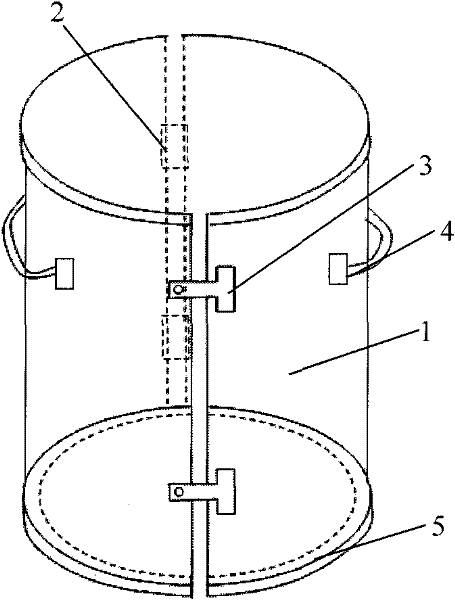

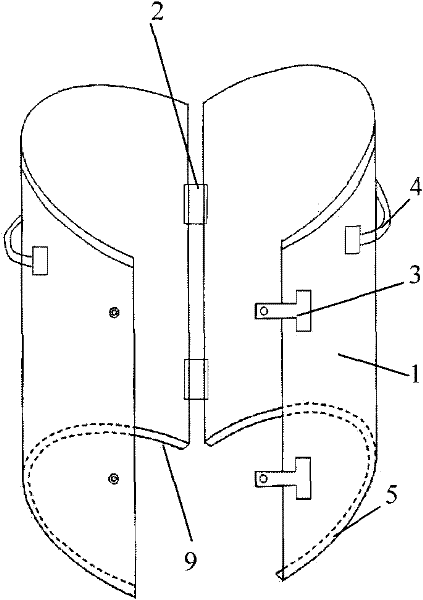

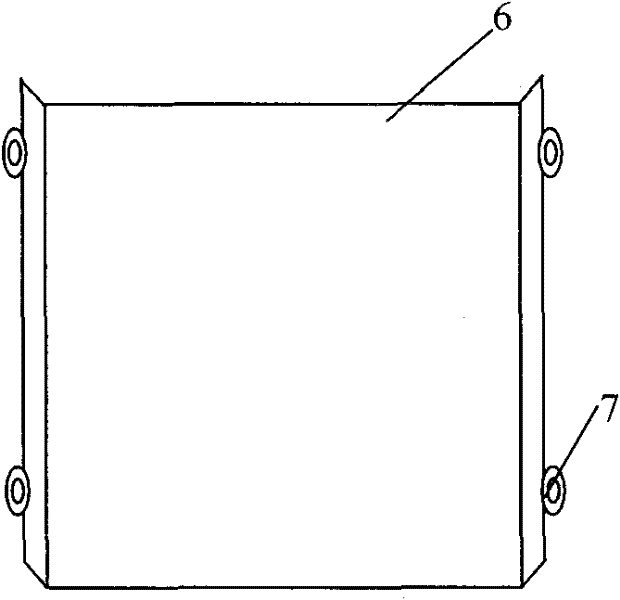

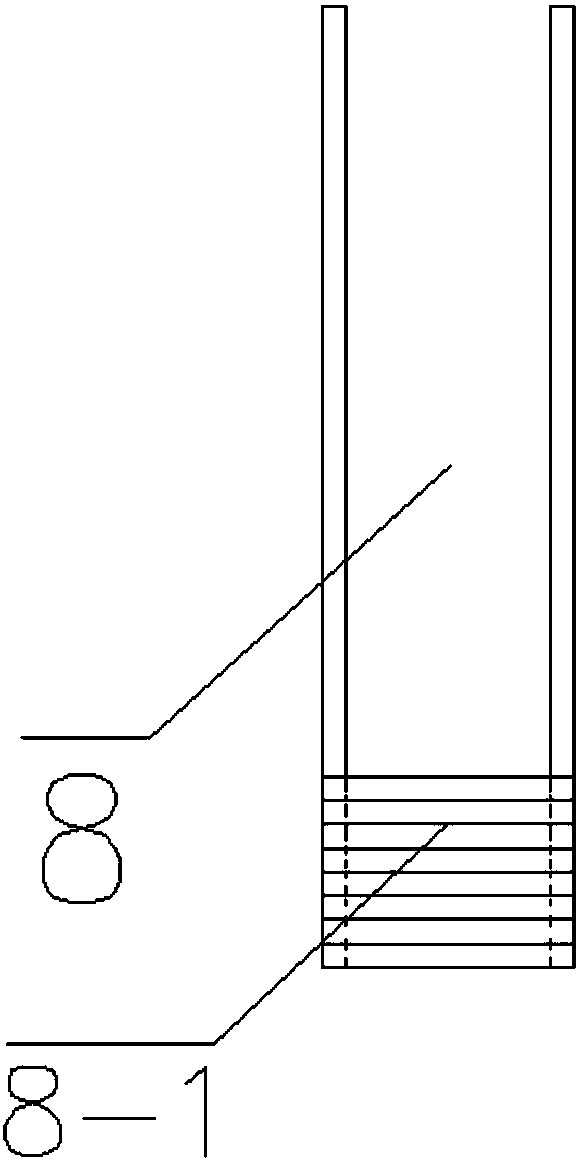

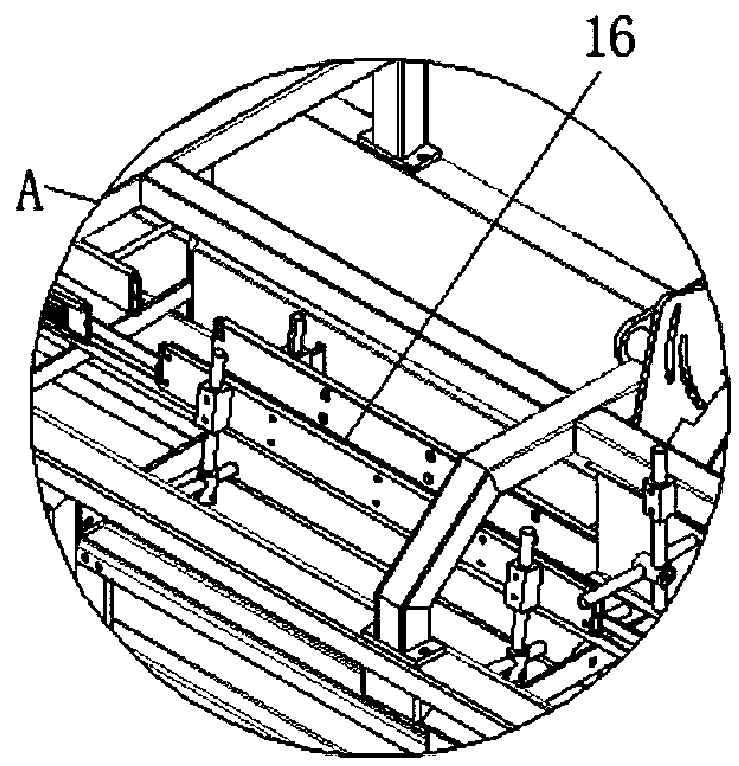

Device and method for extracting undisturbed soil

InactiveCN102235944ASuitable for fillingGuaranteed original conditionWithdrawing sample devicesEngineering

The invention relates to a device and a method for extracting undisturbed soil. The device comprises a main body cylinder, an opening and locking switch and a cylindrical hoisting ring, wherein the main body cylinder consists of two semi-cylindrical surfaces which can be opened and closed by taking a bus as a shaft; the opening and locking switch is arranged at the opening and closing position; and the external surface of the main body cylinder is provided with the cylindrical hoisting ring. The method comprises the following steps of: determining the area of a cylindrical soil sample, and digging at the periphery and on the lower side of the collected soil sample to reach an upper layer sampling depth; switching on the opening and locking switch on the main body cylinder, sleeving the two semi-cylindrical surfaces outside the soil sample, and closing and locking the two semi-cylindrical surfaces; separating the cylindrical soil sample from soil at the bottom of the cylindrical soil sample at the bottom of the main body cylinder; hoisting the main body cylinder carrying the cylindrical soil sample by a certain height, inserting, hoisting a base plate, putting on a transportation tool, and transporting to a specified place. The device has a simple and practical structure and is more suitable for filling the soil sample; and by the method, the original state of the soil sample can be better ensured, the soil sample is convenient to collect, and the safety factor is high.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

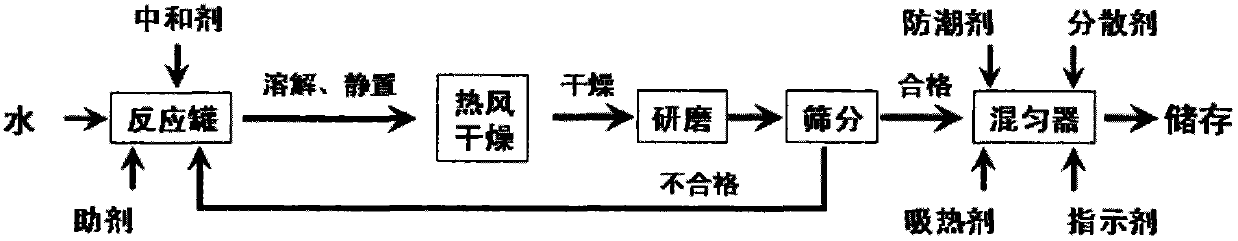

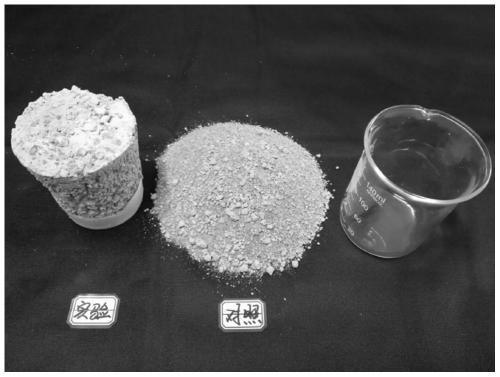

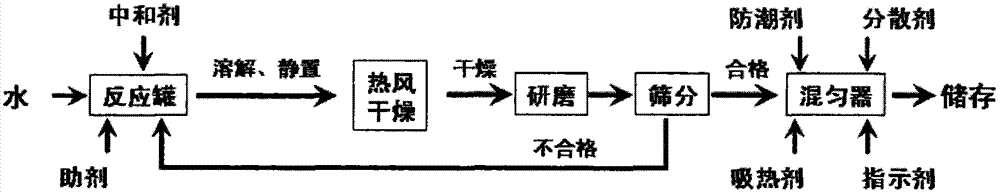

Alkaline powder for treating leaked sulfuric acid and preparation method of alkaline powder

ActiveCN102989114ANo cakingLow hygroscopicityDispersed particle separationMoisture absorptionEnergy consumption

The invention provides alkaline powder for treating leaked sulfuric acid and a preparation method of the alkaline powder. The alkaline powder is prepared from a neutralizer, an aid, a heat absorbent, a moisture-proof agent, a dispersant and an indicator in a certain ratio by a specific method. The raw materials for preparing the alkaline powder are readily available; the preparation method is simple, convenient and low in energy consumption; and the prepared powder does not cake, and is low in moisture absorption and good in settling performance after being sprayed. The alkaline powder can be used for effectively treating the leaked sulfuric acid of which the concentration is 50 to 98 percent or more; and the treatment process has the characteristics of high response speed, low temperature rise, secondary harm prevention, simplicity and convenience in endpoint judgment and the like.

Owner:ENG DESIGN & RES INST OF GENERAL ARMAMENTS DEPT +2

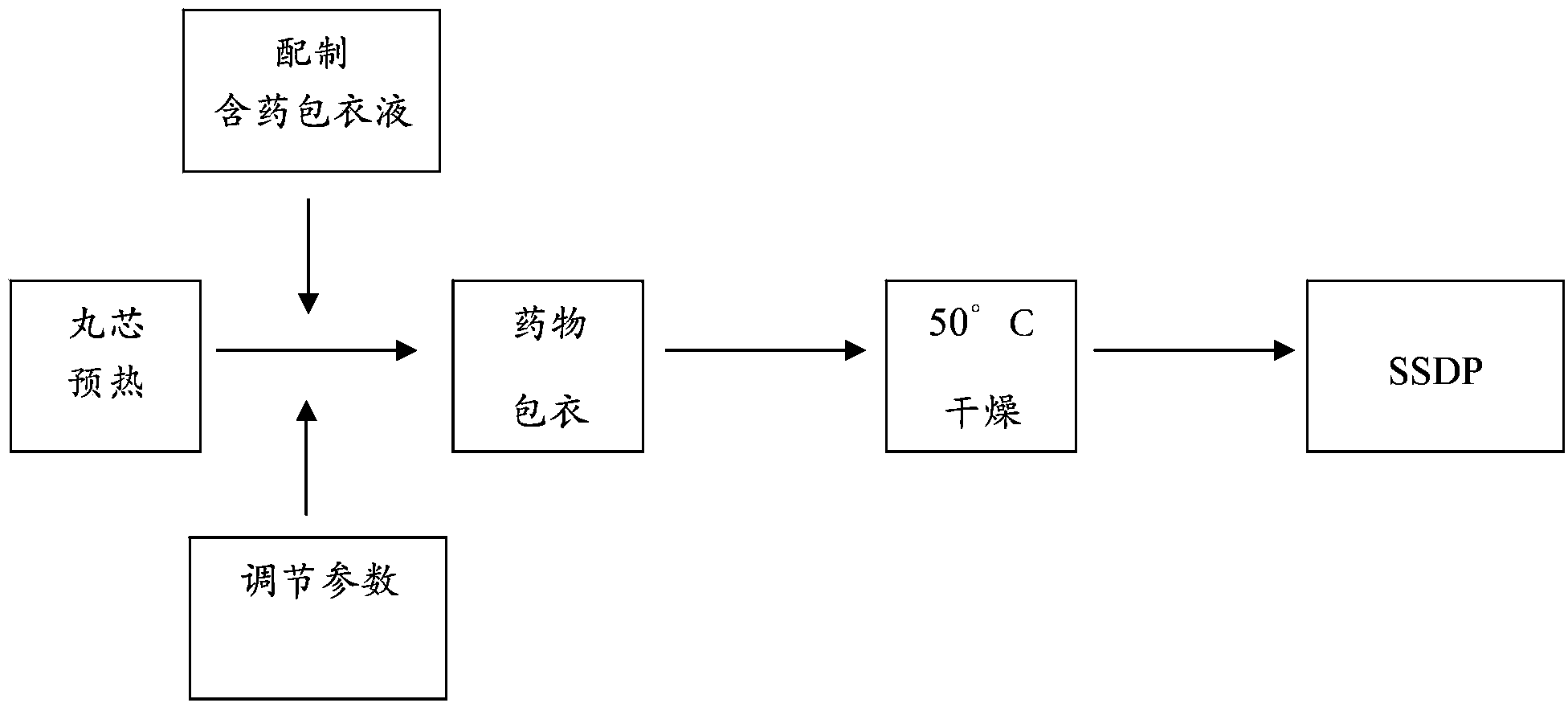

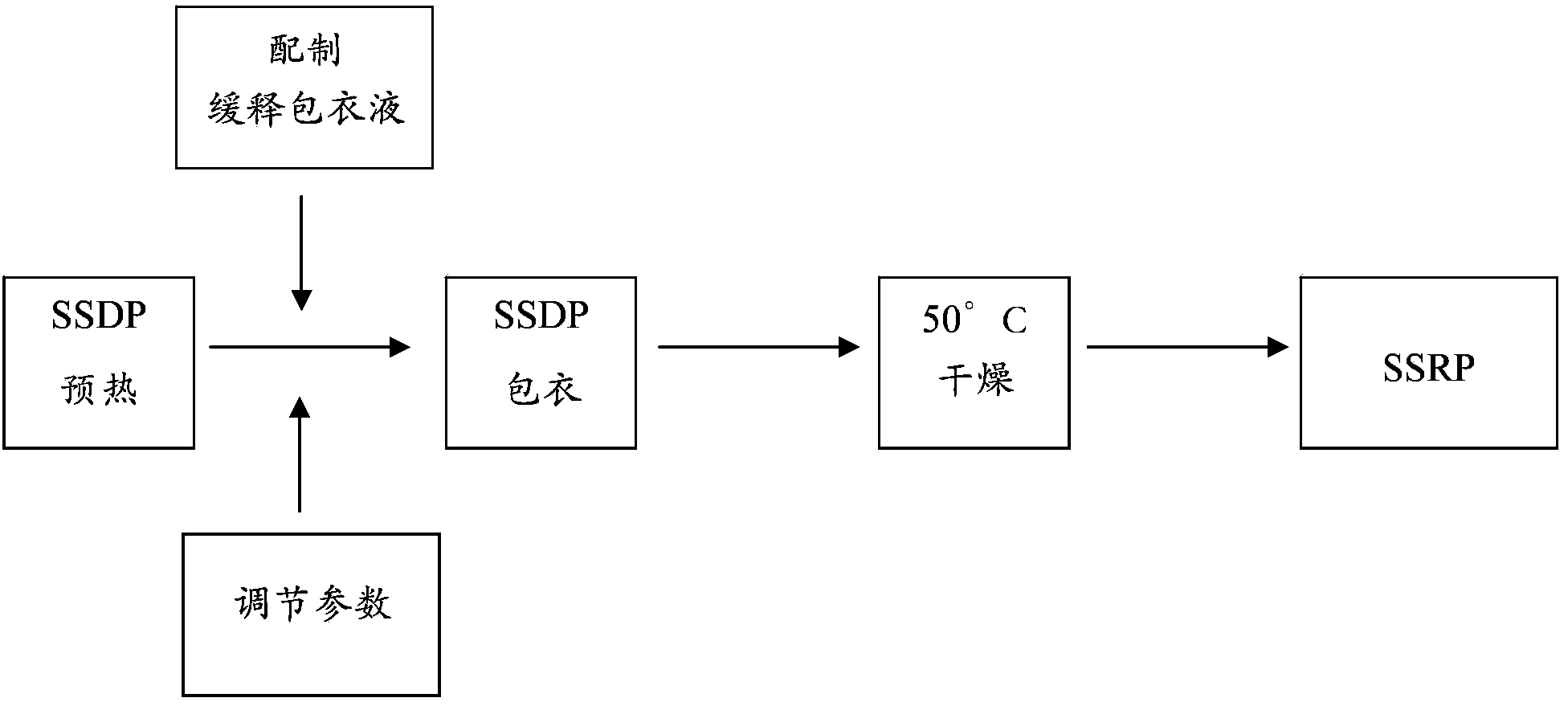

Silibinin slow release micropill with double layers of coatings and preparation method of silibinin slow release micropill

ActiveCN104069071ASuitable for fillingEasy to acceptOrganic active ingredientsDigestive systemSustained release pelletsPlasticizer

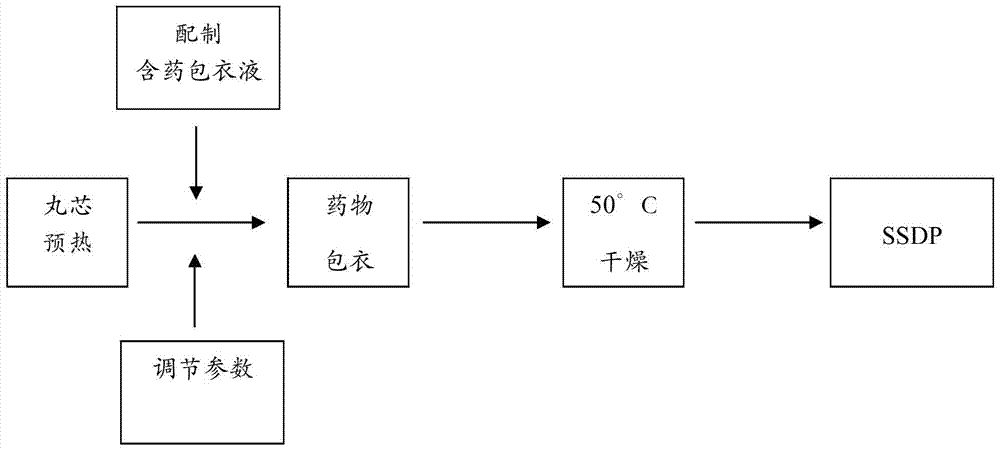

The invention relates to a silibinin slow release micropill with double layers of coatings. The silibinin slow release micropill is formed by a hollow pill core outside which the double layers of coatings are wrapped, wherein the first layer of coating forms a silibinin solid dispersion micropill and comprises silibinin, a solid dispersion carrier, a solubilizer and a sticky-resisting agent which are wrapped outside the hollow pill core so as to form the silibinin slow release micropill; the second layer of coating is formed outside the silibinin slow release micropill and comprises a slow release material, a lubricant and a plasticizer which are wrapped outside the silibinin slow release micropill so as to form silibinin slow release micropill with double layers of coatings. The silibinin slow release micropill provided by the invention is simple and convenient in preparation method, high in industrialized potential, stable in medicine release after being taken orally and high in bioavailability, and has a certain slow release effect.

Owner:JIANGSU UNIV

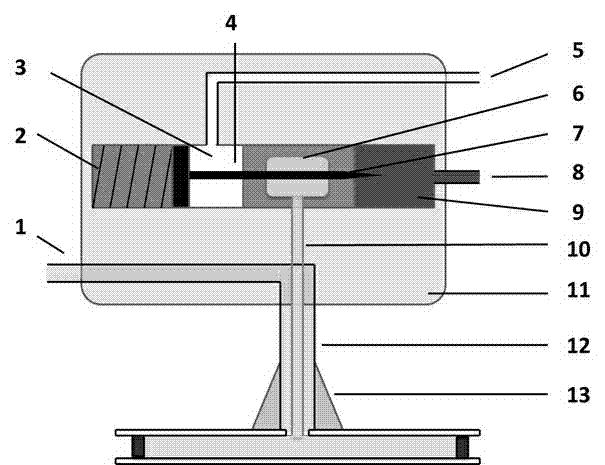

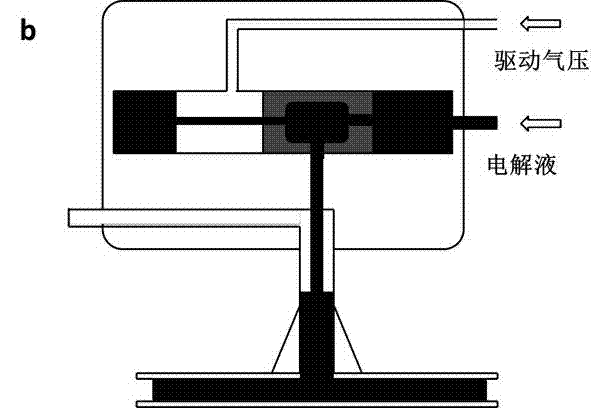

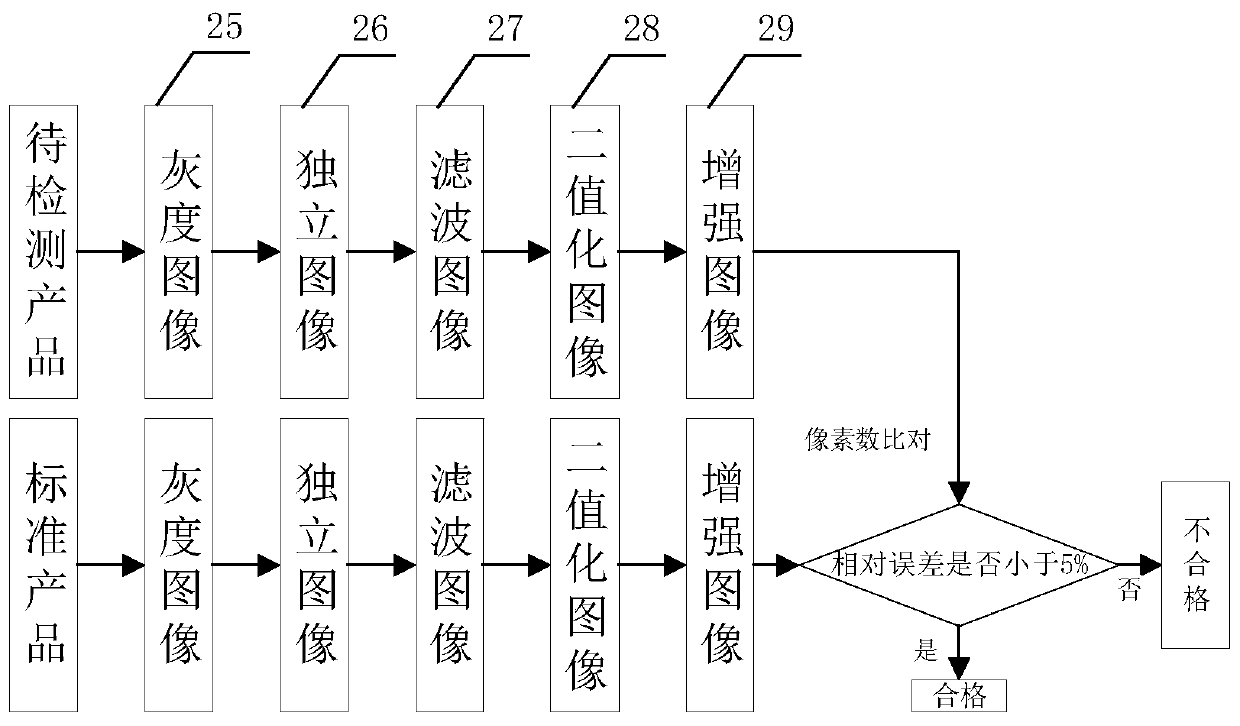

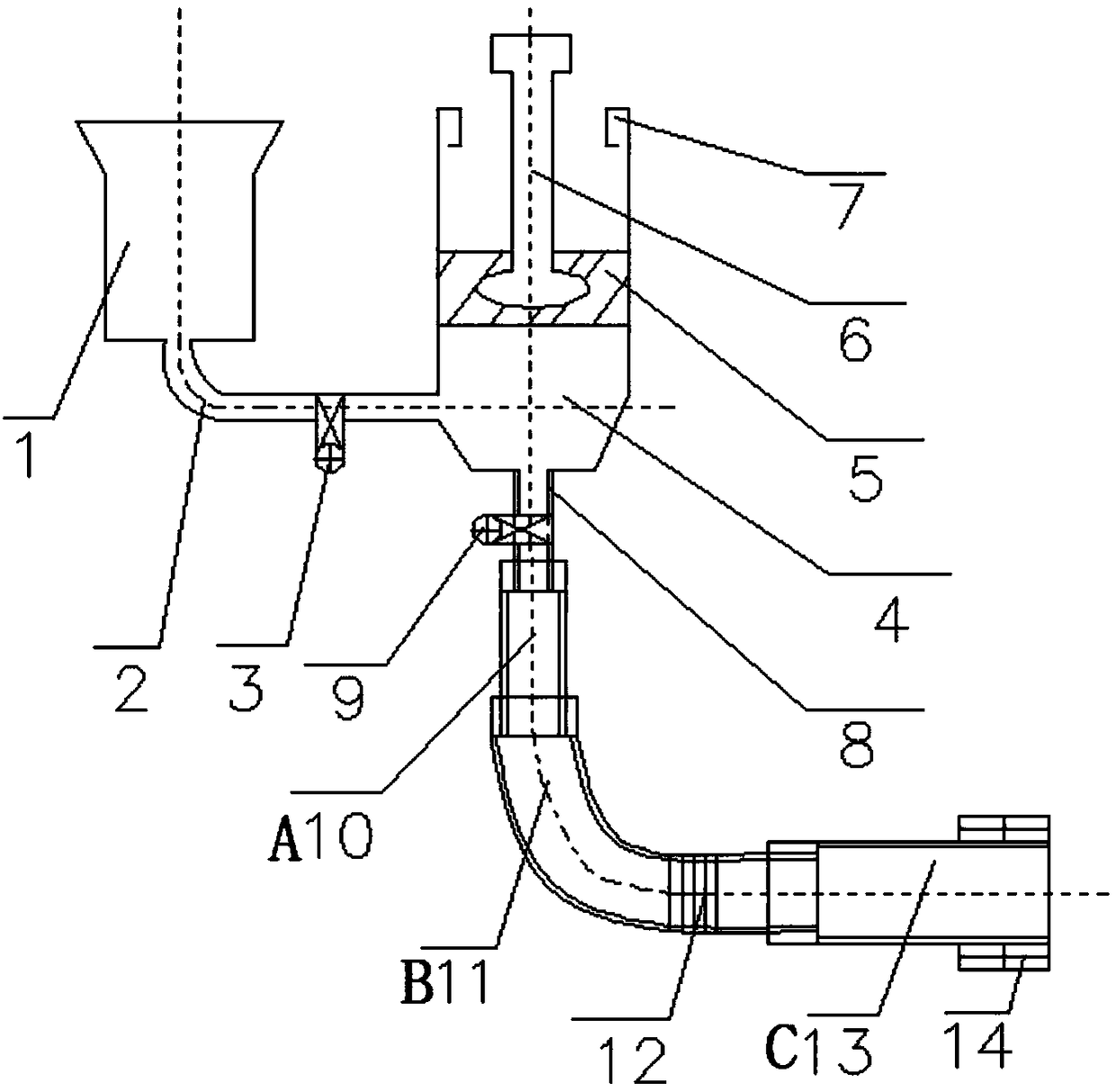

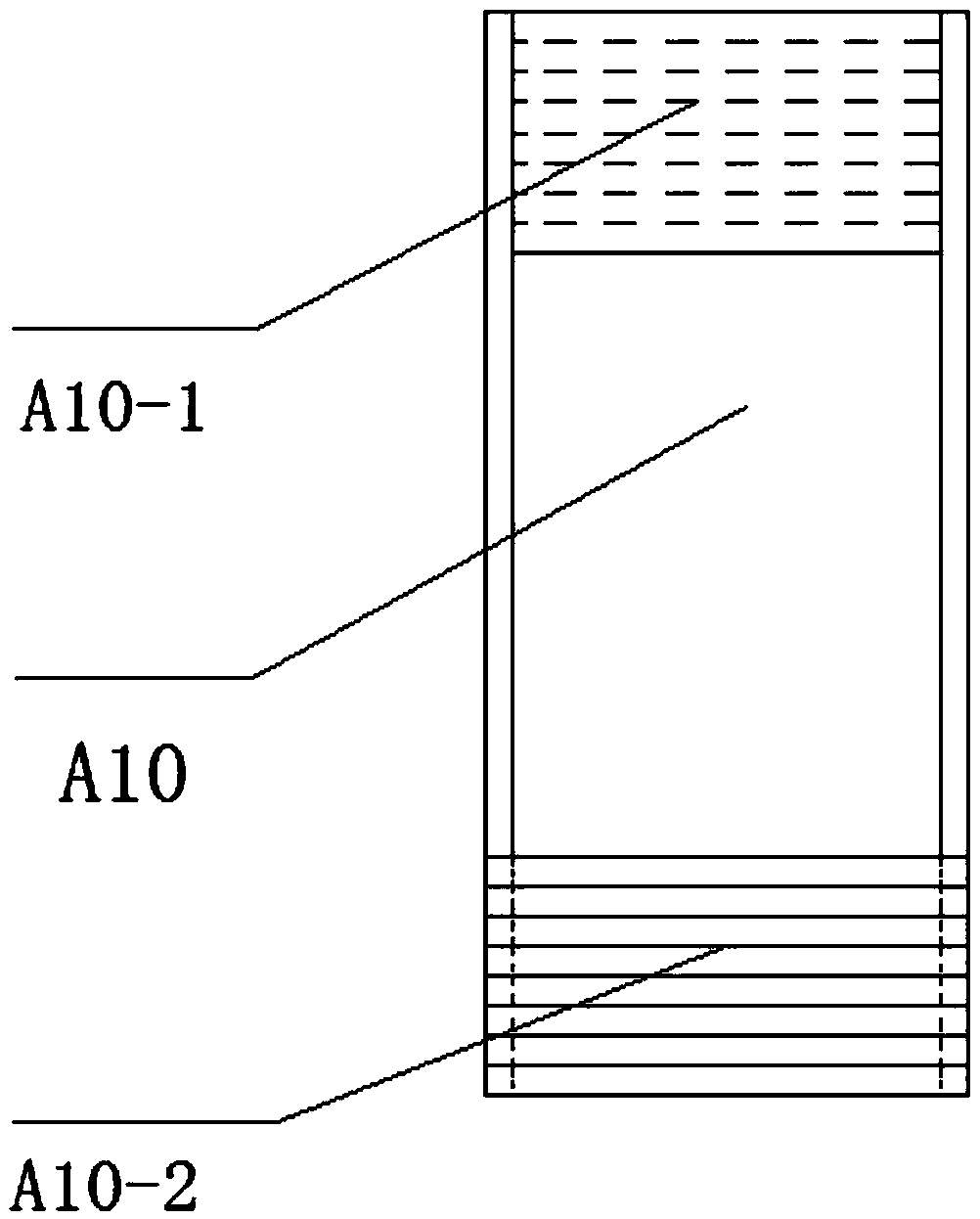

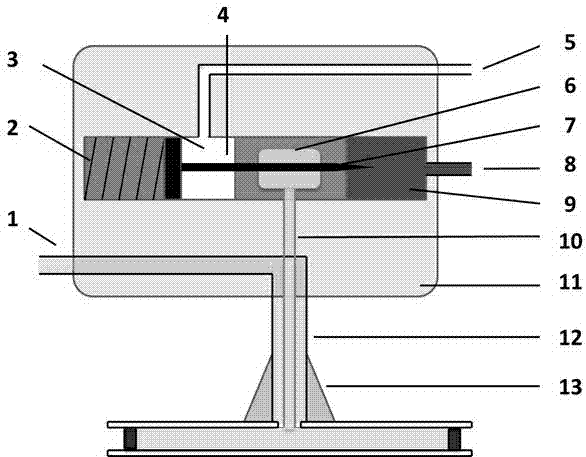

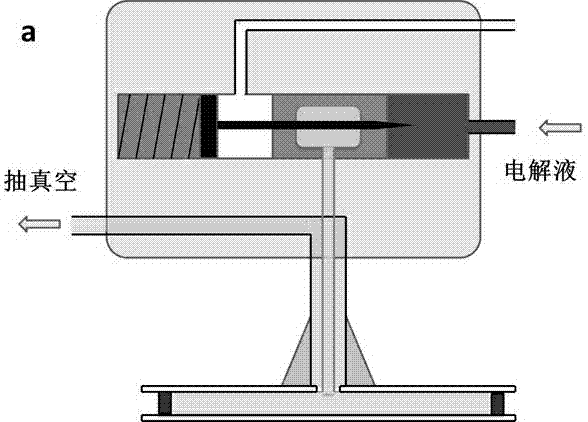

Controllable filling method for vacuum filling

InactiveCN102522223AReduce wasteSimple and fast operationLiquid fillingCapacitor manufactureVacuum pumpingControl room

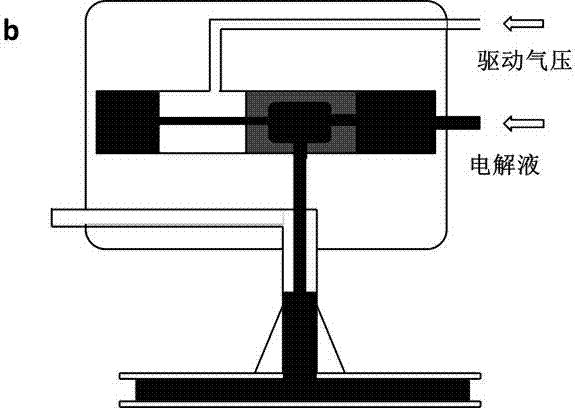

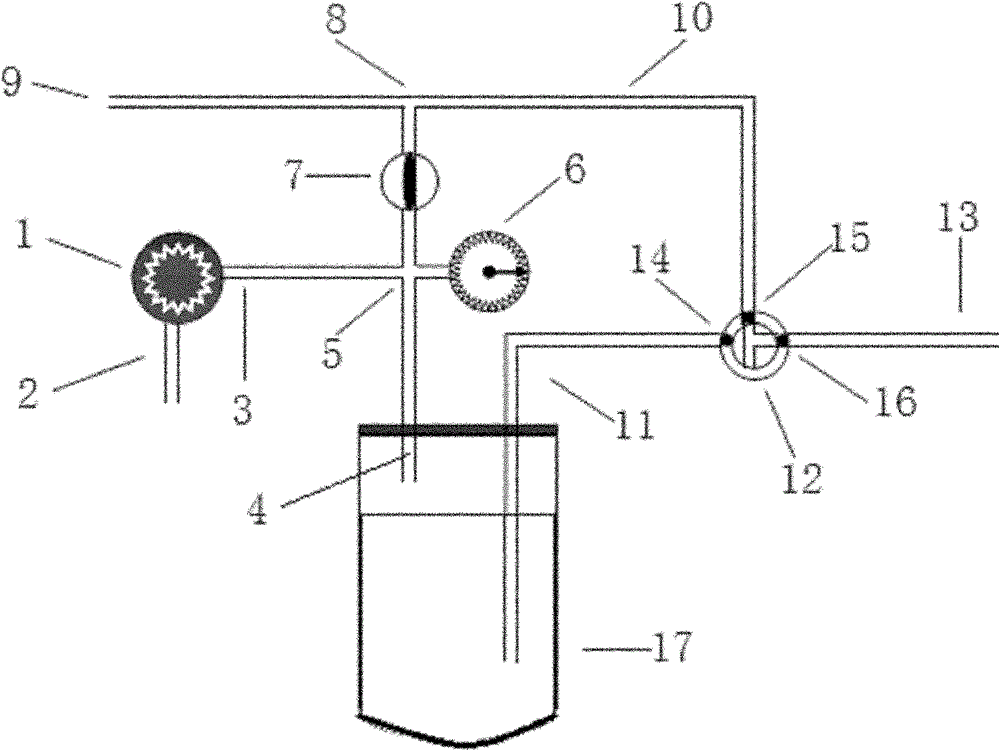

The invention relates to a controllable filling method for vacuum filling, which comprises the following steps that: an inner needle head (10) of a double-layer needle head is firstly connected with the cavity of a workpiece to be filled to ensure that the inner needle head (10) is connected to the inner part of the hole of a main control room of a needle valve without applying an externally-applied control air pressure to enable the needle valve to be kept in a closing state, the inner needle head (10) of the double-layer needle head is connected with the cavity of the workpiece to be filled, and a closed cavity body is formed by the main control room (6) of the needle valve, the inner needle head (10) and the cavity of the workpiece to be filled; a vacuum-accessing pipe (1) is connected with a vacuum negative pressure, and vacuum pumping is carried out through an outer needle head (12); filling is carried out when a required vacuum degree is achieved; after a liquid material is filled in the cavity body of the workpiece to be filled, positive-pressure nitrogen gas is accessed by using the vacuum-accessing pipe (1), the nitrogen gas reaches the open hole of the filled workpiece through the outer needle head (12), and the liquid material in the inner needle head is pressed back to a liquid-material storing room (9) under the pressure of the nitrogen gas; and the controllable filling method can be used for the connection of a vacuum-filling pipeline and the open hole of a filled device.

Owner:NANJING UNIV

Baby body wash and preparation method thereof

InactiveCN106137789AProperly cleanedNon-irritatingCosmetic preparationsToilet preparationsAllergic reactionBalance water

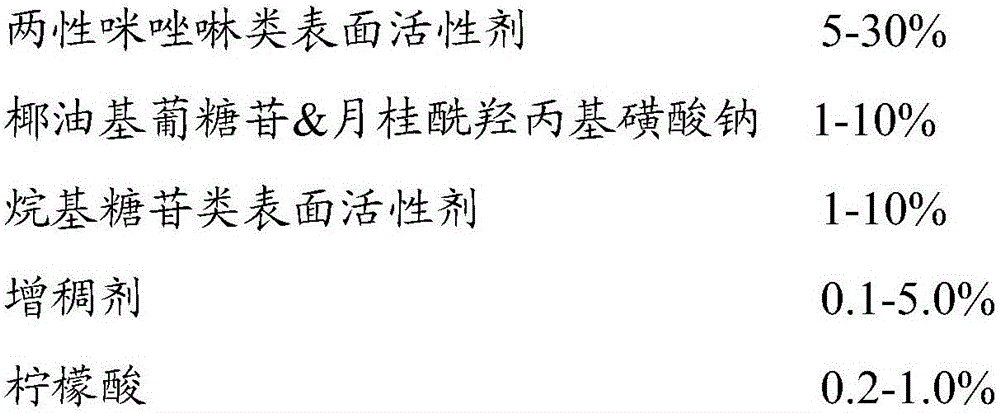

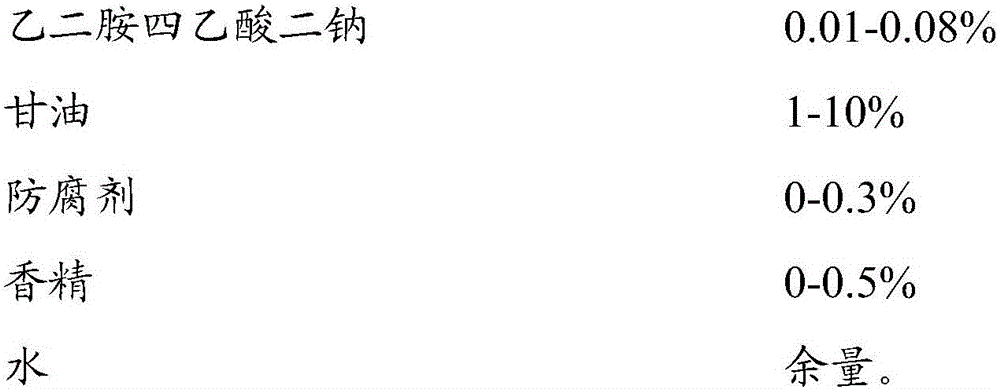

The invention relates to baby body wash and a preparation method thereof. The baby body wash is prepared from, by weight, 5-30% of amphoteric imidazoline surfactant, 1-10% of coco-glucoside and sodium lauroyl hydroxypropyl sulfonate, 1-10% of alkyl glycoside surfactant, 0.1-5.0% of a thickening agent, 0.2-1.0% of citric acid, 0.01-0.08% of ethylenediamine tetraacetic acid, 1-10% of glycerin, 0-0.3% of preservatives, 0-0.5% of essences and the balance water. The baby body wash is quite mild, completely accords with baby skin characteristics and is free of skin irritation and allergic reaction while proper cleaning of baby skin is guaranteed; due to pH of the baby body wash is 5.5-6.5, the baby body wash can better accord with intrinsic pH characteristics of baby skin, maintain a natural barrier function of baby skin and better retain moisture.

Owner:GUANGZHOU HONDU FINE CHEM CO LTD

Method of electroplating copper into a via on a substrate from an acid copper electroplating bath

ActiveCN106609384ASuitable for fillingSemiconductor/solid-state device manufacturingSemiconductor devicesCopperPrimary alcohol

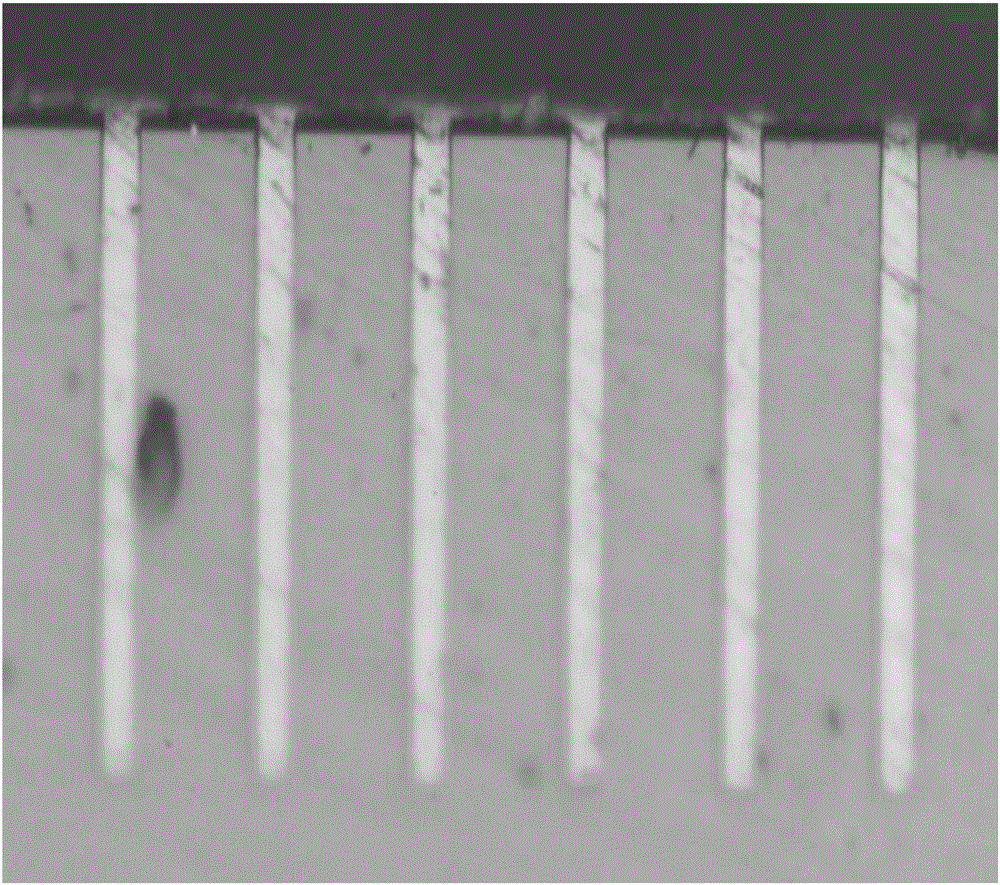

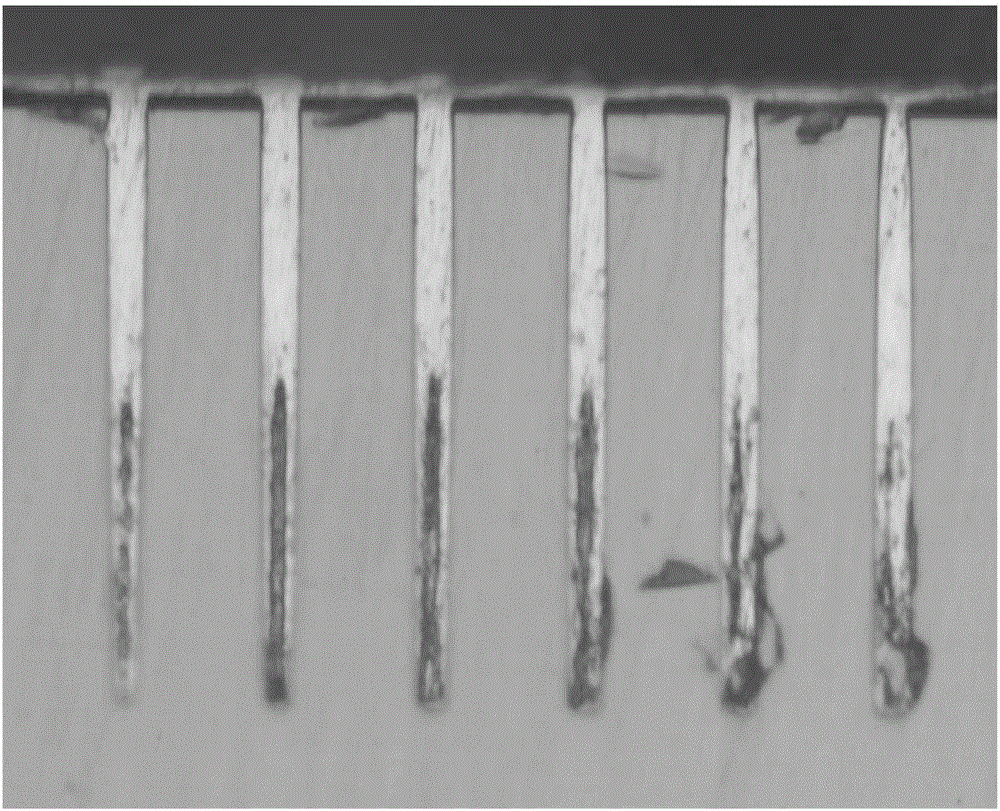

Copper electroplating baths containing primary alcohol alkoxylate block copolymers and ethylene oxide / propylene oxide random copolymers having specific HLB ranges are suitable for filling vias with copper, where such copper deposits are substantially void-free and substantially free of surface defects.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

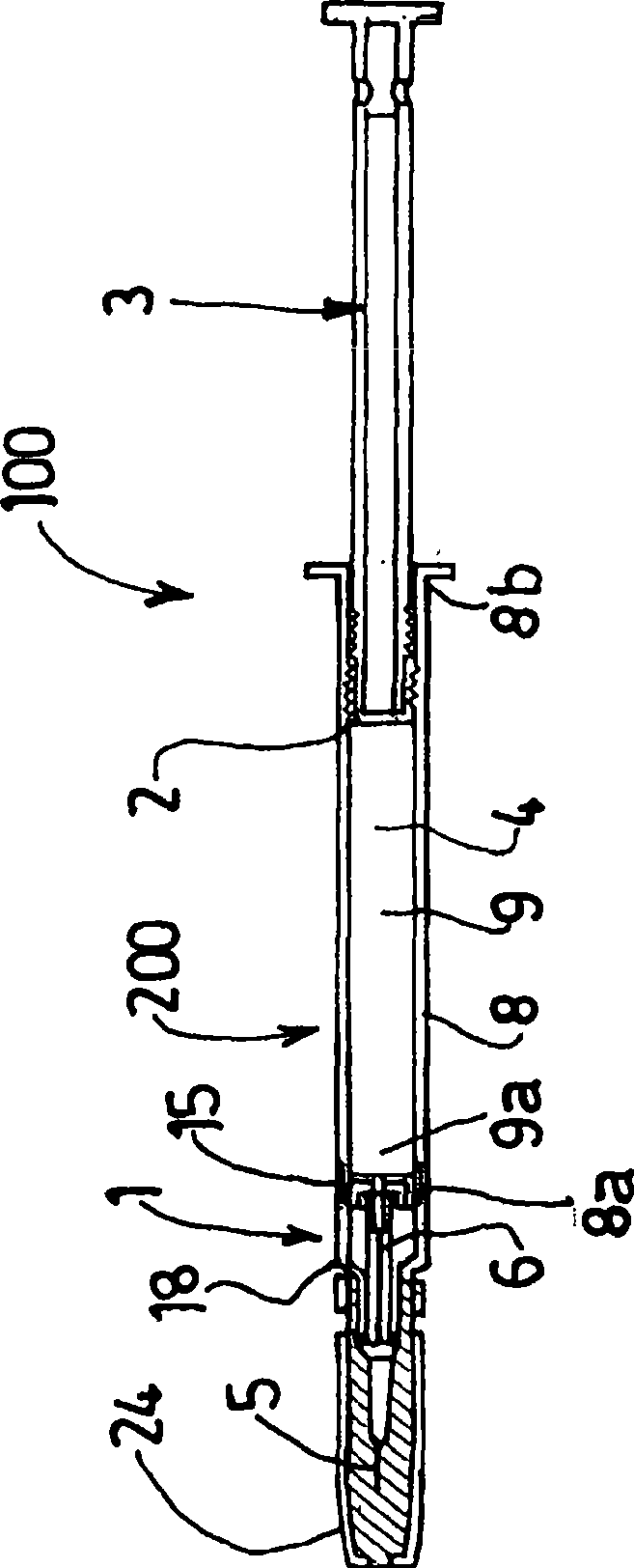

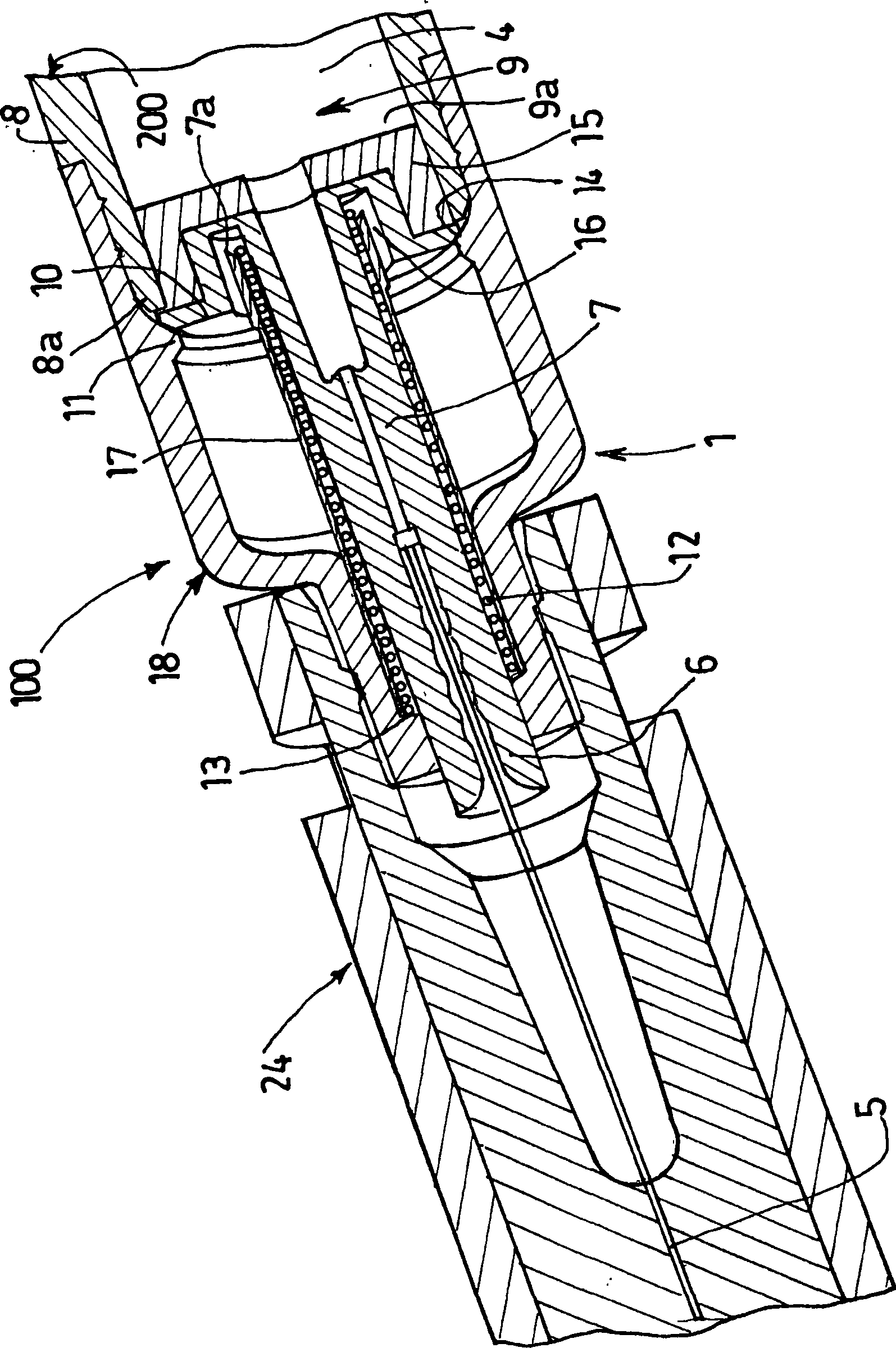

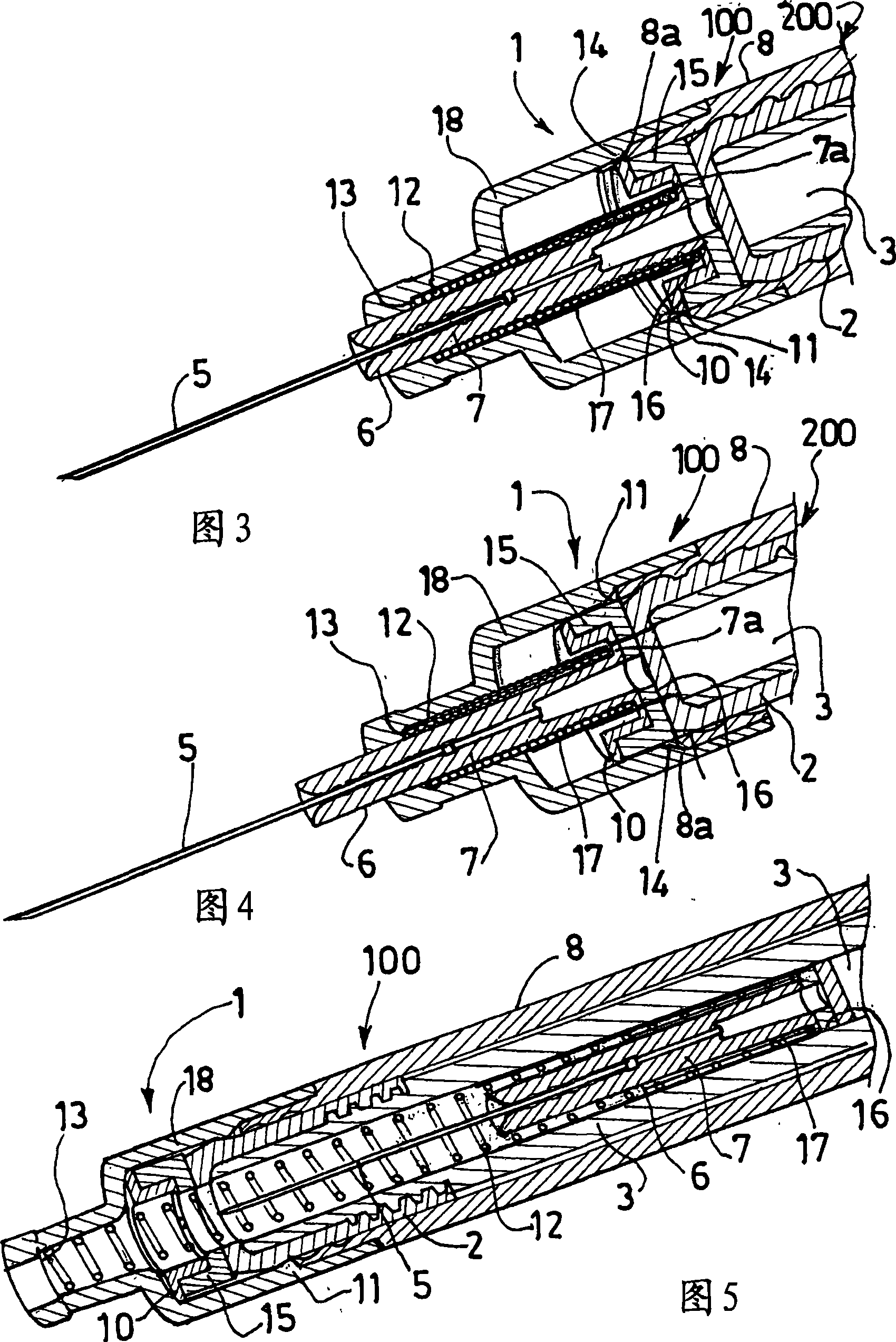

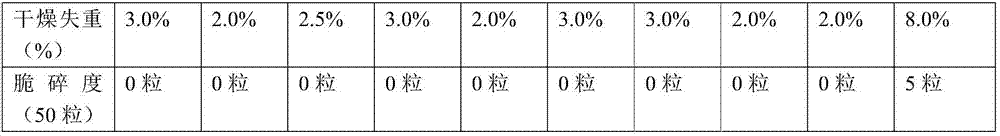

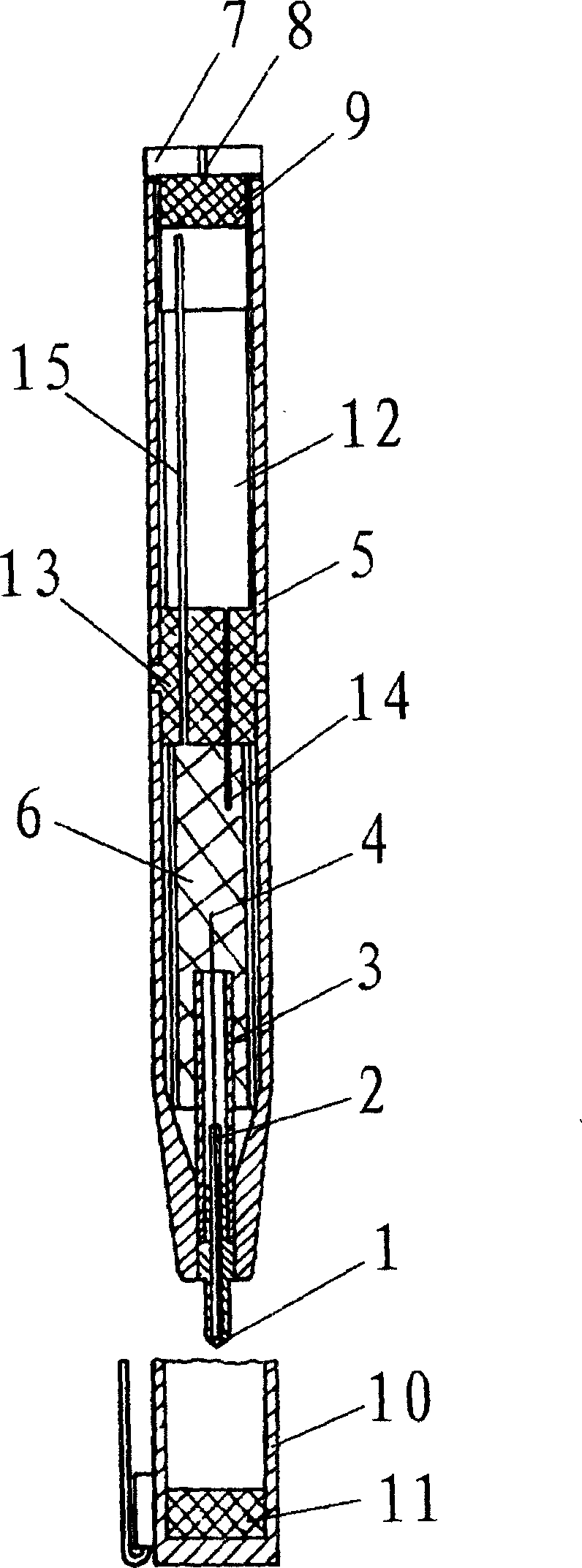

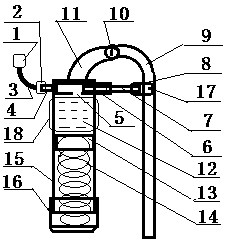

Injection device with retractable needle

ActiveCN101466425ASuitable for fillingNo deteriorationInfusion needlesInjection deviceBiomedical engineering

The present invention relates to a needle assembly (1) to be used in combination with a storing device (200) comprising a barrel (8) defining a chamber (9) receiving a product (4) and a piston (2), the assembly (1) comprising: needle-bearing portion (7) in a first material, movable between an exposed and a retracted positions of the needle (5), engaging means (8a, 10, 11, 18) for securing the needle-bearing portion (7) to the barrel (8) in the exposed position, characterized in that it comprises: sealing means (15) in a second material for tightly sealing the distal end (9a) of the chamber (9) to the needle-bearing portion (7), a breakable portion (7a) located between the engaging means (8a, 10, 11, 18) and the needle-bearing portion (7), which, when broken, allows independent proximal displacement of the needle-bearing portion (7) relative to the engaging means (8a, 10, 11, 18) between the exposed and the retracted positions, the first material being more rigid than the second material. The invention also relates to an injection device (100) comprising the needle assembly (1) and a storing device (200).

Owner:BECTON DICKINSON FRANCE

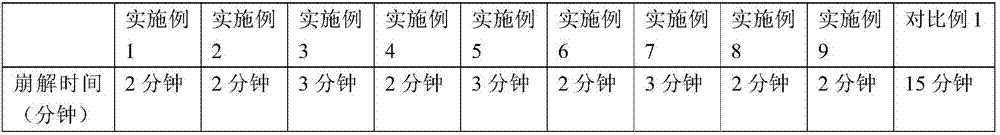

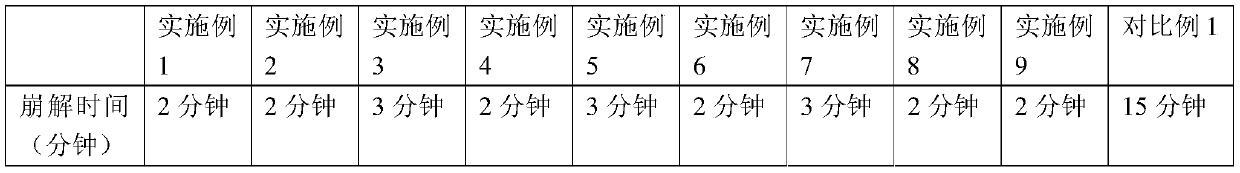

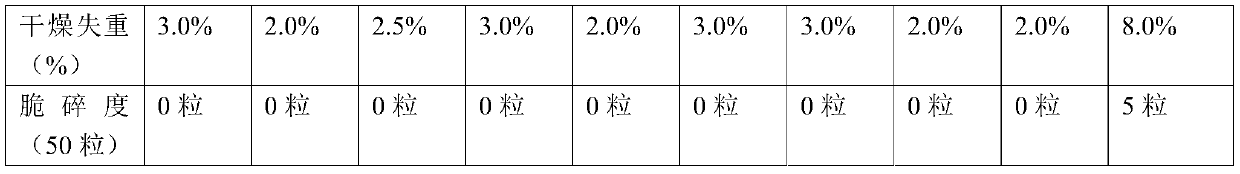

Hydroxypropyl methyl cellulose plant empty capsule

ActiveCN107296801AFast disintegrationLow loss on dryingPharmaceutical non-active ingredientsCapsule deliveryAlcoholOrganic solvent

The invention discloses a hydroxypropyl methyl cellulose plant empty capsule which is prepared through the following method: dissolving hydroxypropyl methyl cellulose in a mixed solvent of an organic solvent and water, preparing a hydroxypropyl methyl cellulose solution with the mass percentage of 10 to 33 percent, and making capsules by using the hydroxypropyl methyl cellulose solution, wherein the organic solvent is ethyl alcohol and / or acetone. The hydroxypropyl methyl cellulose plant empty capsule has the advantages that the capsule is disintegrated fast, is not brittle and has extremely low weight loss on drying; furthermore, according to the preparation method of the capsule, no heating is needed, so that energy consumption is reduced; no gelatinizer is added, so that influence on disintegration due to the gelatinizer is avoided; the capsule is cured and molded only through volatilization of the organic solvent, so that the hydroxypropyl methyl cellulose plant empty capsule is suitable for filling of certain medicines having special requirements.

Owner:ANHUI HUANGSHAN CAPSULE CO LTD

Special ball-point pen with ink controller and ink limiting tube

A special ball-point pen with ink controller and ink limiter for writing, copying and plotting is composed of pen cap, ball tip, ink controller with internal ink guiding tube and ink limiting tube made of fluffy tube with capillary action, ink storage unit, pen holder and sealing end. Its advantages are high adaptability to different inks, low cost, multiple functions and smooth writing.

Owner:上海华科特种墨水研究所

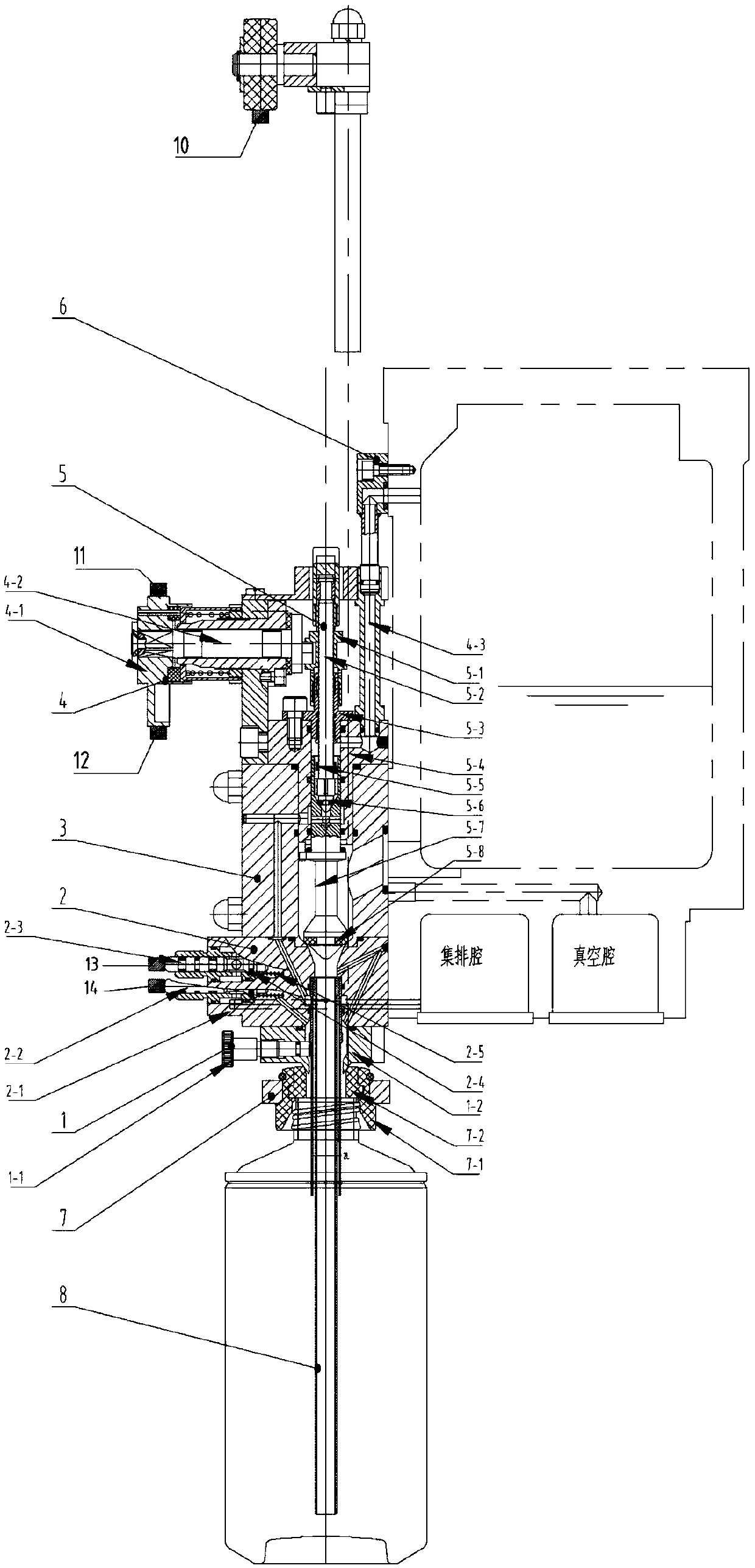

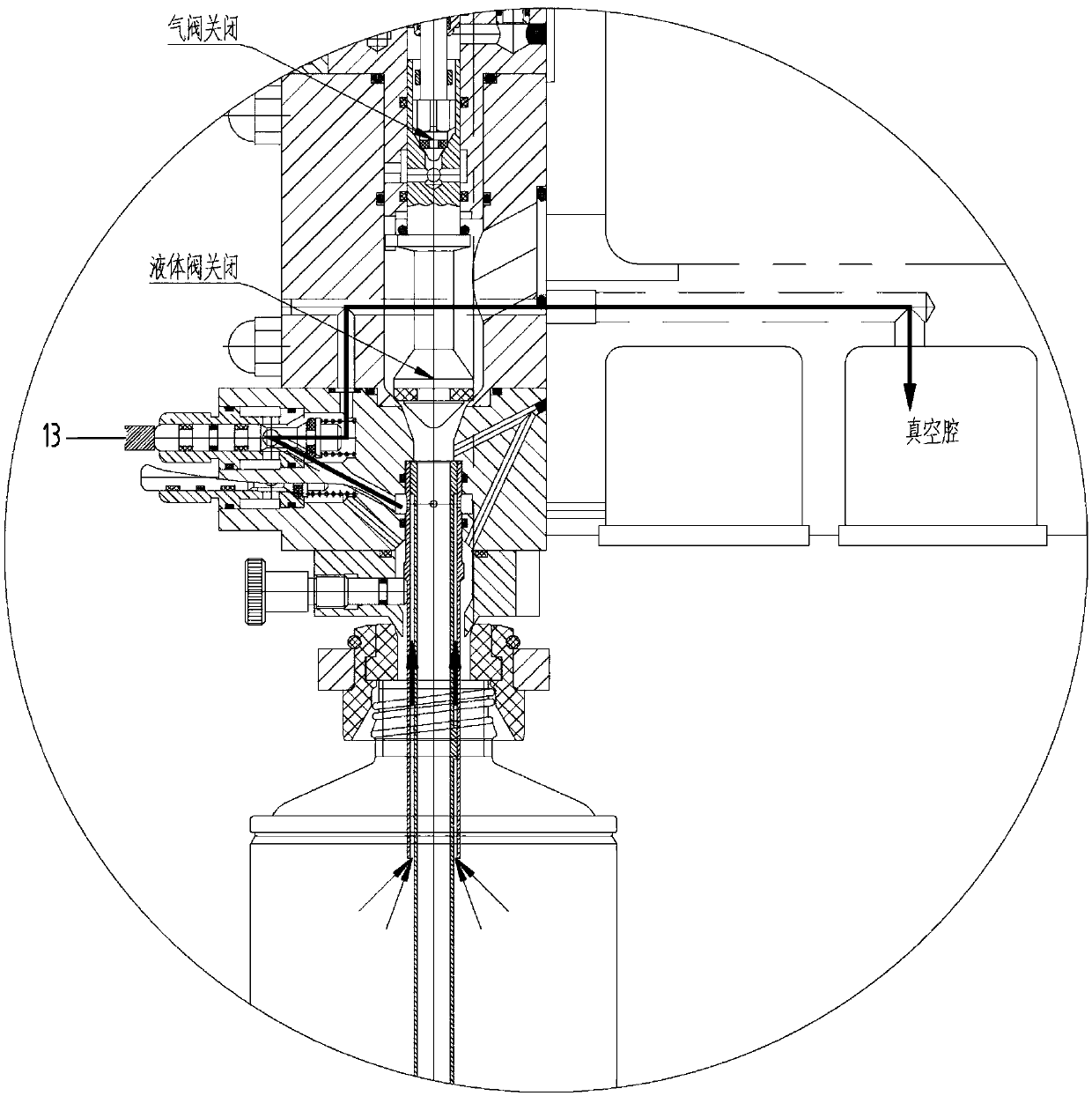

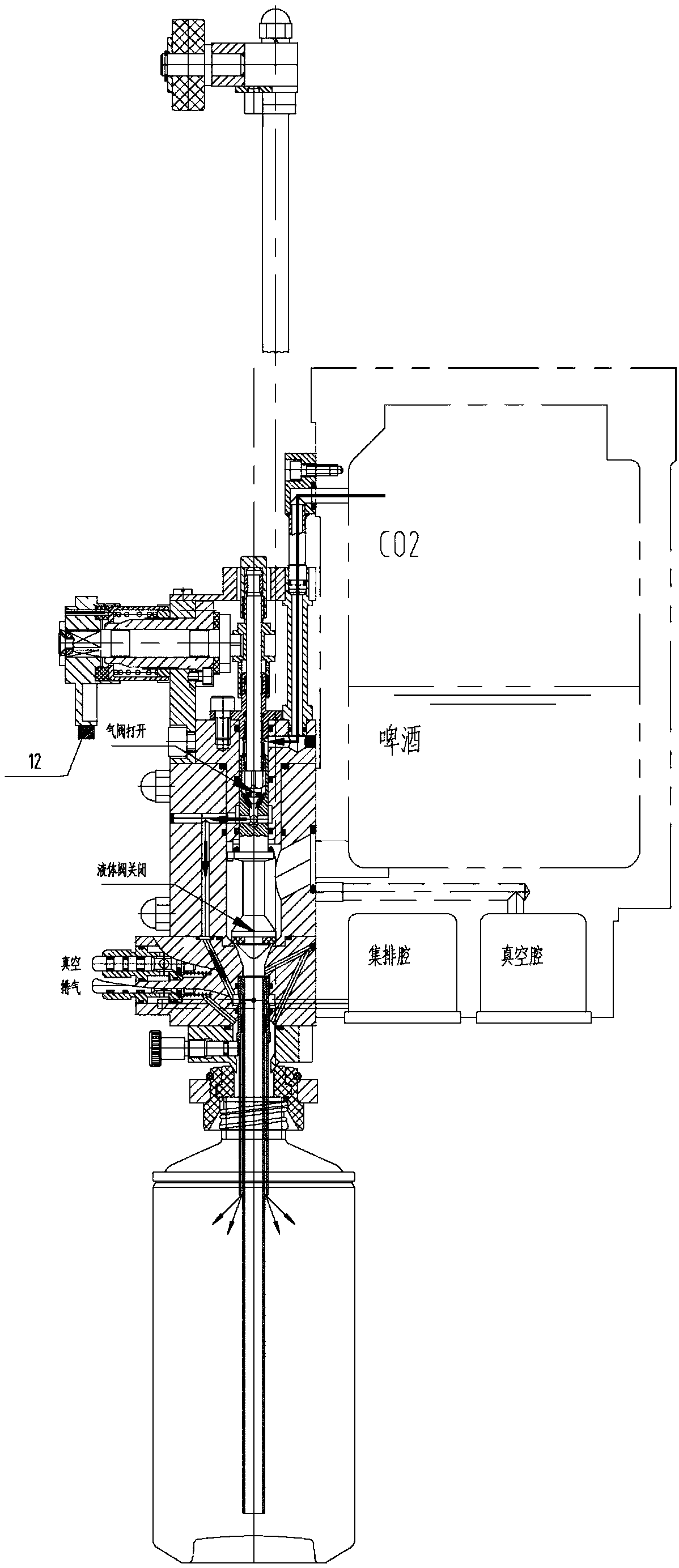

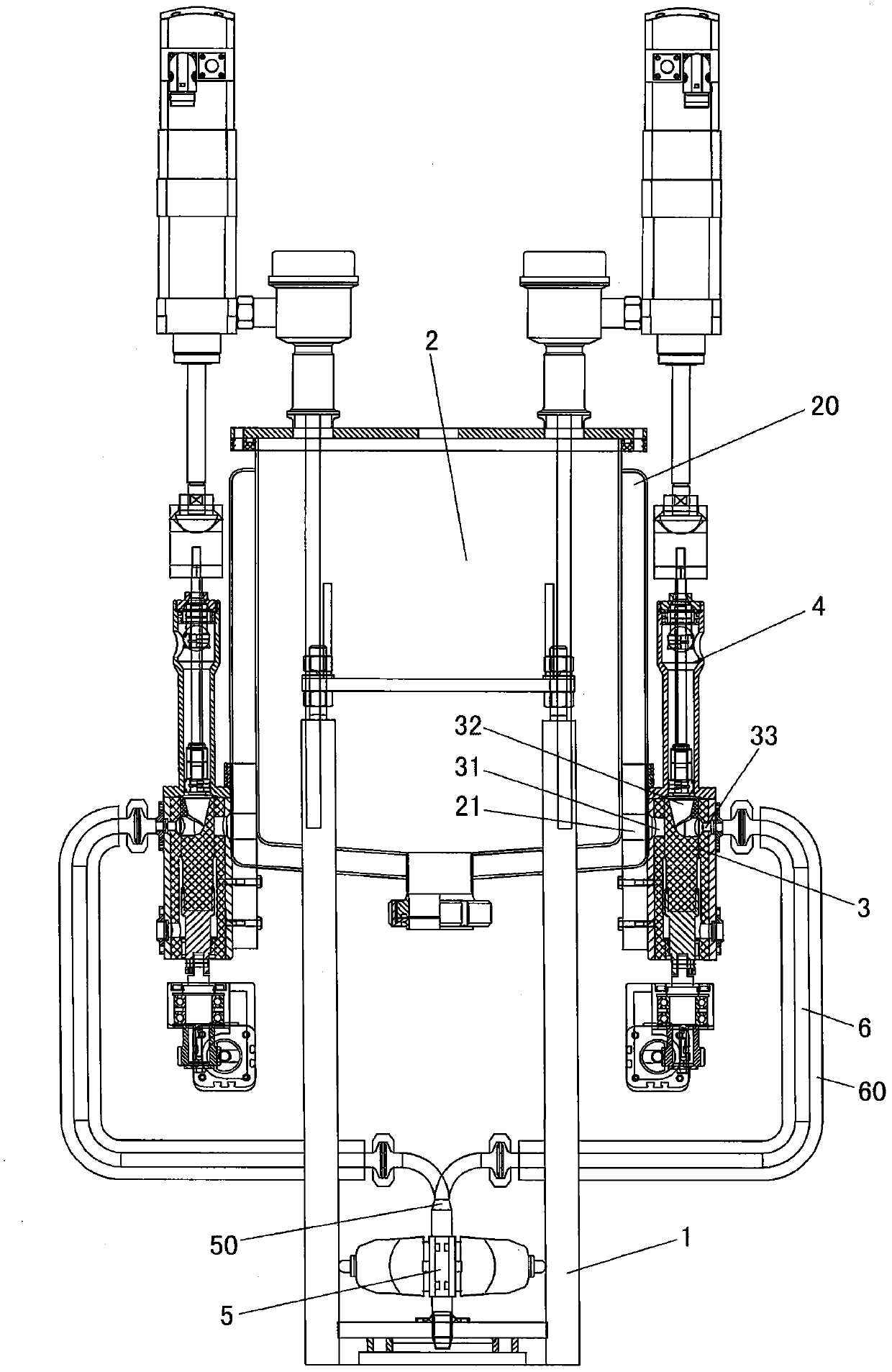

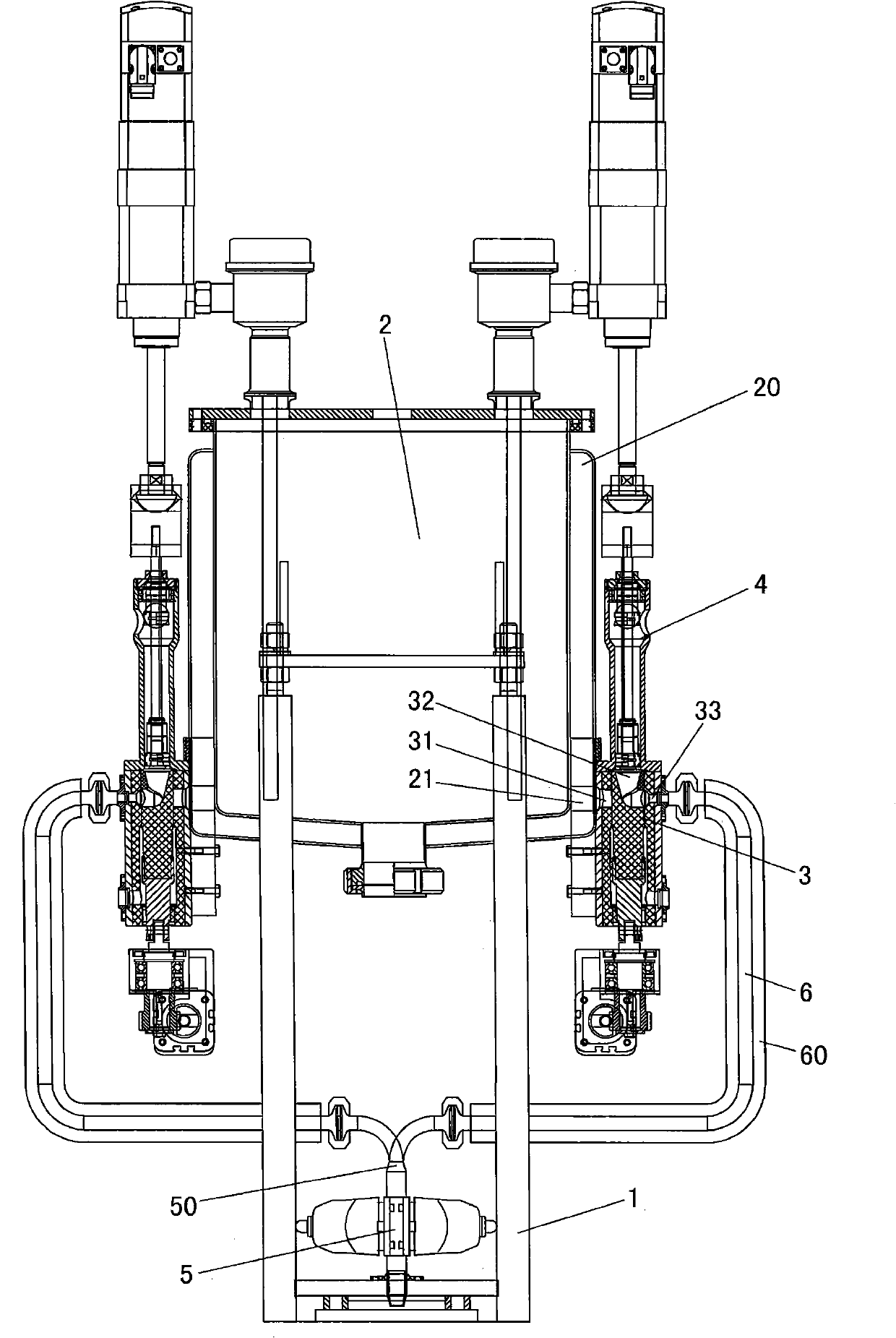

Vacuum long pipe valve and working method thereof

PendingCN110734028ADifferent displacement effectsStable opening and closingFilling using counterpressureBottlePhysics

The invention relates to the technical field of packaging beverage conveying equipment, in particular to a vacuum long pipe valve and a working method thereof. The vacuum long pipe valve comprises a long pipe for inserting into a metal bottle and an air return base for fixing the long pipe, the air return pipe base comprises a fixing base, a valve lower base used for providing a gas switching channel and a material channel is fixed above the fixing base, the valve lower base comprises a valve lower seat, a valve main body used for arranging the gas channel and the material channel is fixed above the valve lower seat, the long pipe is a double-layer long pipe, the outer layer of the long pipe is shorter than the inner layer, the center of the long pipe is the material channel, and the interlayer is the gas channel. According to the vacuum long pipe valve, injecting liquid in the centre and filling from the bottom, a liquid outlet pipe is embedded into the liquid in most part of the filling process, the liquid level is in a mode from bottom to top until filling is finished, and the filling process is stable.

Owner:南京恒昌包装机械有限公司

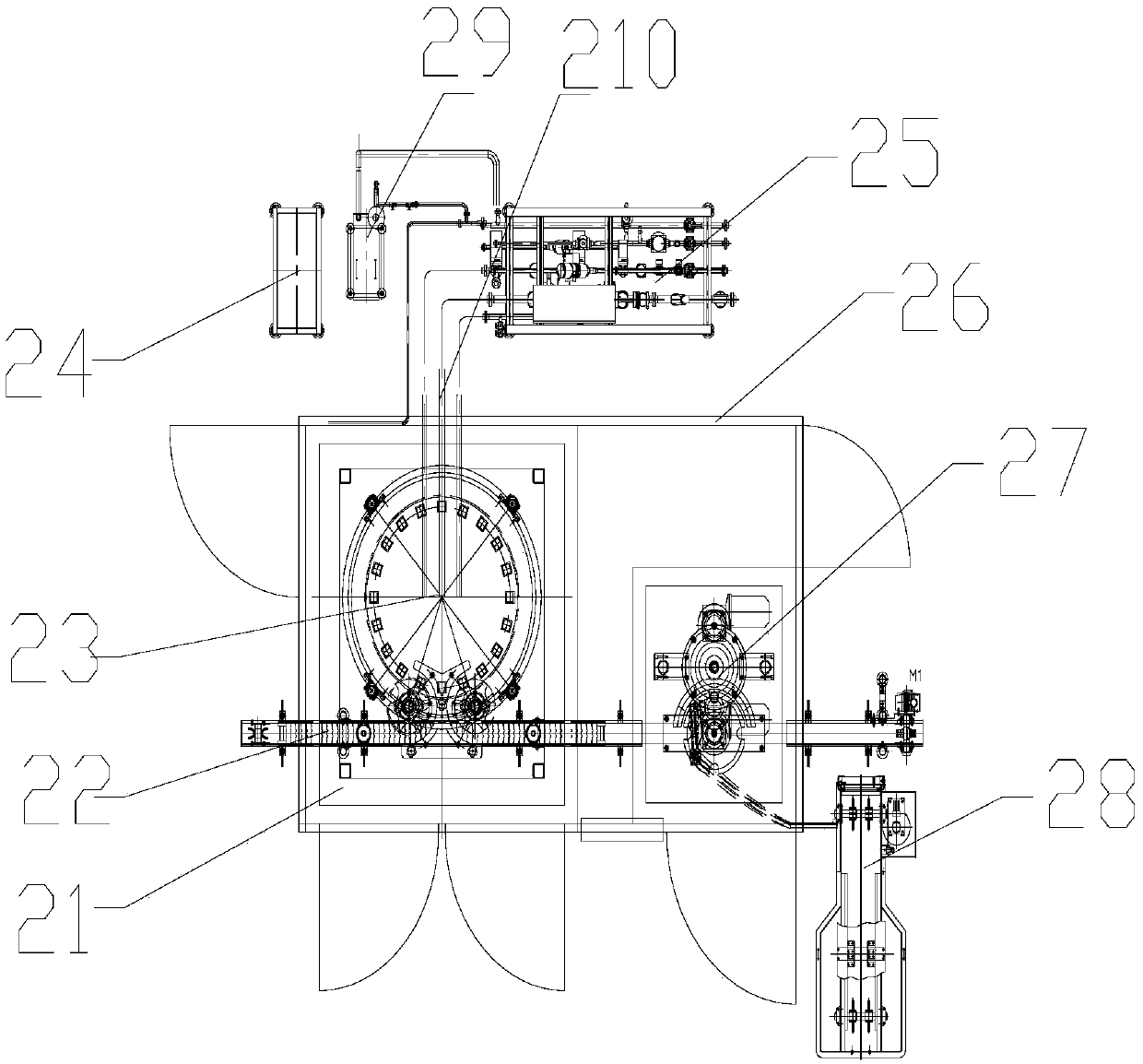

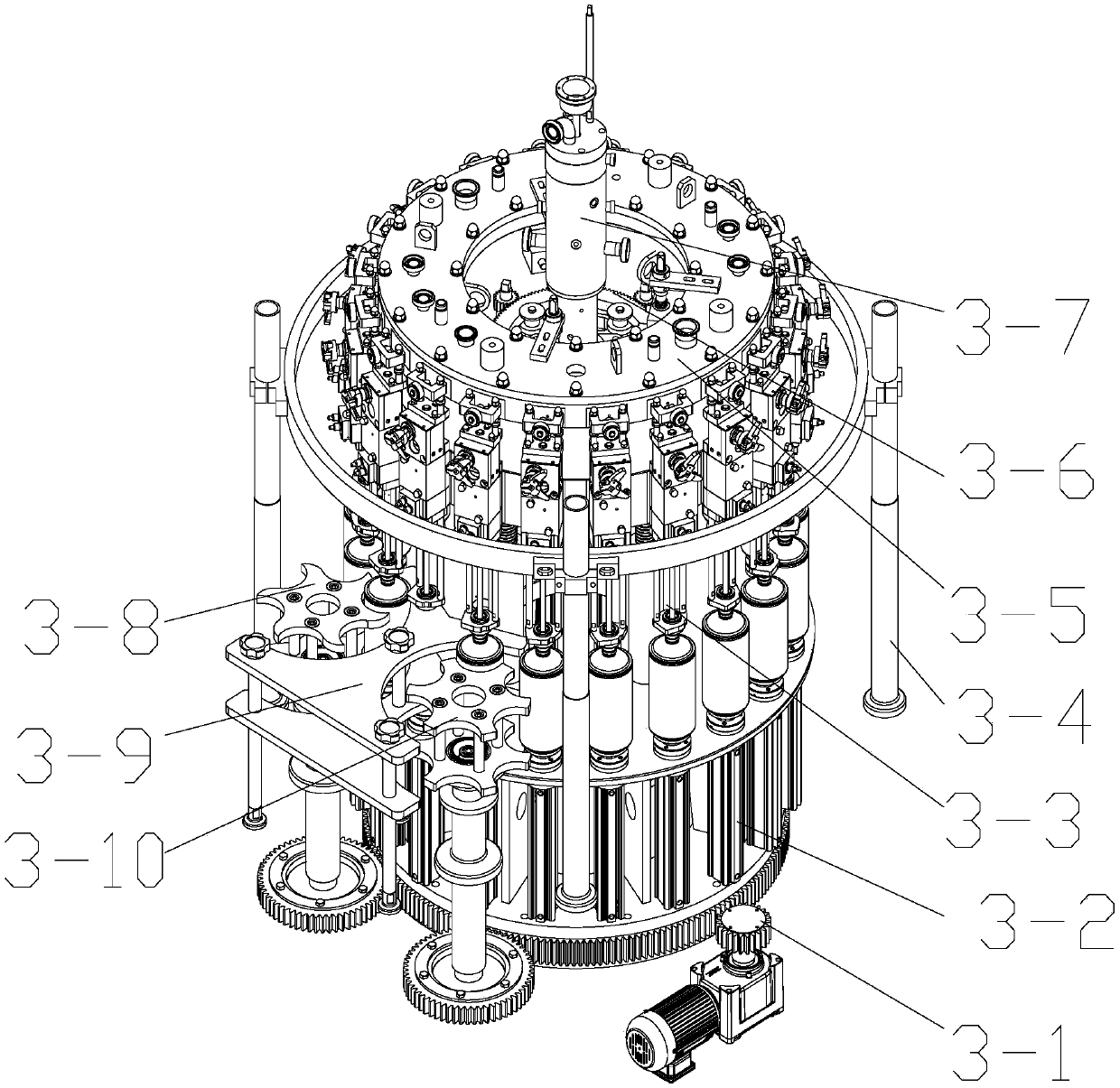

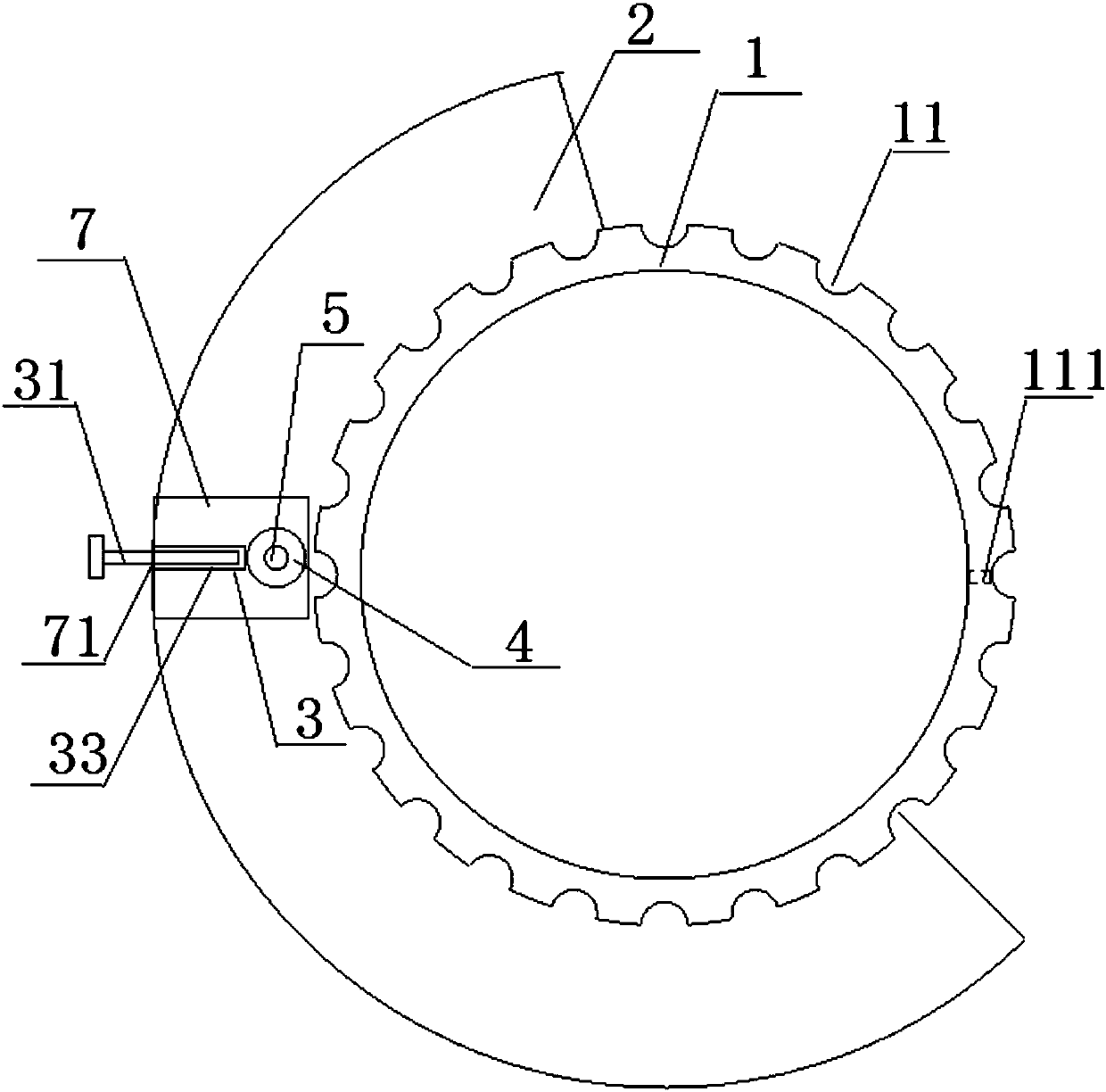

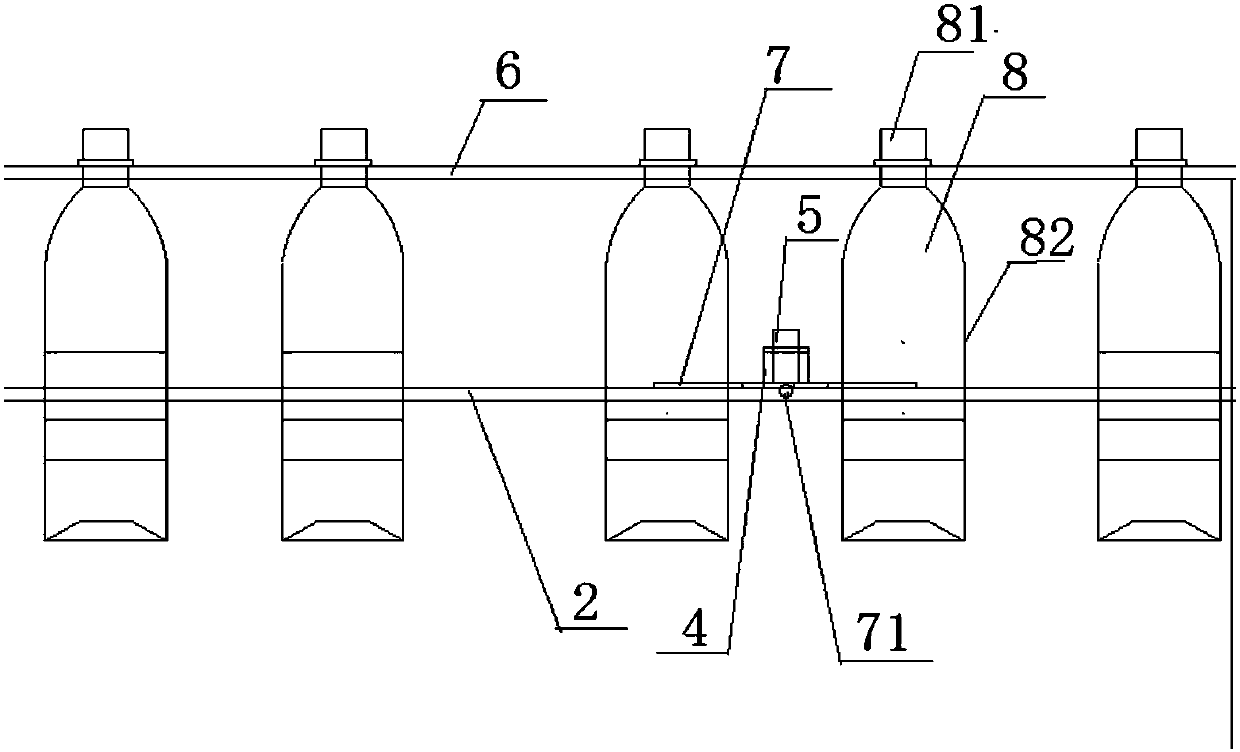

Craft beer filling and capping machine

PendingCN110734024AGuaranteed uptimeTake up a reasonable amount of spaceThreaded caps applicationSynchronising machinesRotary stageWine bottle

The invention relates to the technical field of packaging beverage conveying equipment, in particular to a craft beer filling and capping machine. The machine comprises a workbench, wherein the workbench is provided with a filling mechanism and a cap screwing mechanism, the workbench is provided with a conveying mechanism for conveying empty wine bottles to the filling mechanism and conveying thewine bottles finishing filling to the cap screwing mechanism, the filling mechanism comprises a mounting frame rotated relative to the workbench, a plurality of long tube filling valves are fixed on the mounting frame in the circumferential direction, a rotating table used for bearing the beer bottles is rotatably arranged below the mounting frame, a guide plate mechanism, a bottle feeding shifting wheel and a bottle discharging shifting wheel are arranged between the conveying mechanism and the rotating table, wherein the bottle feeding shifting wheel is used for guiding the beer bottles fromthe conveying mechanism to the rotating table, the bottle discharging shifting wheel is used for exporting the beer bottles from the rotating table to the conveying mechanism, the bottle feeding shifting wheel and the bottle discharging shifting wheel are in a chain gear structure, and the side faces, facing the bottle feeding shifting wheel and the bottle discharging shifting wheel, of the guideplate mechanism are in arc shapes. According to the machine, the liquid level is changed from bottom to top until filling is finished, and the filling process is stable.

Owner:南京恒昌包装机械有限公司

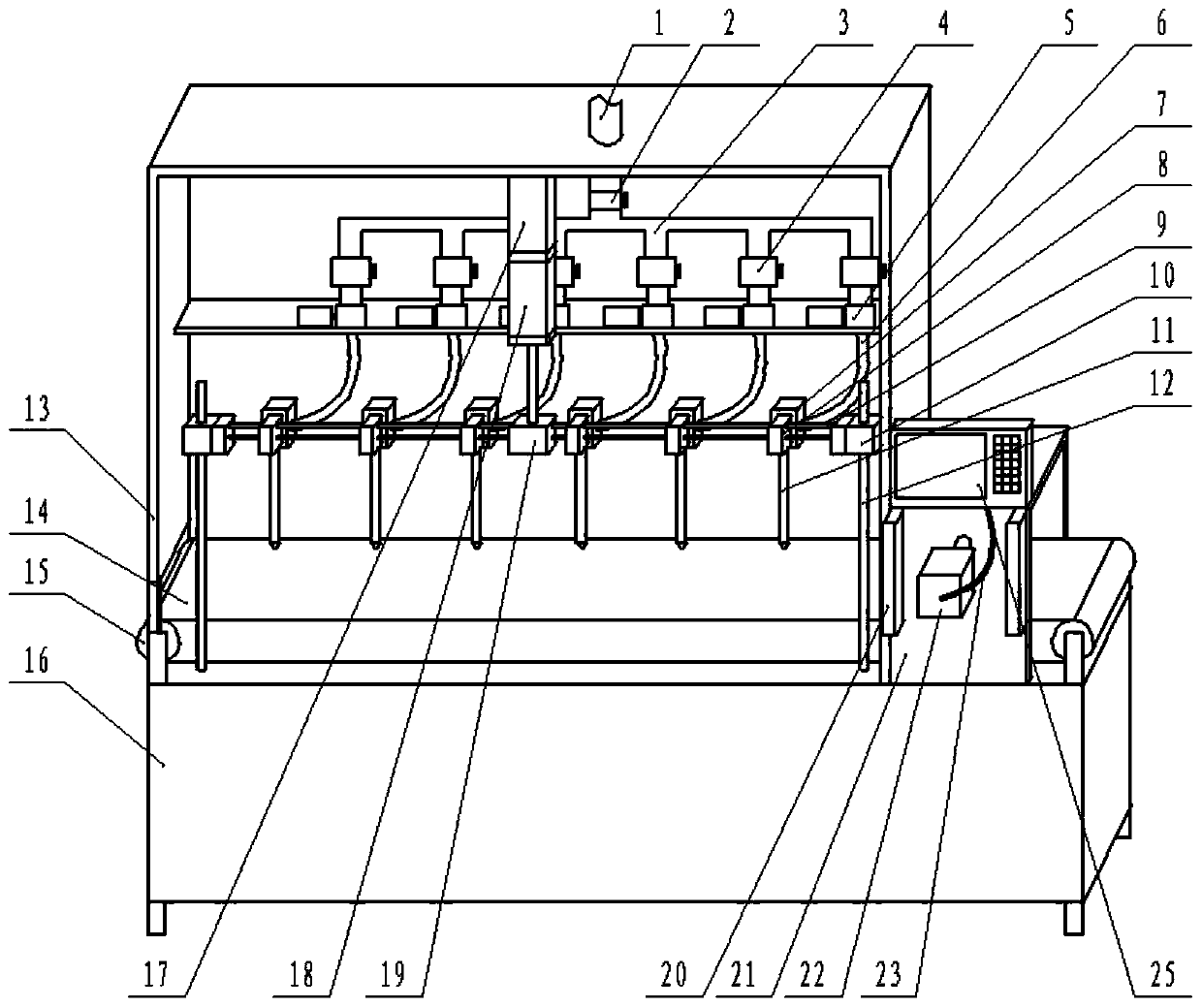

Filling device with transparent liquid level detection function and use method thereof

ActiveCN110723705ARealize liquid level detection functionDiscovered in timeSafety device in filling machineryPhysicsFill device

Owner:ZHONGSHAN FUREY PRINTING MATERIAL CO LTD

Method and device for pumping particle bentonite

InactiveCN108060672ASimple structureLow manufacturing costFoundation engineeringSodium BentoniteEngineering

The invention discloses a method and a device for pumping particle bentonite. The method comprises the following steps: (A) the particle bentonite is poured into a feeding tank; (B) a pumping valve isopened; a sucking valve is closed; and a piston rod moves up and down; (C) along with up-down movement of the piston rod, lubricating oil is extruded from lubricating oil boxes on the two sides of adischarge tank; (D) after the discharge tank is fully filled with the bentonite, the piston rod is downwards pressed; (E) a middle vibrator and a discharge port end vibrator are opened; and (F) the sucking valve is opened; and the pumping valve is closed. The feeding tank and the discharge tank are connected through a sucking pipe; the piston rod is embedded into a piston; the discharge tank is connected with a pumping discharge pipe; the pumping discharge pipe is connected with a single-section discharge pipe; the single-section discharge pipe is connected with a single-section discharge pipe; and the tail end of the single-section discharge pipe is connected with the end vibrator. The method is easy to realize and convenient to operate, and needs no heavy mechanical force for compaction.The device is simple in structure and convenient to use, can use an atmospheric pressure effect for uniformly and densely filling bentonite particles in grooves in underground diaphragm walls, and islow in cost and convenient to construct and operate.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

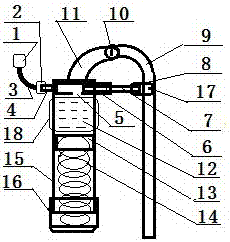

Pressure-proof sealing oil injector

ActiveCN107143478ASimple designEasy to operate manuallyPositive displacement pump componentsPiston pumpsReciprocating motionPiston

The invention discloses a pressure-proof sealing oil injector which comprises an oil outlet pipe nut, an oil outlet valve nut, a steel wire pressure-proof hose, a one-way oil outlet valve, an injection plug sleeve oil inlet, an injection plug sleeve, an injection plug rod, a connecting plate, a lever and handle, a hinge shaft, a lever bracket, a sealing oil cavity, an oil pressing piston, a compression spring, an oil injector housing, a threaded gland, a hinge pin and an electric heating device. The pressure-proof sealing oil injector is characterized in that the oil injector housing is internally provided with the injection plug sleeve; the injection plug sleeve is provided with the injection plug sleeve oil inlet; the injection plug rod is arranged in the middle of the injection plug sleeve; the one-way oil outlet valve is arranged at the front end of the injection plug sleeve, and is connected with the oil outlet valve nut of the steel wire pressure-proof hose; the connecting plate is arranged at the tail end of the injection plug rod, and is in hinge connection with the lever and handle; the lever bracket is arranged at the front end of the oil injector housing, and is hinged to the lever and handle by using the hinge shaft; the injection plug rod makes reciprocating motion; the sealing oil cavity is formed in a front area in the oil injector housing, and is used for storing sealing oil; the oil pressing piston, the compression spring and the threaded gland are arranged in a rear area in the oil injector housing; and the electric heating device is arranged on the outer surface of the oil injector housing for heating. Oil injection operation is carried out immediately after a power supply is disconnected, and the pressure-proof sealing oil injector is ideal.

Owner:湖南飞来峰非金属矿物材料有限公司

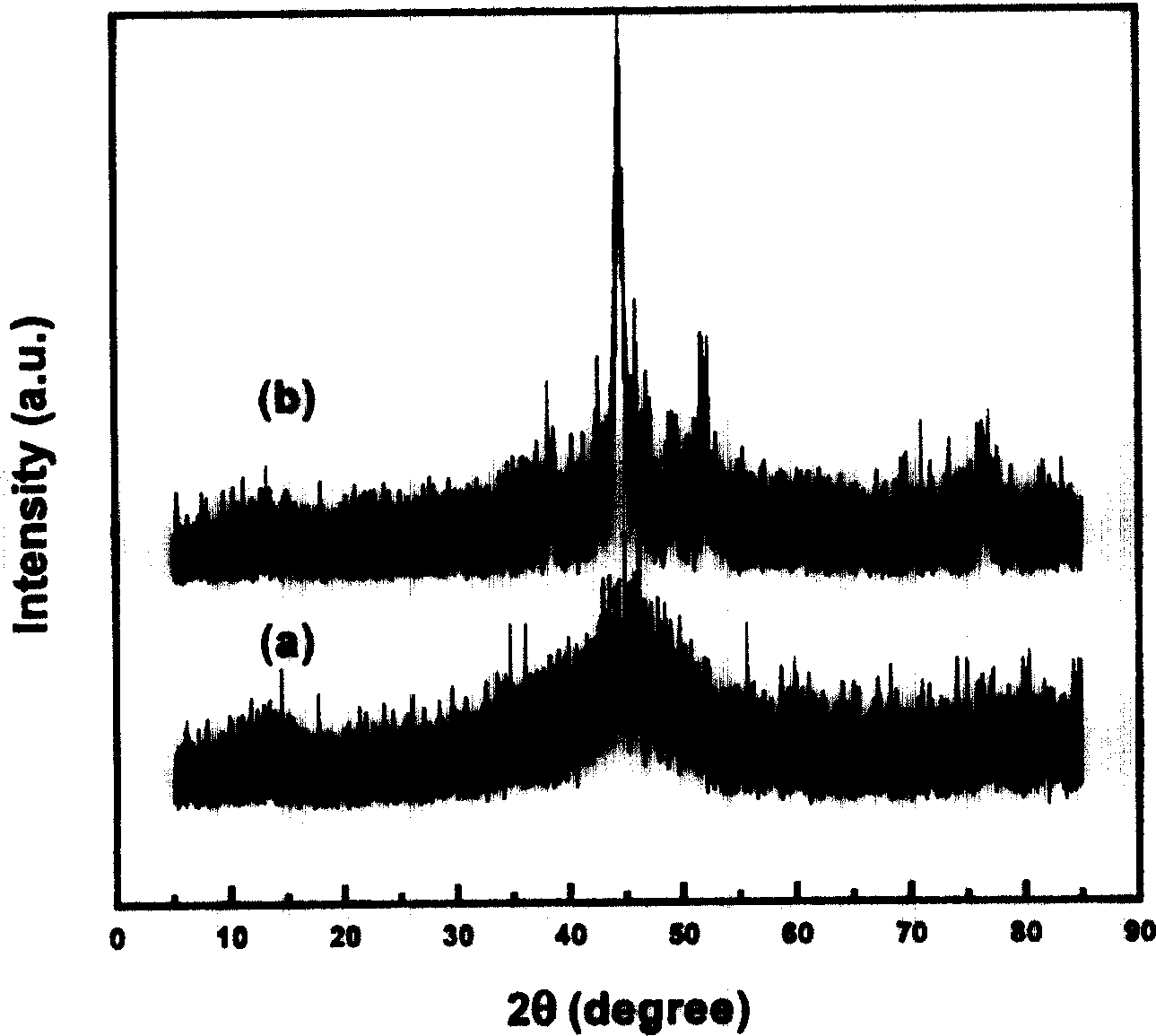

Metal boride catalyst with high activity to hydrogen and its preparing method

InactiveCN1314483CHigh activityHigh dehydrogenation efficiencyPhysical/chemical process catalystsEnergy technologyChemical reaction

The present invention belongs to the field of hydrogen preparation and energy source technology, and provides a kind of metal boride catalyst with dehydrogenation and hydrogenation characteristic. The metal boride catalyst has the general expression of MxB, where, M is Al, Zr, V, Cr, Co or other metal elements or their combination, and x is 1-4. Into the metal boride, O and / or H may be combined chemically or physically. The catalyst has low cost, excellent hydrogenation activity, and dehydrogenation efficiency up to 96 %. The preparation process of the metal boride catalyst is also provided, and the preparation process includes chemical reaction inside solution to prepare precursor and subsequent two stages of heat treatment. The preparation process is simple and suitable for large scale production.

Owner:国家高技术绿色材料发展中心

Filling device capable of filling high-temperature and high-viscosity materials

The invention discloses a filling device capable of filling high-temperature and high-viscosity materials, which comprises a frame, a charging barrel, reversing valves, filling pumps and a filling head, wherein the charging barrel, the filling pumps and the filling head are respectively arranged on the frame. The filling device is characterized in that the reversing valves are arranged on the charging barrel, a feeding port of each reversing valve is connected with a discharging port of the charging barrel, each filling pump is connected with a reversing passage of the corresponding reversing valve, and a discharging port of each reversing valve is connected with a feeding port of the filling head. The filling device is short in filling flow, and the high-temperature and high-viscosity materials are not easy to be cooled and solidified during filling, so that the high-temperature and high-viscosity materials can smoothly flow without retention, smooth filling and accuracy of the filling quantity are guaranteed, filling speed is increased, and production efficiency is also improved.

Owner:GUANGDONG YUEDONG MECHANICAL IND

Controllable filling method for vacuum filling

InactiveCN102522223BReduce wasteSimple and fast operationLiquid fillingCapacitor manufactureVacuum pumpingEngineering

The invention relates to a controllable filling method for vacuum filling, which comprises the following steps that: an inner needle head (10) of a double-layer needle head is firstly connected with the cavity of a workpiece to be filled to ensure that the inner needle head (10) is connected to the inner part of the hole of a main control room of a needle valve without applying an externally-applied control air pressure to enable the needle valve to be kept in a closing state, the inner needle head (10) of the double-layer needle head is connected with the cavity of the workpiece to be filled, and a closed cavity body is formed by the main control room (6) of the needle valve, the inner needle head (10) and the cavity of the workpiece to be filled; a vacuum-accessing pipe (1) is connected with a vacuum negative pressure, and vacuum pumping is carried out through an outer needle head (12); filling is carried out when a required vacuum degree is achieved; after a liquid material is filled in the cavity body of the workpiece to be filled, positive-pressure nitrogen gas is accessed by using the vacuum-accessing pipe (1), the nitrogen gas reaches the open hole of the filled workpiece through the outer needle head (12), and the liquid material in the inner needle head is pressed back to a liquid-material storing room (9) under the pressure of the nitrogen gas; and the controllable filling method can be used for the connection of a vacuum-filling pipeline and the open hole of a filled device.

Owner:NANJING UNIV

Small-sized vacuum filling device with controllable filling speed

InactiveCN102167276BAvoid shockGuarantee rated fillingLiquid transferring devicesVacuum extractionControl valves

The invention discloses a small-sized vacuum filling device with a controllable filling speed. The small-sized vacuum filling device comprises a filling speed control valve, a liquid material container, a two-way control valve, a three-way control valve and an air or liquid conduction pipe. The filling speed control valve is a reducing valve or a needle valve; the upper end of the liquid materialcontainer is provided with a sealed container with two small holes; a liquid material is filled into the container; an air or liquid conduction pipe is inserted into each of two holes and the holes are sealed; one of the two conduction pipes is connected with a four way and the other one is connected with a three-way valve; the air conduction pipe connected with the four way is positioned above the liquid level, and the air conduction pipe connected with the three-way control valve is positioned below the liquid level; one end of the four way is connected with the container, the other three ends of the four way are connected with the reducing valve or the needle valve, a pressure gage, and a two-way valve respectively; one end of the reducing valve or the needle valve is connected with the four way, and the other end of the reducing valve or the needle valve is connected with atmosphere; one end of the two-way valve is connected with one end of the four way and a vacuum extraction pipe; an end 1 of the three-way valve is connected with the liquid material container, an end 2 of the three-way valve is connected with the vacuum extraction pipe and an end 3 of the three-way valve is connected with a workpiece to be filled; and the two-way valve, the three-way valve and the air conduction pipe of the vacuum extraction pipe are connected by a T-shaped air conduction pipe.

Owner:NANJING UNIV

A kind of double-coated silibinin sustained-release pellets and preparation method thereof

ActiveCN104069071BImprove oral bioavailabilitySuitable for fillingOrganic active ingredientsDigestive systemPlasticizerEngineering

The invention relates to a silibinin slow release micropill with double layers of coatings. The silibinin slow release micropill is formed by a hollow pill core outside which the double layers of coatings are wrapped, wherein the first layer of coating forms a silibinin solid dispersion micropill and comprises silibinin, a solid dispersion carrier, a solubilizer and a sticky-resisting agent which are wrapped outside the hollow pill core so as to form the silibinin slow release micropill; the second layer of coating is formed outside the silibinin slow release micropill and comprises a slow release material, a lubricant and a plasticizer which are wrapped outside the silibinin slow release micropill so as to form silibinin slow release micropill with double layers of coatings. The silibinin slow release micropill provided by the invention is simple and convenient in preparation method, high in industrialized potential, stable in medicine release after being taken orally and high in bioavailability, and has a certain slow release effect.

Owner:JIANGSU UNIV

A kind of hydroxypropyl methylcellulose plant hollow capsule

ActiveCN107296801BFast disintegrationLow loss on dryingPharmaceutical non-active ingredientsCapsule deliveryCelluloseOrganic solvent

The invention discloses a hydroxypropyl methyl cellulose plant empty capsule which is prepared through the following method: dissolving hydroxypropyl methyl cellulose in a mixed solvent of an organic solvent and water, preparing a hydroxypropyl methyl cellulose solution with the mass percentage of 10 to 33 percent, and making capsules by using the hydroxypropyl methyl cellulose solution, wherein the organic solvent is ethyl alcohol and / or acetone. The hydroxypropyl methyl cellulose plant empty capsule has the advantages that the capsule is disintegrated fast, is not brittle and has extremely low weight loss on drying; furthermore, according to the preparation method of the capsule, no heating is needed, so that energy consumption is reduced; no gelatinizer is added, so that influence on disintegration due to the gelatinizer is avoided; the capsule is cured and molded only through volatilization of the organic solvent, so that the hydroxypropyl methyl cellulose plant empty capsule is suitable for filling of certain medicines having special requirements.

Owner:ANHUI HUANGSHAN CAPSULE CO LTD

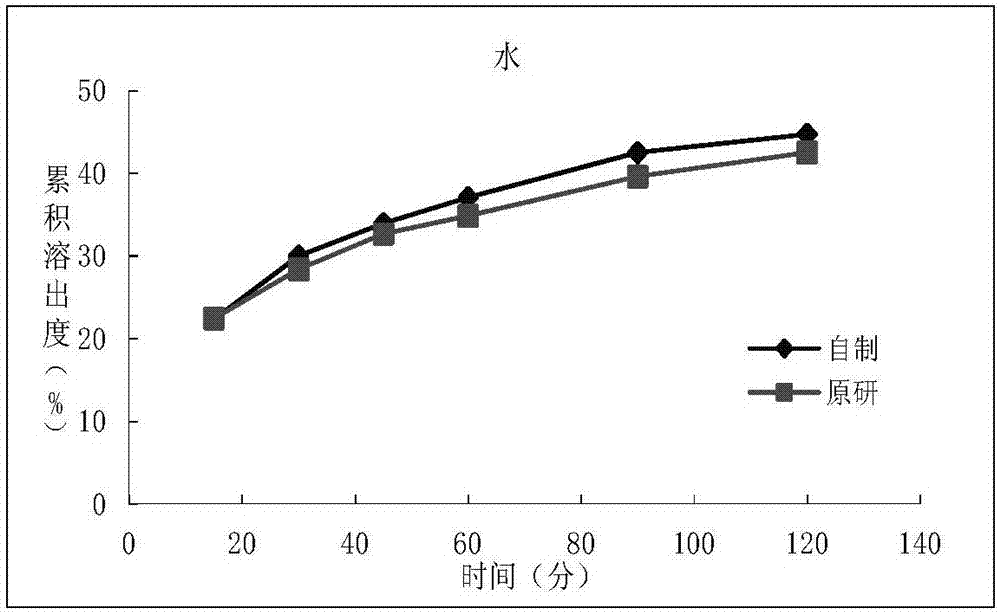

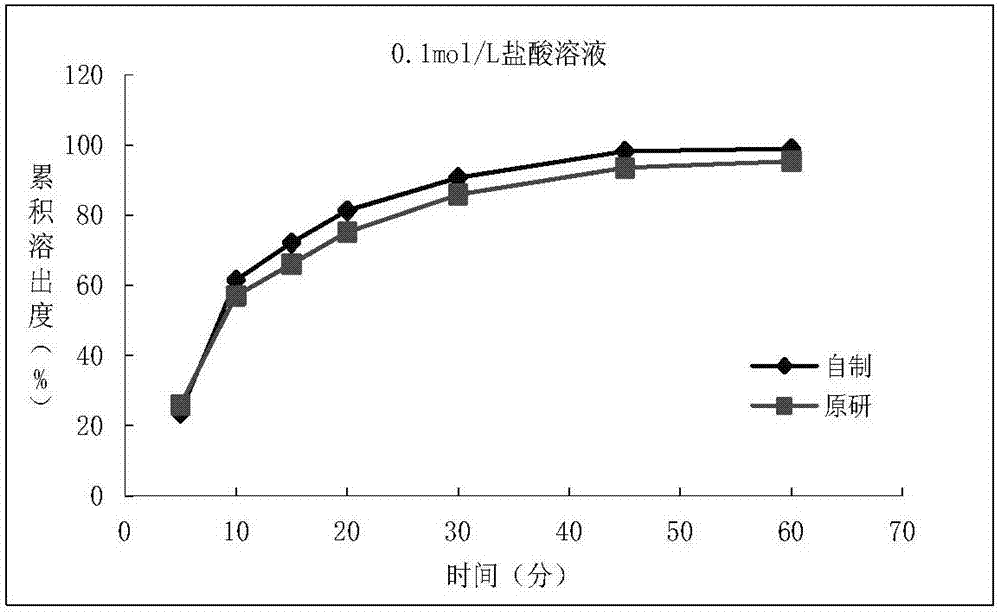

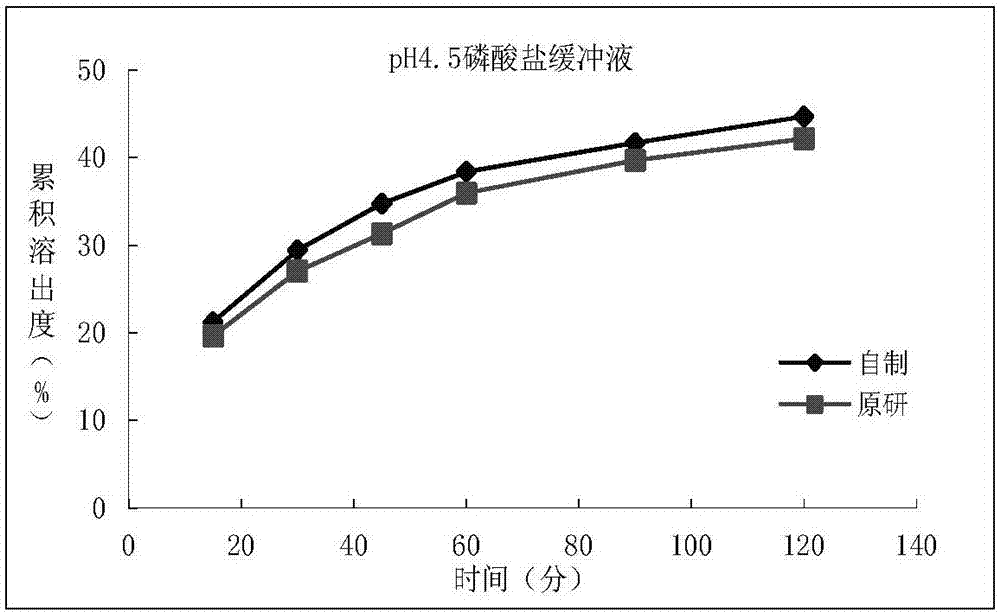

Composition containing flupirtine maleate and preparation method of composition

InactiveCN107412186APrevent unstableSimple processNervous disorderPharmaceutical non-active ingredientsClinical efficacyHigh humidity

The invention relates to composition containing flupirtine maleate and a preparation method of the composition. The composition is prepared from raw materials in percentage by weight as follows: 25%-35% of flupirtine maleate, 50%-70% of a diluent, 1.5%-4.5% of a disintegrating agent, 1.5%-4.5% of a flow aid, 0.5%-1.5% of a cosolvent and 0.5%-1.5% of a lubricant. The problem that the raw materials are unstable under illumination and high-humidity conditions is solved. The composition is stable in quality, the content of flupirtine maleate, related impurities and dissolution rate have no remarkable change, the in-vitro dissolution behavior is consistent with that of flupirtine maleate capsules from the German AWD company, the risk of clinical effect difference is reduced, the process is simple, and realization of industrial production is facilitated.

Owner:REYOUNG PHARMA

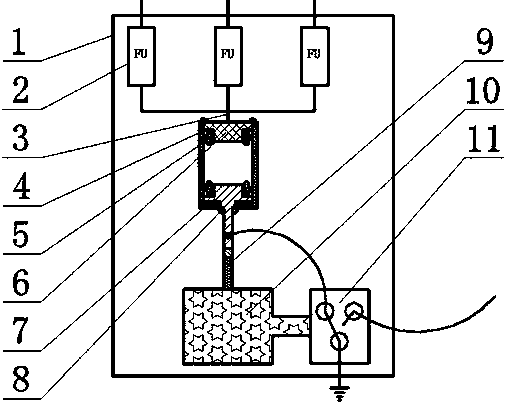

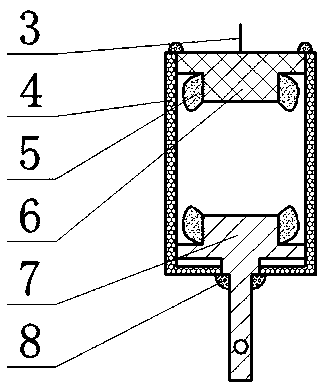

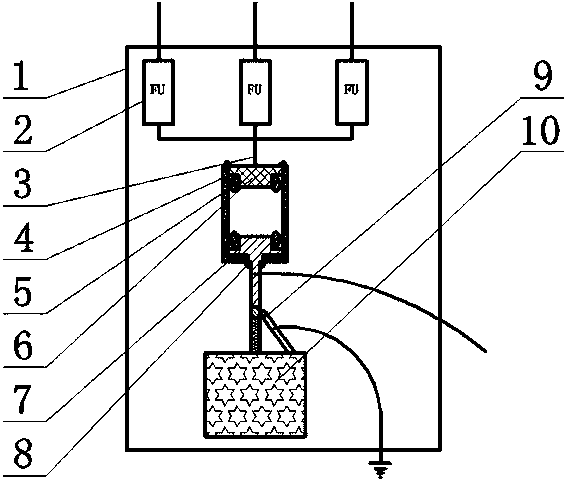

A solid vacuum insulated ring network cabinet and its manufacturing method

ActiveCN106816823BImprove insulation performanceImprove arc extinguishing performanceSwitchgear arrangementsSubstation/switching arrangement casingsNano al2o3Engineering

The invention relates to a solid vacuum insulation ring network cabinet and a manufacturing method thereof. The ring network cabinet comprises a housing, a vacuum interrupter load switch, an isolator, three sets of fuses, a grounding device, a mechanical transmission device, and a bus. The vacuum interrupter load switch consists of an arc-extinguishing-flame-retardant-ceramic-made housing, a fixed power connection unit, a moveable power connection unit and a vulcanized silicone rubber. The arc-extinguishing flame retardant ceramic is further formed in such a way that a nano-alumina fiber is mixed with a silicon dioxide fiber and zirconium dioxide powder under high pressure and dense sintering. The housing is provided with an insulation elastic component, whose end head is connected with a tempered glass joint's elastic element. The gap part utilizes ethyl formate resin for insulation sealing. The isolator is of a three-joint structure with two joints connected with the bus and the other one connected with the grounding device. The solid vacuum insulation ring network cabinet proposed by the invention can realize the operation and linking of circuit disconnection, arc-extinguishing and isolation. The service lifetime of the cabinet is long and it can be used outdoors for a long time. The housing of the vacuum interrupter load switch is not easy to be deformed, does not go rusty and has a low expansion coefficient.

Owner:HUNAN DEYI ELECTRIC

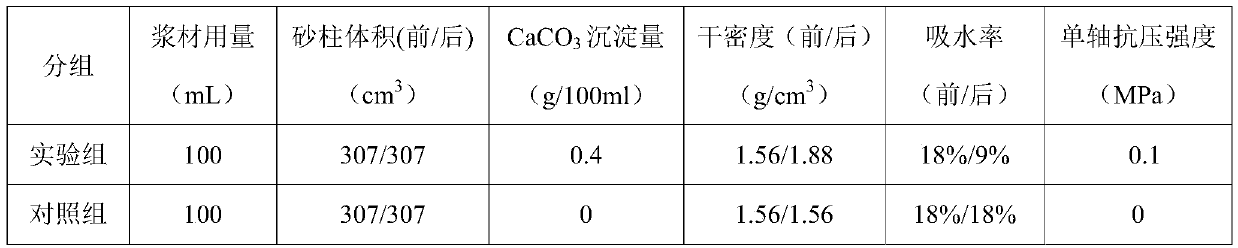

Compensation grouting material and grouting method thereof

ActiveCN109250942BImprove liquidityLow viscosityBacteriaMicroorganism based processesPeristaltic pumpMonopotassium phosphate

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A pressure-resistant sealing oil injector

ActiveCN107143478BSolve the problem that there is no way to add oil to the sealing mechanismSuitable for fillingPositive displacement pump componentsPiston pumpsReciprocating motionPiston

The invention discloses a pressure-proof sealing oil injector which comprises an oil outlet pipe nut, an oil outlet valve nut, a steel wire pressure-proof hose, a one-way oil outlet valve, an injection plug sleeve oil inlet, an injection plug sleeve, an injection plug rod, a connecting plate, a lever and handle, a hinge shaft, a lever bracket, a sealing oil cavity, an oil pressing piston, a compression spring, an oil injector housing, a threaded gland, a hinge pin and an electric heating device. The pressure-proof sealing oil injector is characterized in that the oil injector housing is internally provided with the injection plug sleeve; the injection plug sleeve is provided with the injection plug sleeve oil inlet; the injection plug rod is arranged in the middle of the injection plug sleeve; the one-way oil outlet valve is arranged at the front end of the injection plug sleeve, and is connected with the oil outlet valve nut of the steel wire pressure-proof hose; the connecting plate is arranged at the tail end of the injection plug rod, and is in hinge connection with the lever and handle; the lever bracket is arranged at the front end of the oil injector housing, and is hinged to the lever and handle by using the hinge shaft; the injection plug rod makes reciprocating motion; the sealing oil cavity is formed in a front area in the oil injector housing, and is used for storing sealing oil; the oil pressing piston, the compression spring and the threaded gland are arranged in a rear area in the oil injector housing; and the electric heating device is arranged on the outer surface of the oil injector housing for heating. Oil injection operation is carried out immediately after a power supply is disconnected, and the pressure-proof sealing oil injector is ideal.

Owner:湖南飞来峰非金属矿物材料有限公司

High polymer material pre-filled syringe with needle and forming process of high polymer material pre-filled syringe

The invention belongs to the technical field of medical packaging, and particularly relates to a high polymer material pre-filled syringe with a needle and a forming process thereof.The high polymer material pre-filled syringe with the needle comprises a needle cylinder, an injection needle and an injection needle protective cap, the needle cylinder is made of cycloolefin polymer, the injection needle is embedded in the upper portion of the needle cylinder, and the injection needle protective cap is arranged on the lower portion of the needle cylinder. And the needle cylinder is integrally formed with the needle cylinder. The technological process comprises the steps of raw material dehumidification, injection molding, needle silicification, protective cap installation, needle cylinder spraying silicone oil, paper sealing and bag sealing, boxing, sterilization and analysis and assembly warehousing. The high polymer material pre-filled syringe with the needle is small in specific gravity, light in weight, high in non-breaking strength, suitable for 27G or 31G needle heads, very suitable for hyaluronic acid and other high-viscosity medical beauty products, attractive and high-grade in product, free of explosion risk, deeply loved by medical beauty pharmaceutical enterprises and suitable for the medical packaging fields of vaccines, biology, medical beauty and the like.

Owner:SHANDONG YONGJU MEDICAL TECH

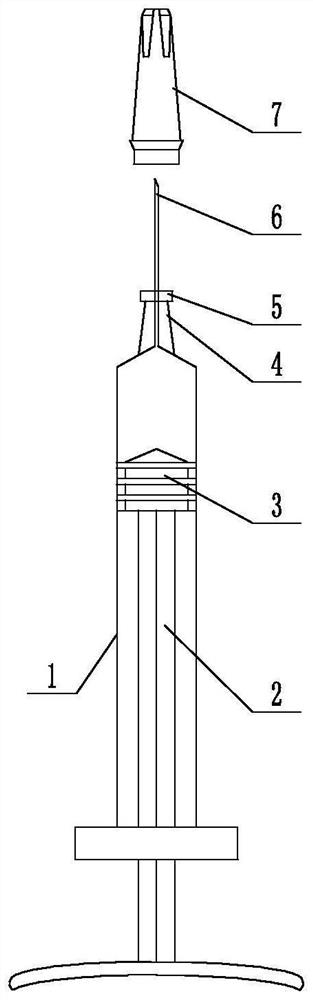

Alkaline powder for treating leaked hydrochloric acid and acid mist thereof and preparation method of alkaline powder

ActiveCN102989113BAccelerated settlementPrevent volatilizationChemical protectionProduct gasMoisture

The invention provides alkaline powder for treating leaked hydrochloric acid and acid mist of the leaked hydrochloric acid and a preparation method of the alkaline powder. The alkaline powder is prepared from a neutralizer, an aid, a volatilization inhibitor, a moisture-proof agent, a dispersant and an indicator in a certain ratio by a specific method. The raw materials for preparing the alkaline powder are readily available, wherein a part of raw materials are reutilized wastes; the preparation method is simple, convenient and low in energy consumption; and the prepared powder has good moisture-proof performance, does not cake, and has good settling performance after being sprayed. The alkaline powder can be used for effectively treating the leaked sulfuric acid of which the concentration is 20 to 38 percent or more, can inhibit the volatilization of the hydrochloric acid and arrest the acid mist gas generated by the leaked hydrochloric acid, has the advantages of high neutralizing speed, simplicity and convenience in endpoint judgment and the like, and can effectively inhibit the volatilization of the hydrochloric acid gas; and the residue after the treatment is grey, loose and easy to clean or is easily sucked by negative pressure.

Owner:ENG DESIGN & RES INST OF GENERAL ARMAMENTS DEPT +2

A control method of a filling liquid level control device

ActiveCN105858573BSuitable for fillingEasy to adjustSafety device in filling machineryEngineeringBottle

The invention discloses a filling liquid level control device and a control method thereof and belongs to the technical field of liquid filling. The filling liquid level control device comprises a lower star wheel protecting plate, a fixing plate and an extruding wheel. The extruding wheel is close to a body of a filling bottle and detachably fixed to the upper surface of the fixing plate. The fixing plate is fixed to the upper surface of the lower star wheel protecting plate. After filling of the filling bottle is finished and before a cover is rotated, the extruding wheel is utilized for extruding the filled body of the bottle, the excessive water level in the bottle body can be forced to be extruded out, and the device is suitable for filling liquid which allows to be wasted a little and is low in raw material cost.

Owner:MAANSHAN ZHICHENG SCI & TECH

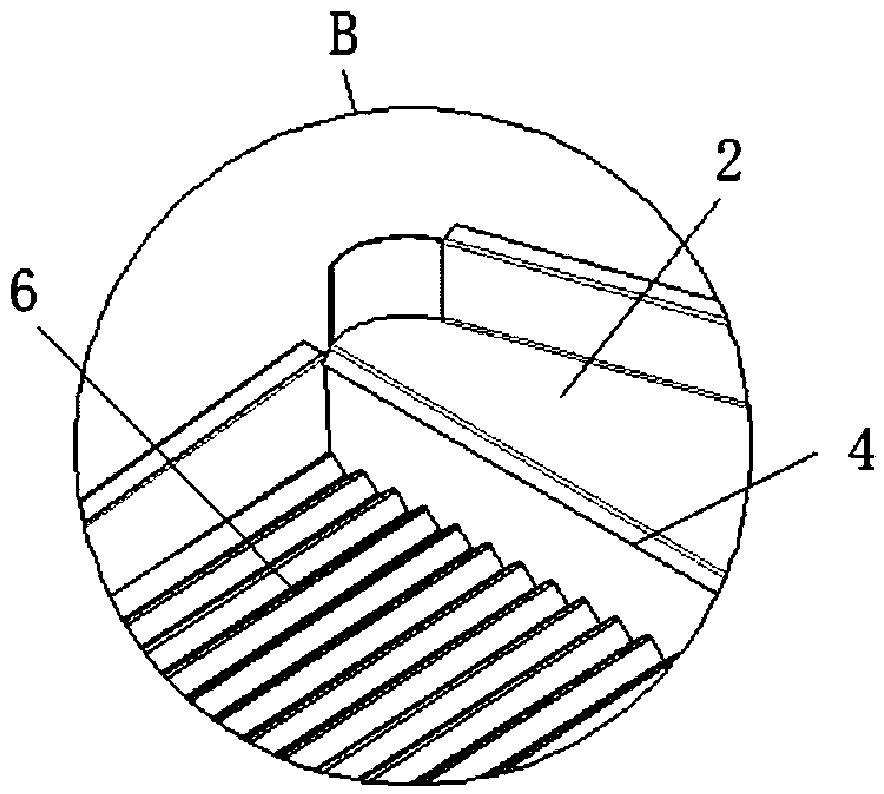

Large-liquid holdup catalytic-reaction rectifying tower plate

InactiveCN101708377BImprove space utilizationIncrease profitChemical/physical processesFractional distillationReaction zoneEngineering

The invention relates to a large-liquid holdup catalytic-reaction rectifying tower plate which consists of a downcomer 1, an overflow weir 2, a partition plate 3, a U-shaped tower plate with a mass transfer element 9 and a liquid holding pot 5, wherein the liquid holding pot 5 is attached on the horizontal line of the U-shaped tower plate 4, the upper edge of the liquid holding pot 5 is slightly higher than the U-shaped tower plate but is lower than the overflow weir 2, and one side wall of the liquid holding pot 5 is used as a tower wall 10; the partition plate 3 divides the U-shaped tower plate into two parts and extends to the middle lower part in the liquid holding pot 5 which is partitioned into a dropping catalytic zone 6 and a lifting catalytic zone 7, and the partition plate 3 is connected with the tower wall. The middle lower part of the liquid holding pot 5 is provided with a screen plate, a screen or a grille as a catalyst support for partitioning a liquid holding zone intoa catalytic reaction zone and a liquid horizontal channel 8, and the catalytic reaction zone can be filled with a catalyst. The liquid holdup and the residence time of the tower plate of the invention are 1.5-3 times those of the traditional tower plate.

Owner:NANJING UNIV

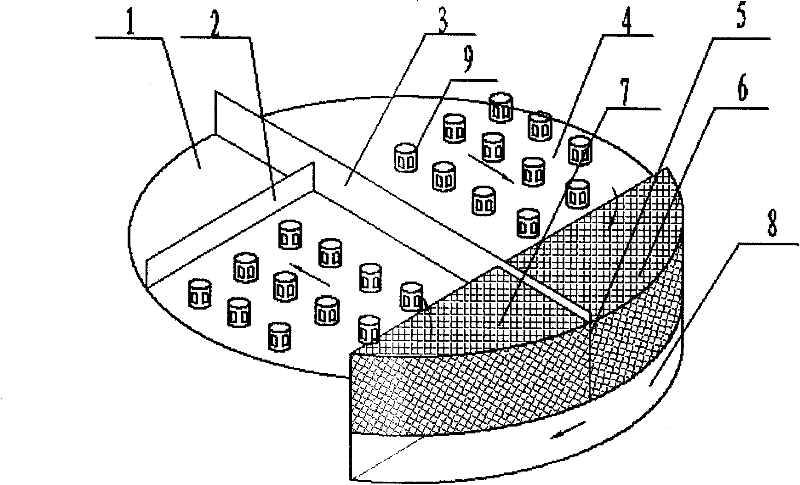

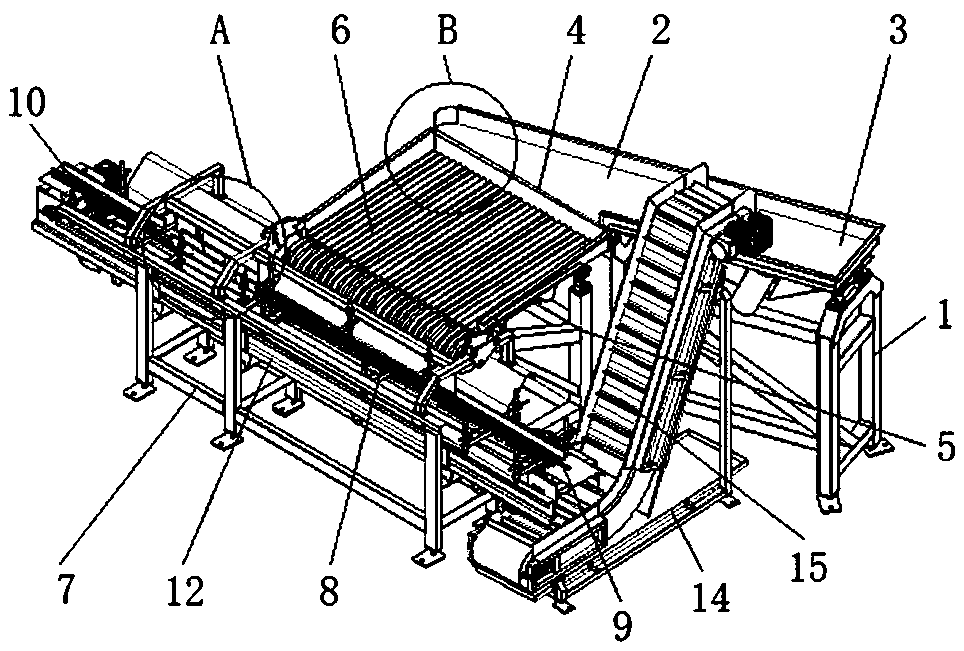

Linear vibration feeding and filling machine

PendingCN111114859AEfficient recyclingImprove distributionSolid materialPackaging machinesEngineeringMachine

The invention discloses a linear vibration feeding and filling machine. The linear vibration feeding and filling machine comprises a conveyor support, a vibration conveying mechanism is arranged at the top of the conveyor support, a feeding end is arranged at the end part of the vibration conveying mechanism, a discharging end is arranged on one side of the other end part of the vibration conveying mechanism, a first supporting frame is arranged on one side of the conveyor support, a vibration material distribution conveying mechanism is arranged at the top of the first supporting frame, and the end part of the vibration material distribution conveying mechanism is connected with one side of the other end part of the vibration conveying mechanism. According to the linear vibration feedingand filling machine, excess materials can be effectively recovered and rapidly reused, linear filling production of a production line is realized, the vibration material distribution conveying mechanism is changed into a wave form, so that material body distribution and filling are even more facilitated, and the linear vibration feeding and filling machine is particularly suitable for filling of the long-strip-shaped material body.

Owner:SHANGHAI LEAD WORLD MACHINERY TECH CO LTD

Alkaline powder for treating leaked sulfuric acid and preparation method of alkaline powder

ActiveCN102989114BLow hygroscopicityAccelerated settlementDispersed particle separationSecondary preventionMoisture absorption

The invention provides alkaline powder for treating leaked sulfuric acid and a preparation method of the alkaline powder. The alkaline powder is prepared from a neutralizer, an aid, a heat absorbent, a moisture-proof agent, a dispersant and an indicator in a certain ratio by a specific method. The raw materials for preparing the alkaline powder are readily available; the preparation method is simple, convenient and low in energy consumption; and the prepared powder does not cake, and is low in moisture absorption and good in settling performance after being sprayed. The alkaline powder can be used for effectively treating the leaked sulfuric acid of which the concentration is 50 to 98 percent or more; and the treatment process has the characteristics of high response speed, low temperature rise, secondary harm prevention, simplicity and convenience in endpoint judgment and the like.

Owner:ENG DESIGN & RES INST OF GENERAL ARMAMENTS DEPT +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com