Small-sized vacuum filling device with controllable filling speed

A filling speed and vacuum filling technology, which is applied in distribution devices, special distribution devices, liquid distribution, conveying or transfer devices, etc., can solve the problems of reduced vacuum degree and shortened service life of vacuum pumps, and achieves easy installation and simple operation , The effect of low equipment manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

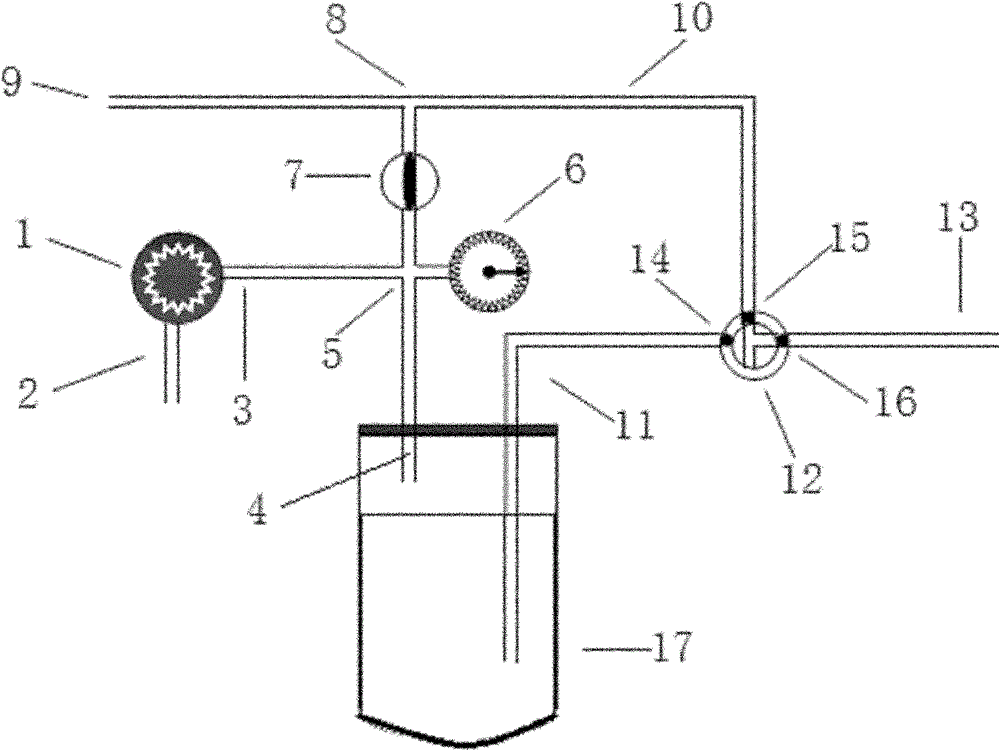

[0022] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, the small vacuum filling device with controllable filling speed of the present invention includes a filling speed control valve 1, a liquid material container 17, a two-way control valve 7, a three-way control valve 12, an air guide tube 4, and a liquid guide tube 11 And vacuum tube 9 and the vacuum pump connected thereto; the work of the filling speed control valve 1, liquid material container 17, two-way control valve 7, three-way control valve 12 and vacuum pump is controlled by the control system. The control system can realize the switching of various valves and motors by means of a microcontroller or PLC in the prior art through driving devices.

[0024] Filling speed control valve 1 adopts pressure reducing valve (or needle valve);

[0025] The liquid material container 17 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com