Method and device for pumping particle bentonite

A bentonite and particle technology, applied in the field of pumping particle bentonite and pumping particle bentonite, can solve the problems of high manufacturing cost and maintenance cost, uneven material vibration, and inability to convey materials, and achieve low manufacturing cost and maintenance cost. , Simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for pumping granular bentonite, the steps are:

[0030] A. Pour 15kg or 20 or 25kg of granular bentonite into feed tank 1;

[0031] B. Open the pumping valve 3, close the suction valve 9, and move the piston rod 6 up and down to press the bentonite particles in the feed tank into the discharge tank 4 by atmospheric pressure;

[0032] C. As the piston rod 6 moves up and down, the lubricating oil box 7 on both sides of the discharge tank 4 will squeeze out a small amount of lubricating oil due to the effect of atmospheric pressure;

[0033] D. When the discharge tank 4 is full of bentonite and the piston rod 6 is difficult to press down, stop moving the piston rod 6;

[0034] E, open the vibrator 12 in the middle and the vibrator 14 at the end of the discharge port;

[0035] F. Then open the suction valve 9, close the pumping valve 3, and push the piston rod 6 to pump out the granular bentonite in the discharge tank 4 to achieve the purpose of pumping the granula...

Embodiment 2

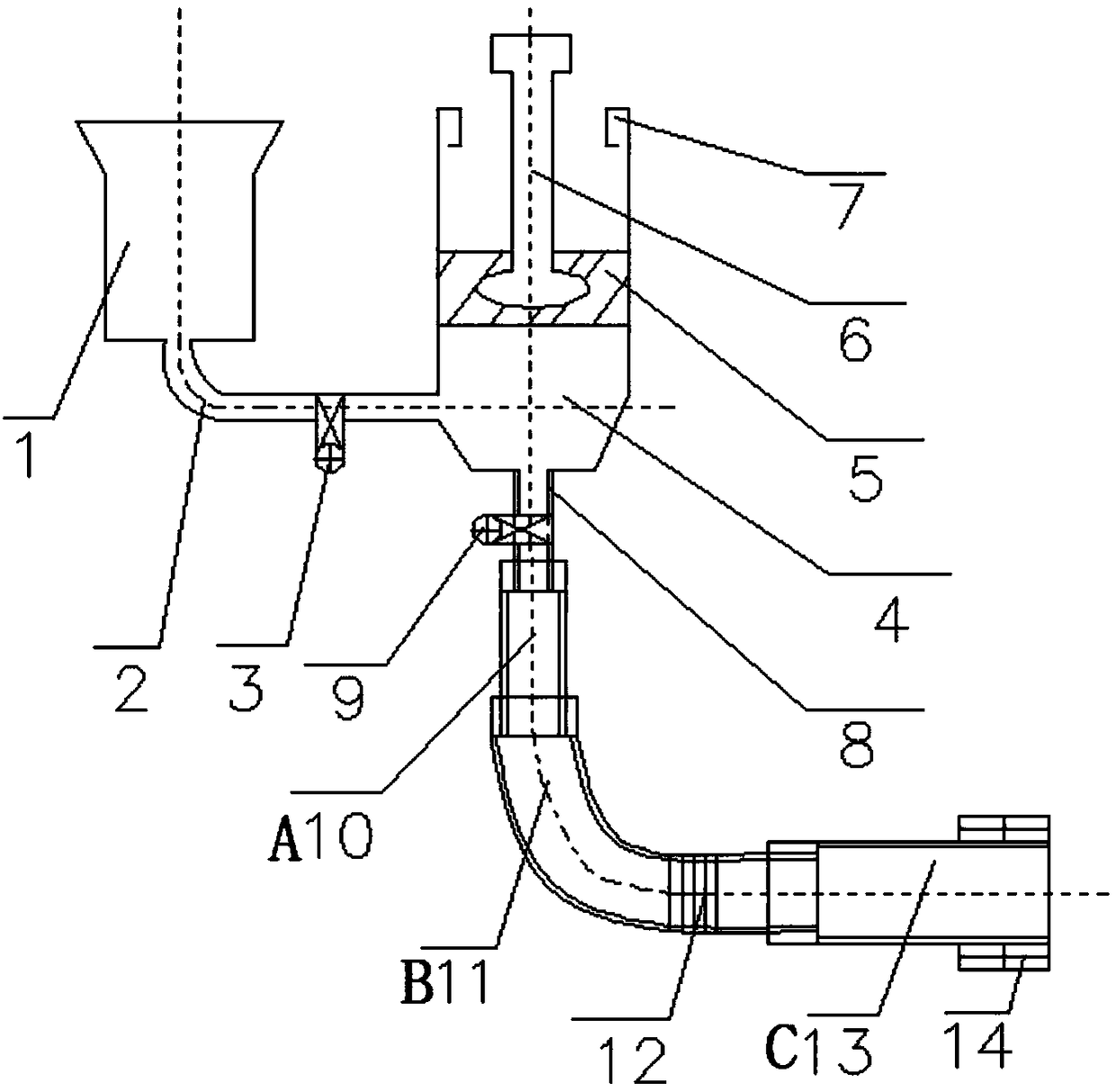

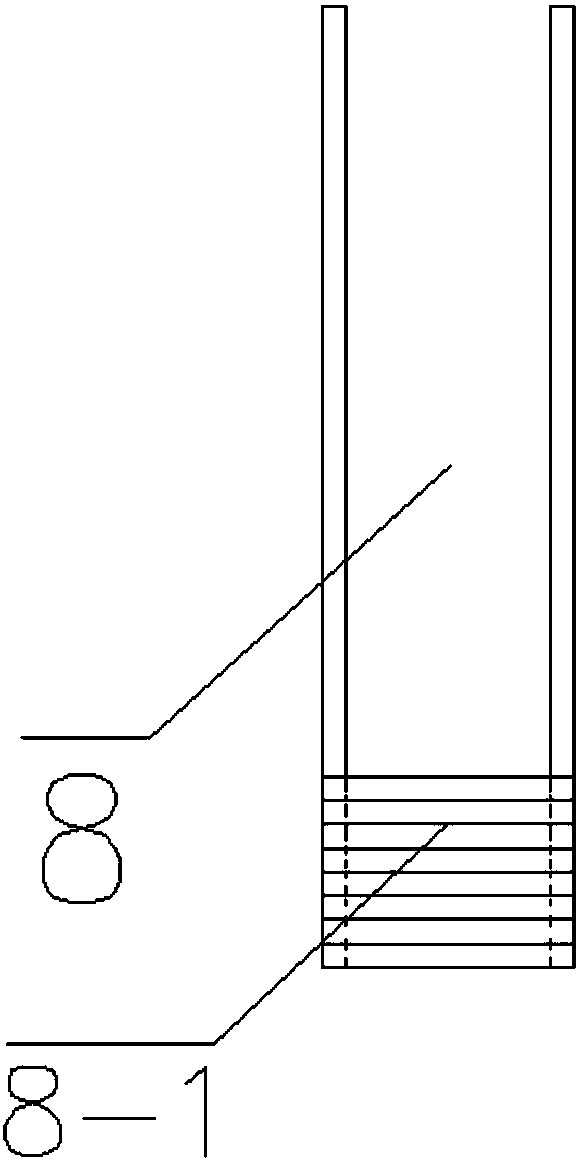

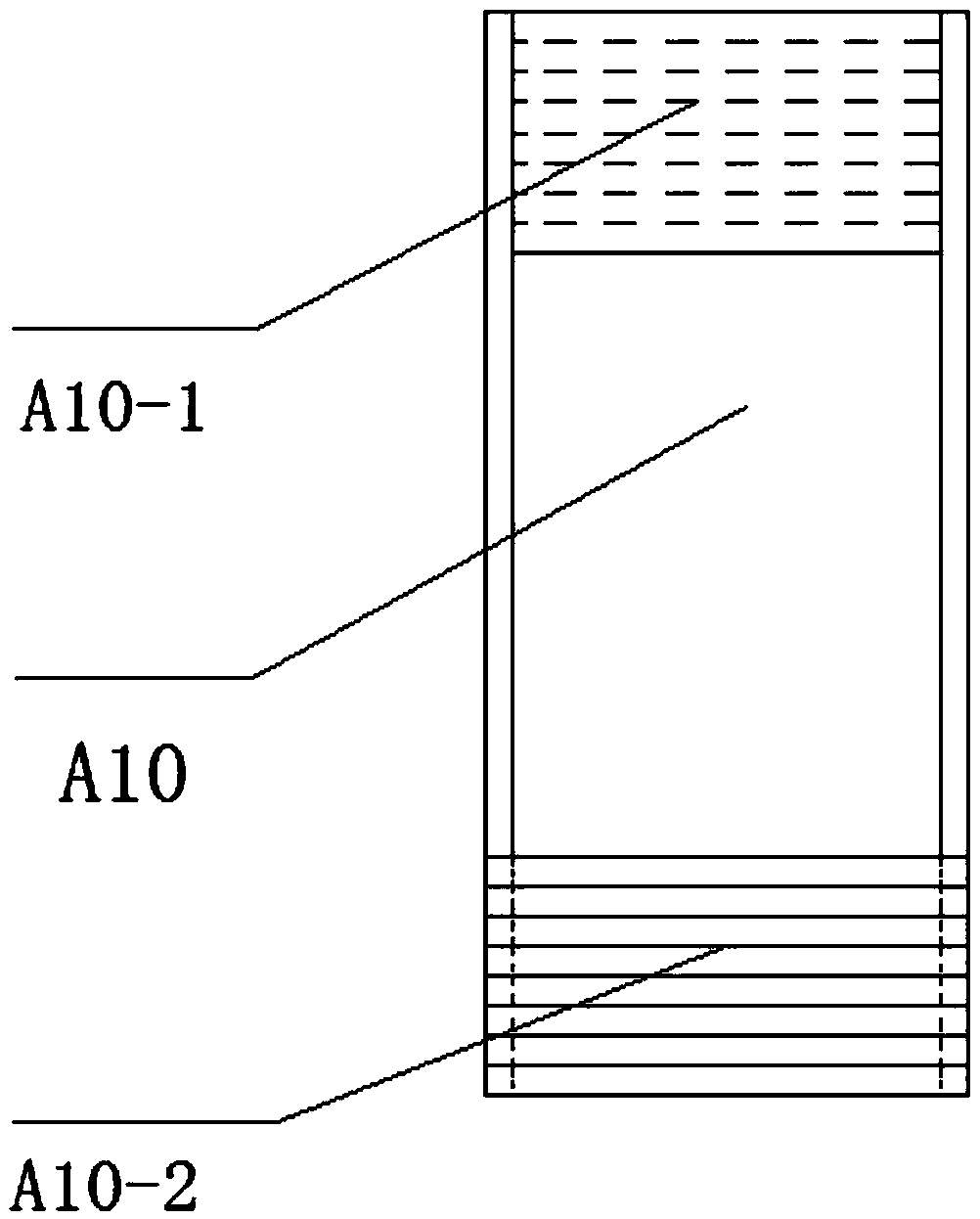

[0038] according to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 It can be seen that a device for pumping granular bentonite consists of a feed tank 1, a suction pipe 2, a pump valve 3, a discharge tank 4, a piston 5, a piston rod 6, a lubricating oil box 7, and a pump discharge pipe. 8. Pumping discharge pipe outer pattern steel sleeve 8-1, single-section discharge pipe A10, single-section discharge pipe A10 inner-grain steel sleeve A10-1, single-section discharge pipe A10 outer-grain steel sleeve A10-2, Single-section discharge pipe B11, single-section discharge pipe B11 inner thread steel sleeve B11-1, single-section discharge pipe B11 outer-grain steel sleeve B11-2, middle vibrator 12, single-section discharge pipe C13, single-section outlet Material pipe C13 is composed of inner grain steel sleeve C13-1 and end vibrator 14. The connection relationship is: feed tank 1 and discharge tank 4 are fixedly connected through suction pipe 2, and pumping valve is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com