Compensation grouting material and grouting method thereof

A kind of grouting material and deep-layer technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of large disturbance of the foundation, poor groutability, large particle size of grout solid particles, etc., and achieve cost savings and investment , fast reaction rate, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

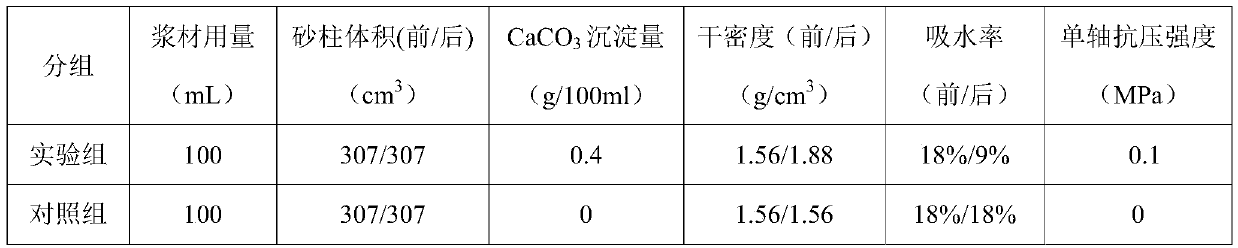

Examples

Embodiment 1

[0037] A solution-type compensating grouting material for grouting blind areas of the present invention, which is mainly prepared from Pseudomonas sp. bacterial liquid and mixed salt solution with a volume ratio of 3:10; wherein, the mixed salt solution contains Nutrient salt, calcium acetate, calcium nitrate and deionized water; Nutrient salt is potassium dihydrogen phosphate, magnesium sulfate heptahydrate and sodium chloride that the mass ratio is 2.8:1:1; The mass ratio of calcium acetate and calcium nitrate is 1:1.6.

[0038] The preparation method of the solution-type compensation grouting material in the grouting blind area of this embodiment, the steps are as follows:

[0039] (1) Preparation of denitrification Pseudomonas (Pseudomonas sp.) bacteria liquid:

[0040] S1: Put 100mL beef extract peptone liquid medium (peptone 1g, beef extract 0.3g, sodium chloride 0.5g, deionized water 100mL) in a 250mL Erlenmeyer flask, heat to fully dissolve and adjust the pH to 7.6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com