A pressure-resistant sealing oil injector

A pressure-resistant seal and oiler technology, which is applied to machines/engines, piston pumps, pump components, etc., can solve the problem of missing oiler, and achieve the effect of convenient manual operation and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

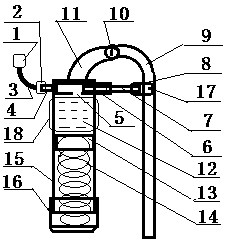

[0025] A pressure-resistant sealed oil injector, comprising: oil outlet pipe nut 1, oil outlet valve nut 2, steel wire pressure-resistant hose 3, one-way oil outlet valve 4, plunger sleeve oil inlet 5, plunger sleeve 6, column Plug rod 7, connecting plate 8, carrying rod and handle 9, hinge shaft 10, lever bracket 11, sealed oil chamber 12, pressure oil piston 13, compression spring 14, oiler shell 15, threaded gland 16, hinge pin 17. Electric heating device 18.

[0026] It is characterized in that: a plunger sleeve 6 is installed transversely in the front end of the oil injector shell 15, and the plunger sleeve 6 has an oil inlet 5 in the sealed oil chamber 12.

[0027] There is a plunger rod 7 in the middle of the plunger sleeve 6, and the reciprocating motion of the plunger rod 7 presses the sealing oil out from the one-way oil outlet valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com