Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

542results about "Safety device in filling machinery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

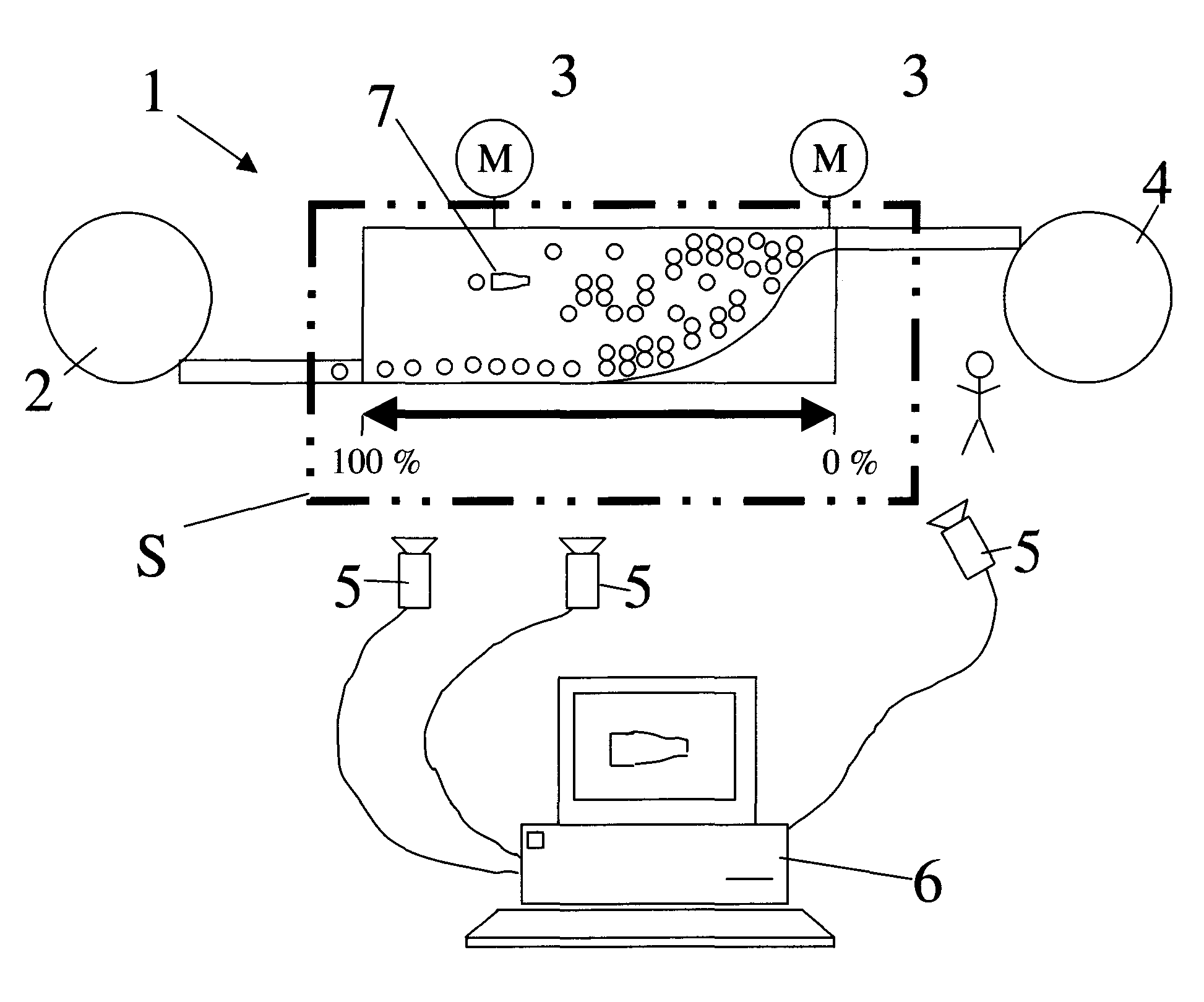

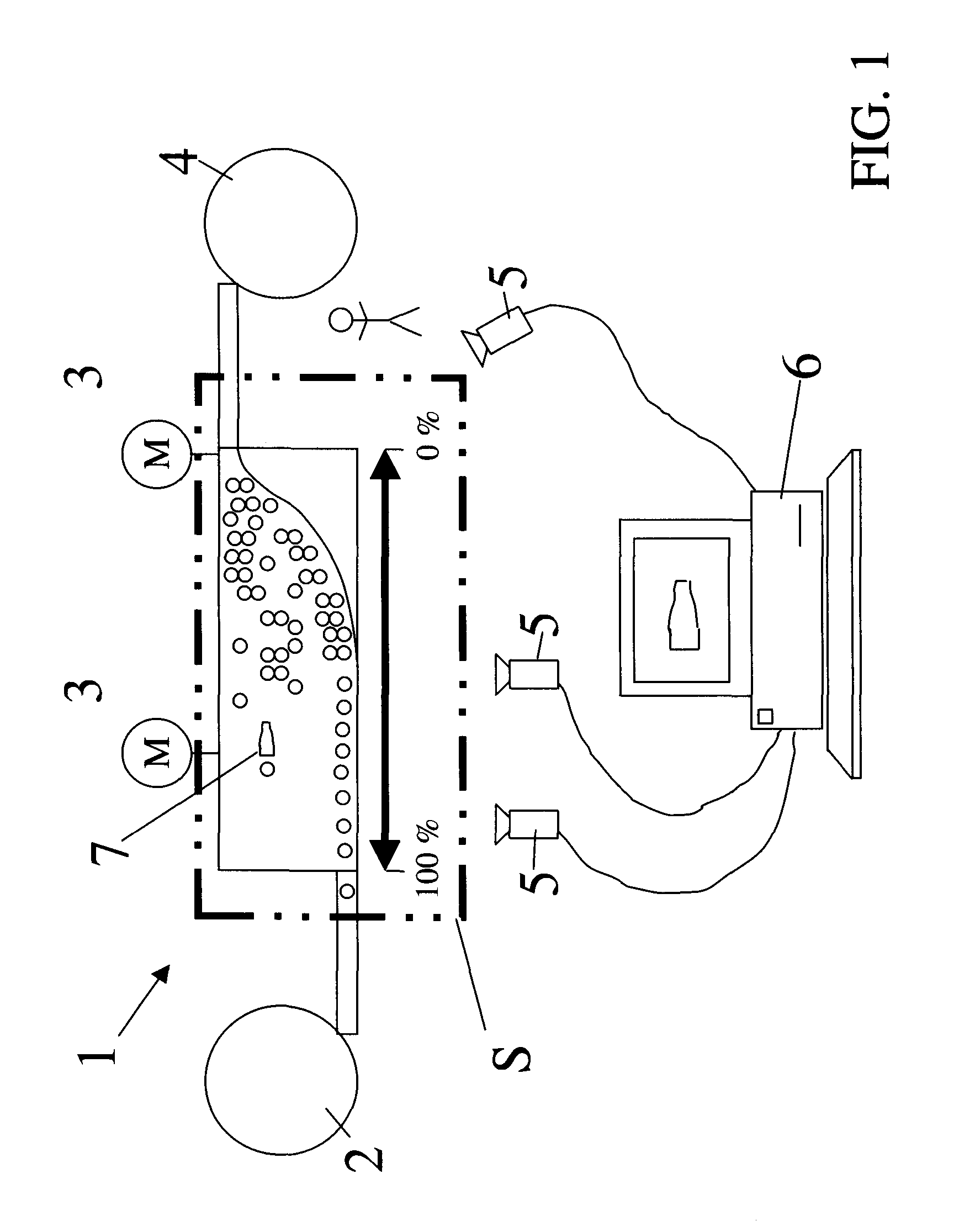

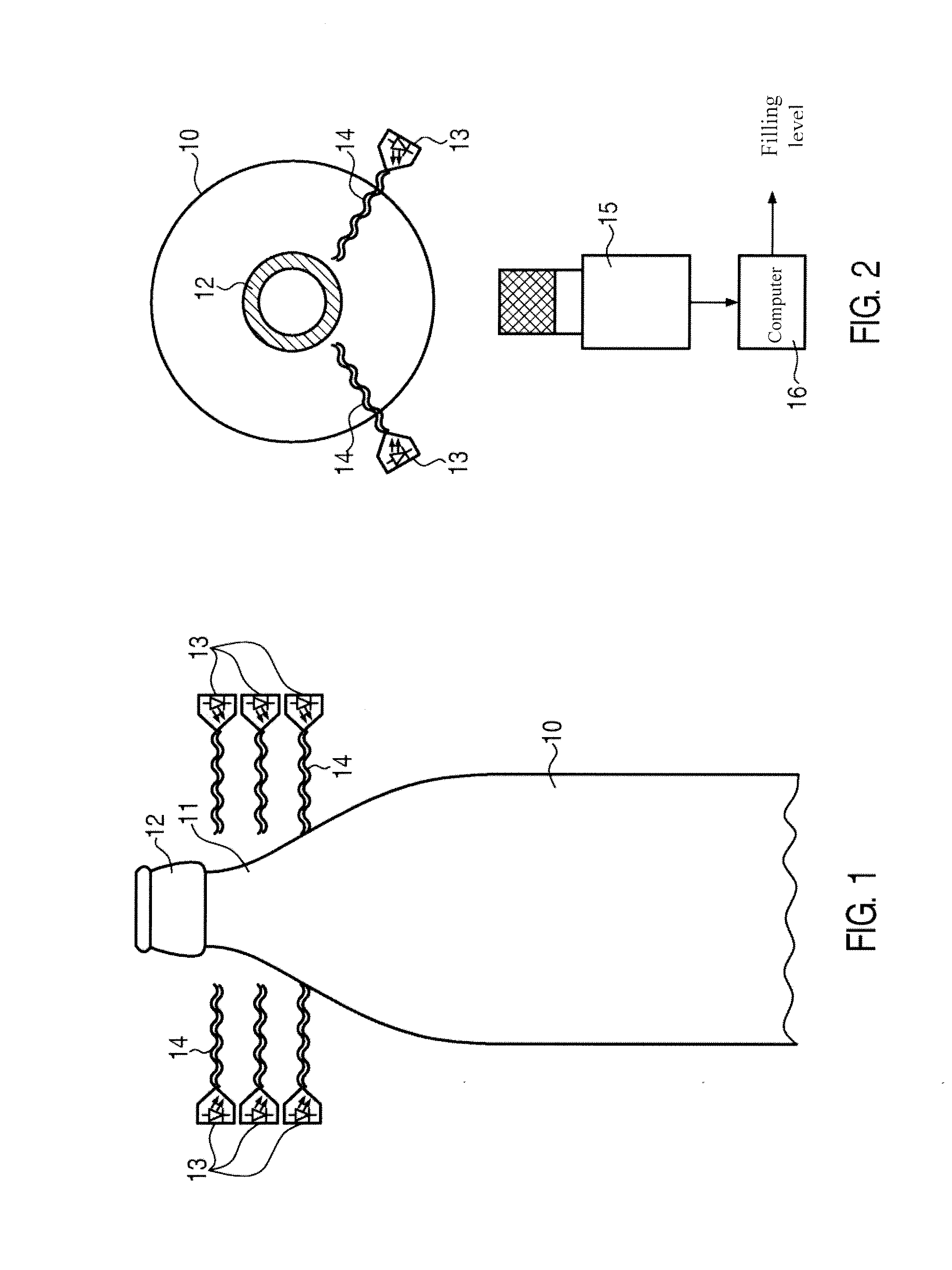

Bottle filling machine with sensor and method thereof

InactiveUS20070107801A1Reduce generationImprove trustVolume measurement and fluid deliverySafety device in filling machineryEngineeringBottle

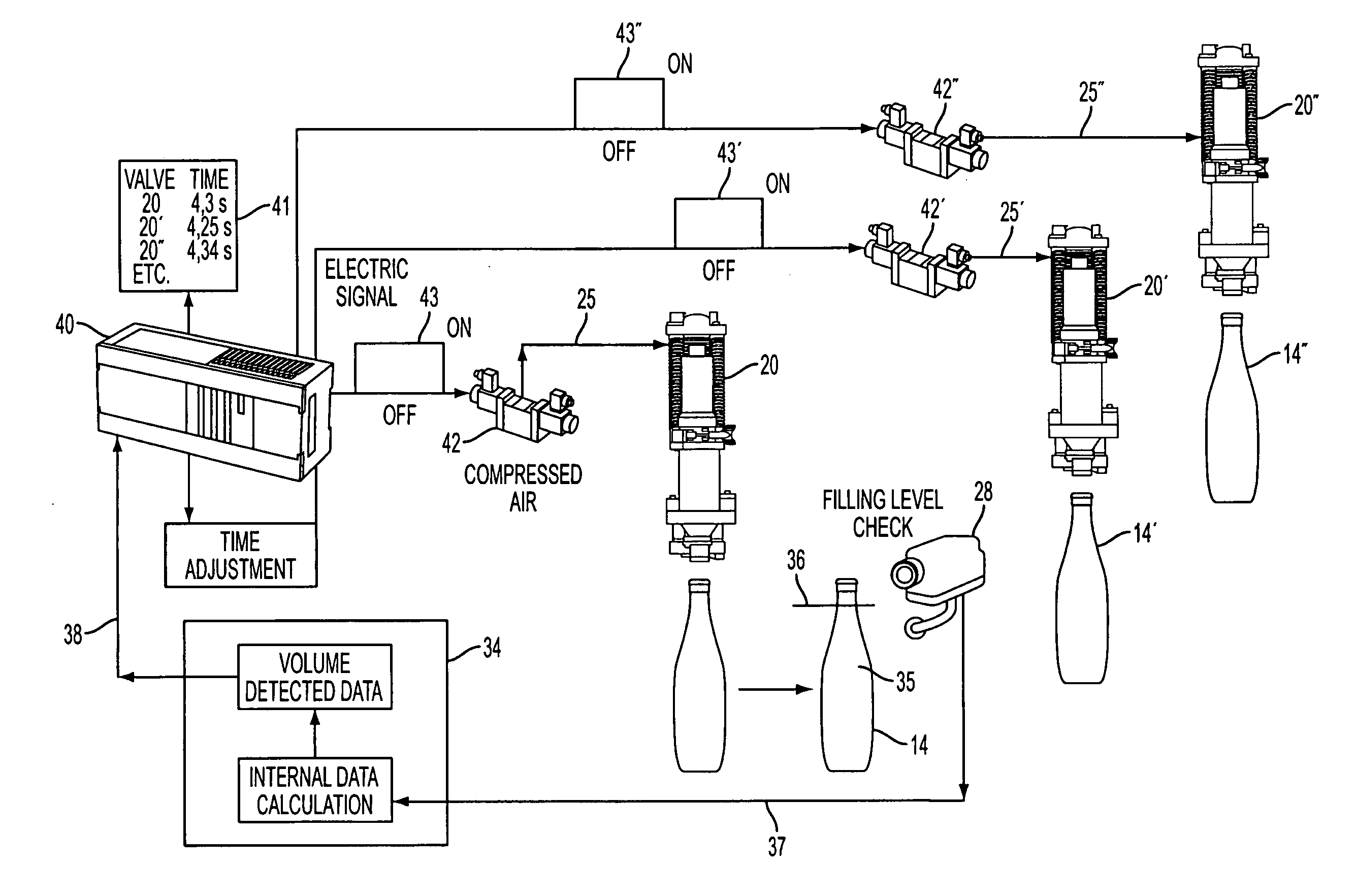

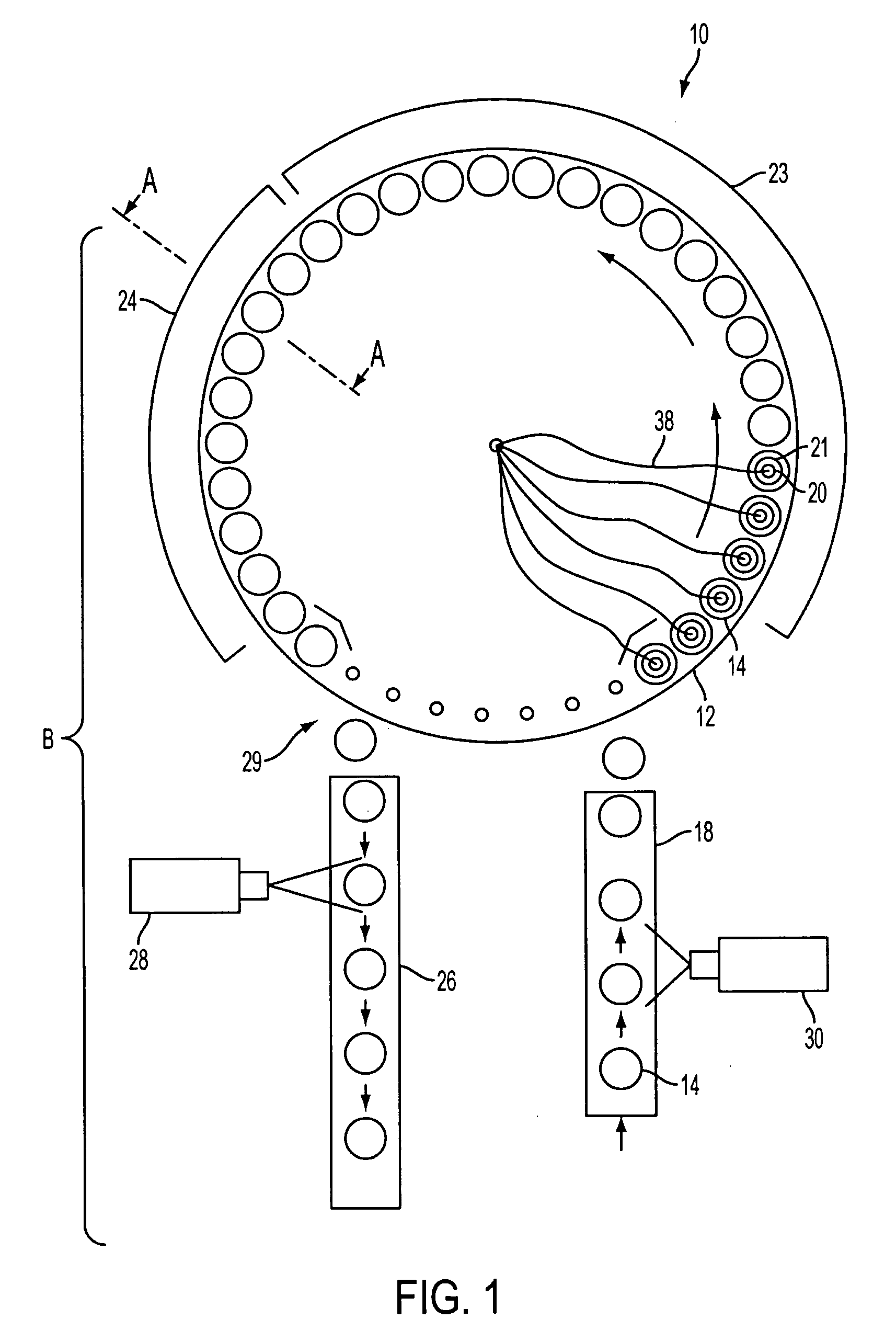

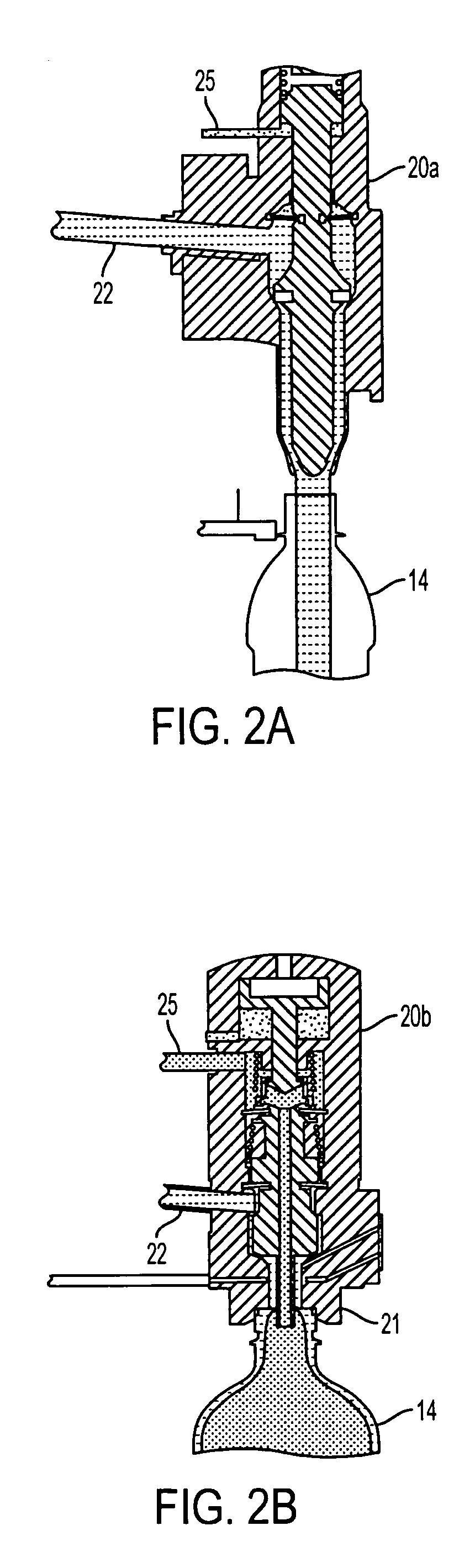

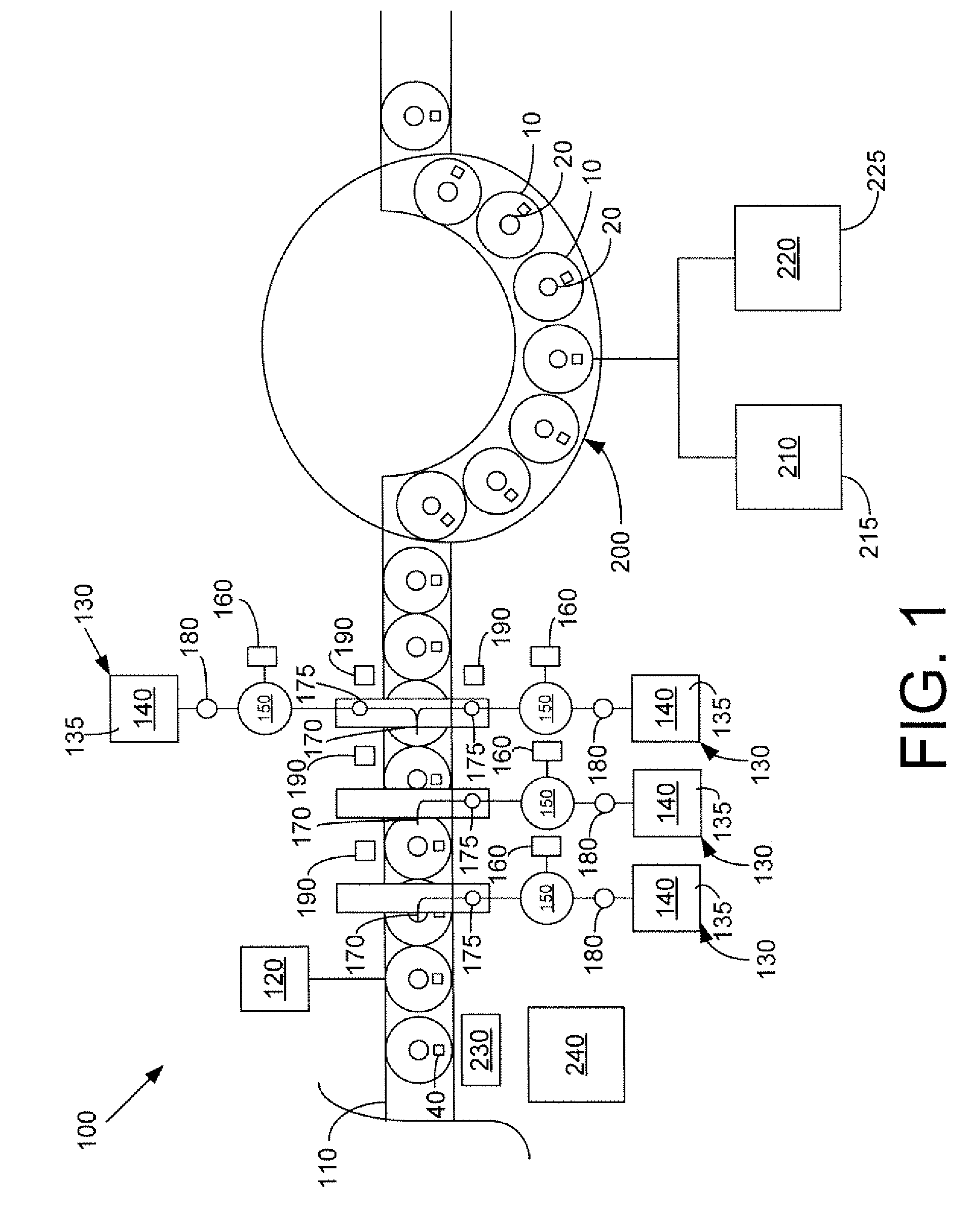

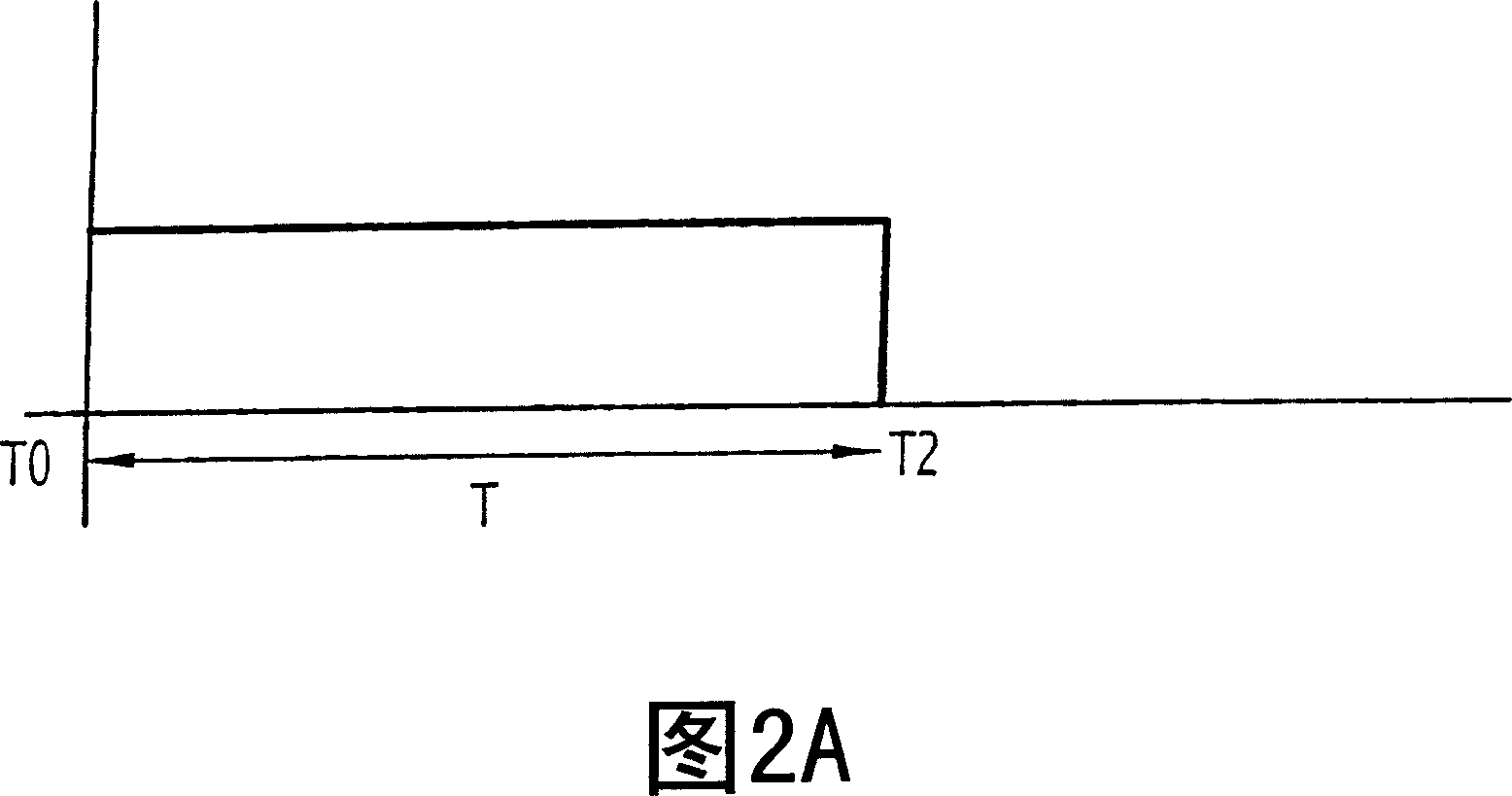

A filling apparatus and method including a carrier for transporting containers and having a plurality of valves, each of the valves being opened for an individual, specific period of time to control a flow of liquid into the respective containers, while the containers are transported by the carrier. An exit feed path transports the containers after the containers have been filled, and a sensor, such as a camera, detects a level of liquid in the respective containers, while the containers are on the exit feed path. The sensor produces a signal that is stored as data representing the level of liquid for the individual containers. The data is then tracked and used for valve optimization. A period of time that each individual valve is opened for subsequent fillings is adjusted based on the signal and the historical performance of each valve.

Owner:SIDEL PARTICIPATIONS SAS +1

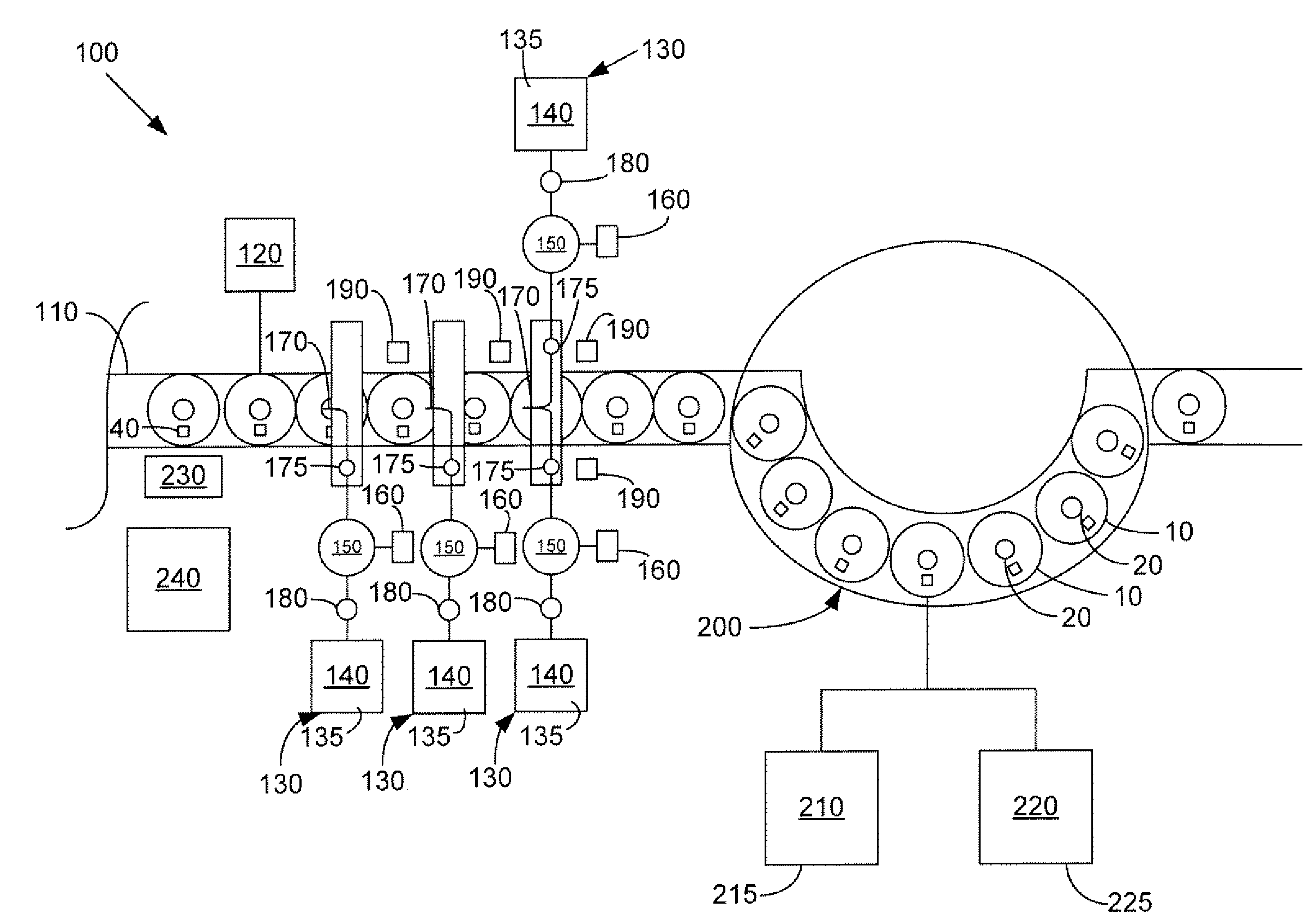

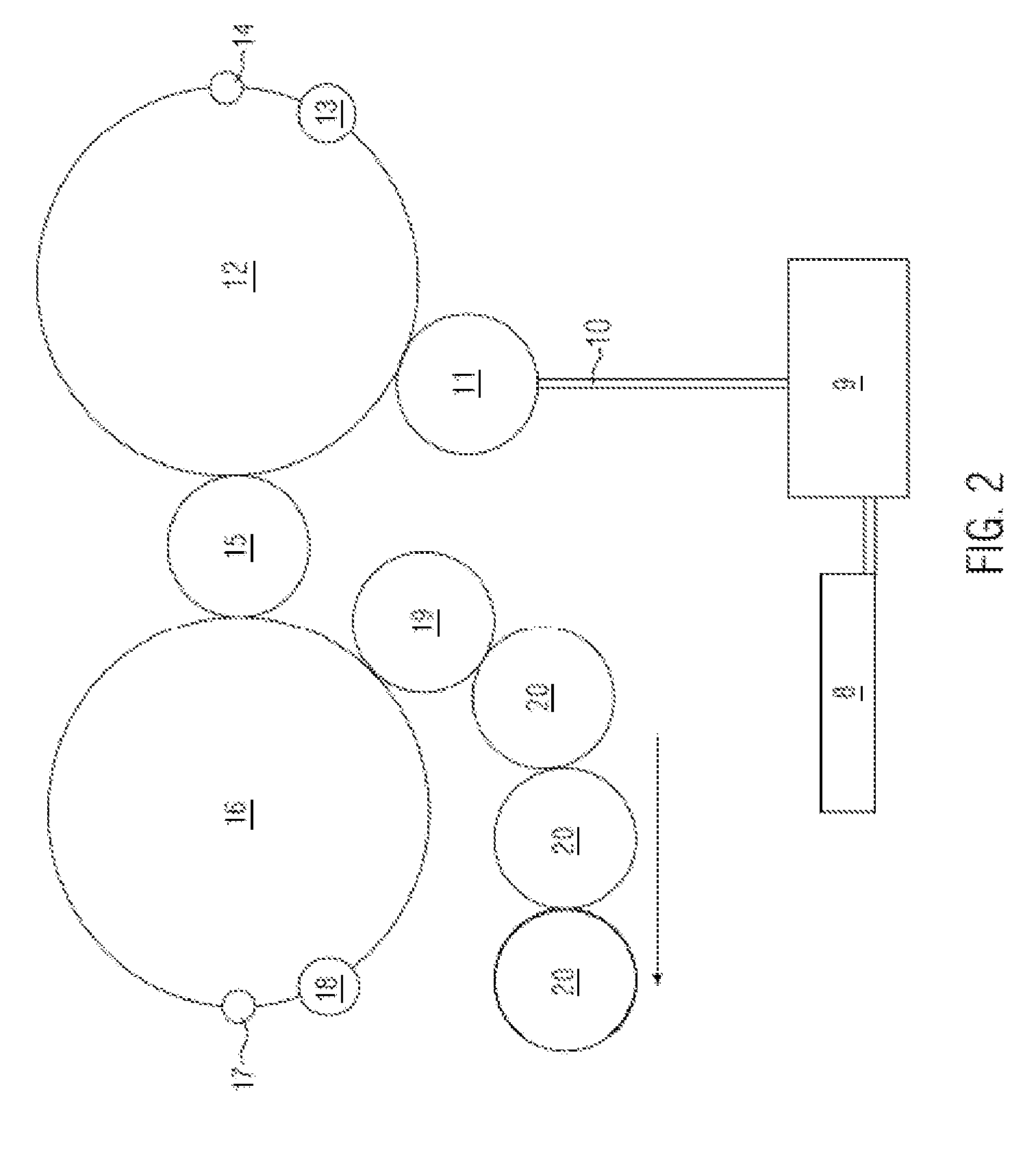

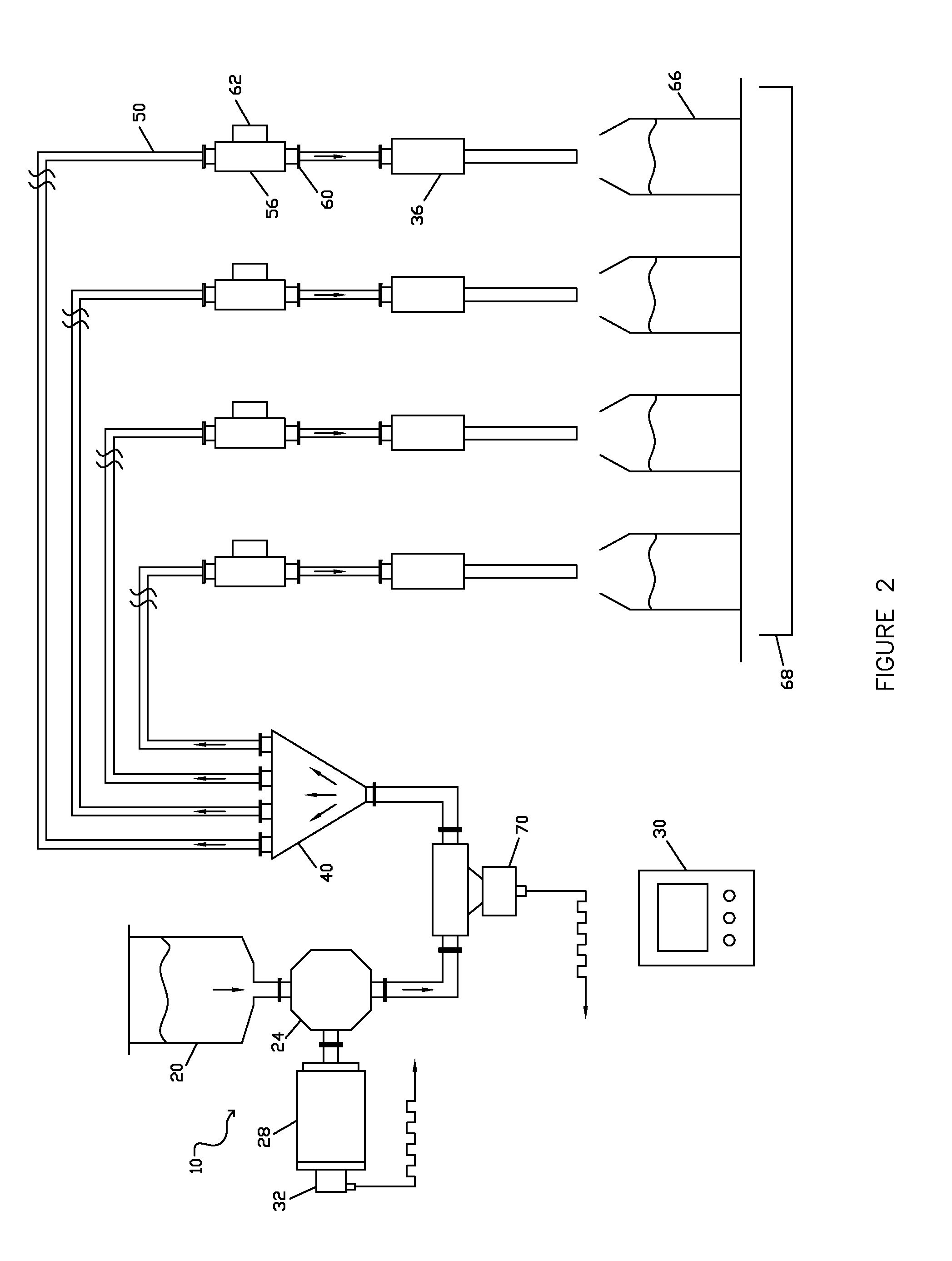

Multiple Stream Filling System

A filling line for filling a number of containers. The filing line may include a continuous conveyor, one or more micro-ingredient dosers positioned about the continuous conveyor, and one or more macro-ingredient stations positioned along the continuous conveyor.

Owner:THE COCA-COLA CO

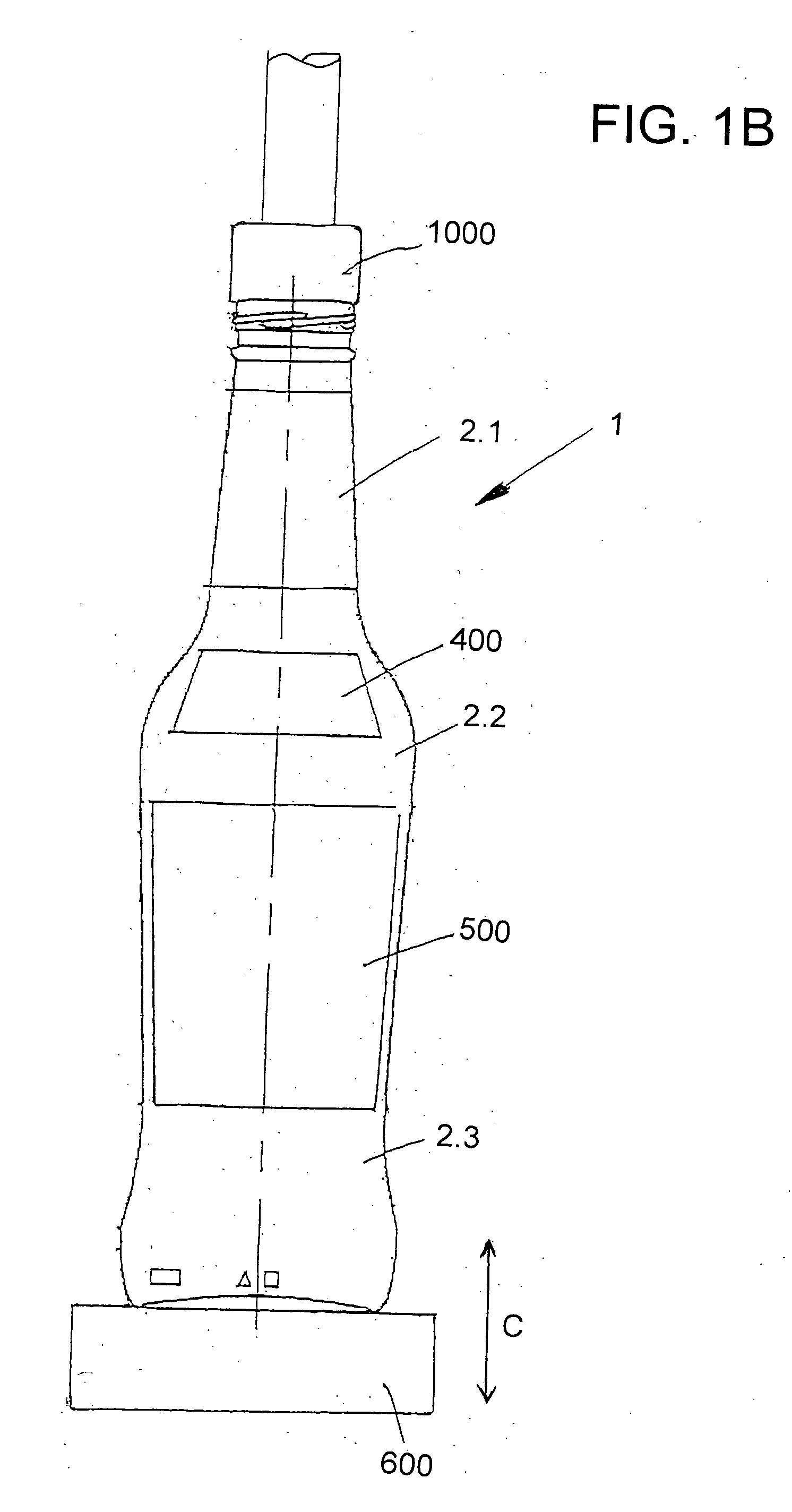

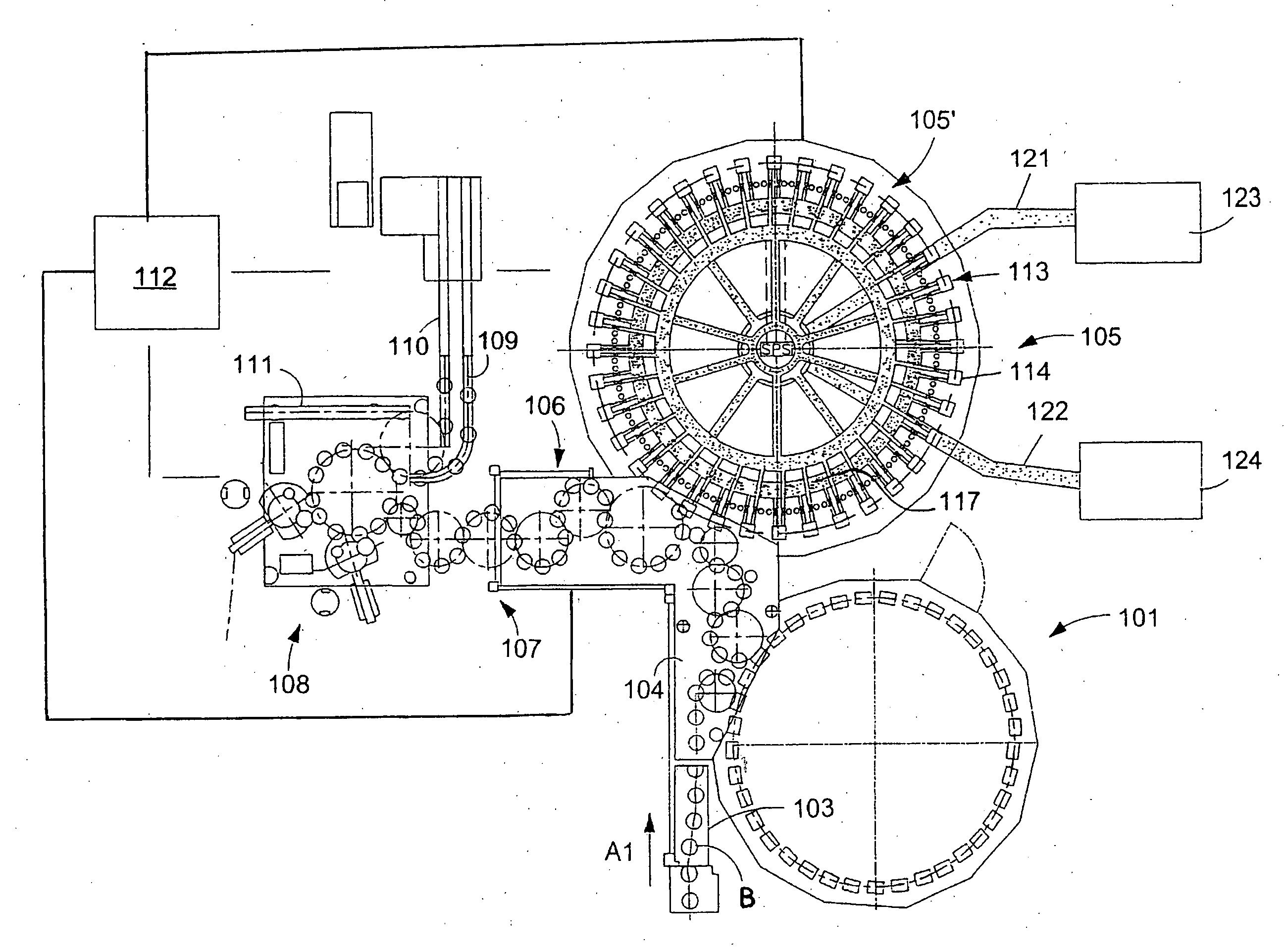

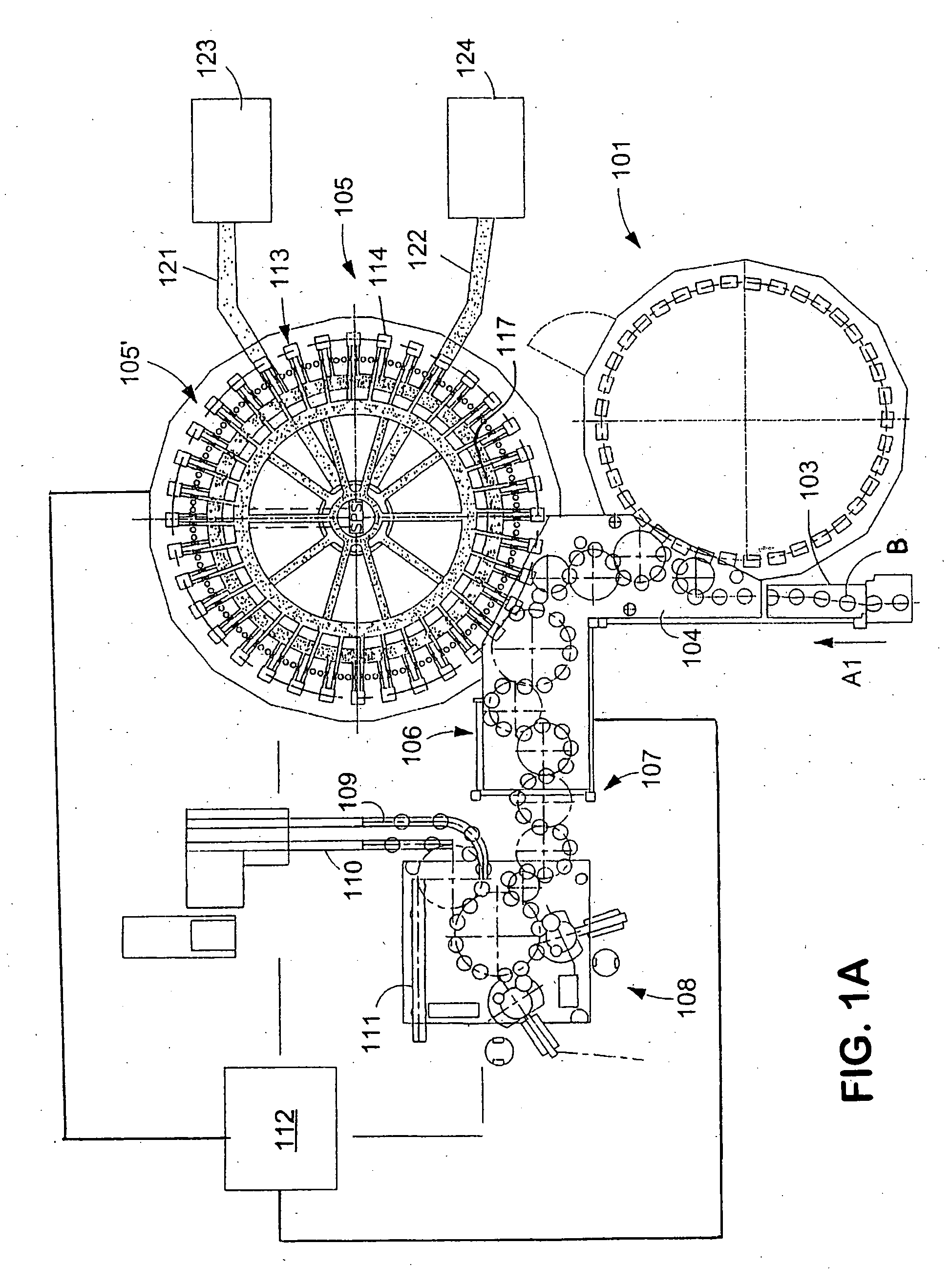

Method of treating at least one container in a container treatment plant

InactiveUS20120085071A1Simple and efficient mannerSynchronising machinesLiquid fillingEnvironmental engineeringPlant based

A method of treating at least one container in a container treatment plant, including marking at least one container with a marking, detecting the marking of the at least one container, selecting at least one container treatment machine of a container treatment plant and / or at least one operation setting of the at least one container treatment machine of the container treatment plant based on the detected marking, and treating the at least one container based on the selection of the at least one container treatment machine and / or the at least one operation setting.

Owner:KRONES AG

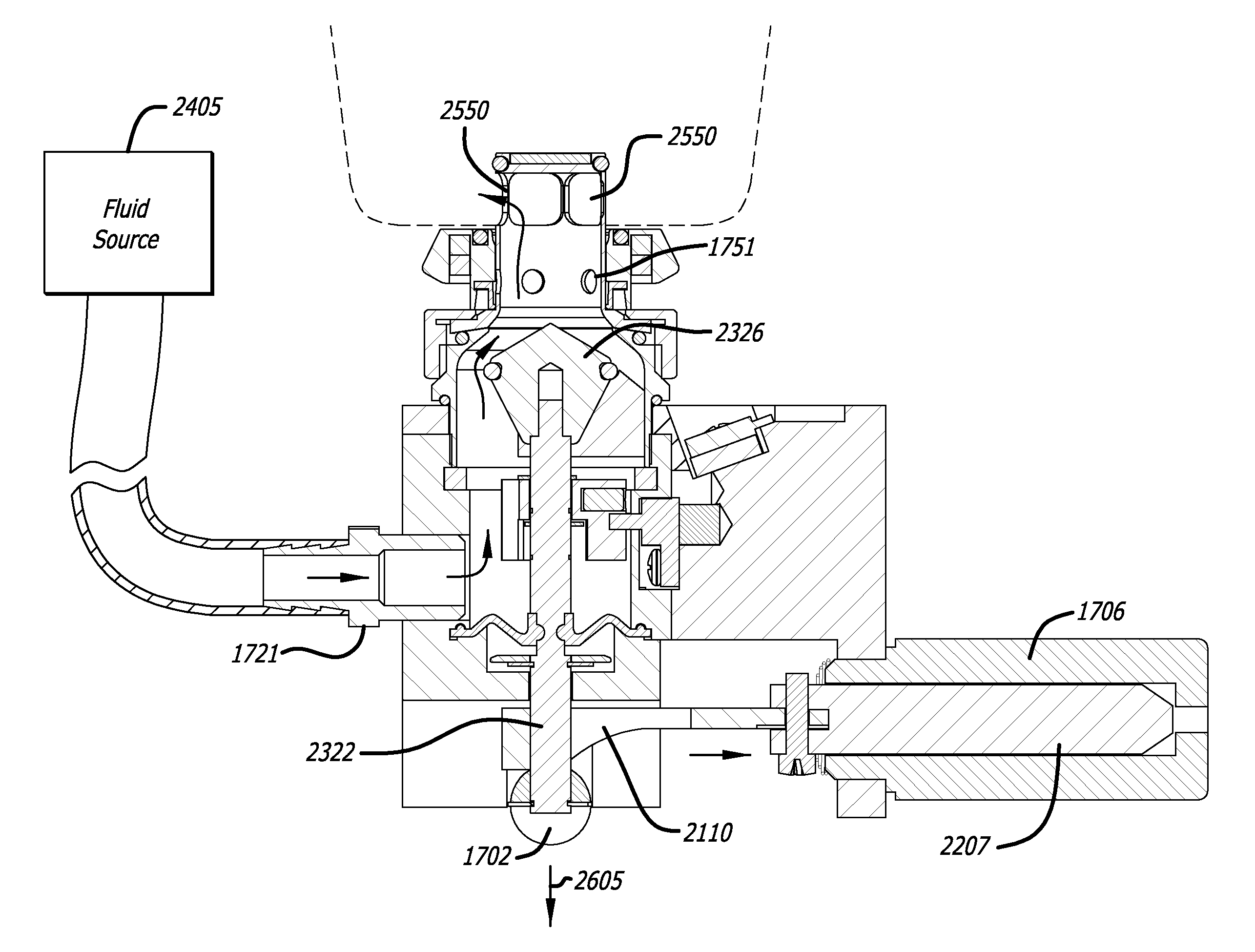

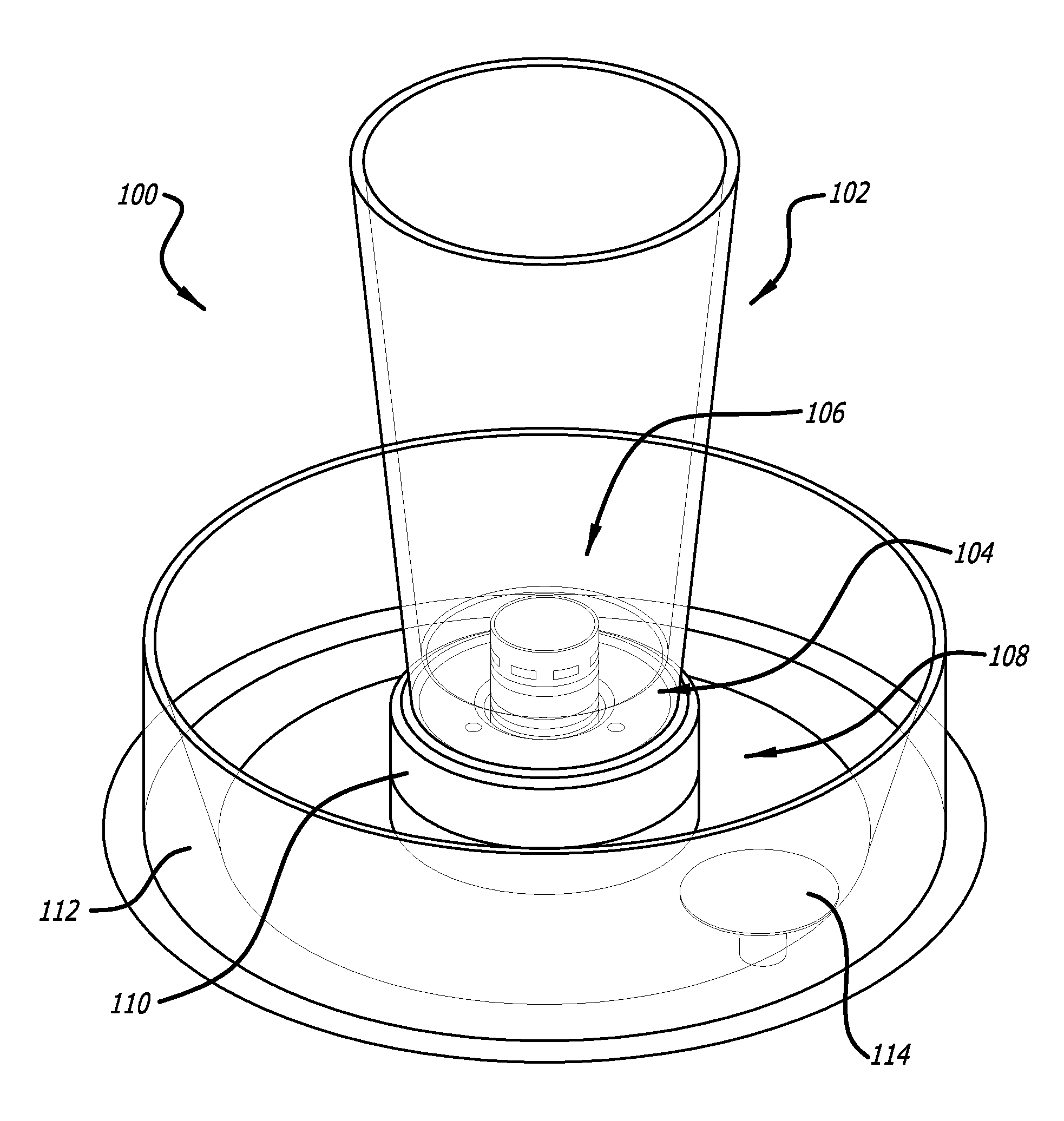

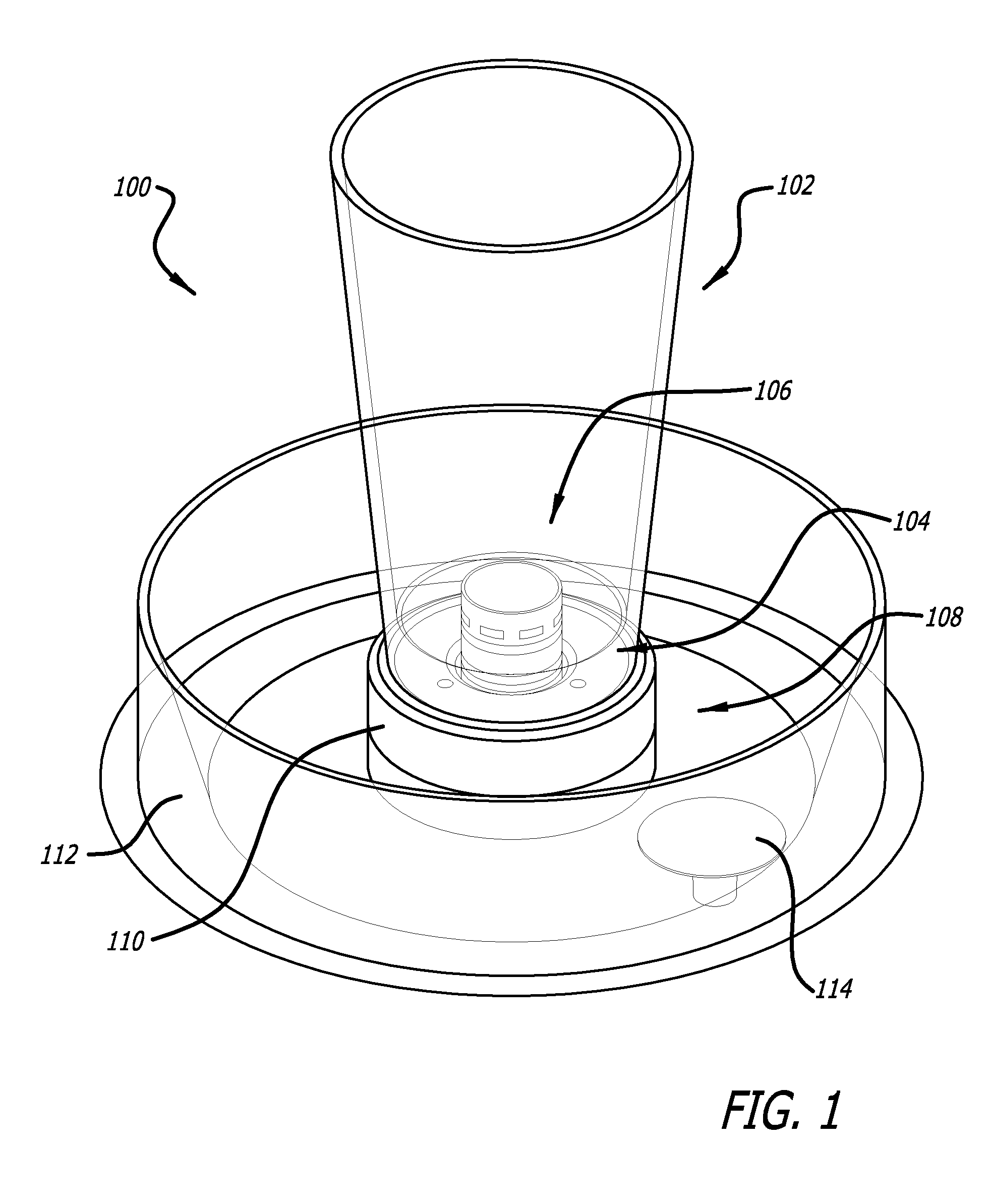

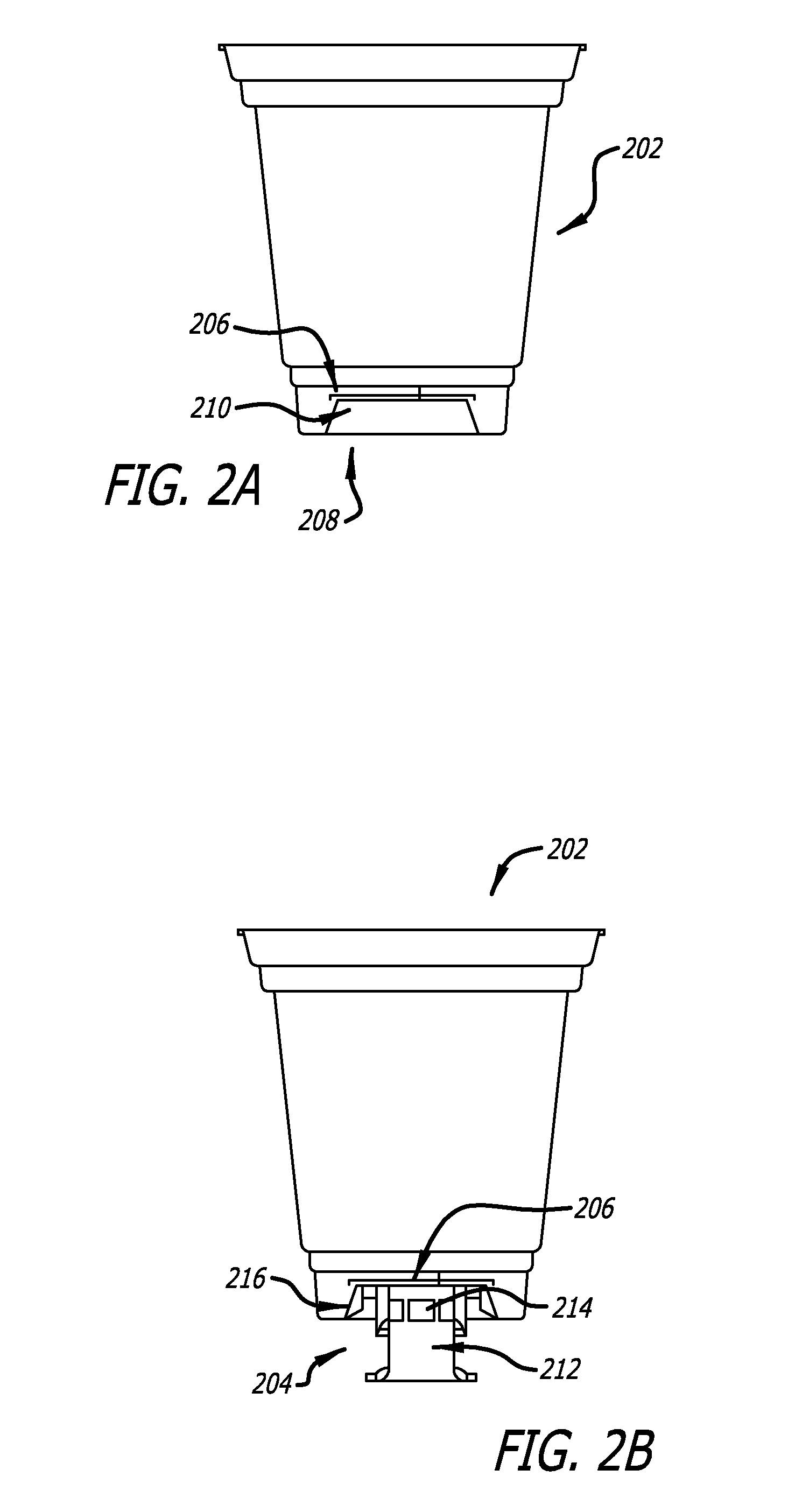

Fluid transfer assembly and methods of fluid transfer

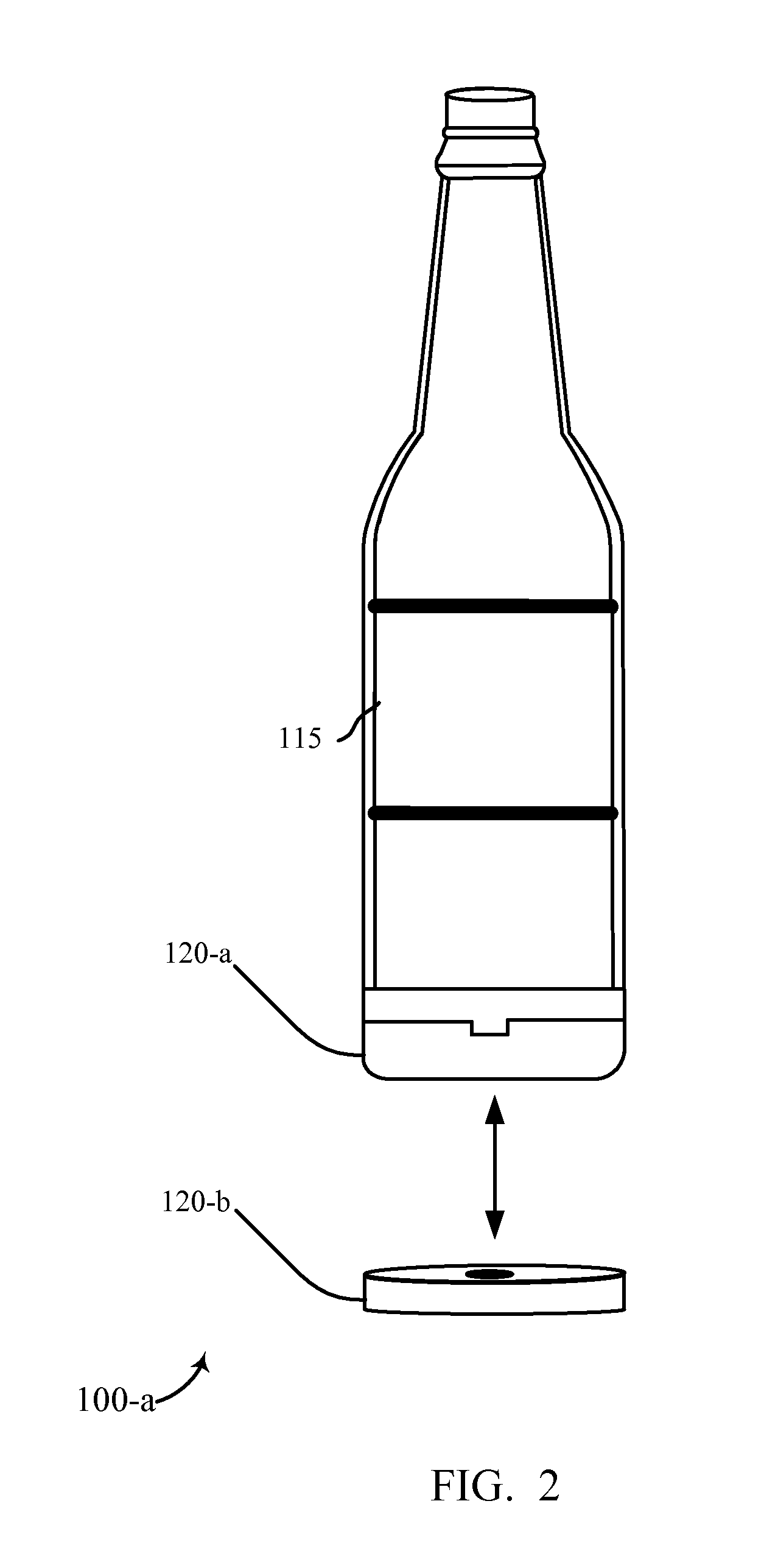

ActiveUS8777182B2Reduce the potential for stale liquidDrain fastLiquid fillingPower operated devicesBiomedical engineeringUser interface

A fluid dispensing assembly, including a valve, a housing, a user interface, and a fitting to couple to a fluid source. The valve may include a first sensor detecting proper placement of the fluid container based on a magnetic material positioned at the bottom of the fluid container, a plunger having a plunger shaft coupled thereto, the plunger selectively placing the valve in fluid communication with the fluid container, and a solenoid coupled to the plunger shaft and moving the plunger shaft to transition the plunger between an open position and a closed position. The user interface may be coupled to the valve to enable selection of at least a fluid container size and a dispensing mode.

Owner:GRINON INDS

Fluid transfer assembly and methods of fluid transfer

ActiveUS20110121020A1Drain fastEasy to removePower operated devicesBottlesBiomedical engineeringUser interface

A fluid dispensing assembly, including a valve, a housing, a user interface, and a fitting to couple to a fluid source. The valve may include a first sensor detecting proper placement of the fluid container based on a magnetic material positioned at the bottom of the fluid container, a plunger having a plunger shaft coupled thereto, the plunger selectively placing the valve in fluid communication with the fluid container, and a solenoid coupled to the plunger shaft and moving the plunger shaft to transition the plunger between an open position and a closed position. The user interface may be coupled to the valve to enable selection of at least a fluid container size and a dispensing mode.

Owner:GRINON INDS

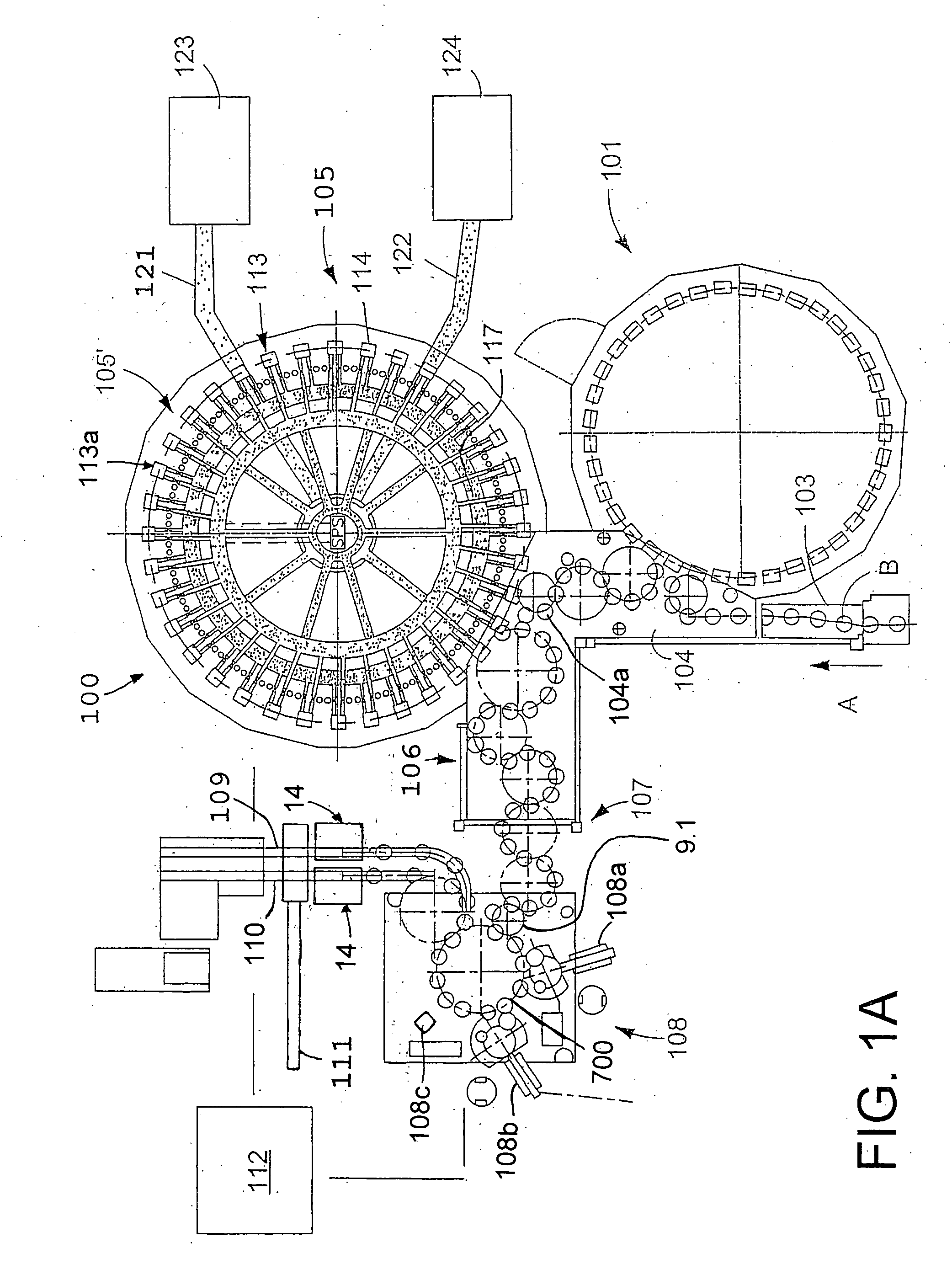

Beverage bottling plant for filling bottles with a liquid beverage material having an inspection apparatus for inspecting bottles

InactiveUS20060283145A1Material analysis by optical meansSafety device in filling machineryTrademarkEngineering

A beverage bottling plant for filling bottles with a liquid beverage material having an inspection apparatus for inspecting bottles. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS MASCHEN UND ANALAGENBAU AKTIENGES

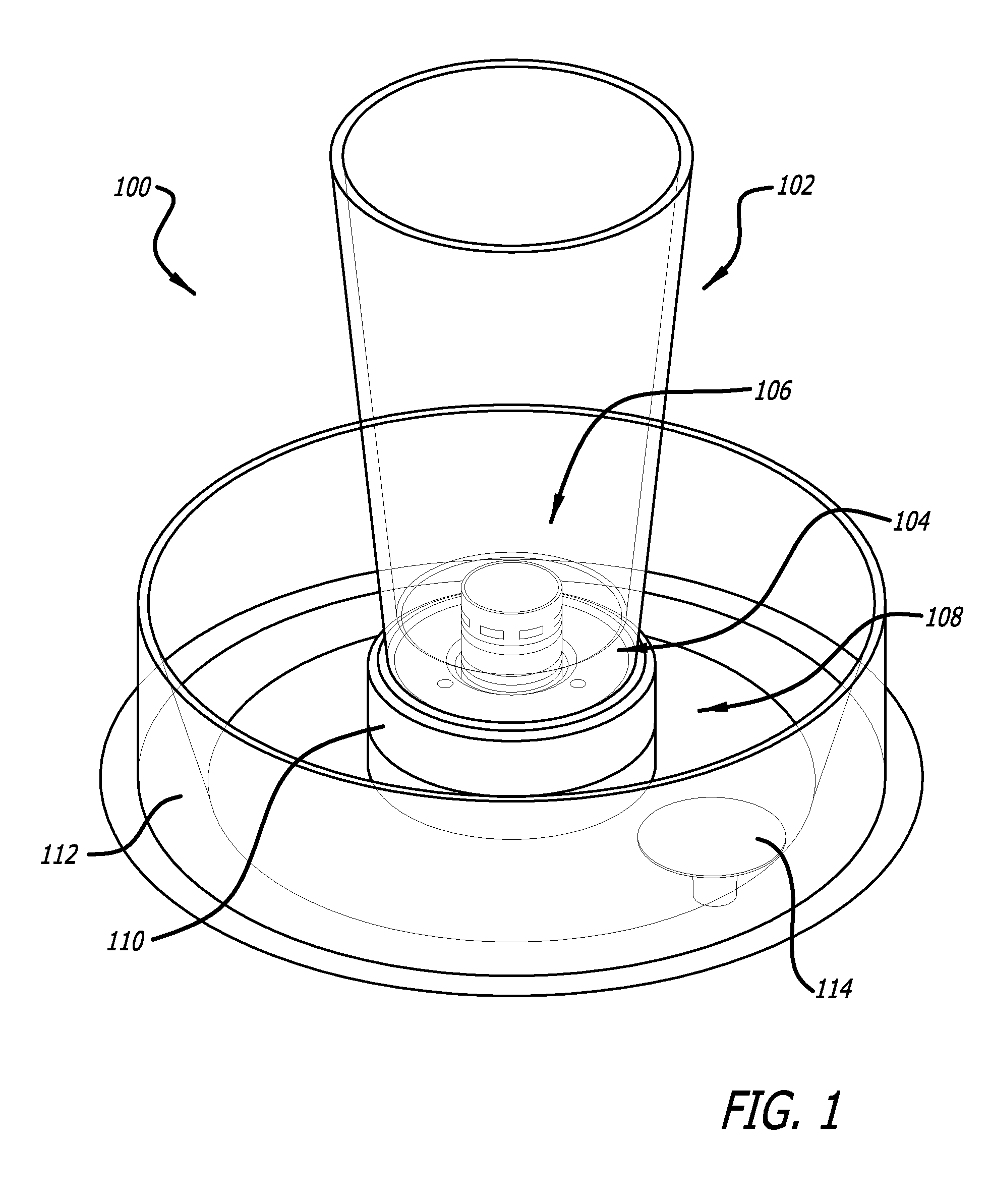

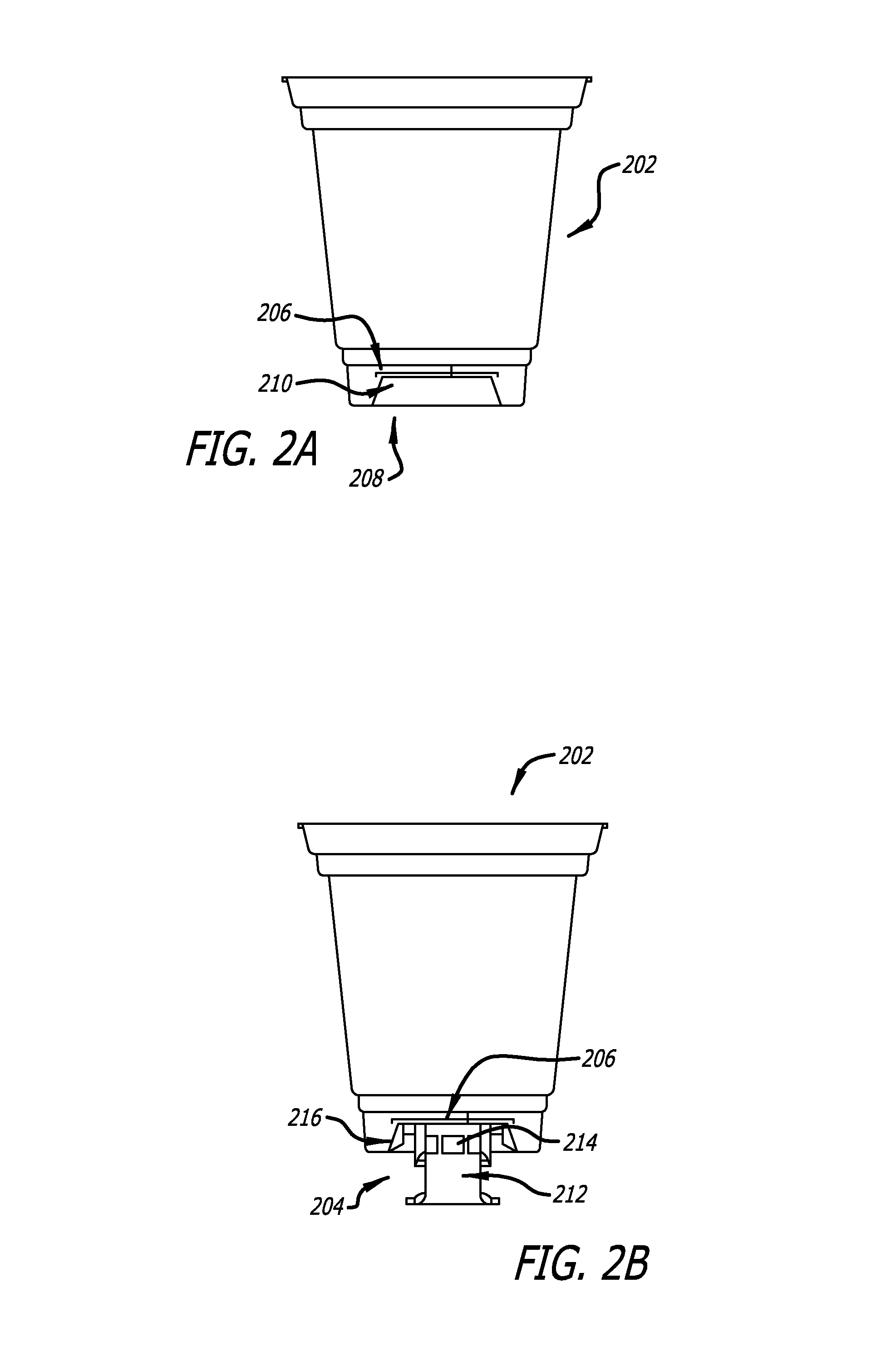

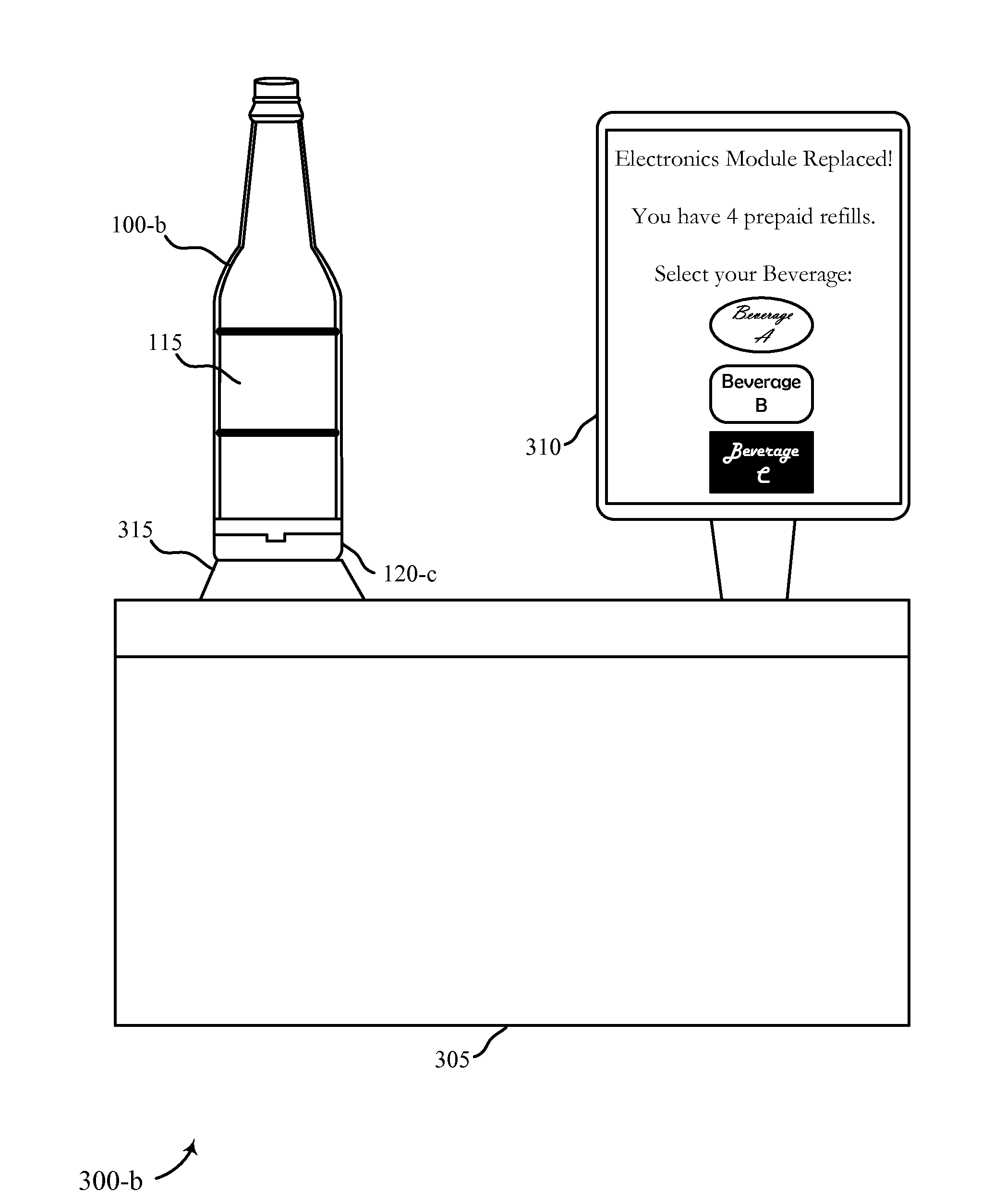

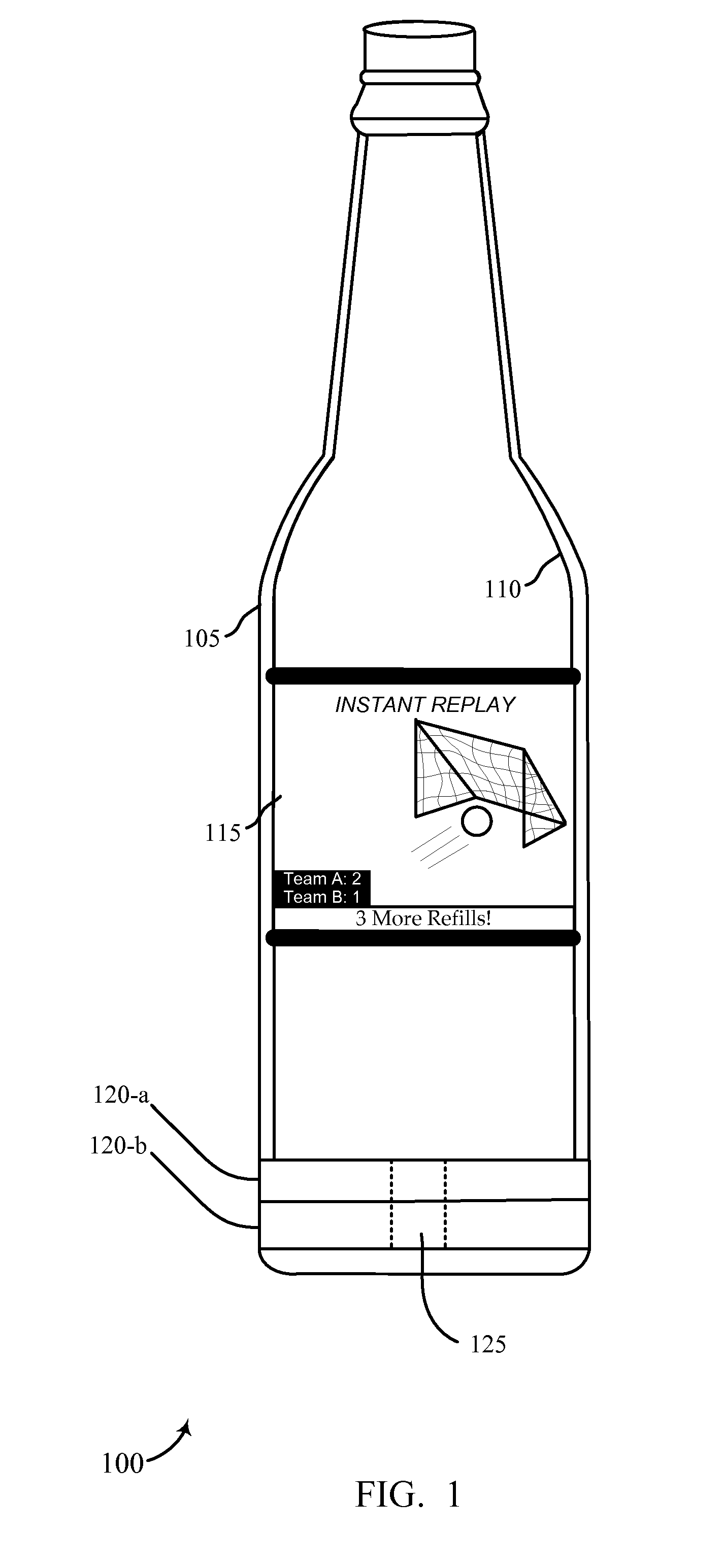

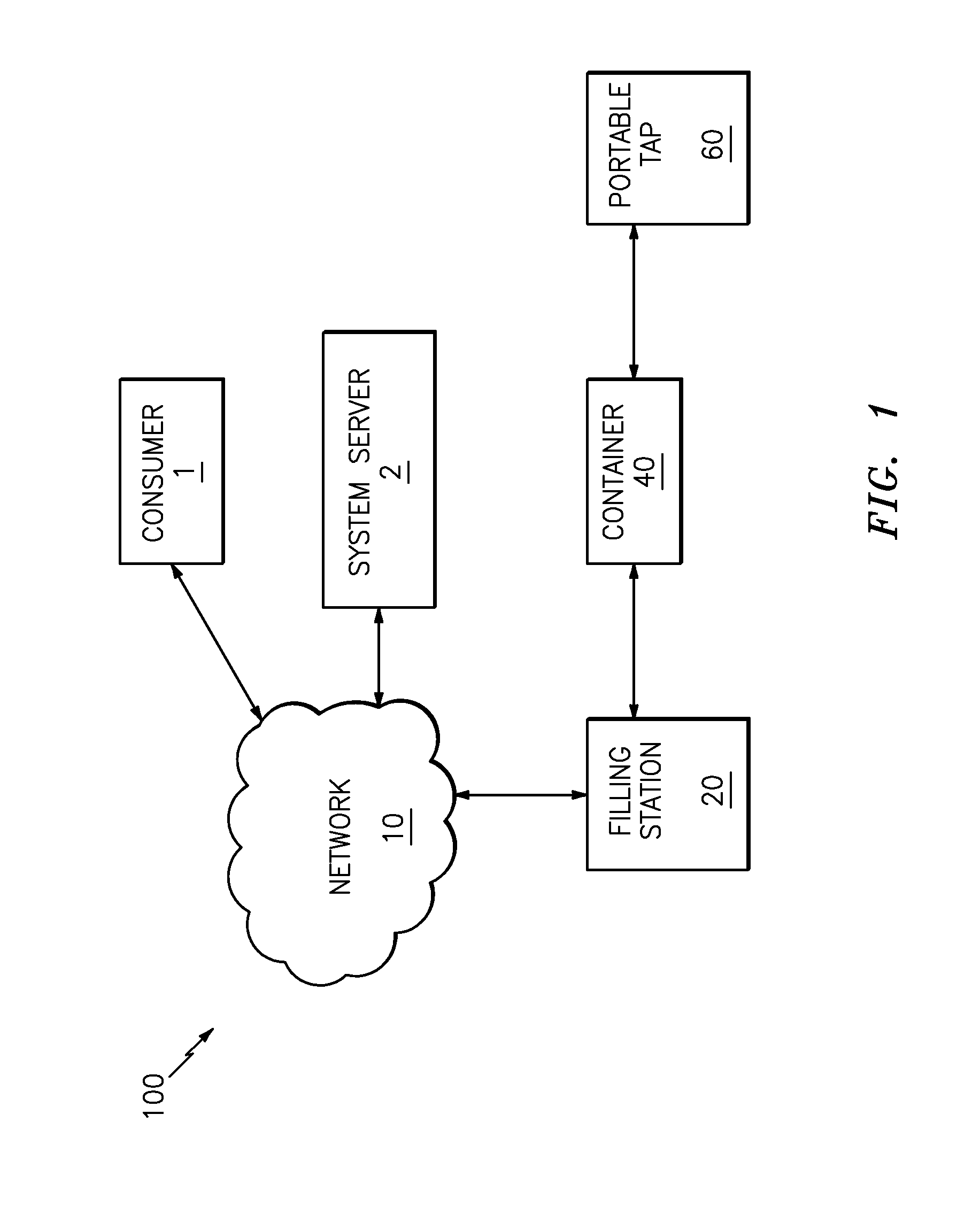

Refill station using an intelligent beverage container

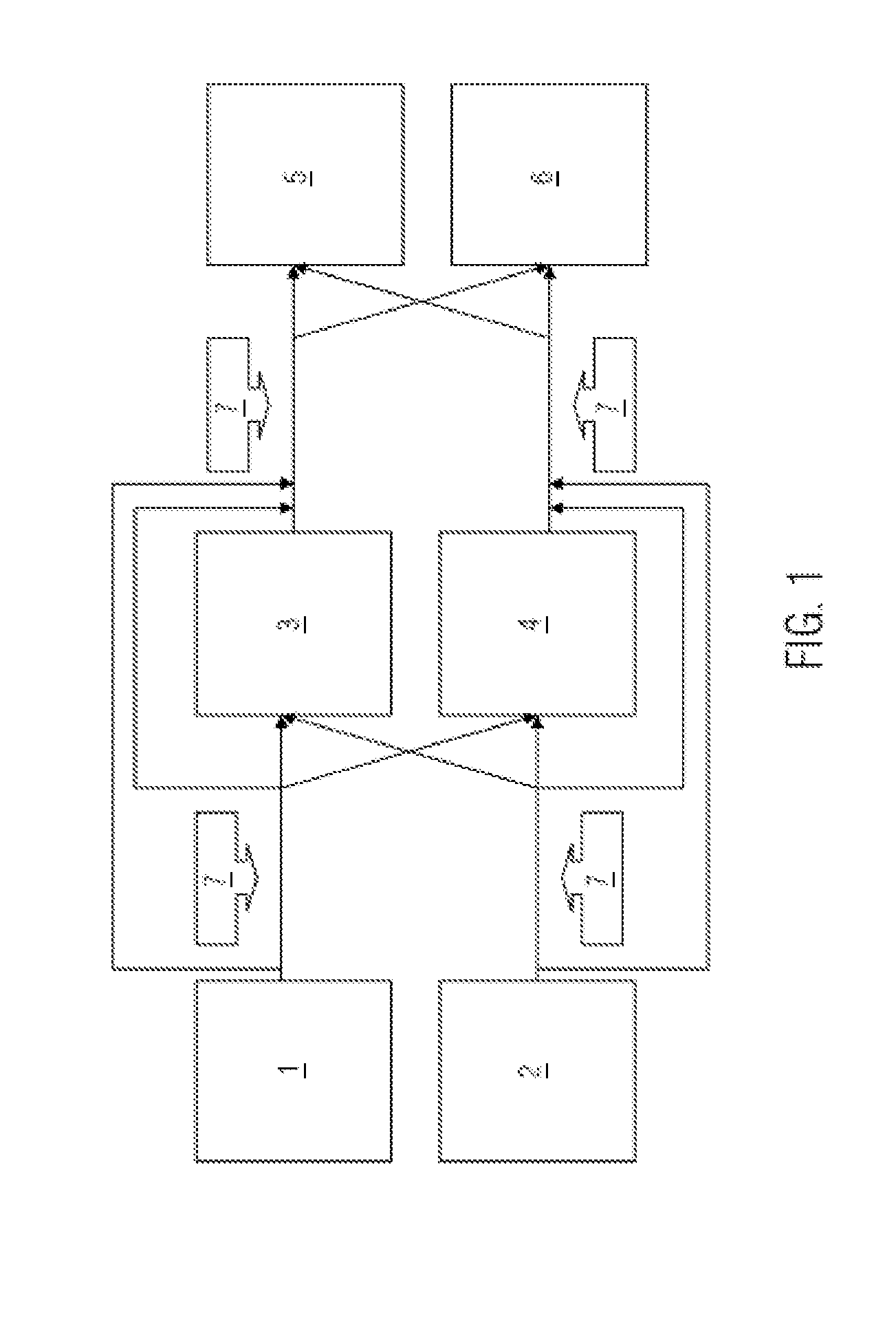

Systems, devices, and methods are provided for conducting a refill of a beverage container. A beverage container may be detected at a refill station. The beverage container may be associated with a user account. The refill station may access information stored in the user account to determine if the beverage container is permitted to be refilled. Based on the determination, the refill station may refill the beverage container. Information indicative of the refill process may be displayed on an electronic display of the refill station. The refill station may also capture an image of the user of the beverage container and compare the captured image with an image stored in the associated user account to confirm the identity of the user. The determination that the beverage container may be refilled may be based, at least in part, on the identity confirmation.

Owner:ANHEUSER BUSCH INBEV SA

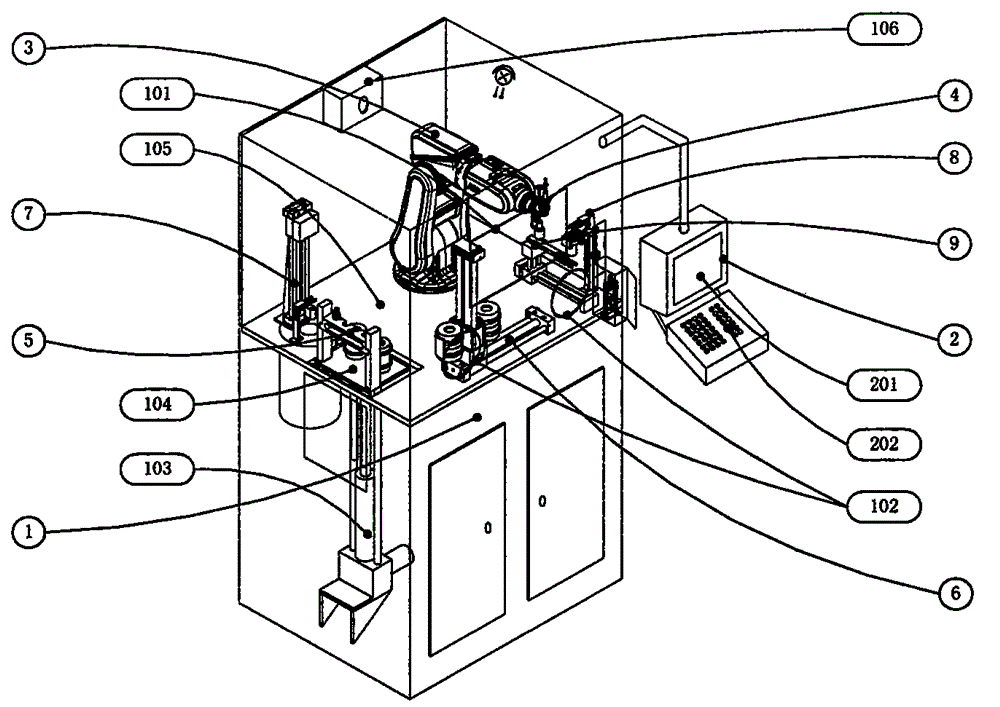

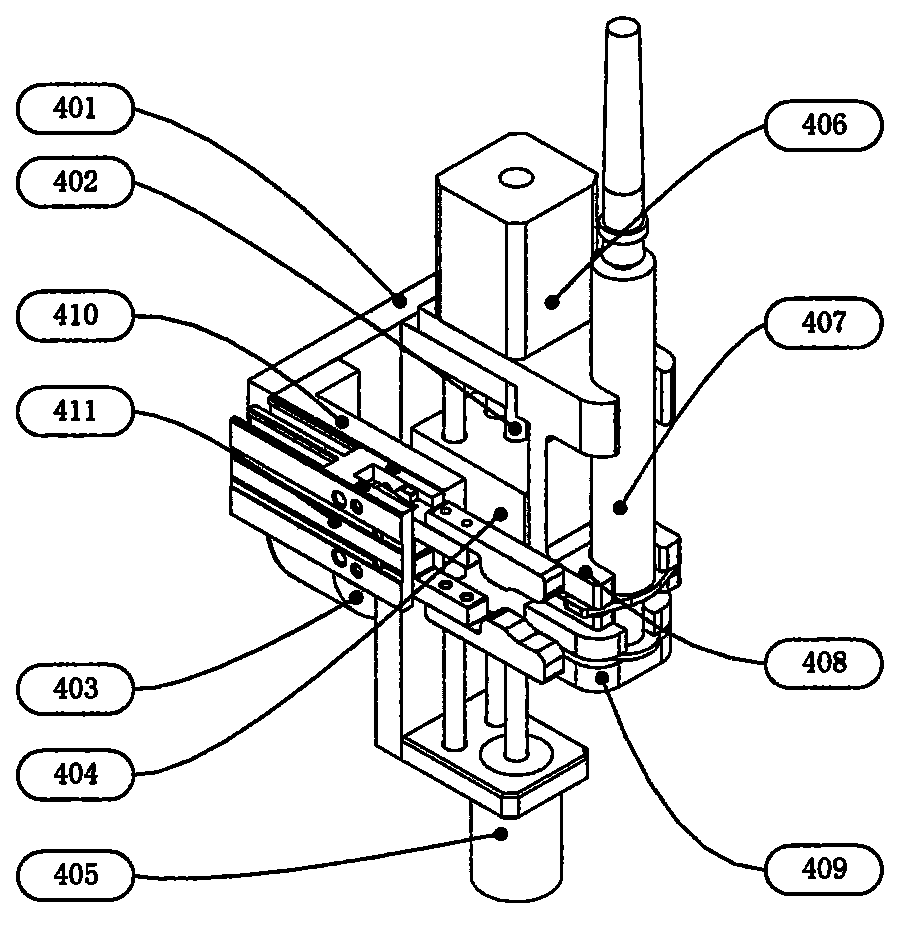

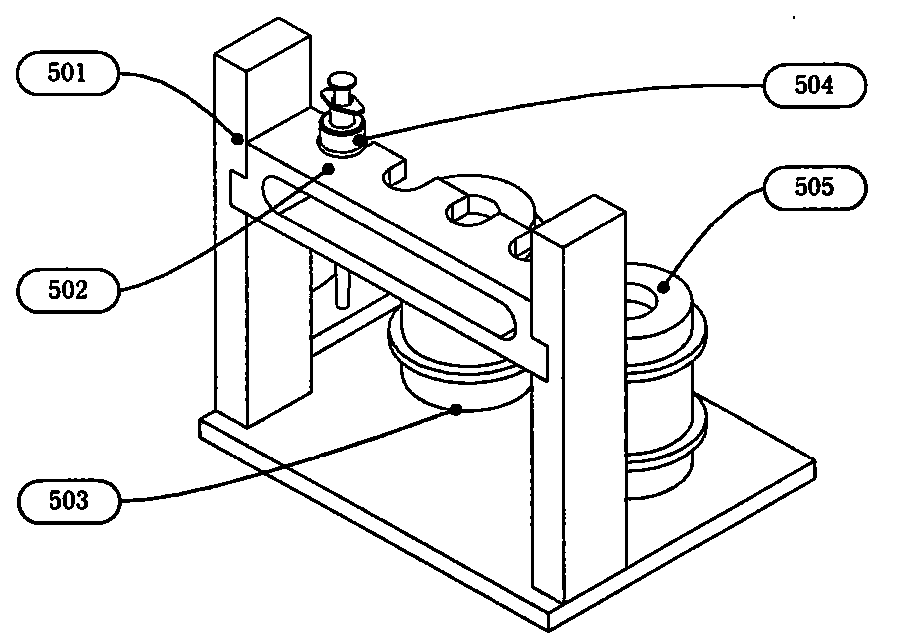

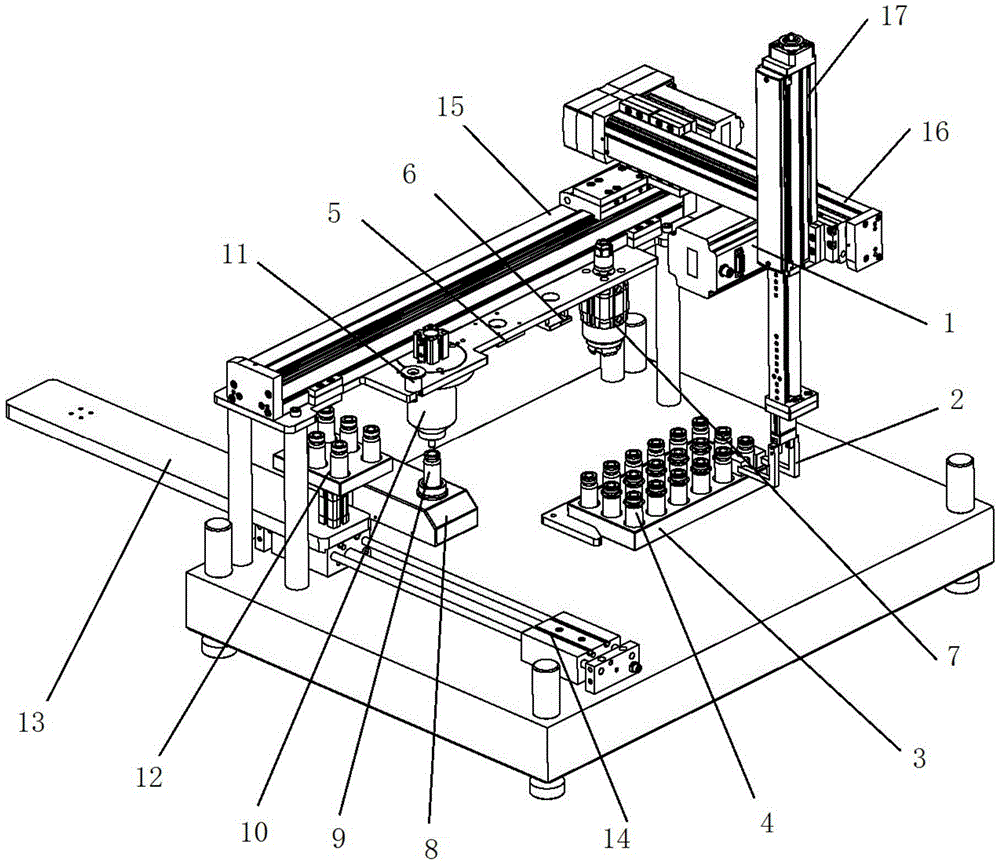

Radiopharmaceutical automatic split charging process method and system

The invention aims at providing a radiopharmaceutical automatic split charging process method and system based on an industrial robot. The system mainly consists of a split charging heat chamber, a control system, an industrial robot, an end picker module, a feeding and discharging module, a radiopharmaceutical tank bracket module, an activity detection module, a protection combination bracket module and an injector discharging module. The system uses the industrial robot as a core for connecting all work procedures for the radiopharmaceutical split charging in series, and the work links such as the automatic material feeding and discharging, injector protection sleeve and injector needle cap detaching, penicillin bottle radiopharmaceutical total activity detection, needle insertion and liquid extraction, injector activity detection, injector protection sleeve installation and injector output are realized. The system has the advantages that the automatic split charging and detection technical process of radiopharmaceuticals can be accurately and reliably completed, the work mode conforms to relevant industrial standards, the artificial participation is avoided, the liquid extraction precision is high, no bubble or liquid residue exists, and the use of purpose-made high-cost consumables and the detection and the processing of residue radiopharmaceuticals are avoided.

Owner:程鹏志

Automatic detection machine capable of synchronously tracking and acquiring images

ActiveCN101799432ASolve the running speedKeep clearOptically investigating flaws/contaminationSafety device in filling machineryFree rotationEngineering

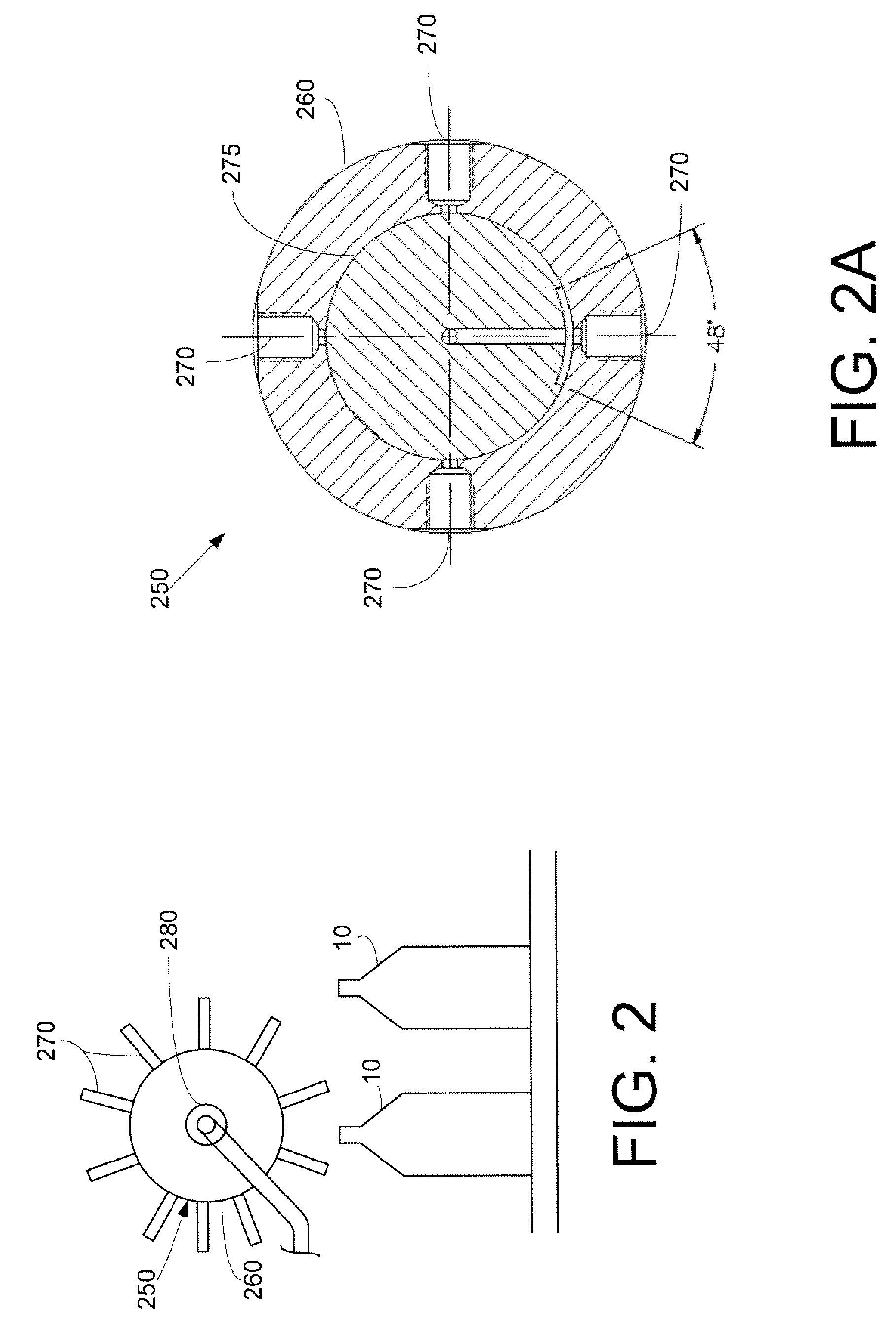

The invention discloses an automatic detection machine capable of synchronously tracking and acquiring images. The machine comprises a central rotating shaft, a rotating disk, a swing arm, a camera, a first light source and an independent driver, wherein the rotating disk is fixedly installed on the central rotating shaft, and objects to be detected are installed along the peripheral direction of the rotating disk; the swing arm is installed on the central rotating shaft in a free rotation mode; the camera and the first light source are fixed on the swing arm, either one of the camera and the first light source is positioned at the inner side of a bottle to be detected, and the other the camera and the first light source is positioned at the outer side of the bottle to be detected; and the independent driver is connected to the swing arm, and is connected with the central rotating shaft through a transmission mechanism. The invention can ensure that the tracked and acquired images of the bottle to be detected are clearer.

Owner:HUNAN CHINASUN PHARMA MASCH CO LTD

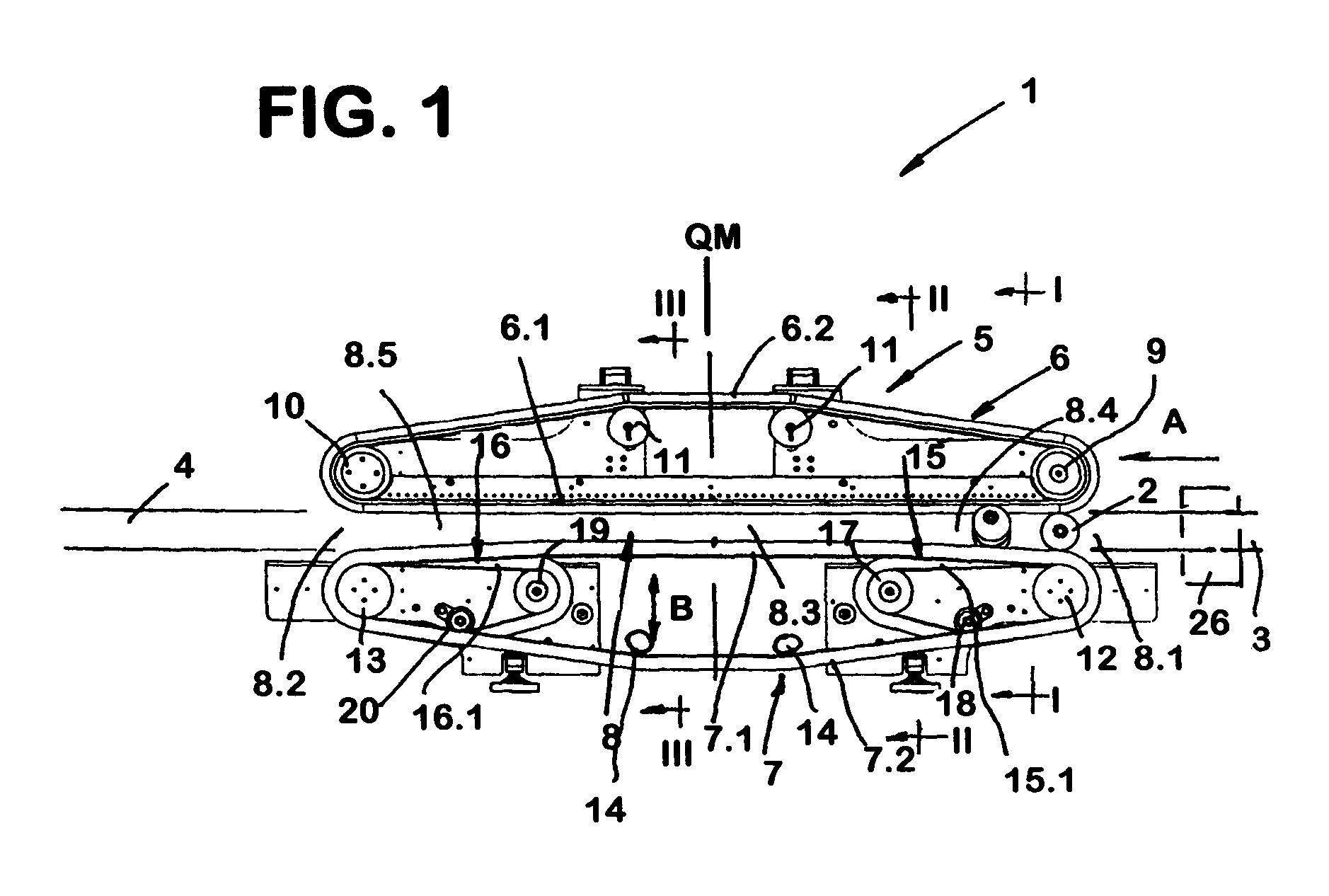

Liquid filler using single motive force

InactiveUS20150114515A1Eliminate requirementsSafety device in filling machinerySolid materialEngineeringMechanical engineering

A dosing method and apparatus for filling containers in an automatic in-line or linear liquid filling machine where a single positive displacement dosing apparatus produces a repeatable volumetric or net weight master dose which is precisely subdivided hydraulically into a plurality of equal and repeatable subdoses. Each equal subdose synchronously fills a container such that with each dosing apparatus cycle all containers are simultaneously and equally filled. A precision dose control is located in each subdose flow branch.

Owner:ODEN MACHINERY

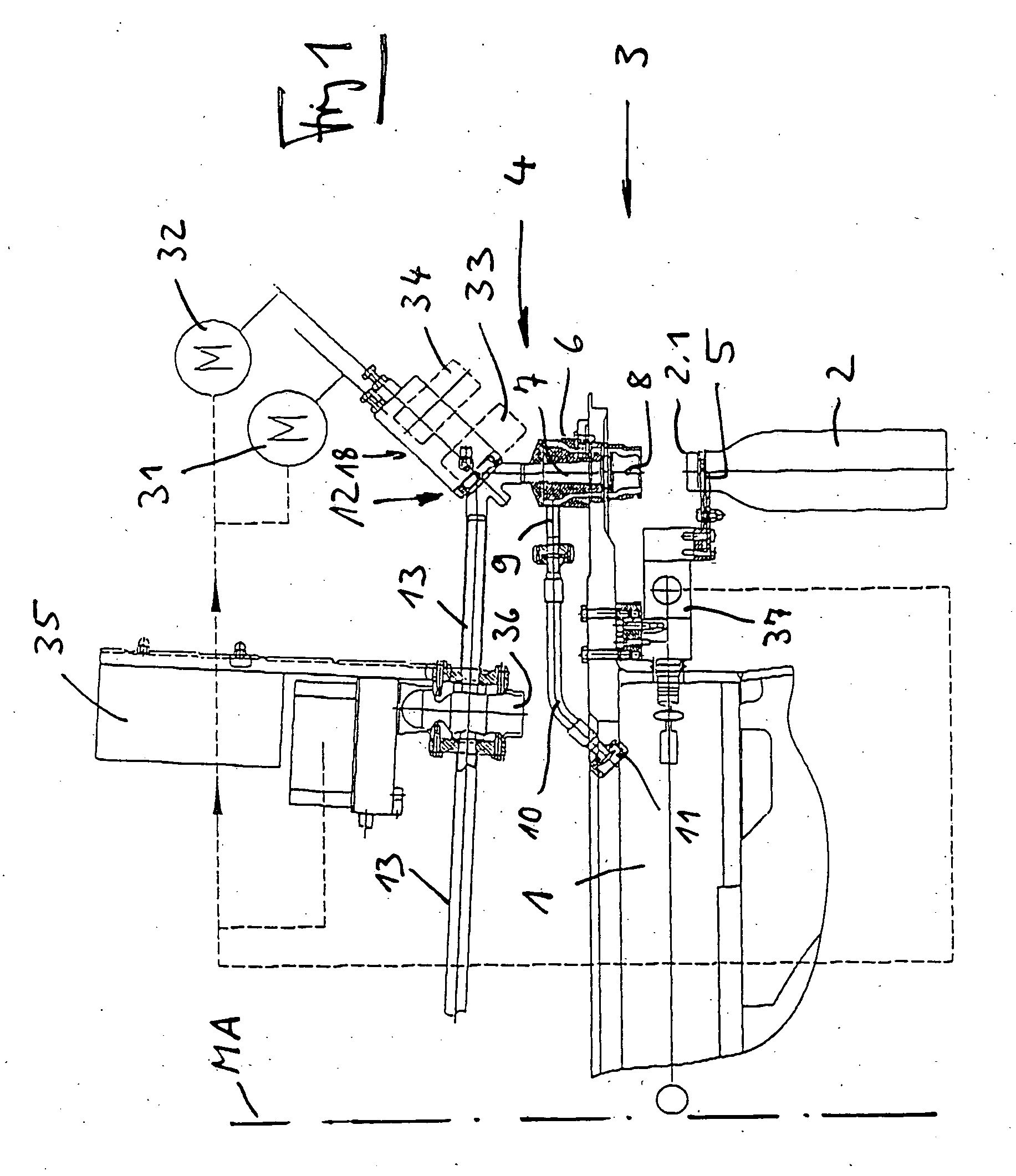

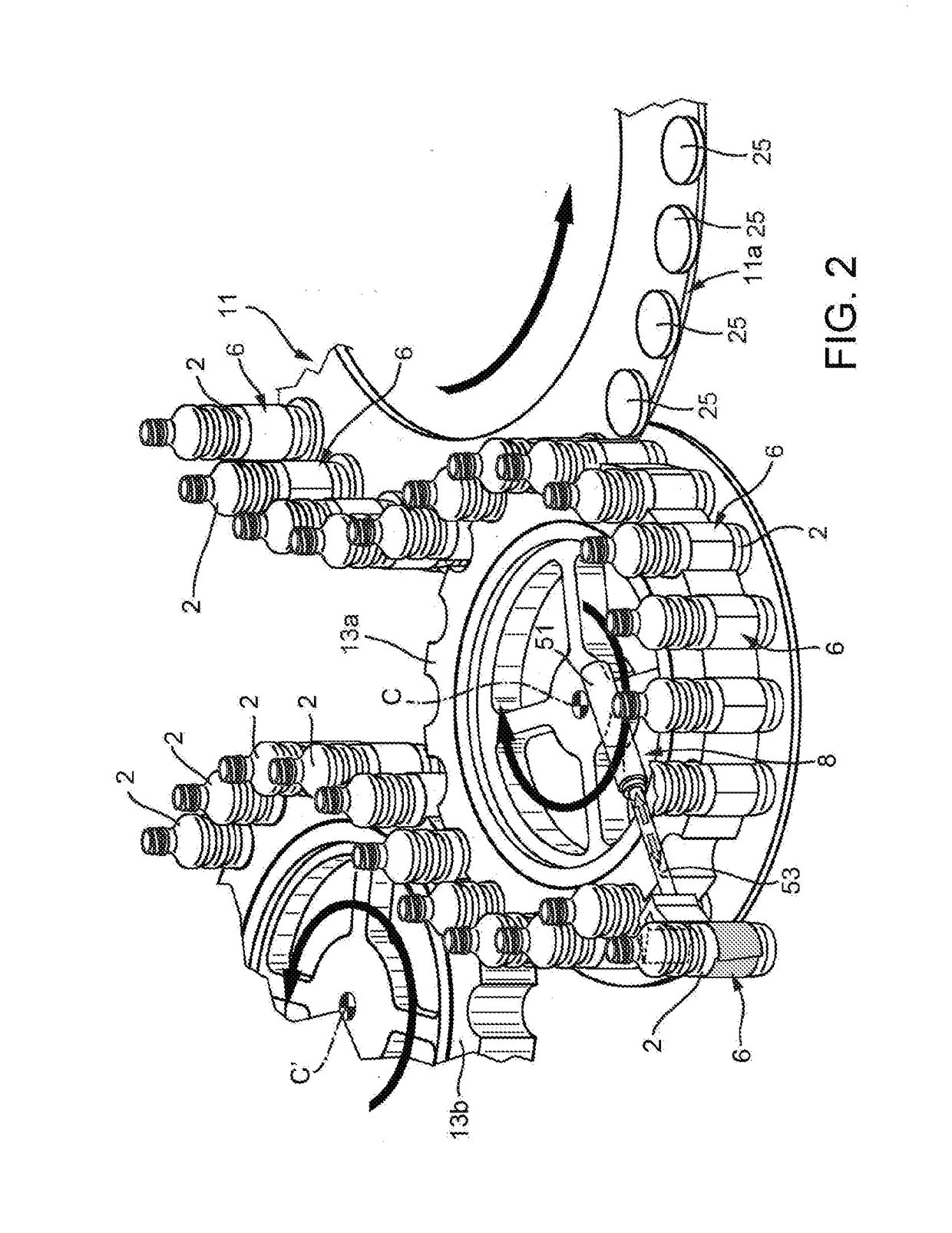

Beverage bottling plant for filling bottles with a liquid beverage filling material having a filling machine with a filling control element

InactiveUS20060266003A1Easy to adjustQuickly easily convertServomotorsSafety device in filling machineryTrademarkFilling materials

A beverage bottling plant for filling bottles with a liquid beverage filling material having a filling machine with a filling control element. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS MASCHEN UND ANALAGENBAU AKTIENGES

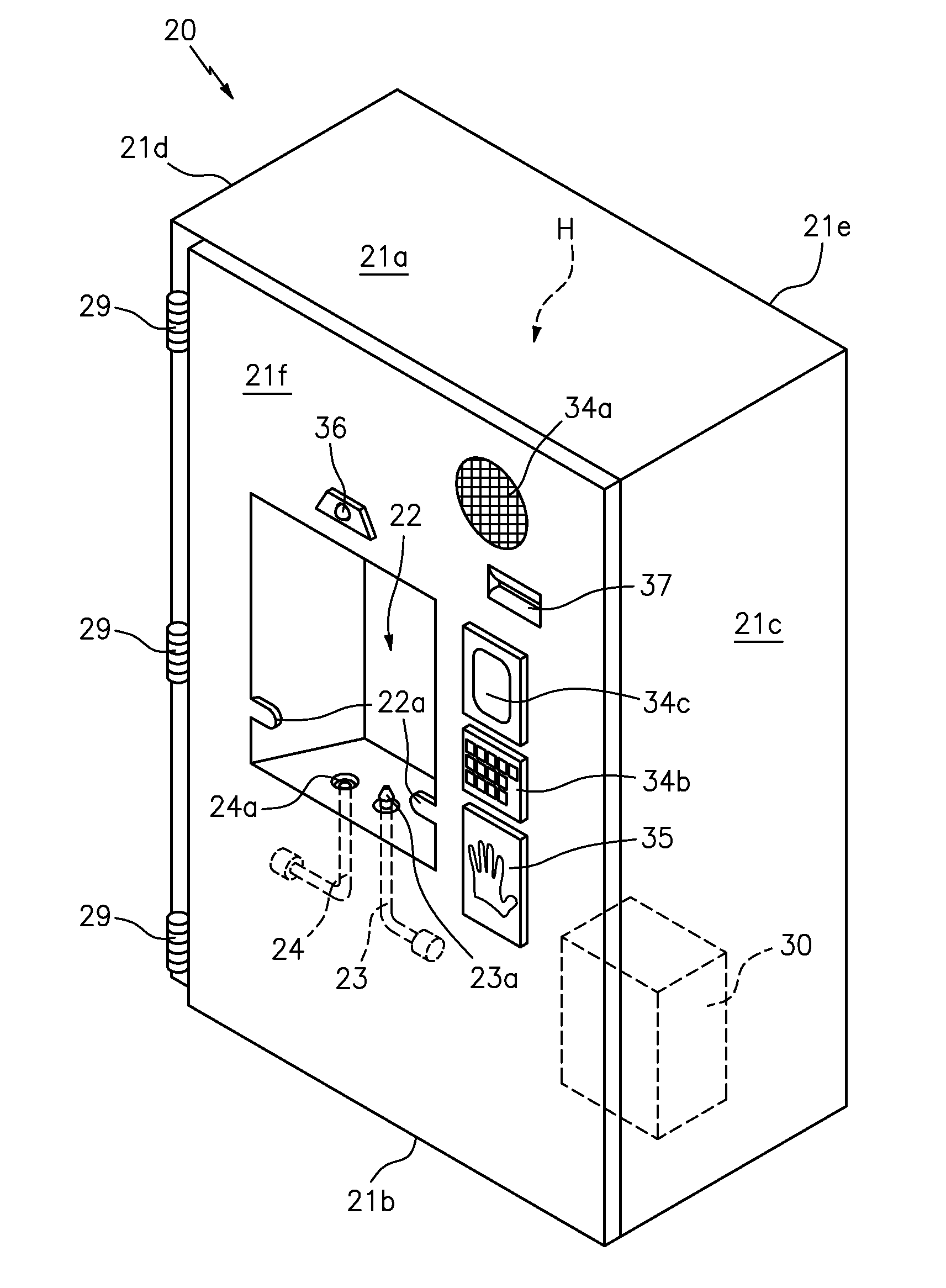

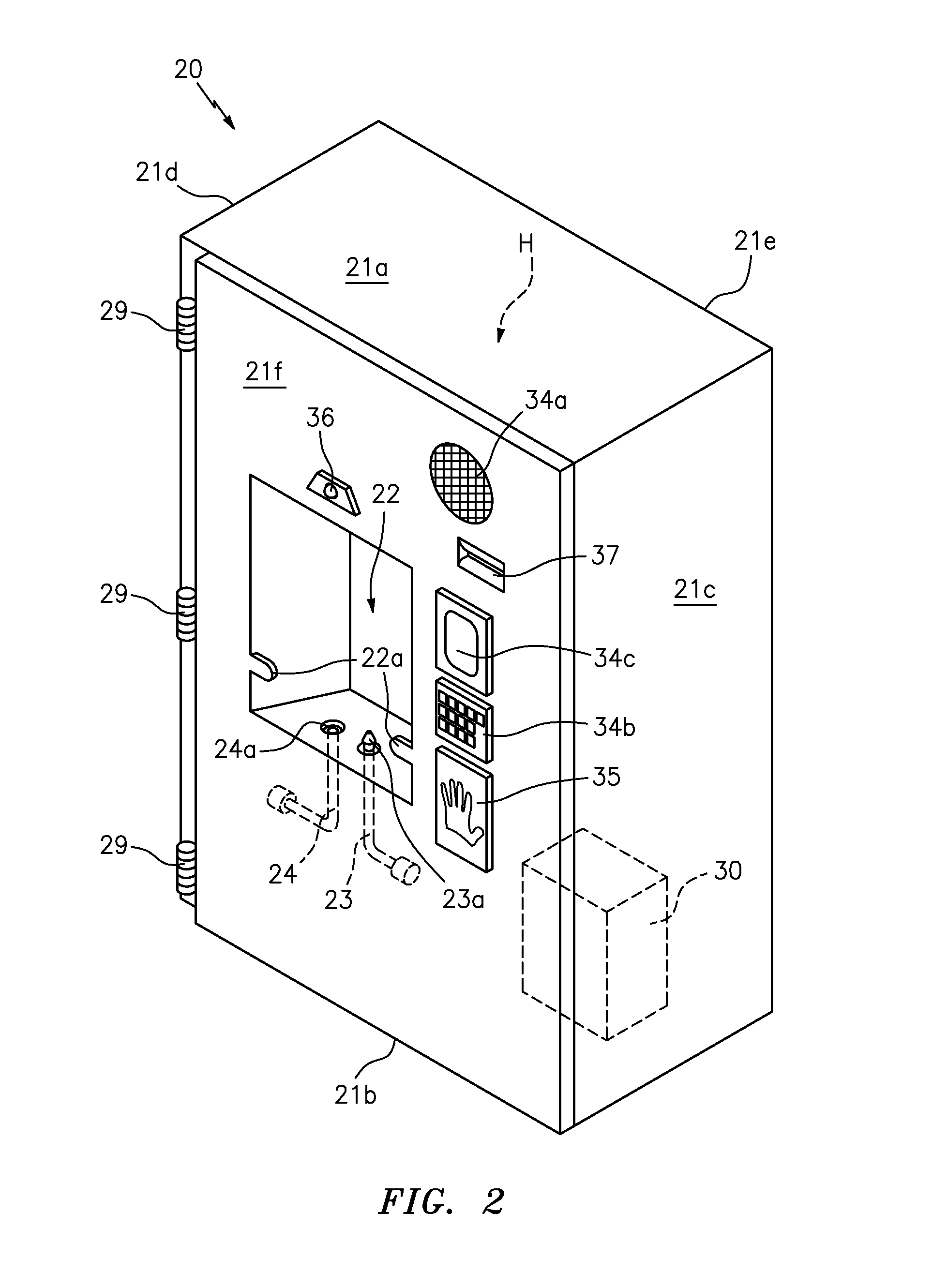

Self service controlled beverage dispensing system

InactiveUS20140110018A1Liquid flow controllersSafety device in filling machineryCommunication unitEngineering

A self service controlled beverage dispensing system that includes a self-service container filling station, a reusable beverage container, and a dispensing tap. The self service station including a communication unit and a biometric identity unit capable of confirming the identity and age of a user.

Owner:SCARVELLI MISTEE

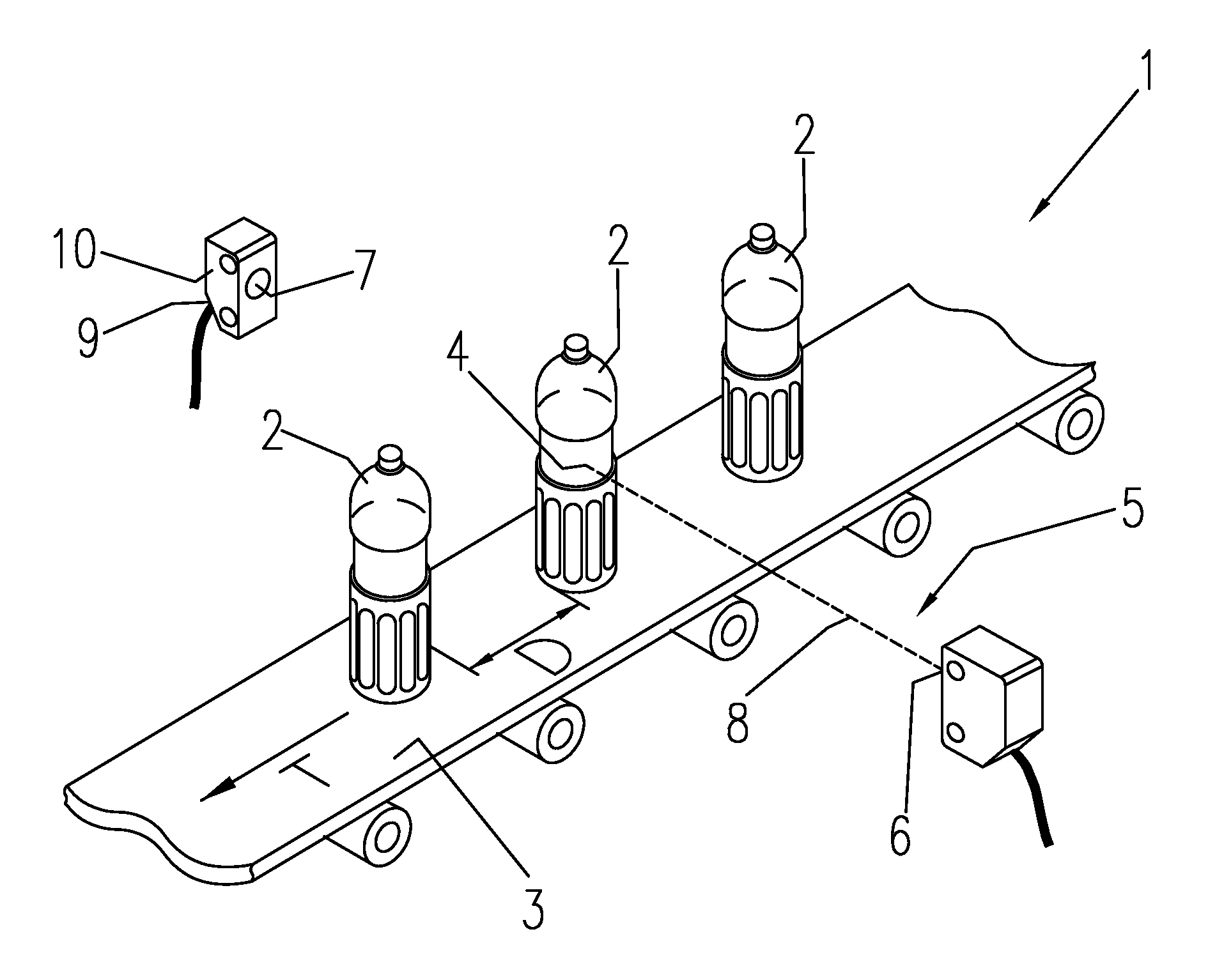

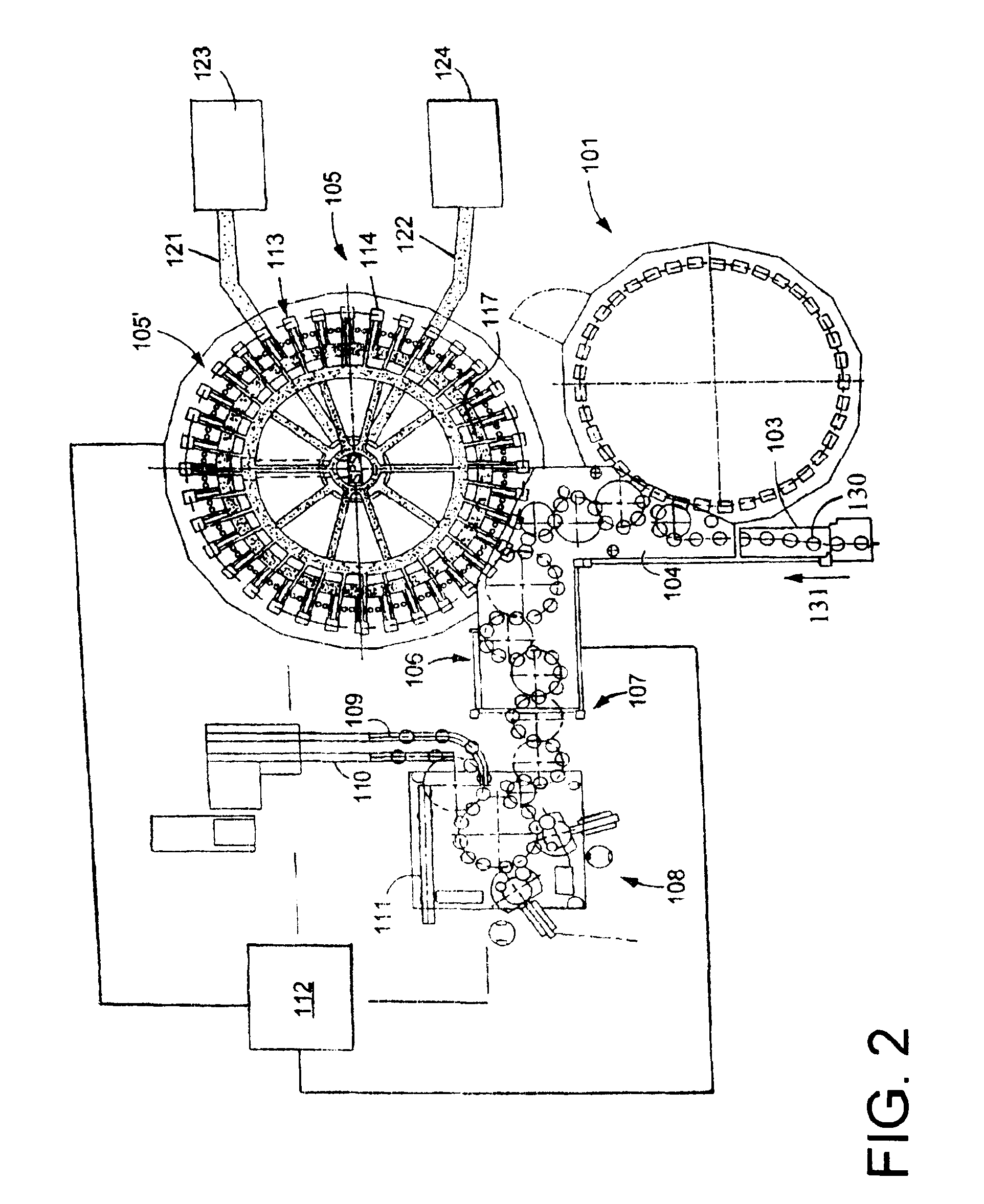

Bottle filling machine with sensor and method thereof

InactiveUS20090178728A1Good filling effectFunction increaseVolume measurement and fluid deliverySafety device in filling machineryEngineeringBottle

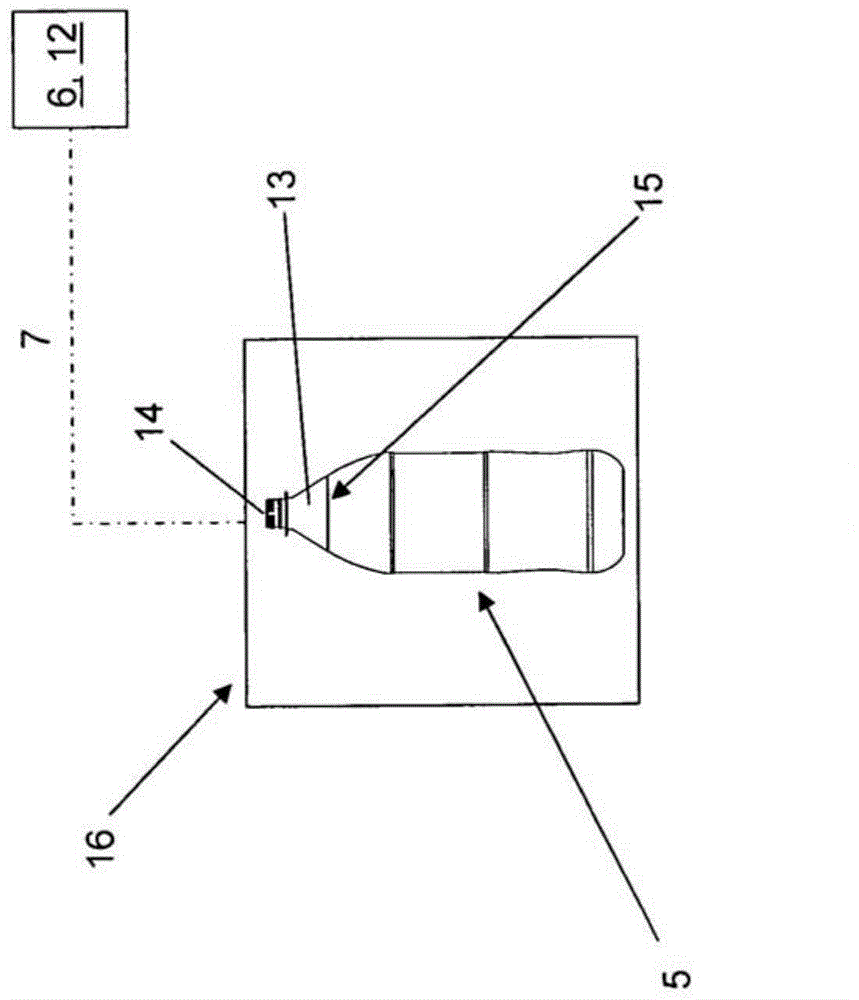

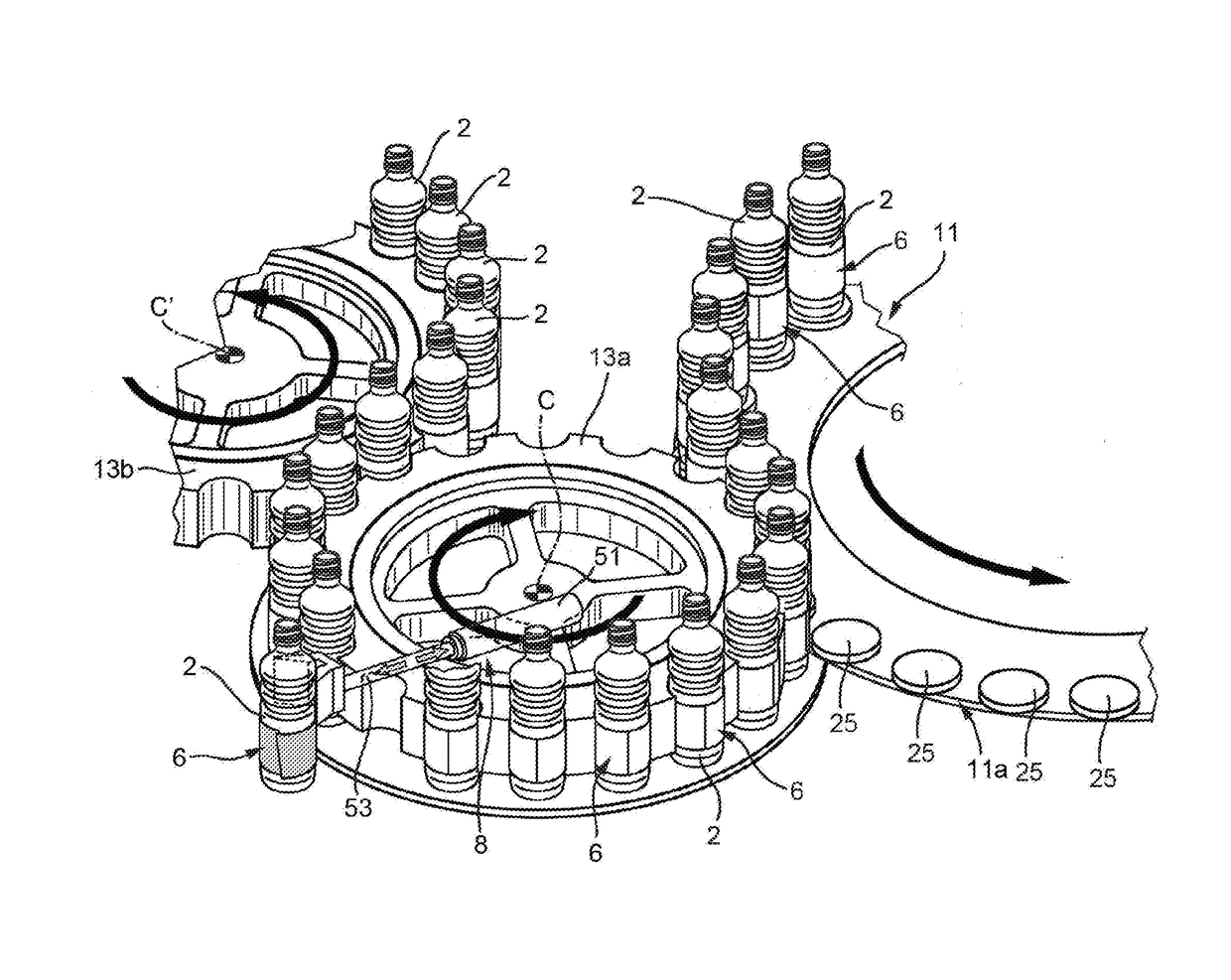

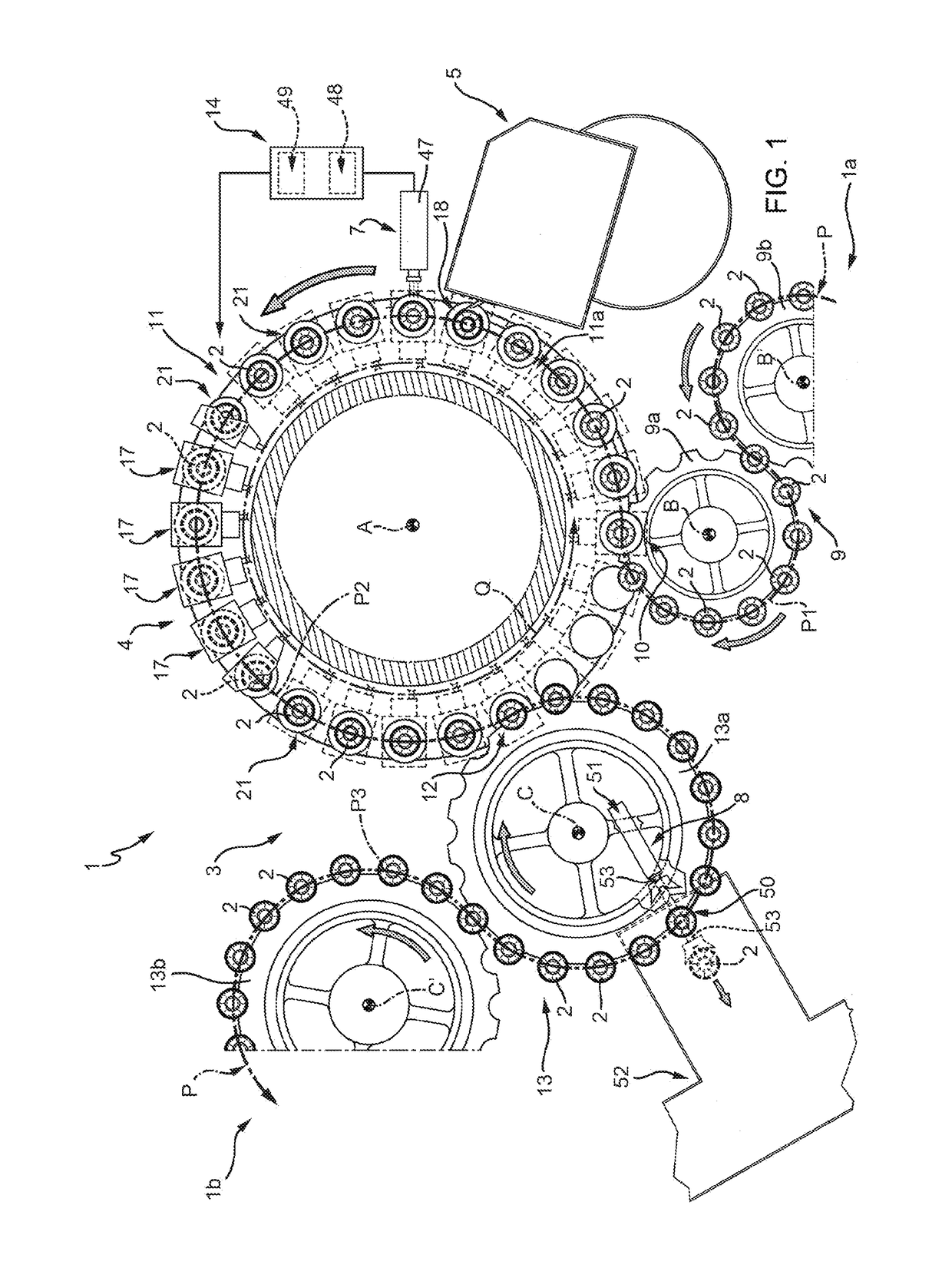

A filling apparatus and method including a carrier for transporting containers and having a plurality of valves, each of the valves being opened for an individual, specific period of time to control a flow of liquid into the respective containers, while the containers are transported by the carrier. An exit feed path transports the containers after the containers have been filled, and a sensor, such as a camera, detects a level of liquid in the respective containers, while the containers are on the exit feed path. The sensor produces a signal that is stored as data representing the level of liquid for the individual containers. The data is then tracked and used for valve optimization. A period of time that each individual valve is opened for subsequent fillings is adjusted based on the signal and the historical performance of each valve.

Owner:SIDEL PARTICIPATIONS SAS +1

Method and device for monitoring moving objects

InactiveUS20120256096A1Simple and cost-efficient to realizeHighly reliable monitoringInvestigating moving fluids/granular solidsOptical detectionLight beamClassical mechanics

A method and a device for monitoring objects moving along a trajectory. The objects include a section that is transparent or translucent. The objects subsequently cross a light beam at the section. The presence or absence of an object is determined during a transitional time period during which substantially no light or light within a wavelength range substantially untransmittable through the section is detected. A monitoring device generates an output signal based on the light detection indicating the presence or absence of an object.

Owner:OPTOSYS SA

Beverage bottling plant for filling beverage bottles having a bottle handling station and a method of operation thereof

A beverage bottling plant for filling beverage bottles having a bottle handling station and a method of operation thereof. The bottle handling station has an inspection station for inspecting bottles for observable contaminants that have been rinsed off of the interior of the bottles using an amount of liquid introduced into the bottles by a liquid dispenser, and then gathered in the amount of liquid in a bottom area of the bottles.

Owner:KHS GMBH

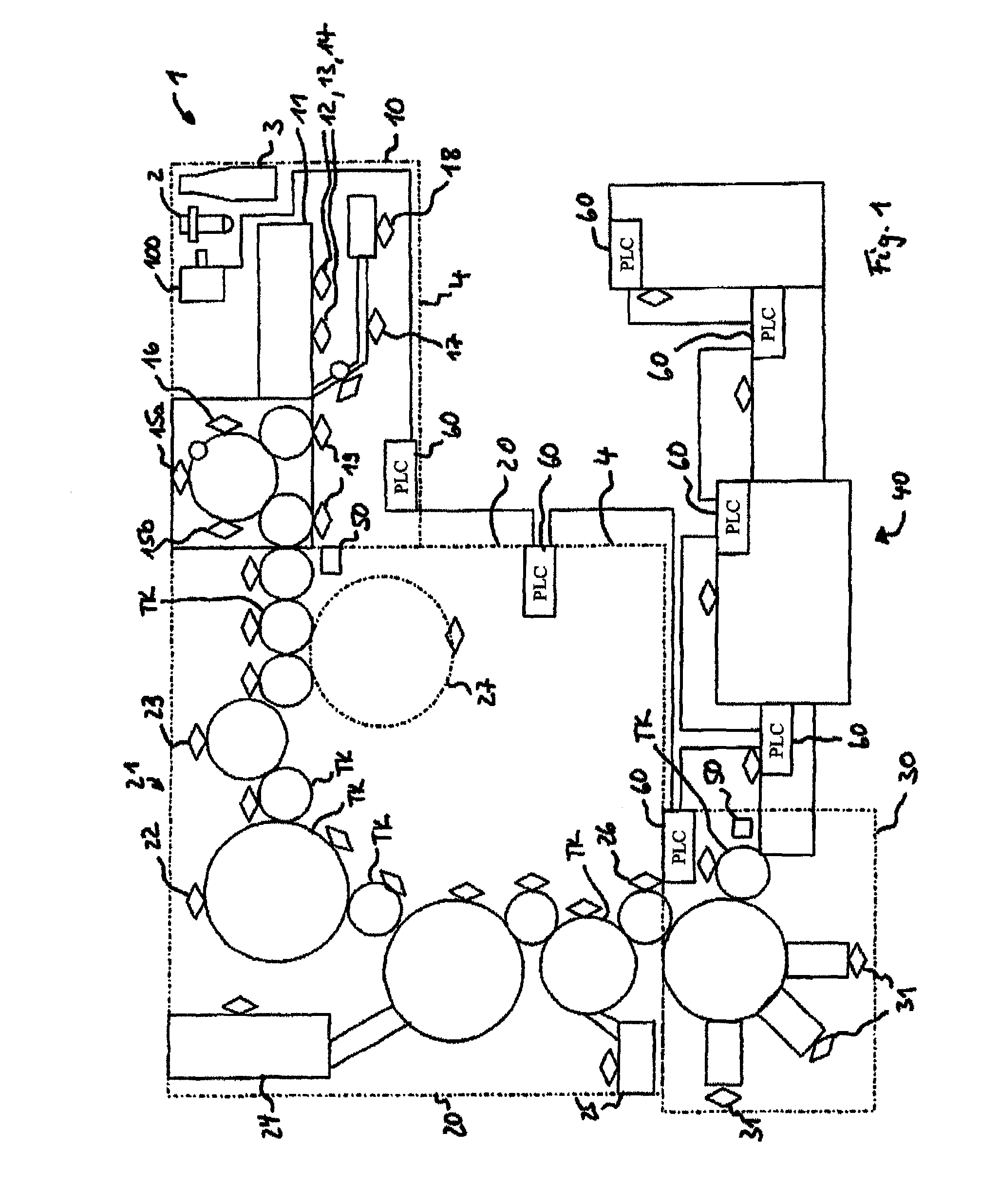

Method for the monitoring, control and optimization of filling equipment for foods and beverages, such as, for beverage bottles

ActiveUS20100082149A1Reduce in quantityImprove reliabilityLevel controlCapping machinery safety/controlTrademarkEngineering

A method for the monitoring, control and optimization of filling equipment for foods and beverages, such as, for beverage bottles. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

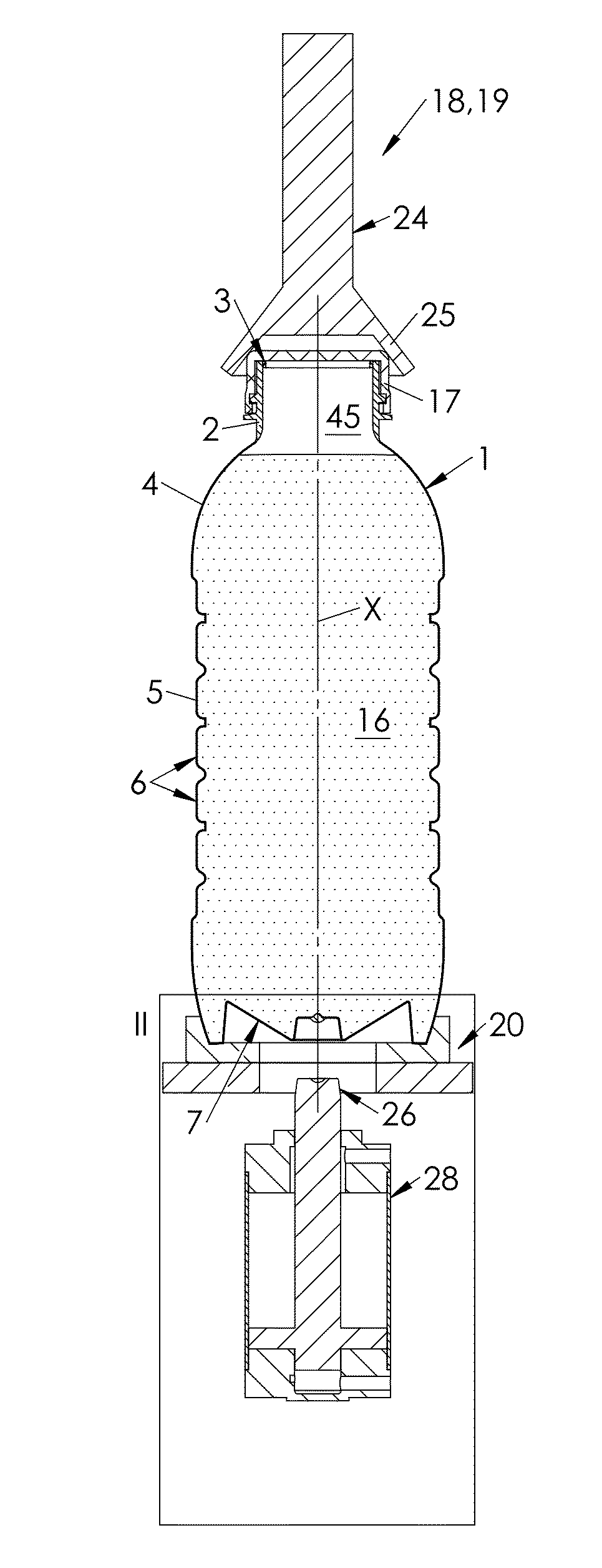

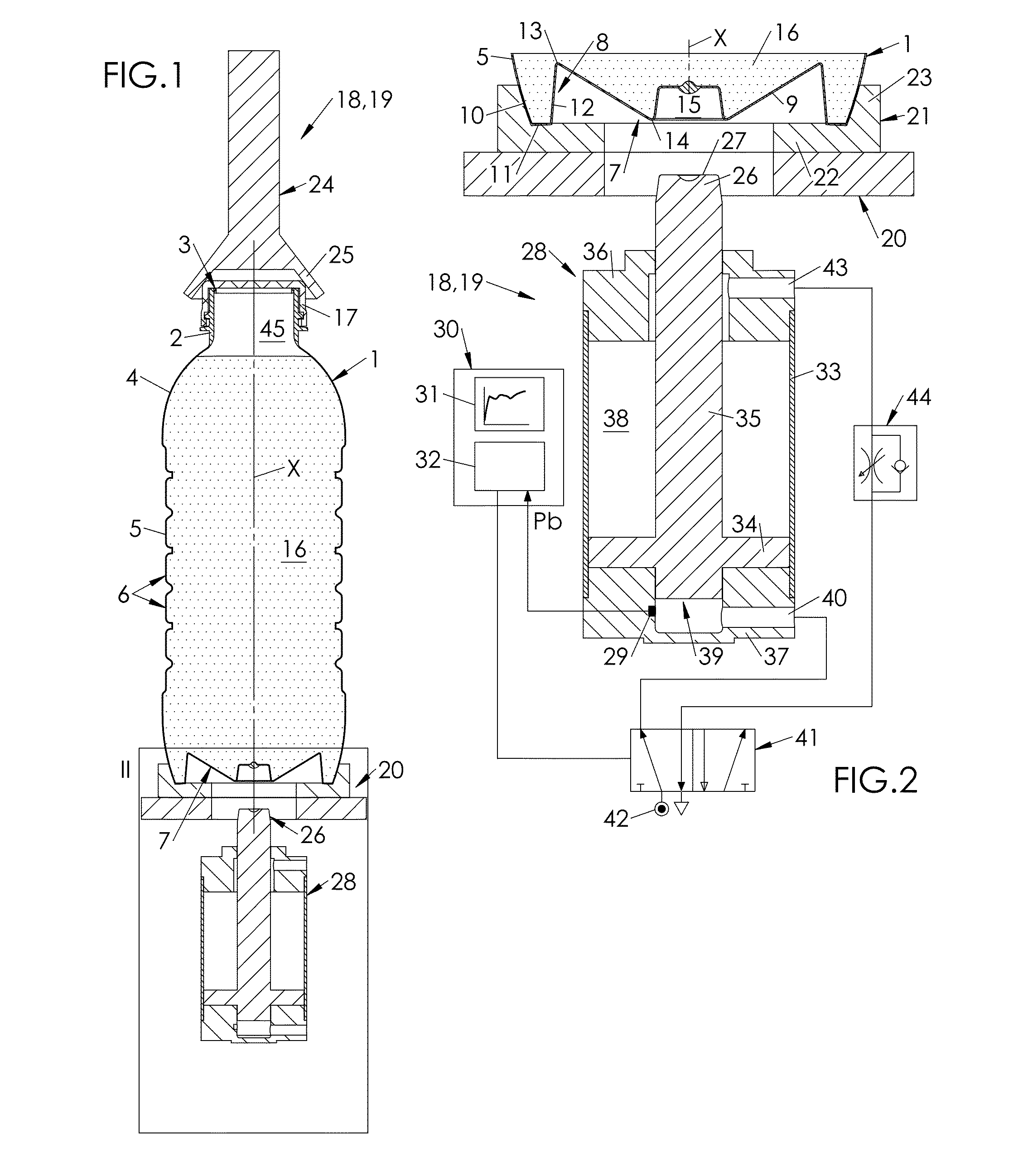

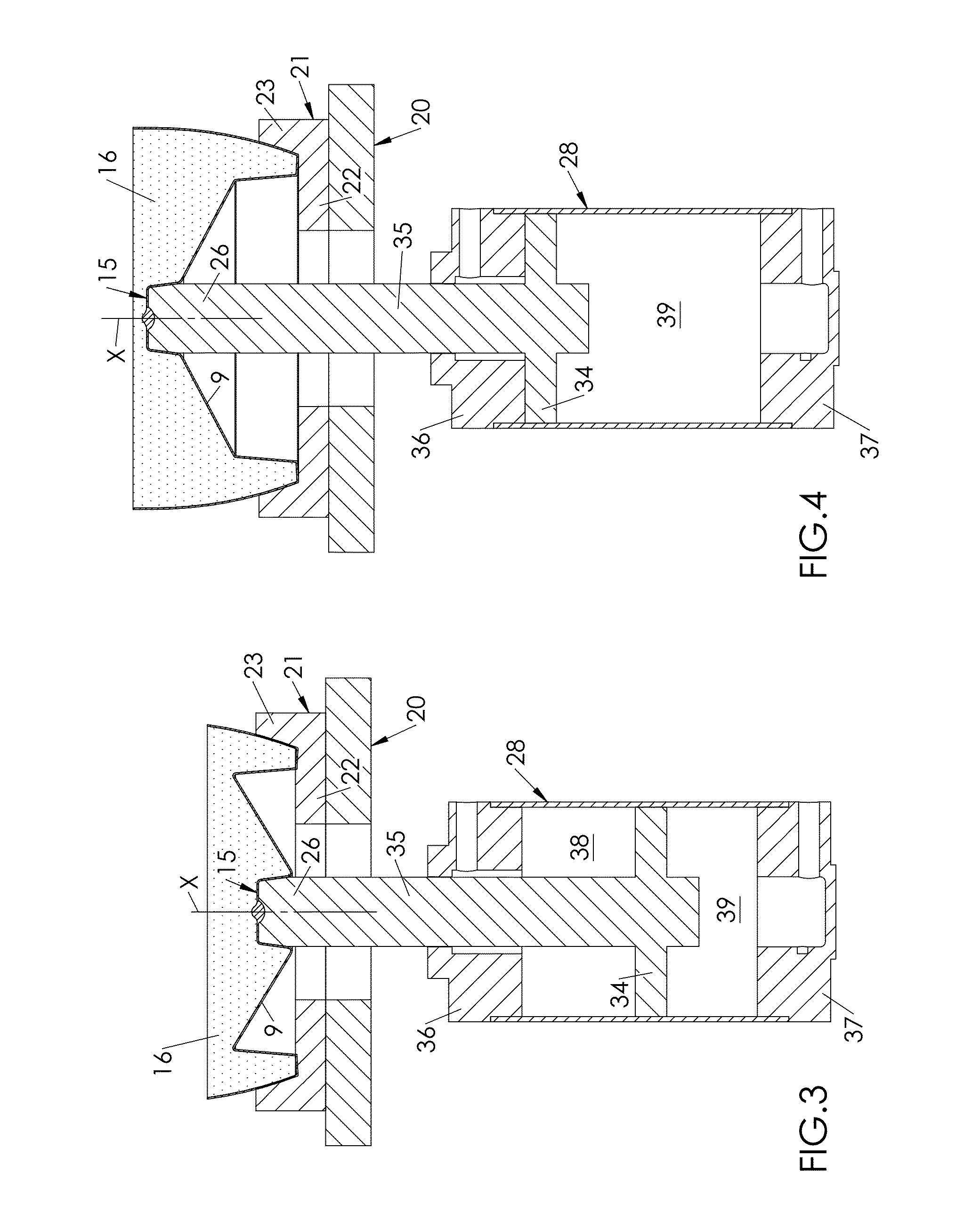

Machine and method for processing filled containers having an invertible diaphragm

Machine (18, 19) for processing containers (1) including a base (7) having a high standing ring (8) and a central invertible diaphragm (9), the machine (18, 19) including:a container supporting frame (20) including a hollow support ring (21) for engaging a container base (7),a pusher (26) movable with respect of the container supporting frame (20), capable of coming into abutment with the container base (7) through the supporting frame (20),an actuator (28) for slidingly moving the pusher (26) frontwards towards the container base (7) through the supporting frame (20), and backwards,a strain gauge (29) coupled to the actuator (28) for gauging a strain applied by the actuator (28) to the pusher (26),a control unit (30) including a processor (32) connected to the strain gauge (29) and programmed for comparing a gauged strain value to a memorized strain reference value.

Owner:SIDEL PARTICIPATIONS SAS

Method of filling bottles or similar containers in a bottle or container filling plant and a filling system for filling bottles or similar containers in a bottle or container filling plant

InactiveUS20100192521A1Increase diameter of rotorIncrease the number ofSafety device in filling machinerySolid materialTrademarkEngineering

A method of filling bottles or similar containers in a bottle or container filling plant and a filling system for filling bottles or similar containers in a bottle or container filling plant. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

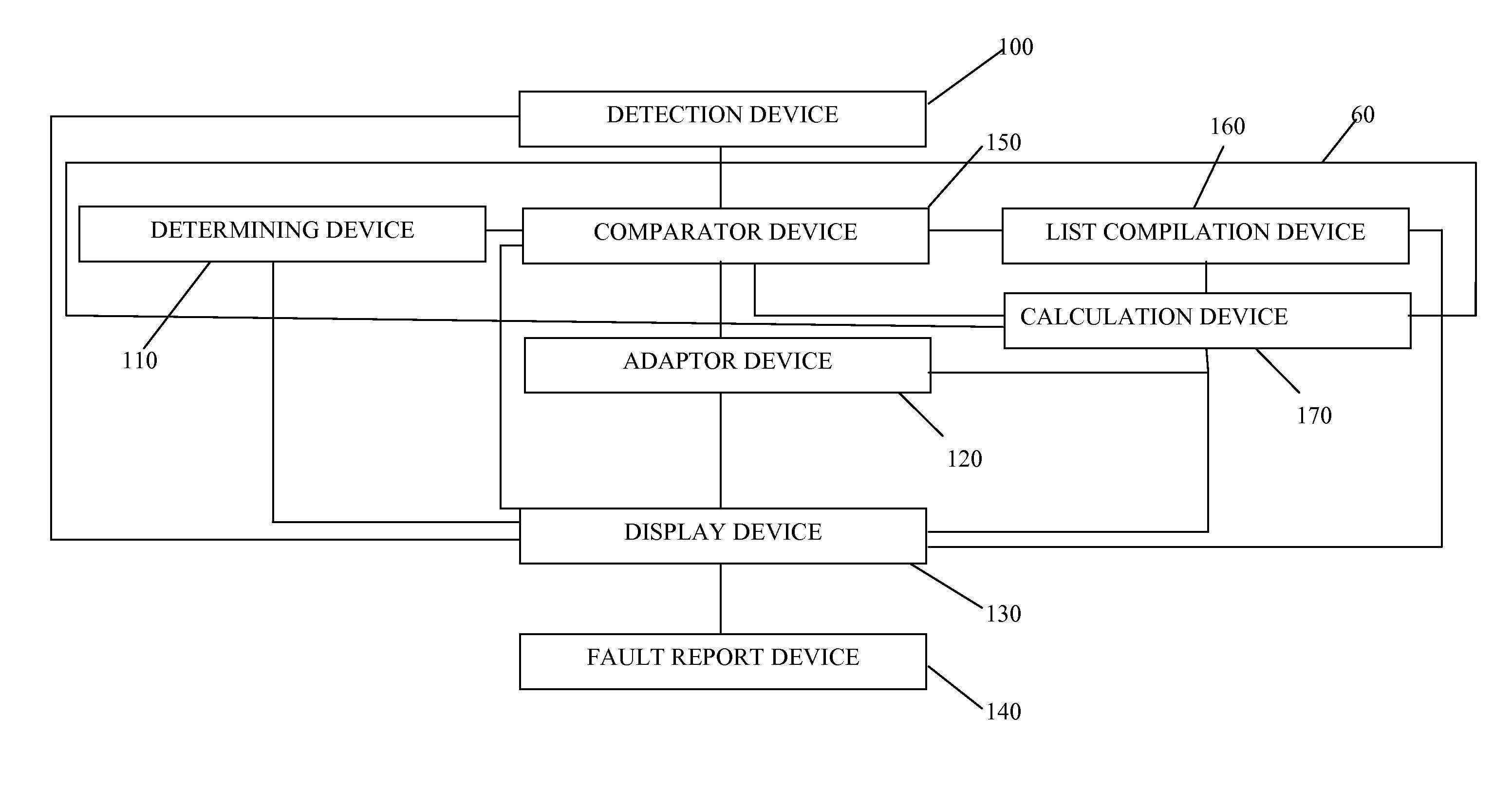

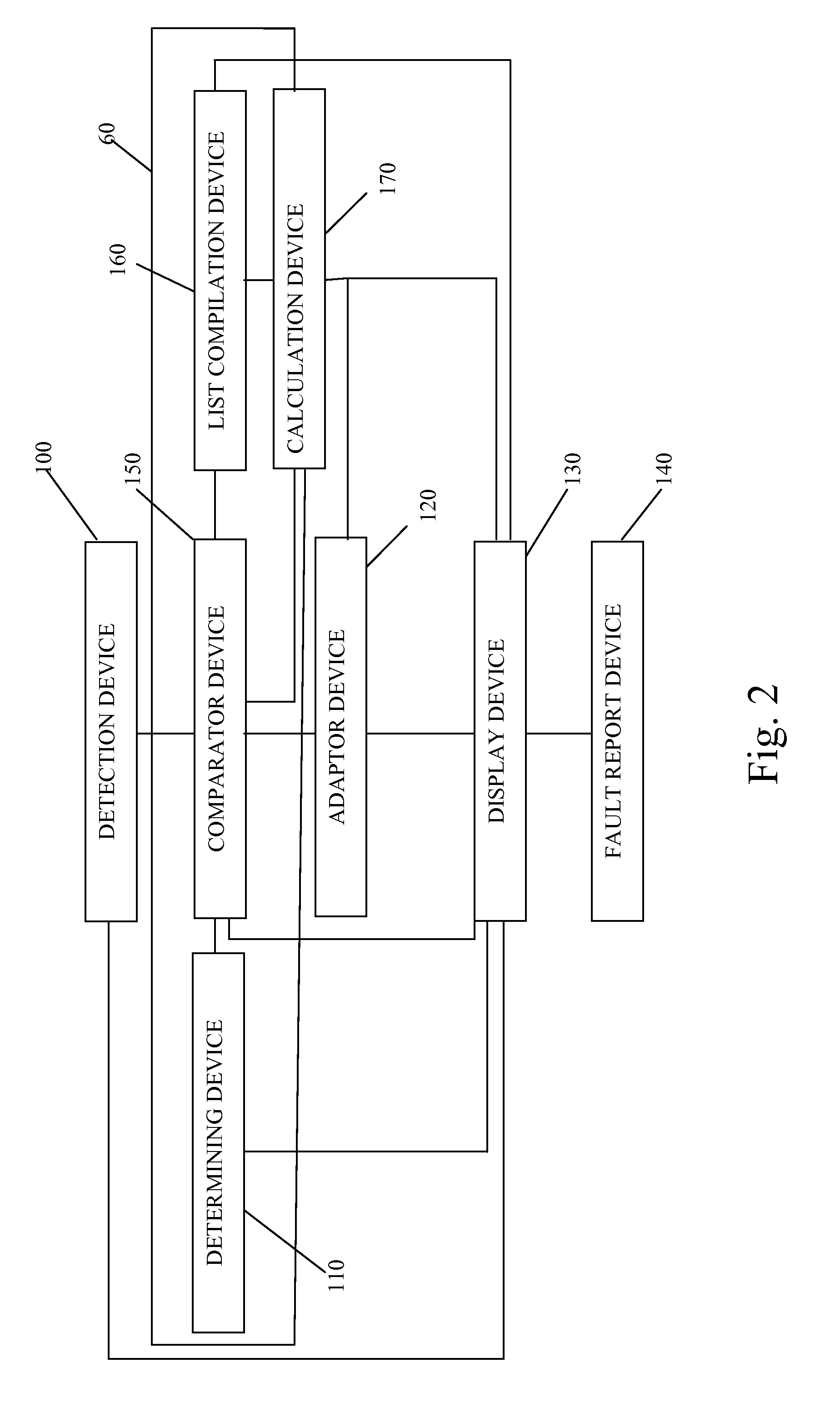

Container treatment plant and method for the treatment of containers

ActiveUS8505268B2Not impedeCapping machinery safety/controlSafety device in filling machineryEnvironmental engineeringComparator

A container treatment plant and a method for the treatment of containers are described. The container treatment plant includes a plurality of treatment elements, wherein each treatment element is used for a pre-determined treatment of the containers and each treatment element has associated therewith a container nominal value which indicates which type of container the treatment element can treat, a detection device for detecting properties of one of the containers to be treated, and a comparator device for comparing a detection result of the detection device with the container nominal value for at least one treatment element.

Owner:KRONES AG

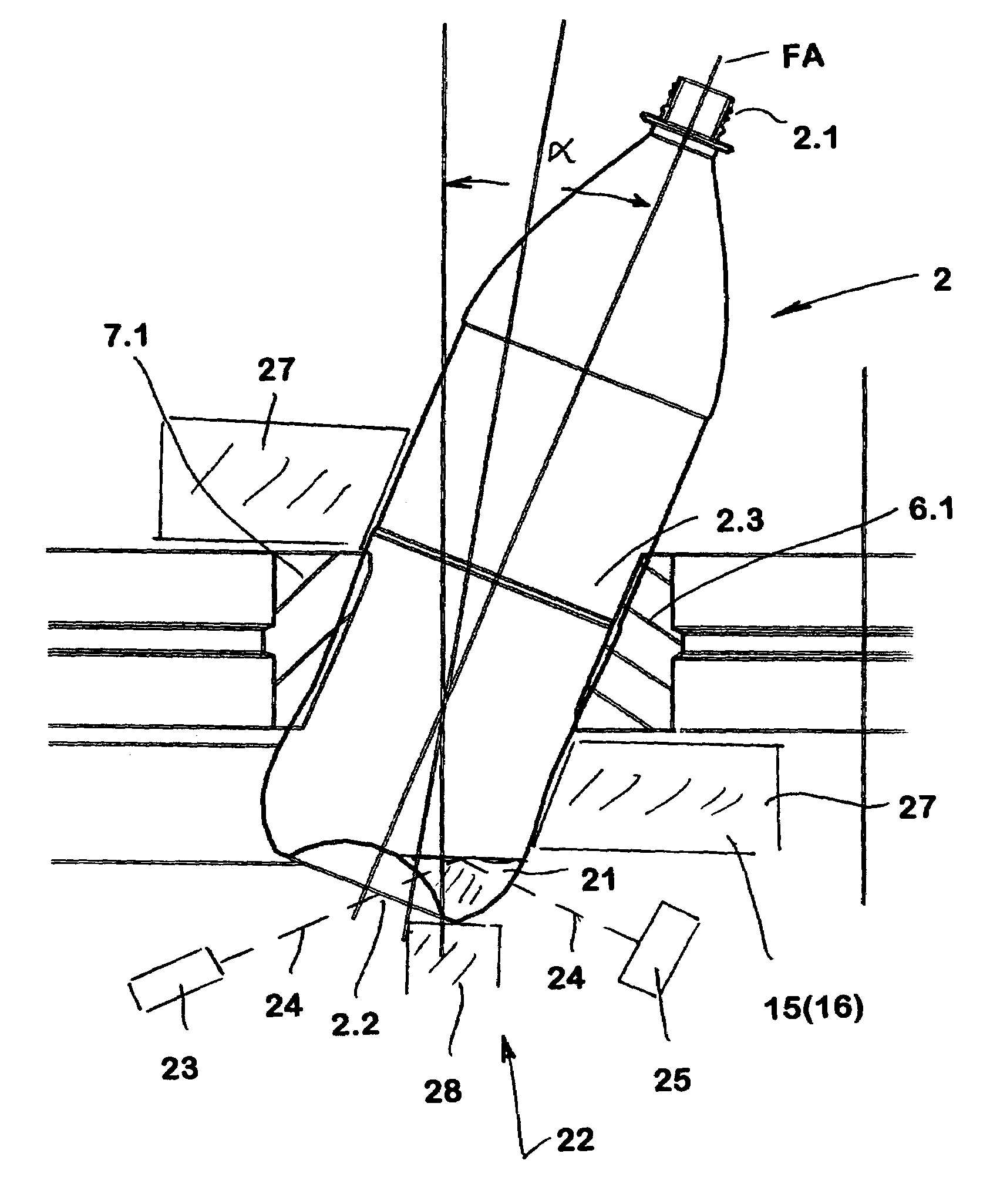

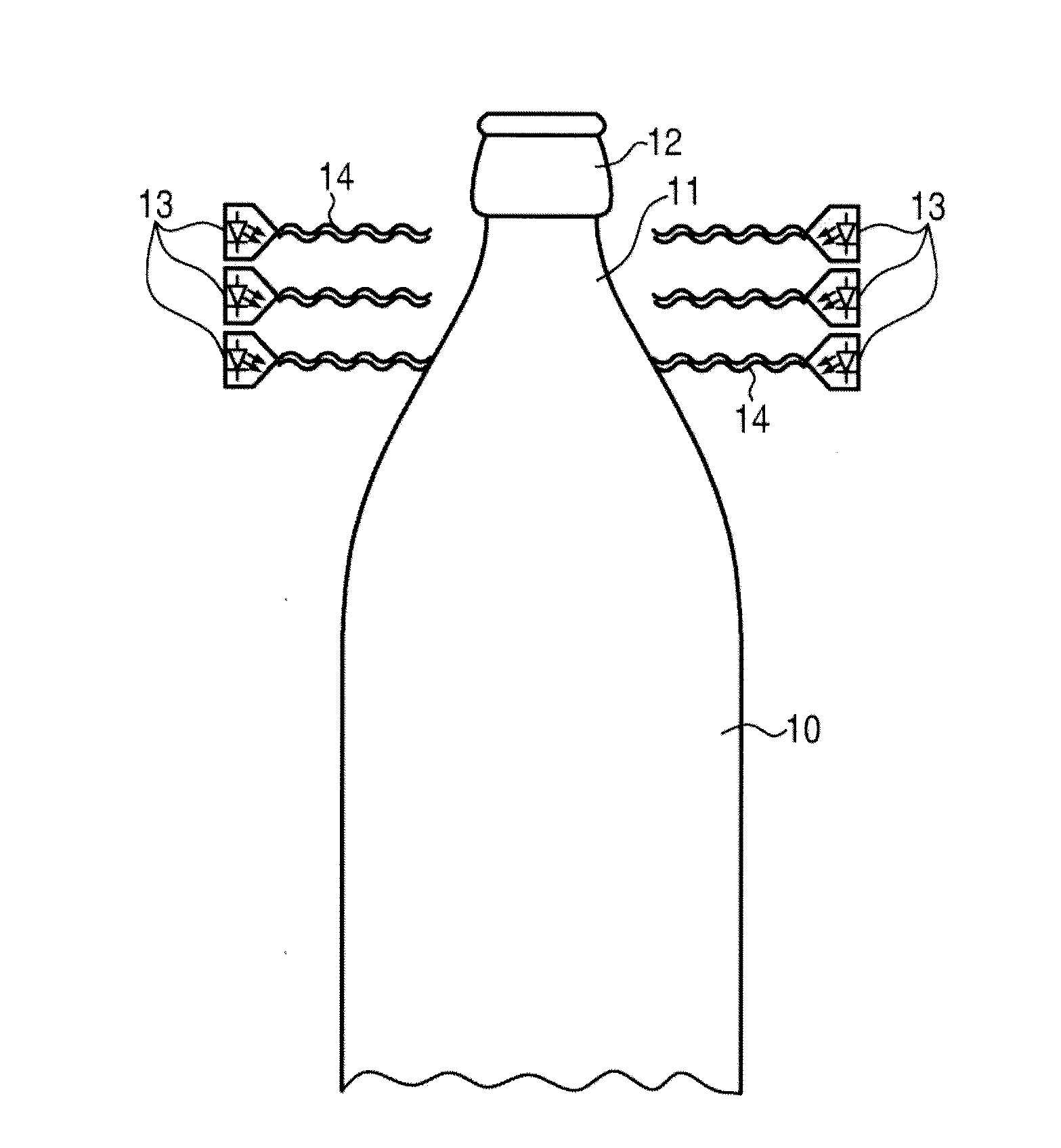

Method and apparatus for measuring fill level in bottles

InactiveUS20030052288A1Prevent oxidationSolving precise measurementsInvestigating moving fluids/granular solidsScattering properties measurementsLight beamBottle neck

Method and apparatus for measuring the liquid fill level in bottles while the bottles are still within the turret section of the filler system. A source of focused light, such as that generated by a laser, is directed onto a series of targets positioned on the turret behind the bottles. The beam is directed back through the bottle neck and detected by a remote camera. The detected image varies depending upon whether the bottle was underfi

Owner:INDAL DYNAMICS

Beverage bottling plant for filling beverage bottles having a bottle handling station and a method of operation thereof

A beverage bottling plant for filling beverage bottles having a bottle handling station and a method of operation thereof. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

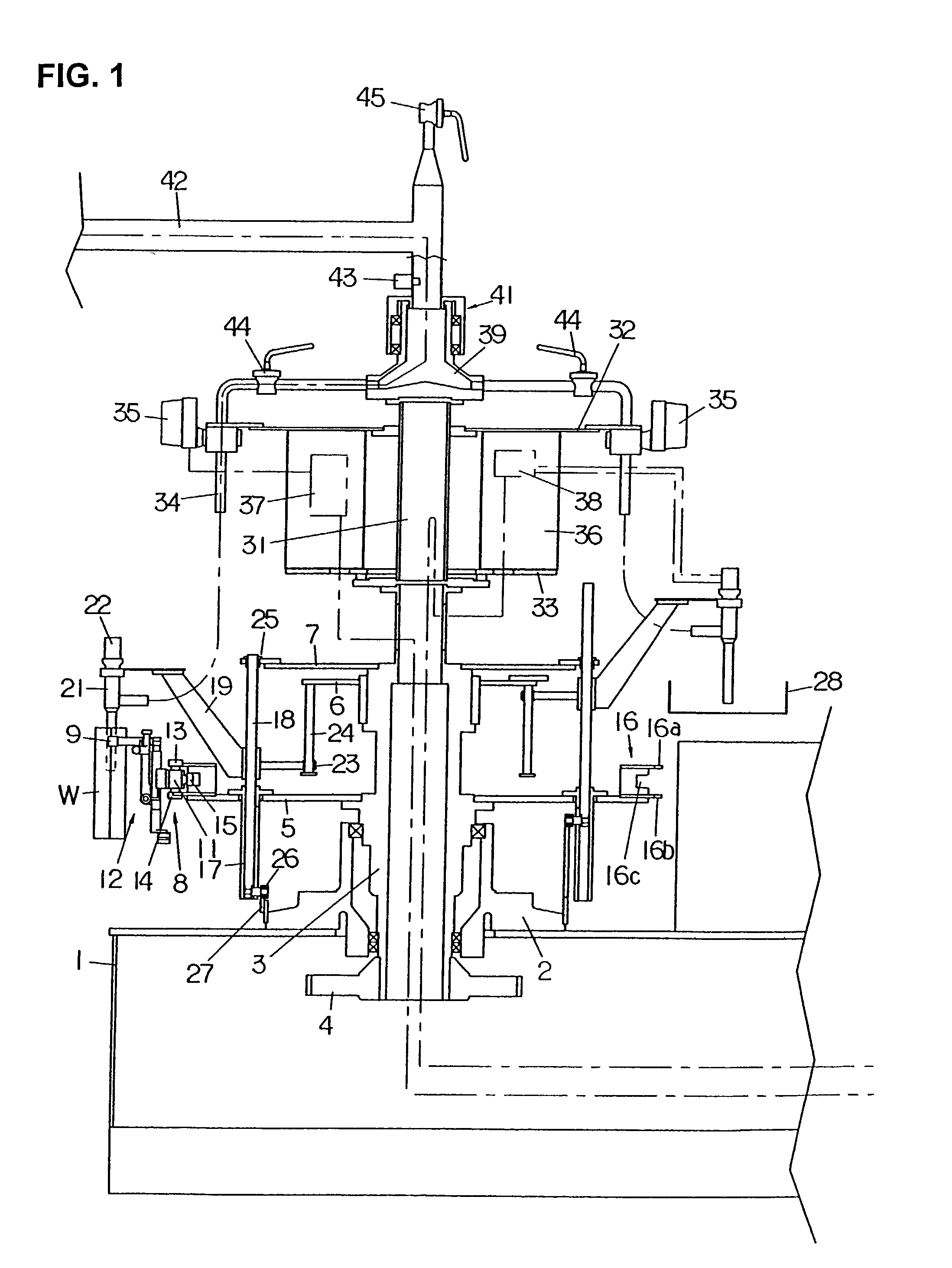

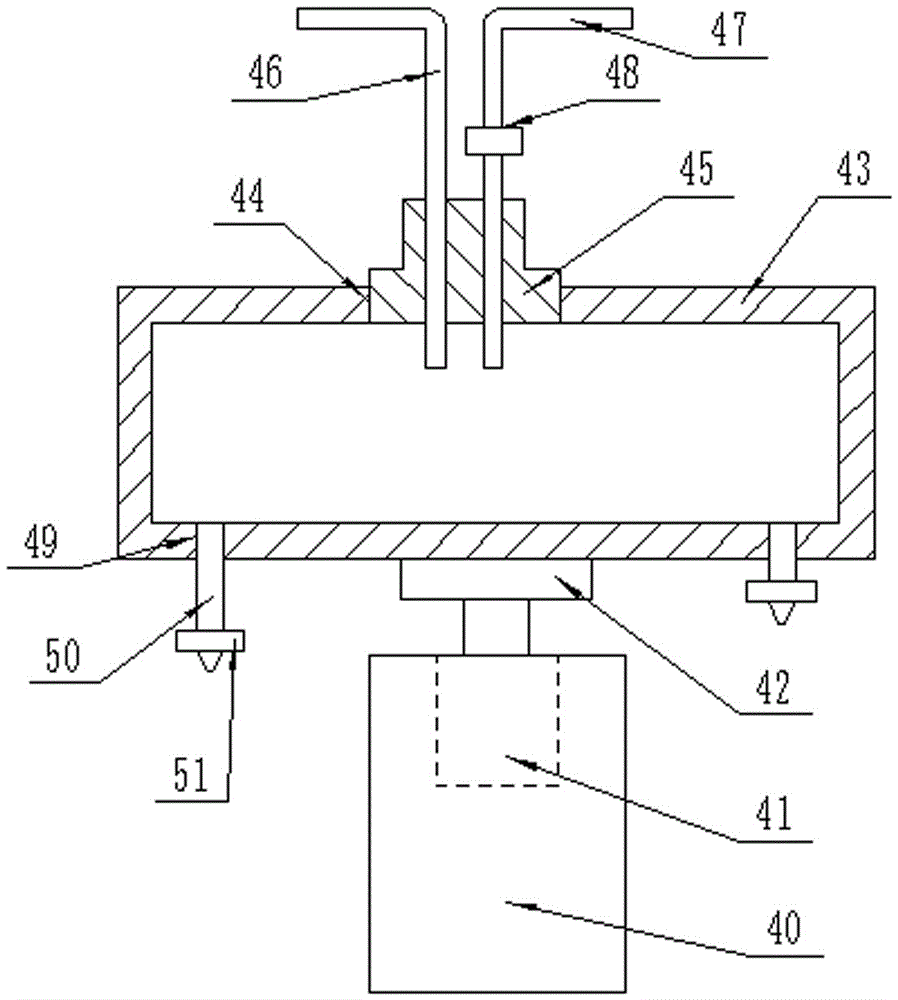

Flow meter type liquid filling apparatus

InactiveUS20030010398A1A large amountEasy to controlLiquid fillingSafety device in filling machineryAtmospheric airLiquid tank

A rotary and flow meter type liquid filling apparatus including a liquid reservoir tank that stores and supplies liquid to filling nozzles, and air supply paths for different amount of air supply and air discharge paths for different amount of air discharge being connected to the liquid reservoir tank. An air compressor is connected to the air supply paths, and the air discharge paths open into the atmosphere. A liquid pressure sensor disposed near the filling nozzles sense the increase or decrease of the liquid pressure inside a pipe that connects the liquid reservoir tank and liquid filling nozzles, and the electromagnetic valves provided on the air supply and air discharge paths are opened or closed, thus supplying air to and discharging air from the liquid reservoir tank so as to control the air pressure inside the liquid reservoir tank and the liquid pressure near the liquid filling nozzles.

Owner:TOYO JIDOKI CO LTD

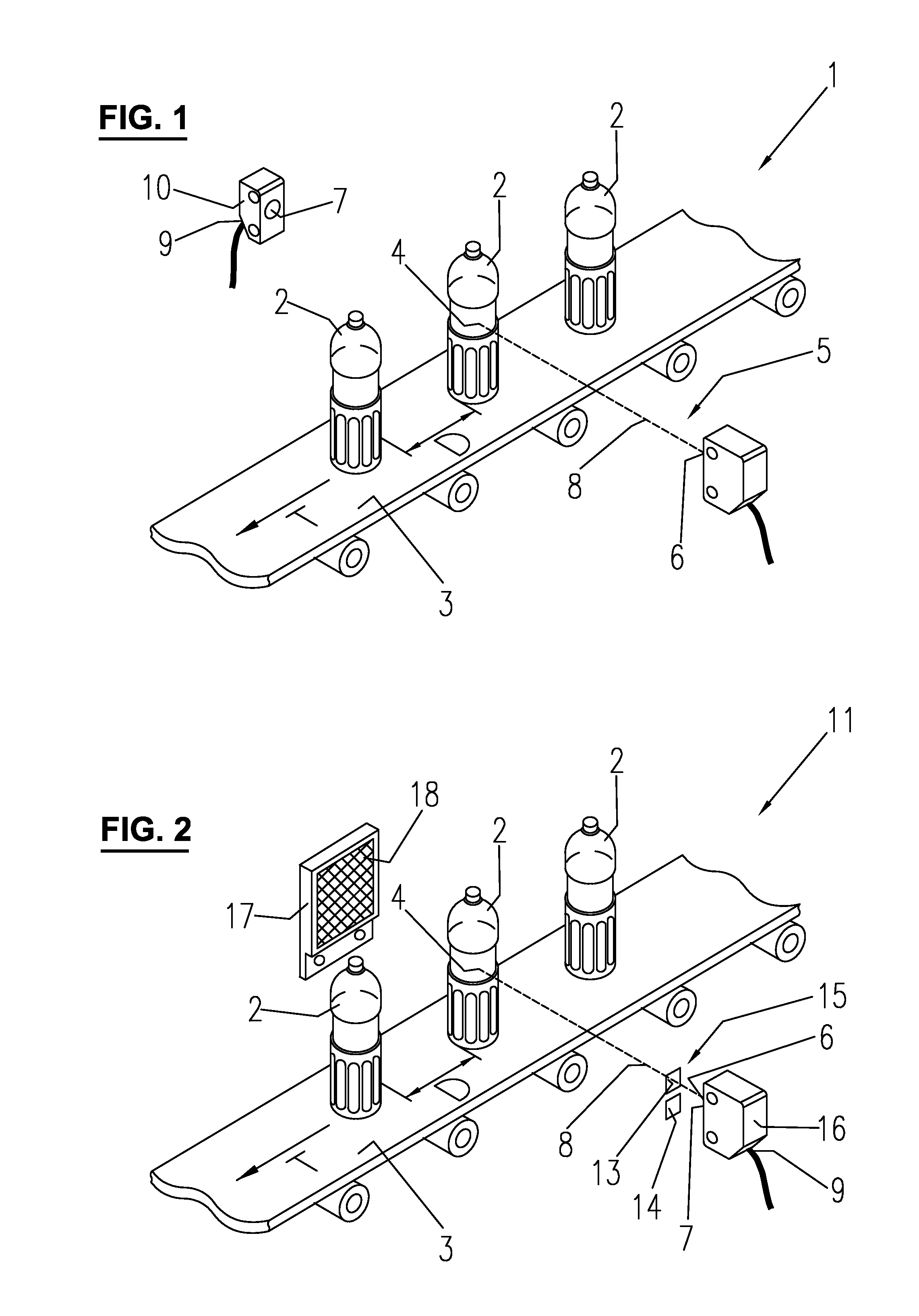

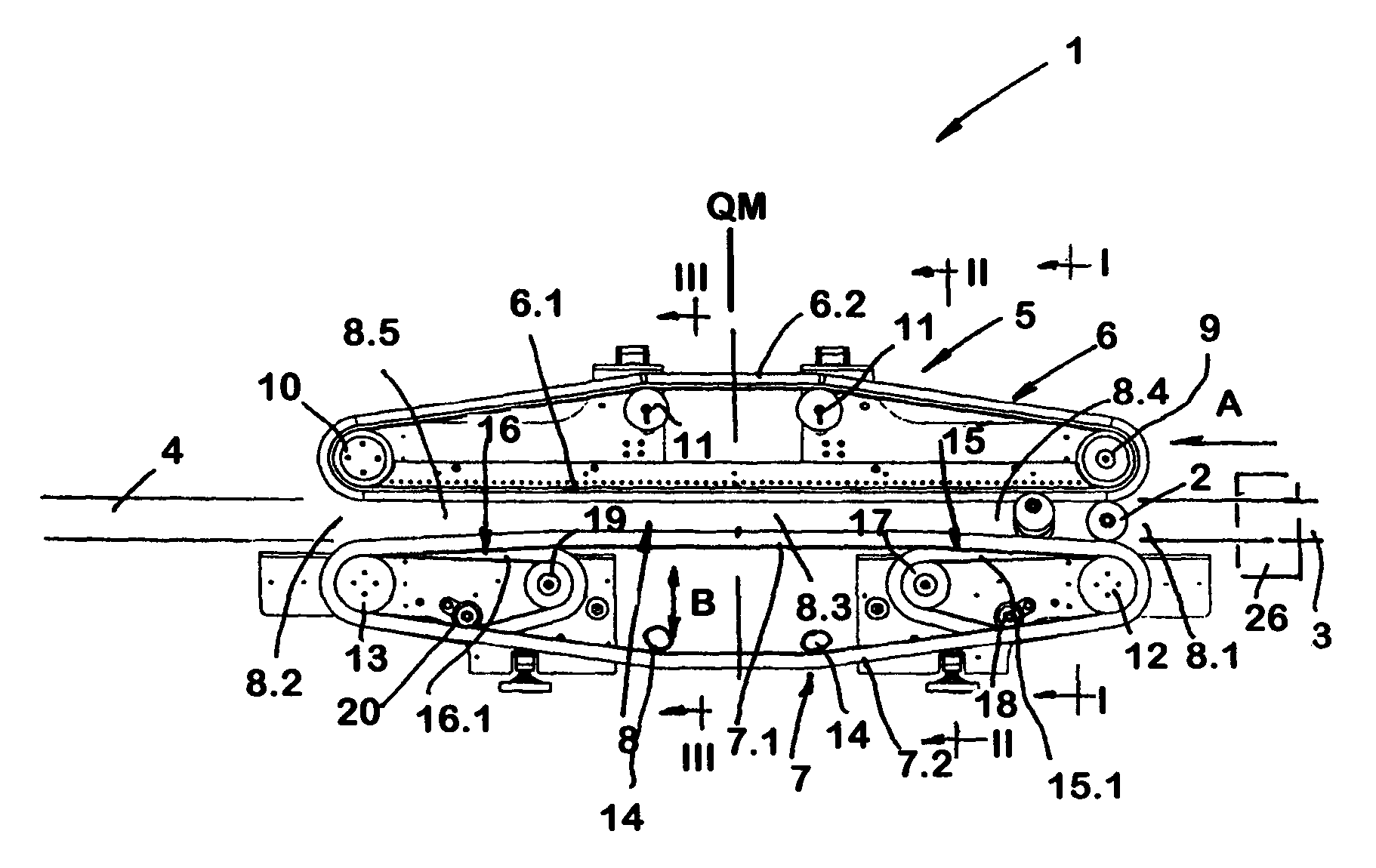

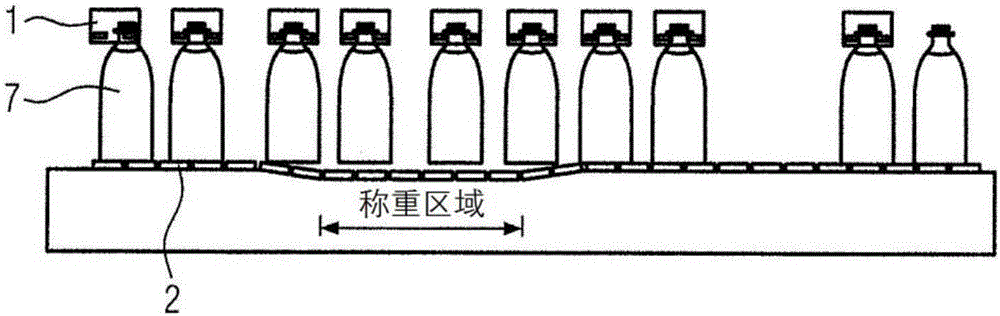

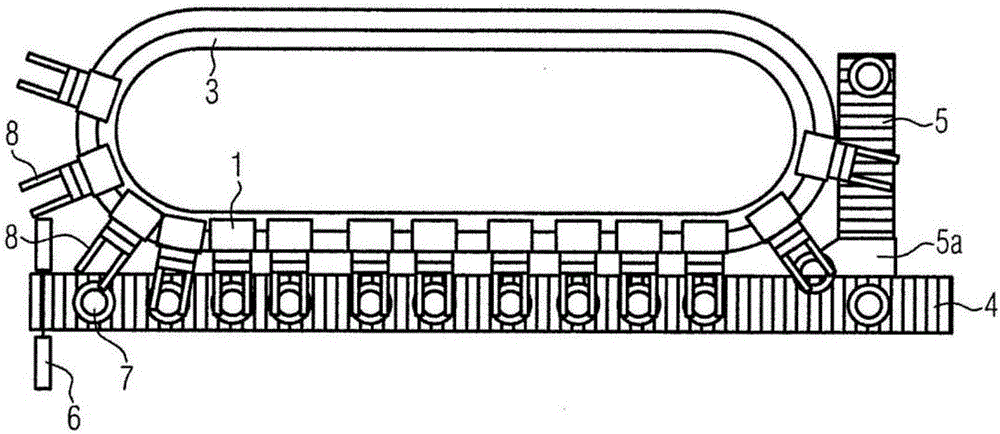

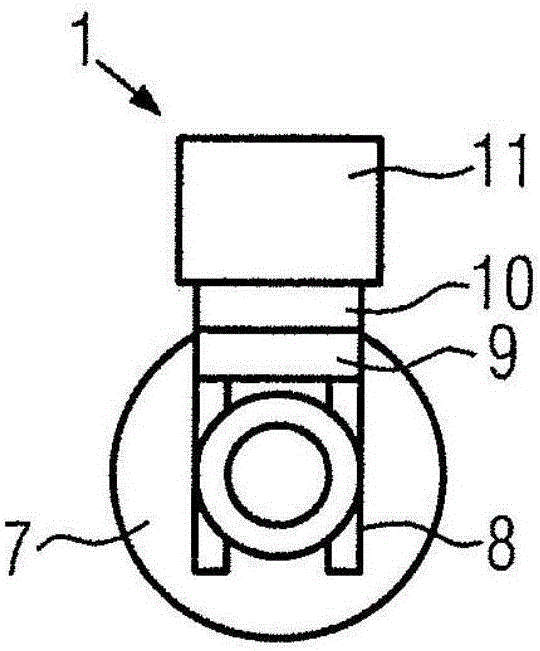

Method for monitoring a filled container, and monitoring system for filled containers

ActiveCN106163970AExecutive controlConveyorsControl devices for conveyorsMonitoring systemEngineering

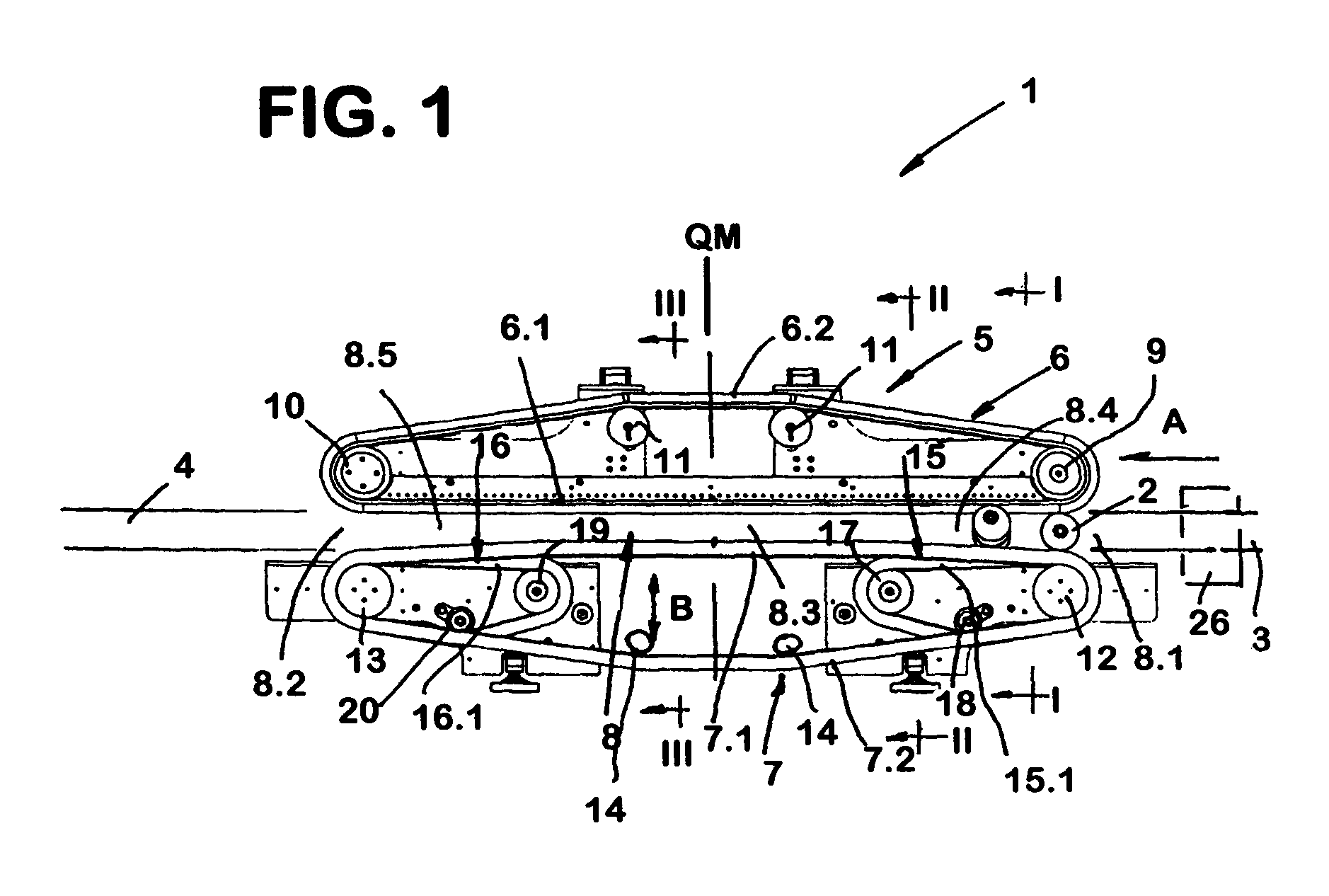

A method for monitoring a filled container (7), in particular a filled drinks container, which is conveyed on a conveyor (4), having the following steps: the container is accommodated on a carriage (1), a spacing is produced between the container and the conveyor, and therefore the entire weight of the container is retained by the carriage in a weighing region, and the retained container is weighed in the weighing region using a load cell of the carriage, the carriage being driven, during implementation of the method, by a linear motor, and a monitoring system for filled containers, in particular filled drinks containers, for implementing such a method.

Owner:KRONES AG

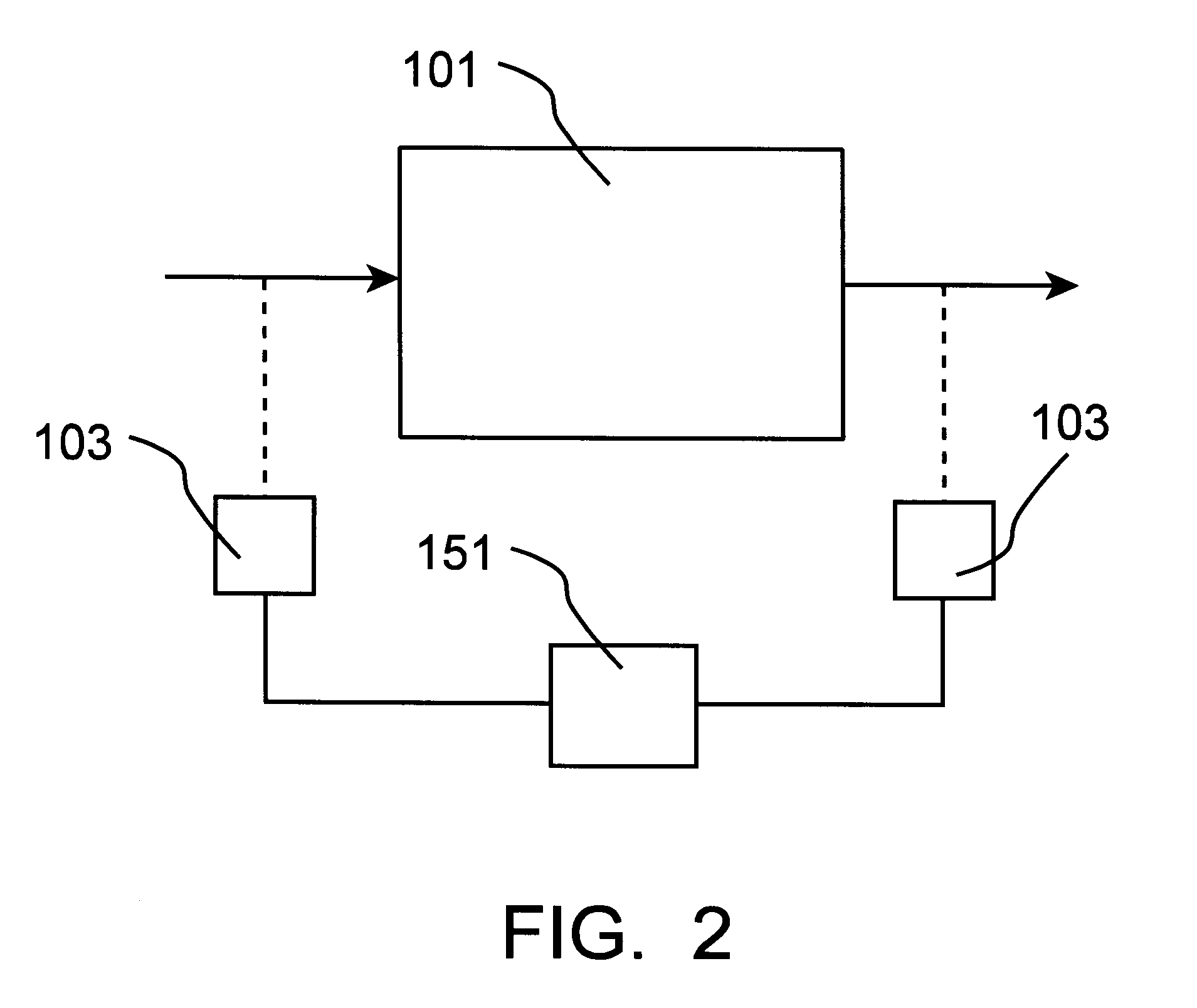

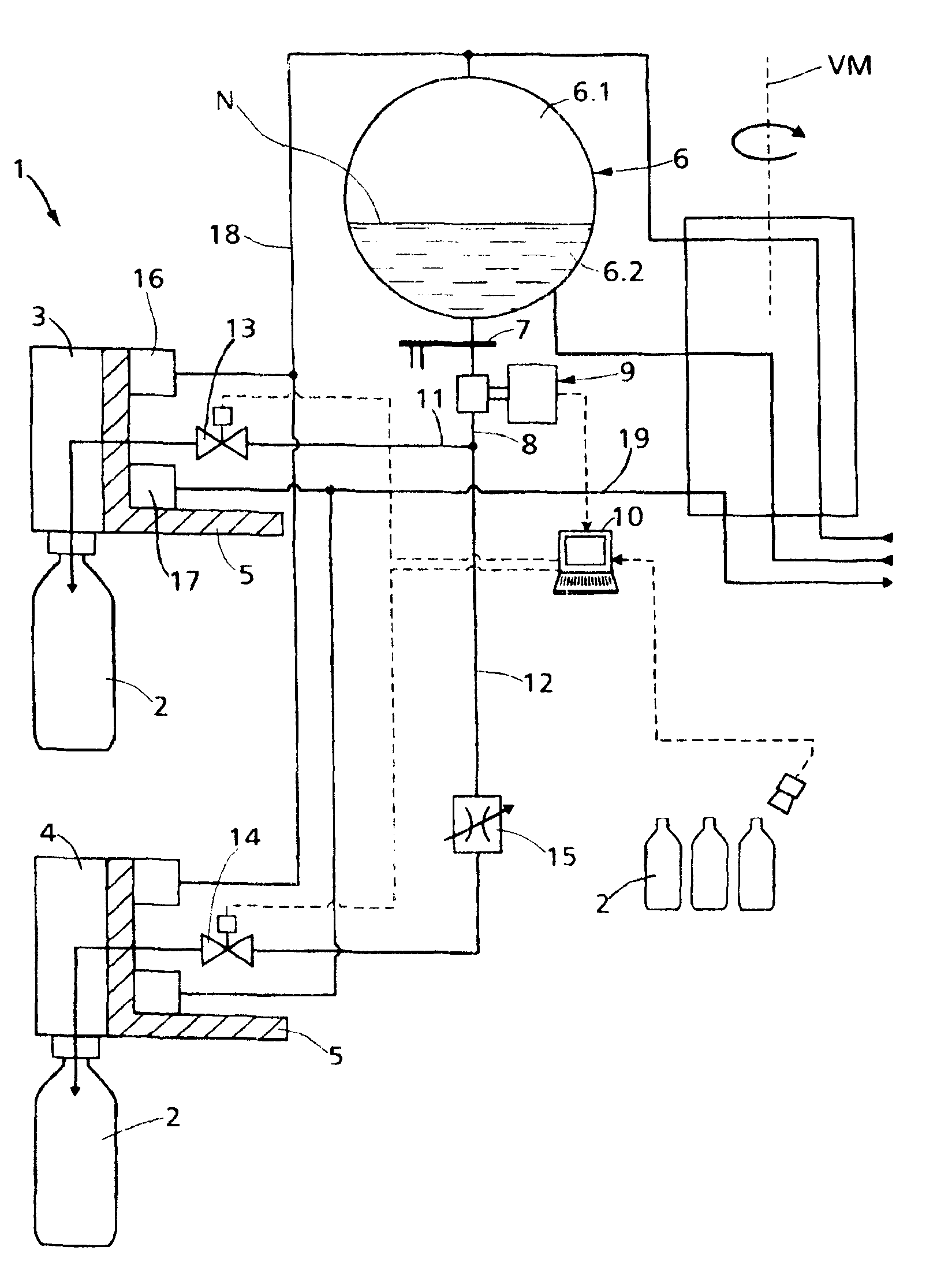

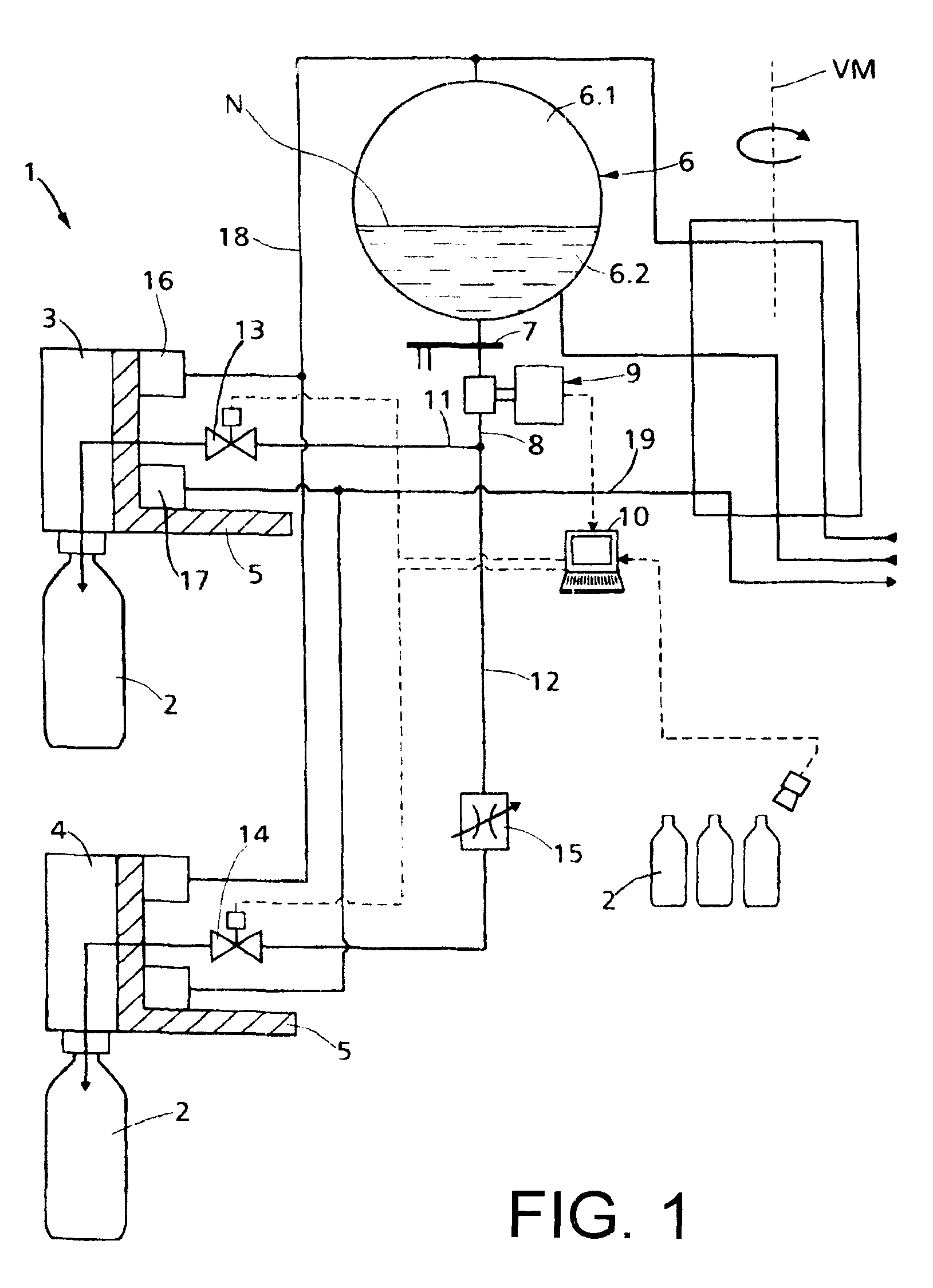

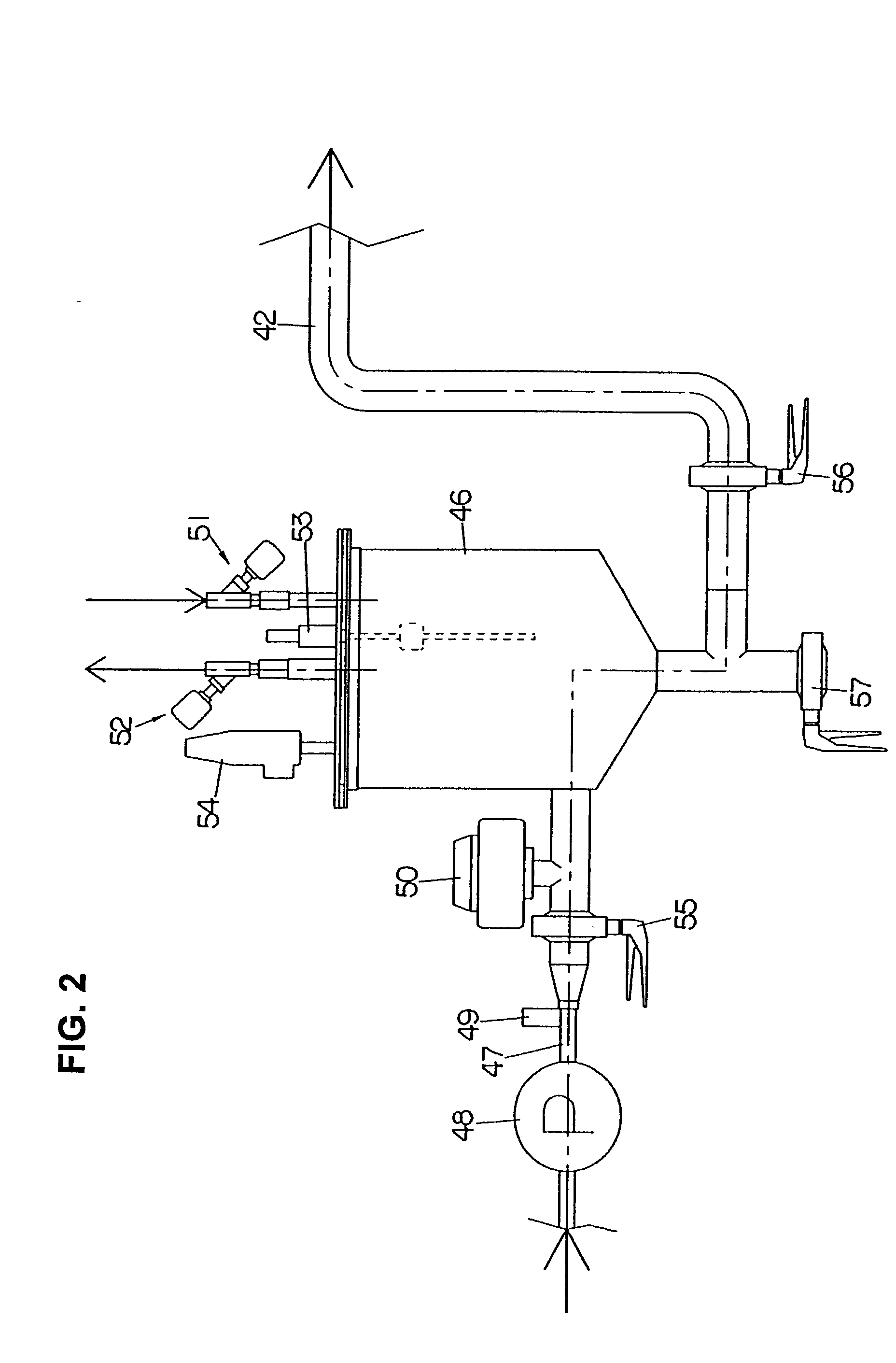

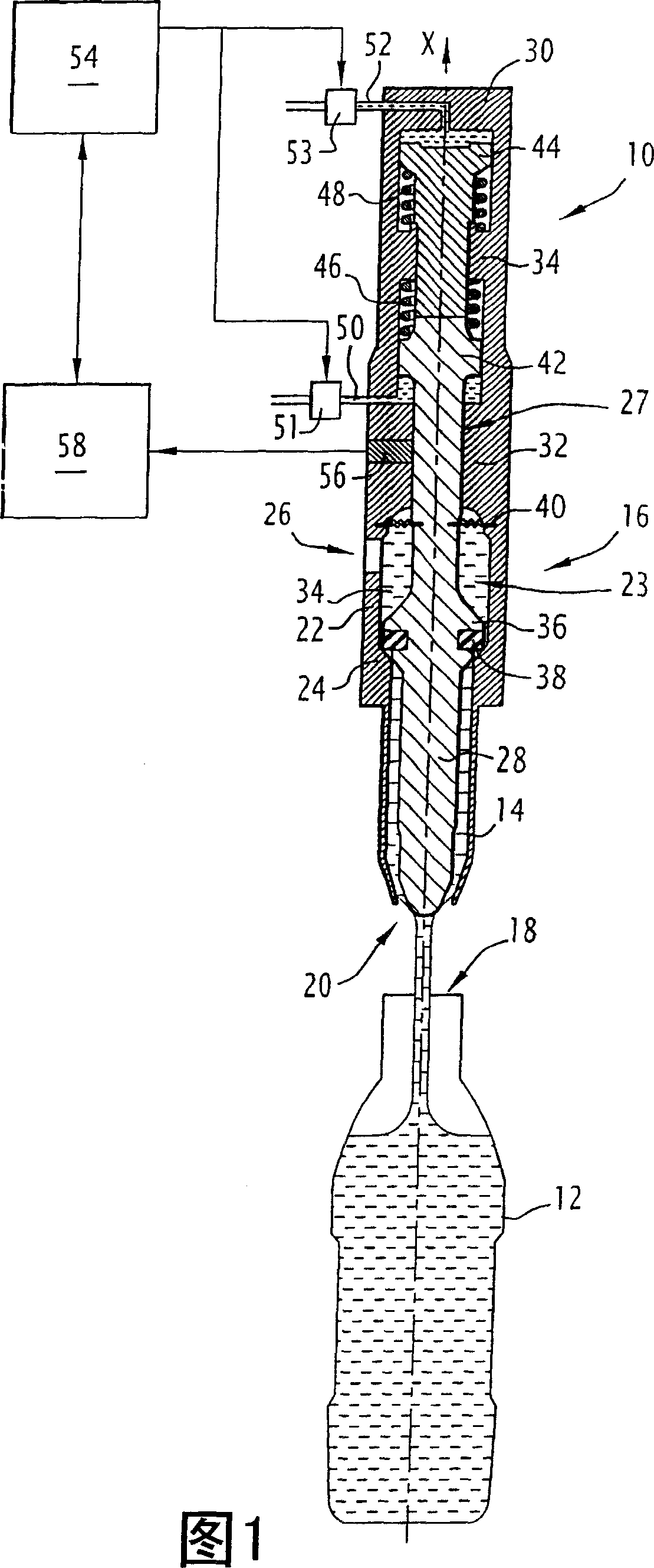

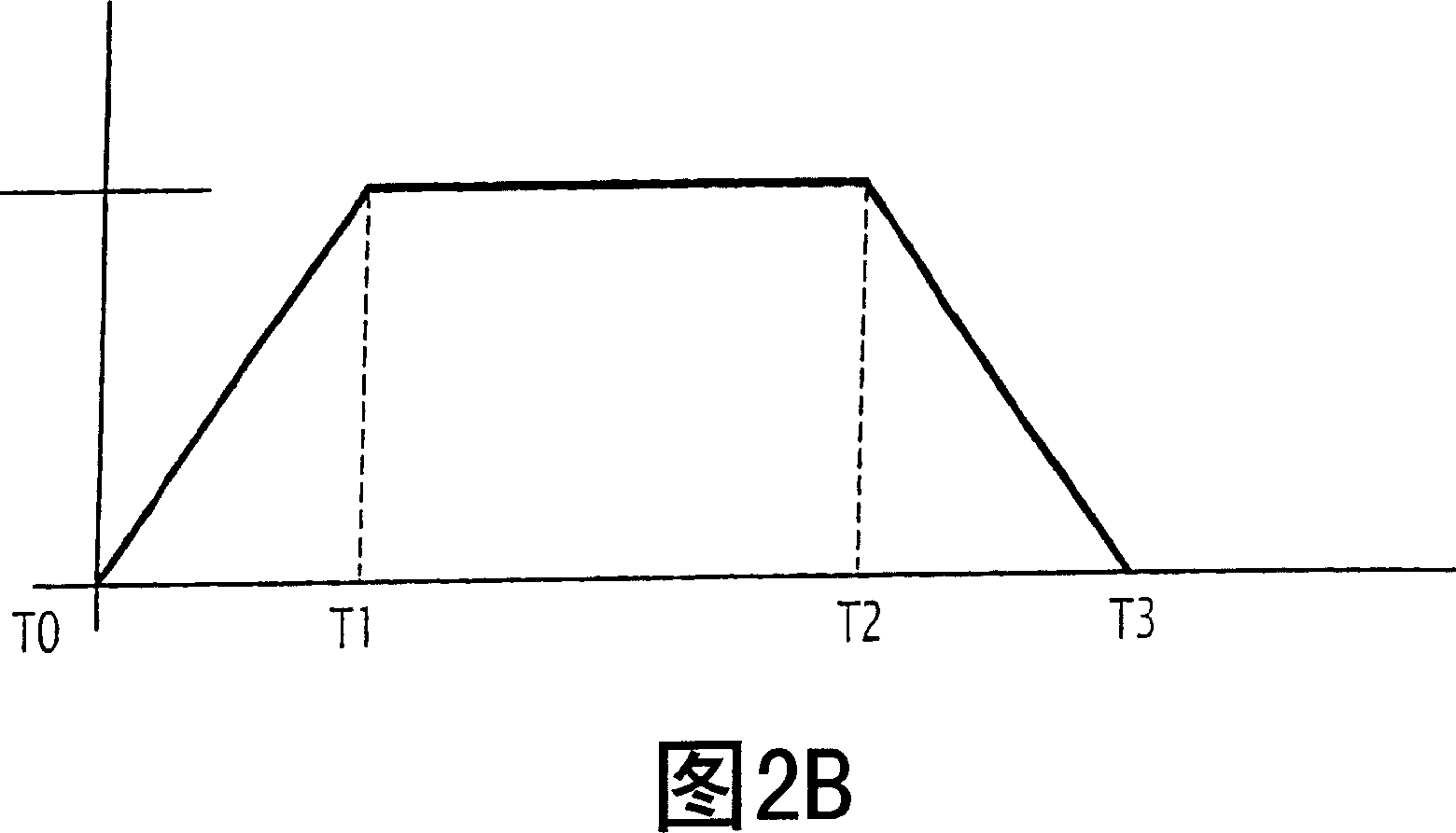

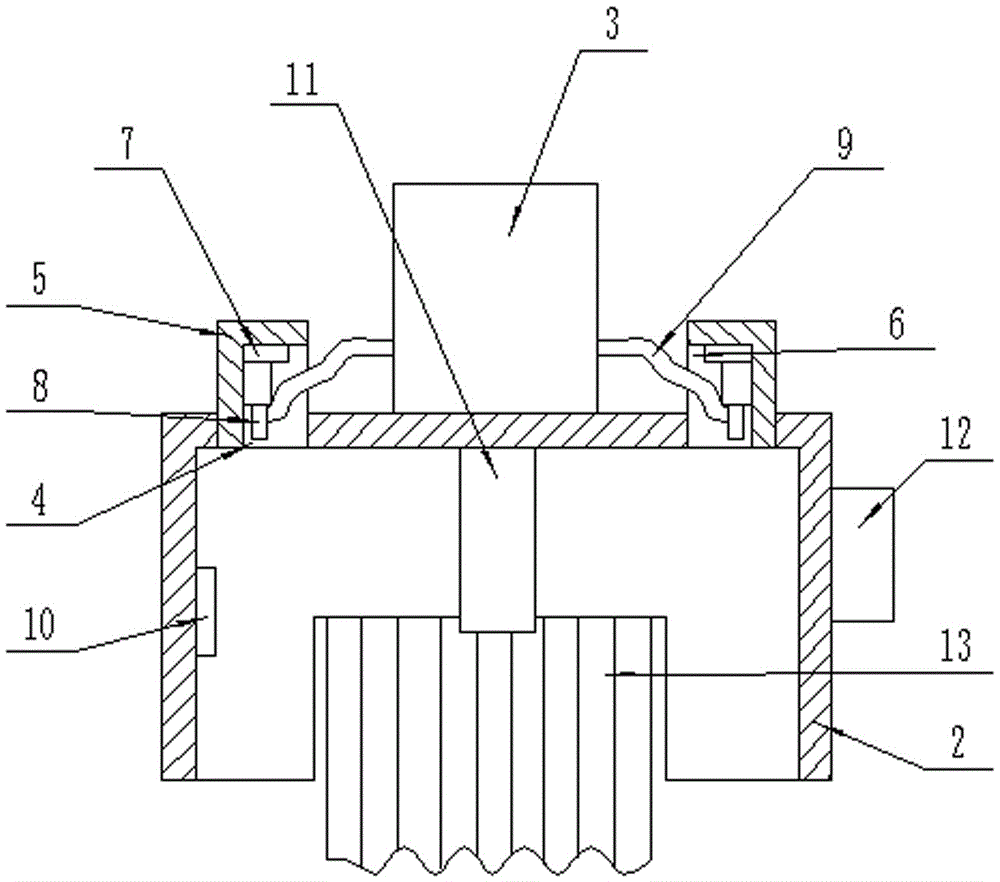

Method and device for filling a container with a predetermined quantity of fluid and related filling machine

The device comprises a nozzle (14) for delivering a fluid flow into the container (12), a valve (16) comprising a movable valve member (27) for controlling the fluid flow, a means (54) for sending a position control signal to the movable valve member (27), such that said movable valve member (28) is expected to follow an expected displacement vs. time curve which adjusts the quantity of fluid delivered into the container (12) to the predetermined quantity. The device further comprises a sensing means (56) for sensing a point of the actual displacement vs. time curve followed by the movable valve member (27) in response to the position control signal, and a comparing means (58) for comparing the sensed point to the corresponding point of the expected displacement vs. time curve.

Owner:西德尔分享公司

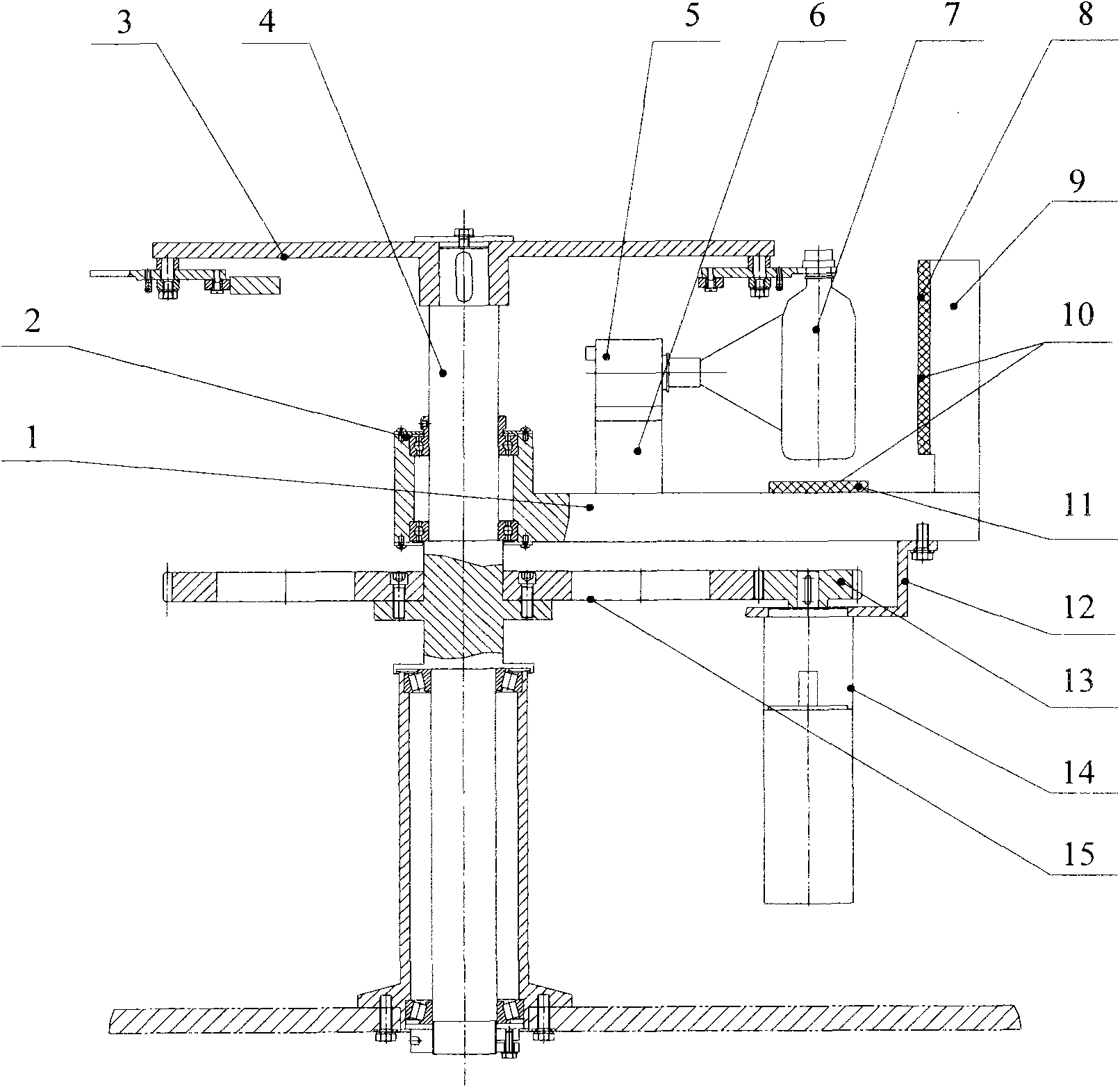

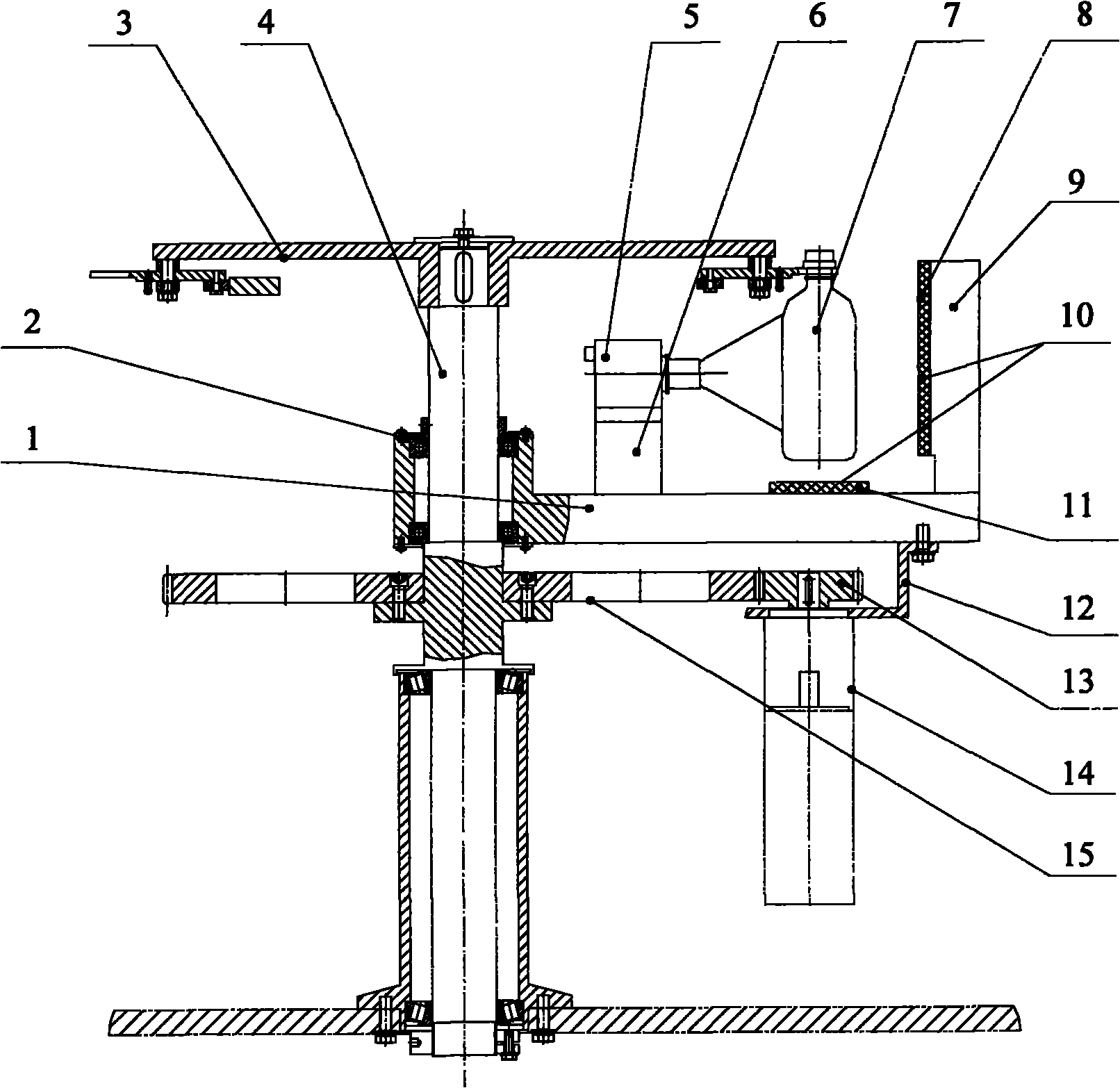

Automatic filling system for radioactive isotope medicament

ActiveCN106800268AReduce the risk of radiation exposureFully automatedCapsSynchronising machinesIsotopeMechanical engineering

The invention relates to an automatic filling system for a radioactive isotope medicament. The automatic filling system comprises a filling worktable and a control table. The filling worktable is arranged in a protective box. The control table is arranged outside the protective box and connected with the filling worktable. The automatic filling system further comprises a medicament pot storage module arranged at a feeding inlet of the filling worktable, an automatic grabbing module, a medicament pot processing module, a weighing and filling module and a finished product conveying module, wherein the automatic grabbing module, the medicament pot processing module and the weighing and filling module are arranged on the filling worktable, the finished product conveying module is located at a discharging outlet of the filling worktable, and all the modules are connected with the control table. Firstly, the automatic grabbing module grabs a medicament pot in the medicament pot storage module to the medicament pot processing module to be unsealed, next, the medicament pot is conveyed to the weighing and filling module to be filled automatically, then, the medicament pot is conveyed to the medicament pot processing module to be sealed, and finally, the medicament pot is conveyed to the finished product conveying module for conveying process. Compared with the prior art, the automatic filling system has the advantages of high filling accuracy, safety, reliability and the like.

Owner:SHANGHAI ATOM KEXING PHARMA +1

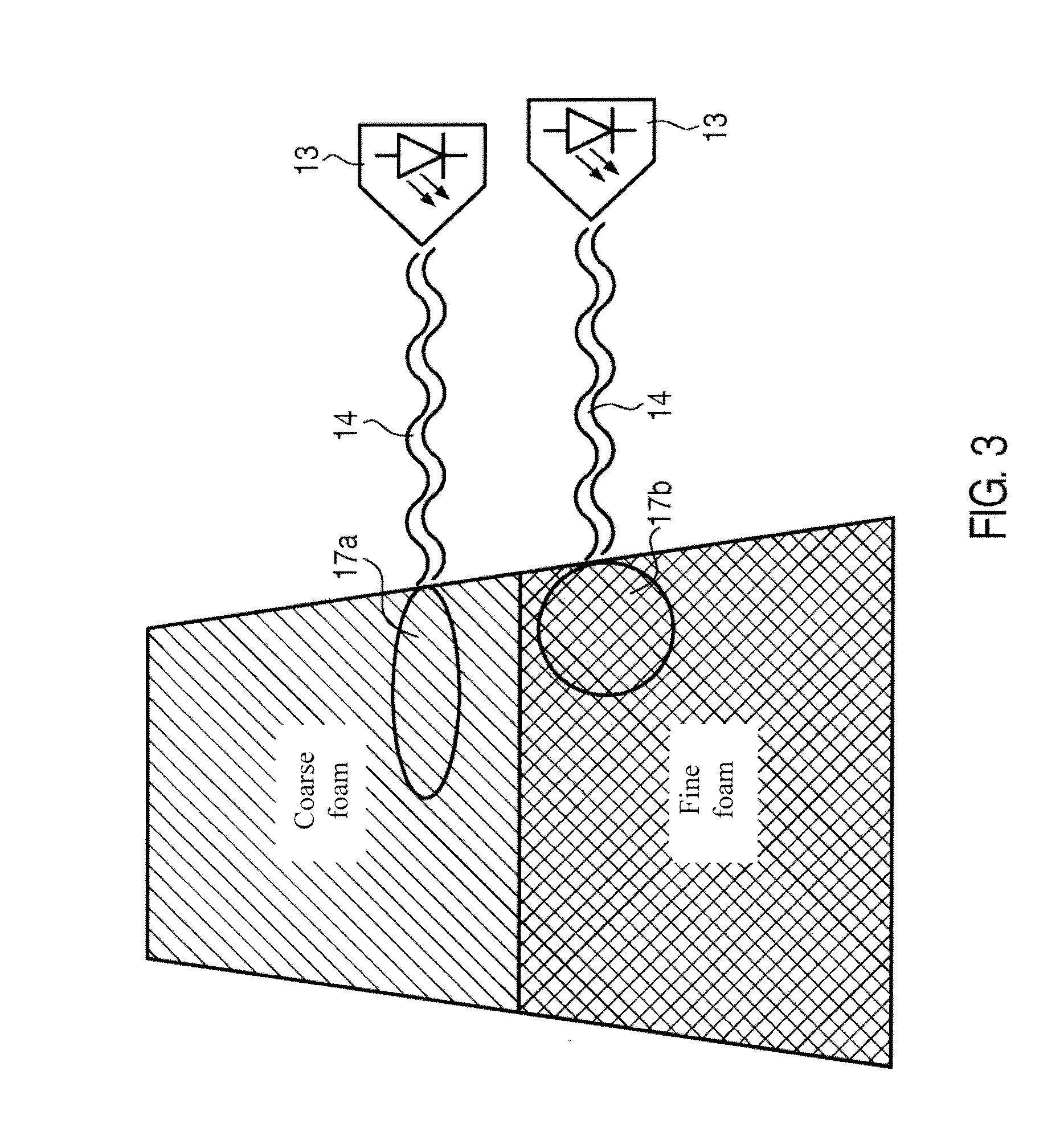

Method and device for determining a foam density

InactiveUS20100302540A1Little timeLittle effortScattering properties measurementsSafety device in filling machineryMeasurement deviceLight spot

Method and device for determining a foam density of foam in beverage containers utilizing the Tyndall effect, and having a focused light bundle emitted into the foam by means of a light source, where the light bundle is refracted in the foam and a scattered ray becomes visible on a surface of the foam. Via a measurement of the contour of such a light spot, conclusions on the foam density can be drawn. For this, one or several lasers can be integrated into existing filling level measuring means which are coupled to the already existing measuring means.

Owner:KRONES AG

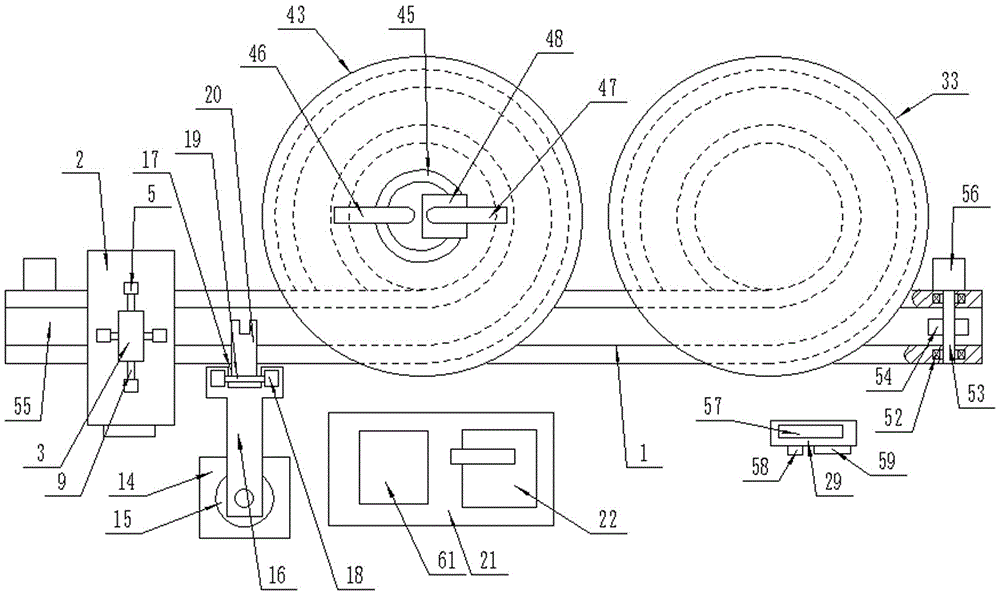

Novel contraction type sterilizing and detecting pharmacy assembly line

InactiveCN105668492AGuaranteed filling qualityAvoid pollutionSynchronising machinesFlanged caps applicationChain typeEngineering

The invention discloses a novel contraction type sterilizing and detecting pharmacy assembly line. The novel contraction type sterilizing and detecting pharmacy assembly line comprises a double-ring-shaped support fixed to the ground. A chain type double-ring-shaped conveying belt mechanism is arranged in the double-ring-shaped support. An ozone sterilizing mechanism and a medicine bottle detecting device are arranged at the front end of the double-ring-shaped support. A multifunctional liquid medicine filling mechanism is arranged at the position of one center ring of the double-ring-shaped support, an annular bottle cap hot-pressing sealing mechanism is arranged at the position of the other center ring of the double-ring-shaped support, and a control box is arranged on the ground. The novel contraction type sterilizing and detecting pharmacy assembly line has the beneficial effects of being simple in structure and high in practicability.

Owner:廖淑梅

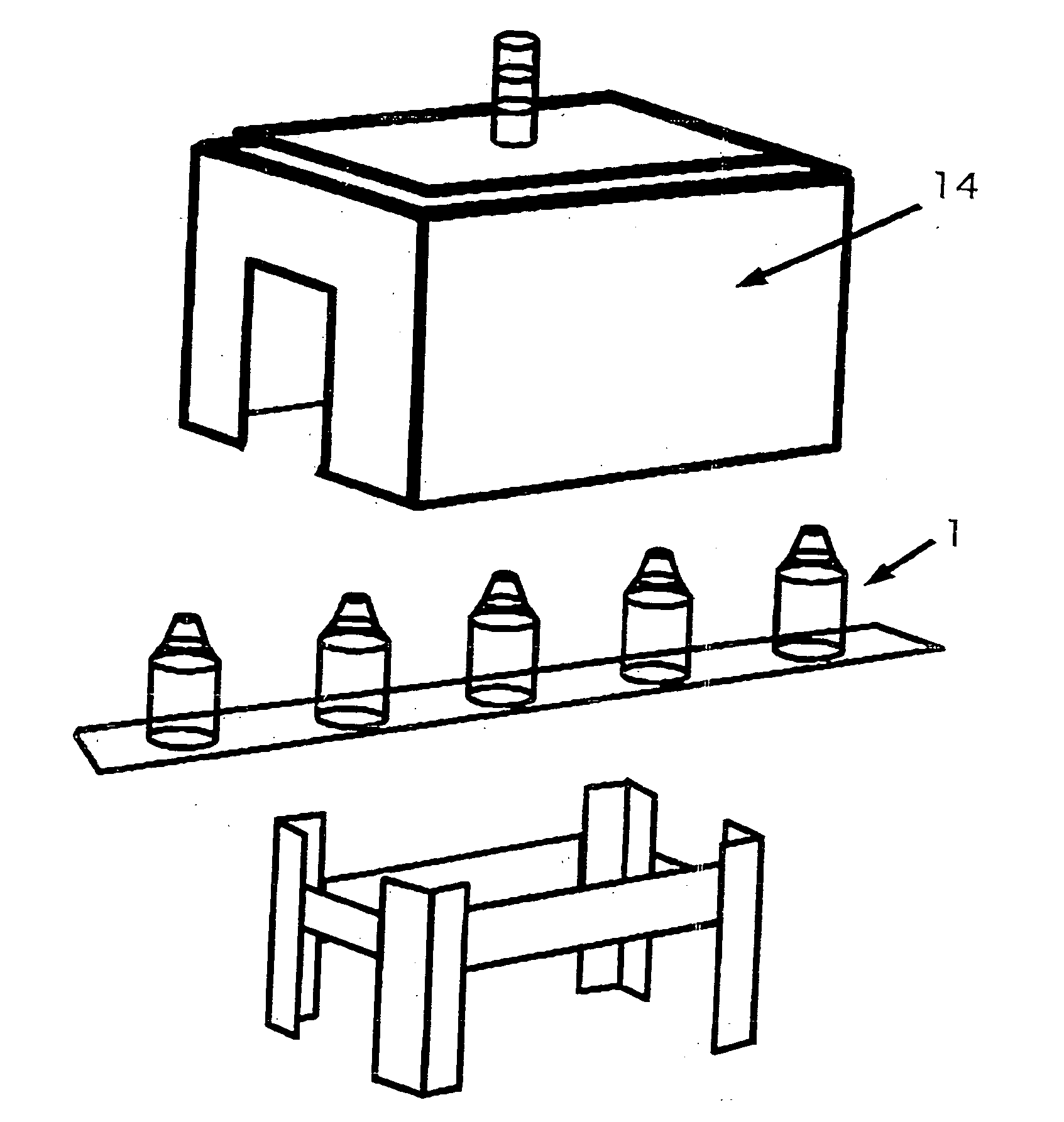

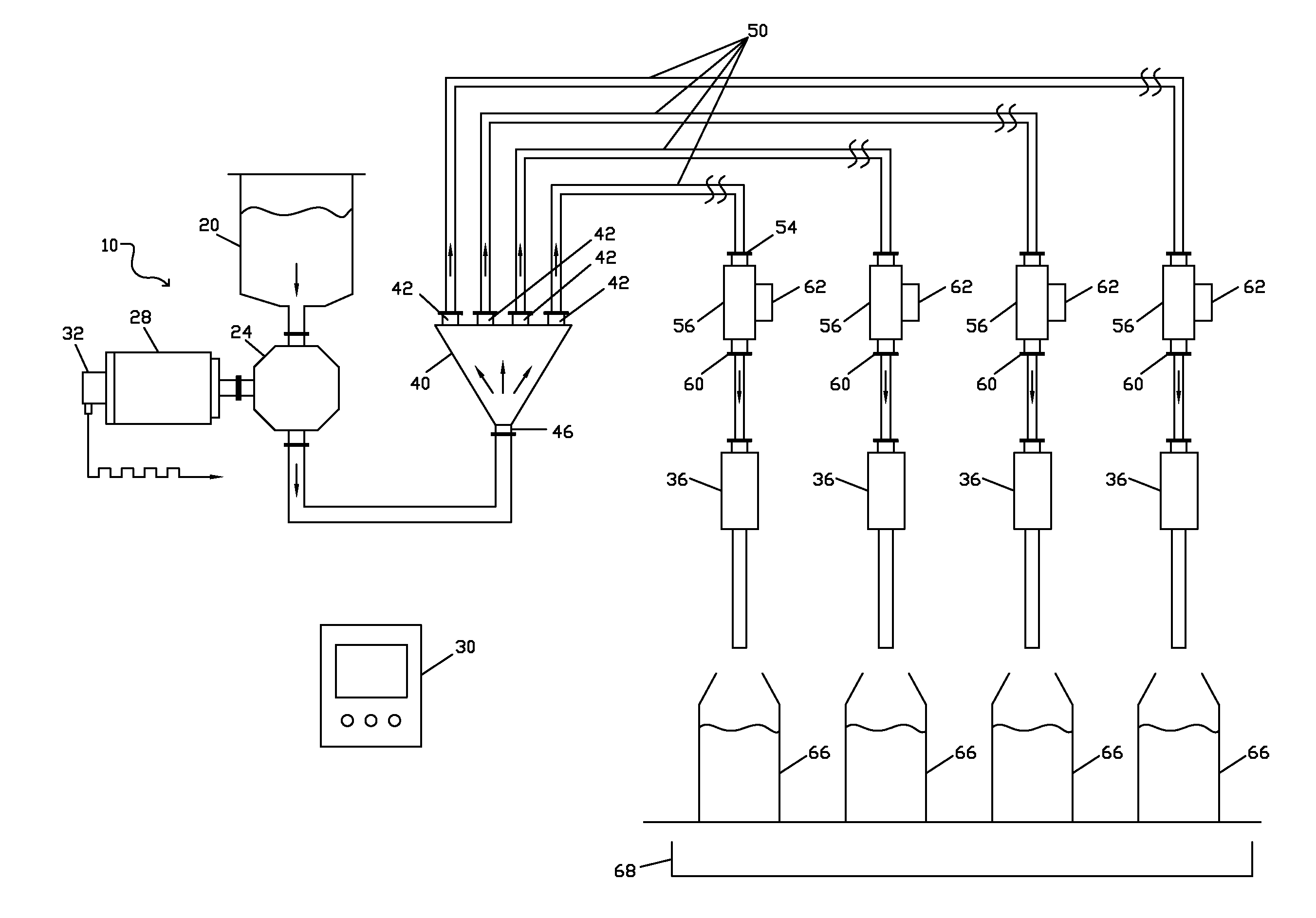

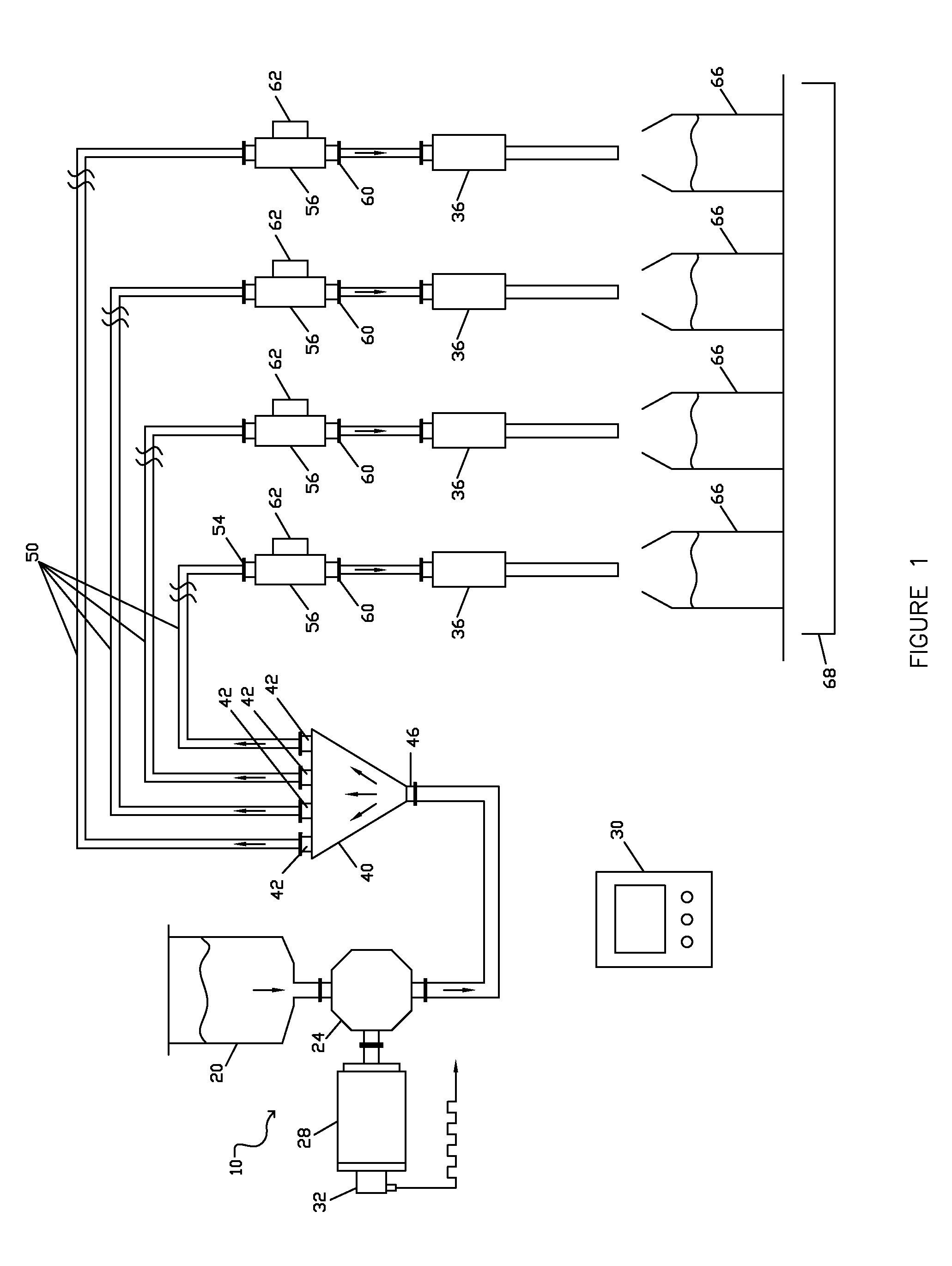

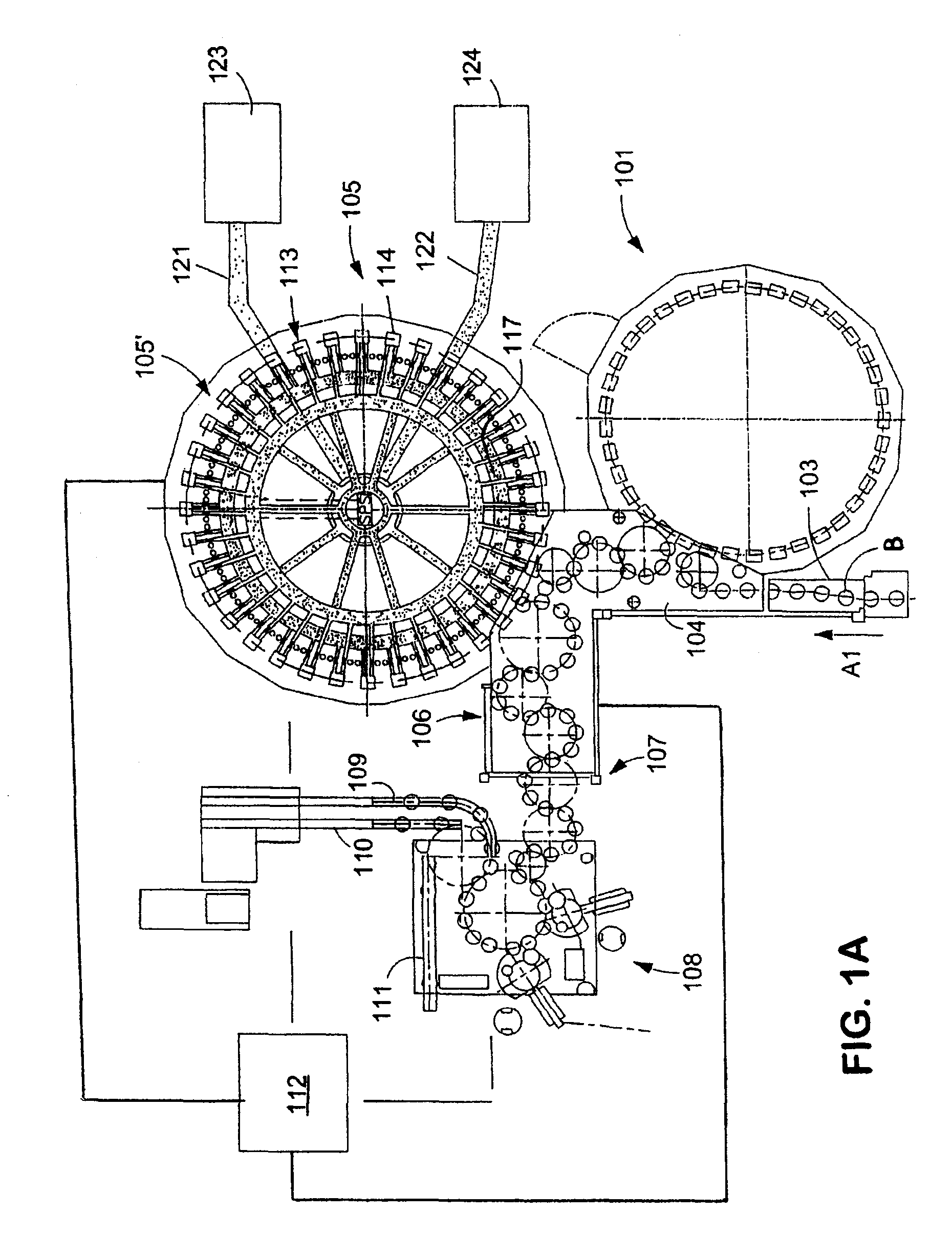

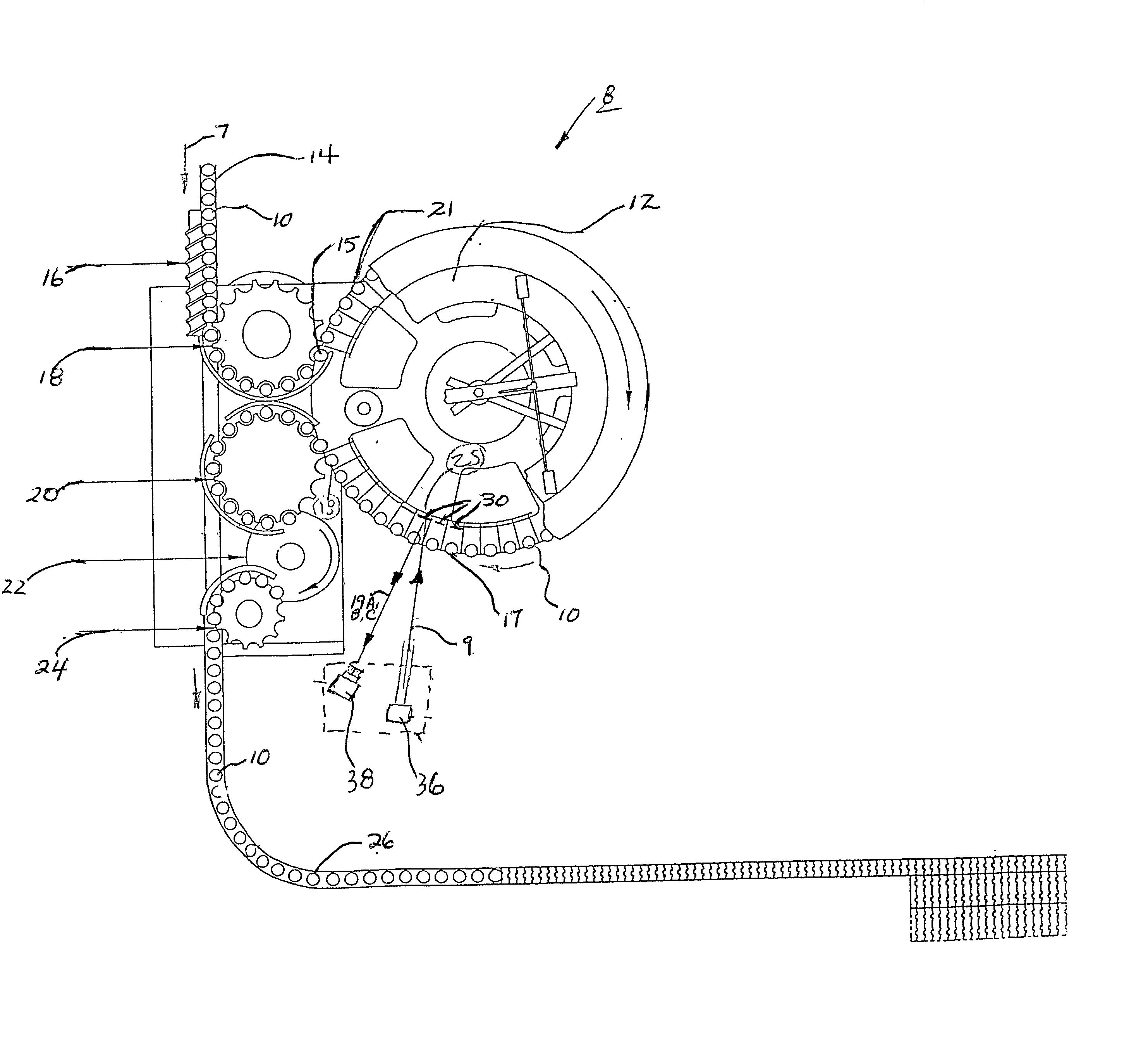

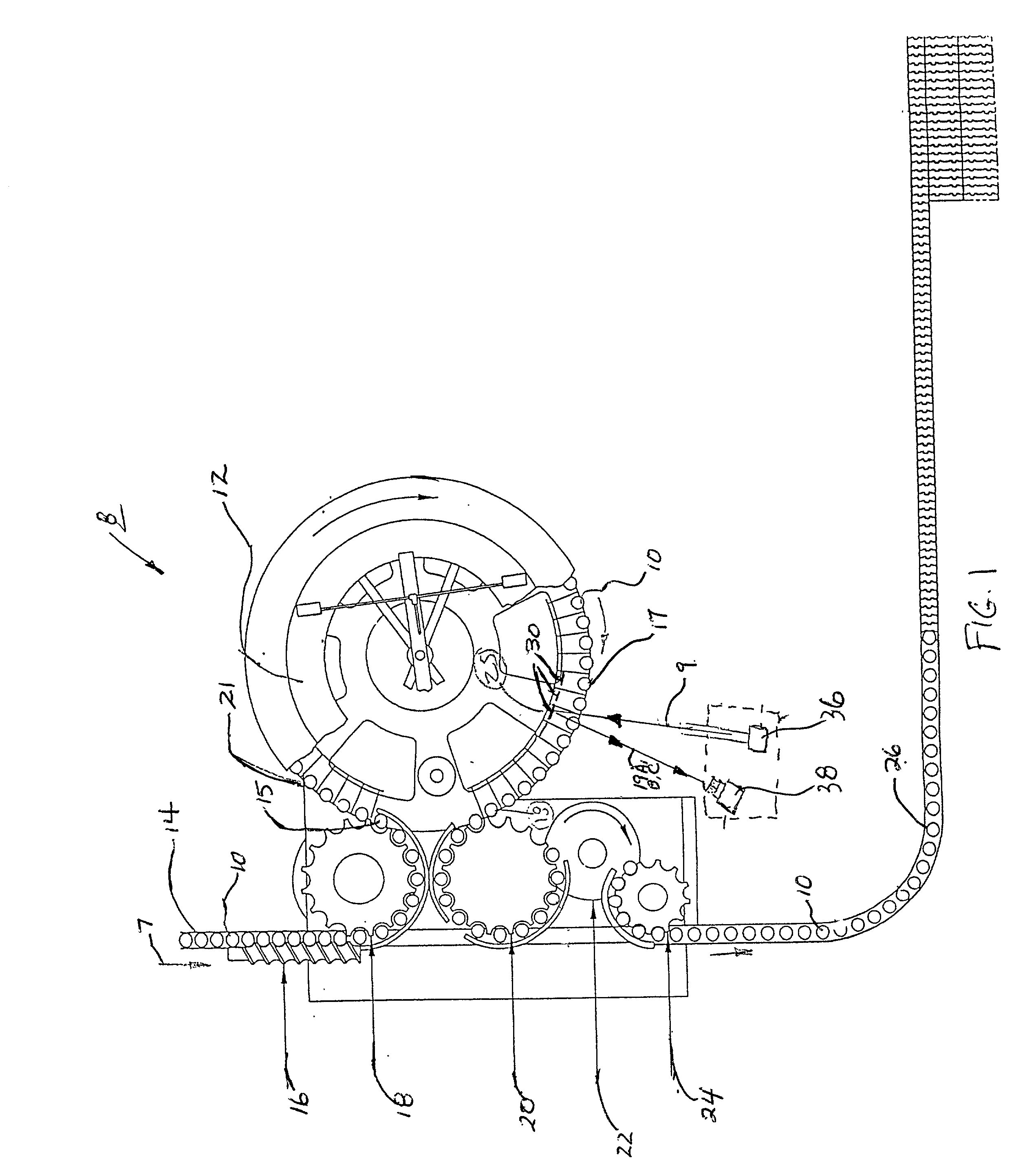

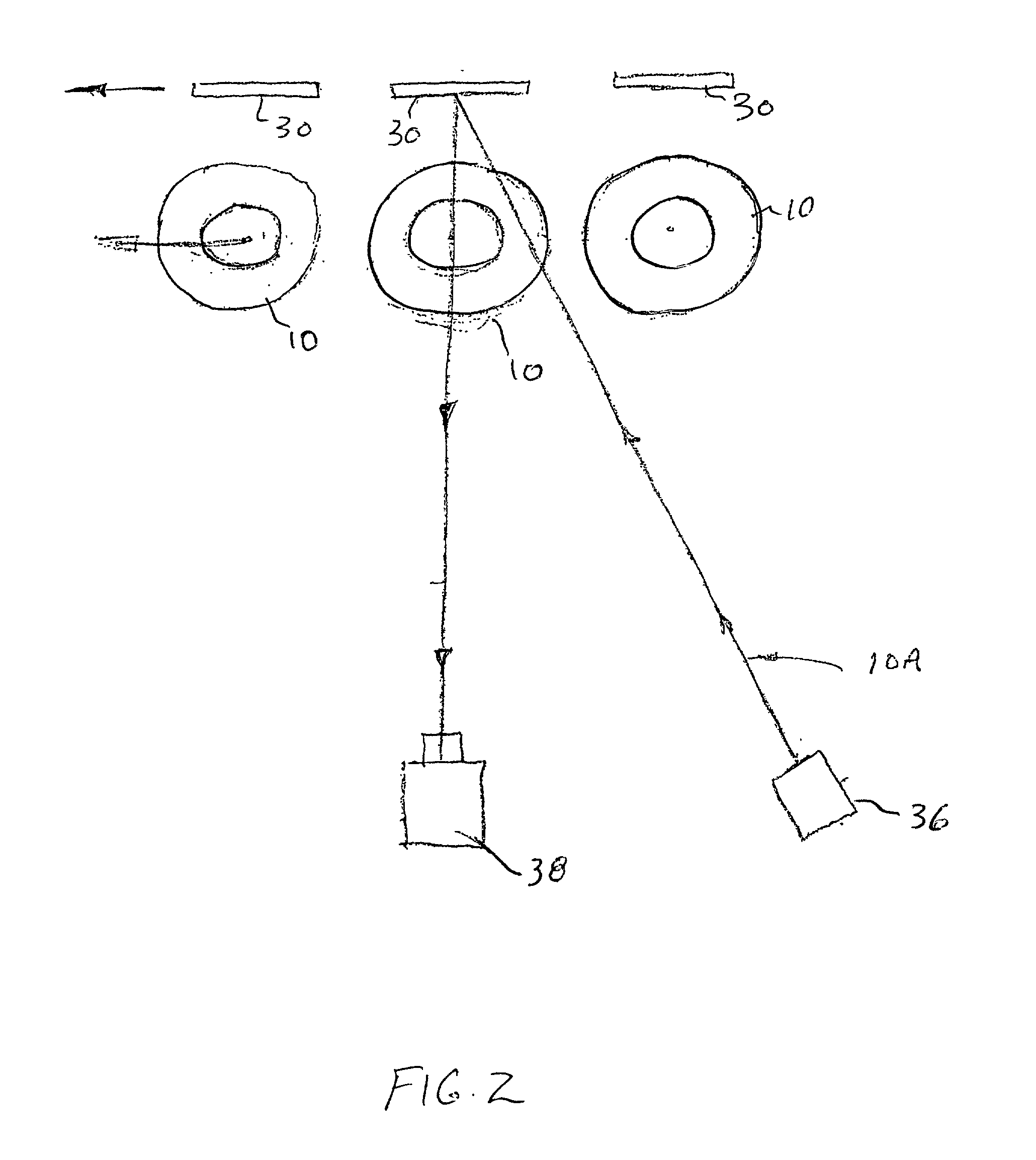

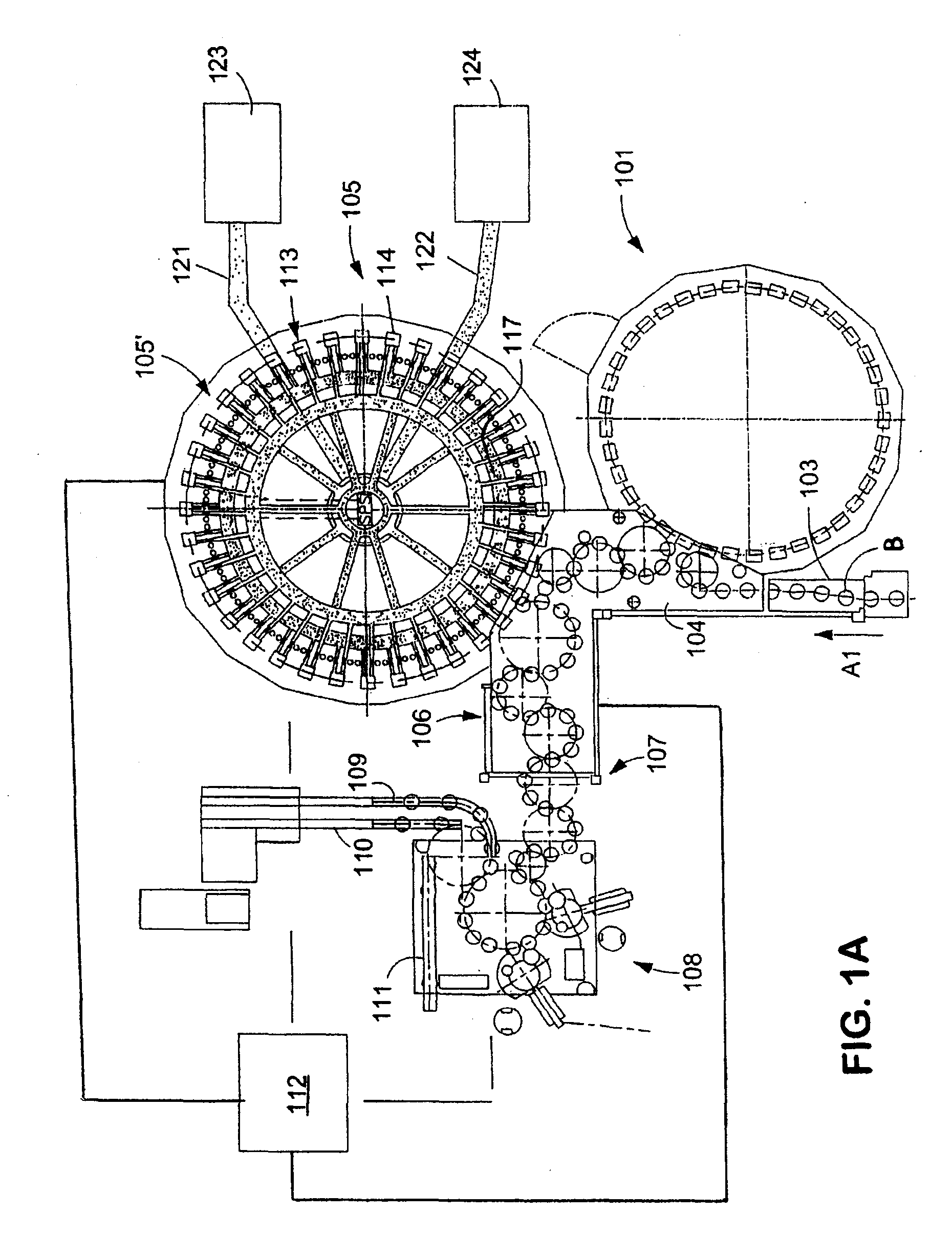

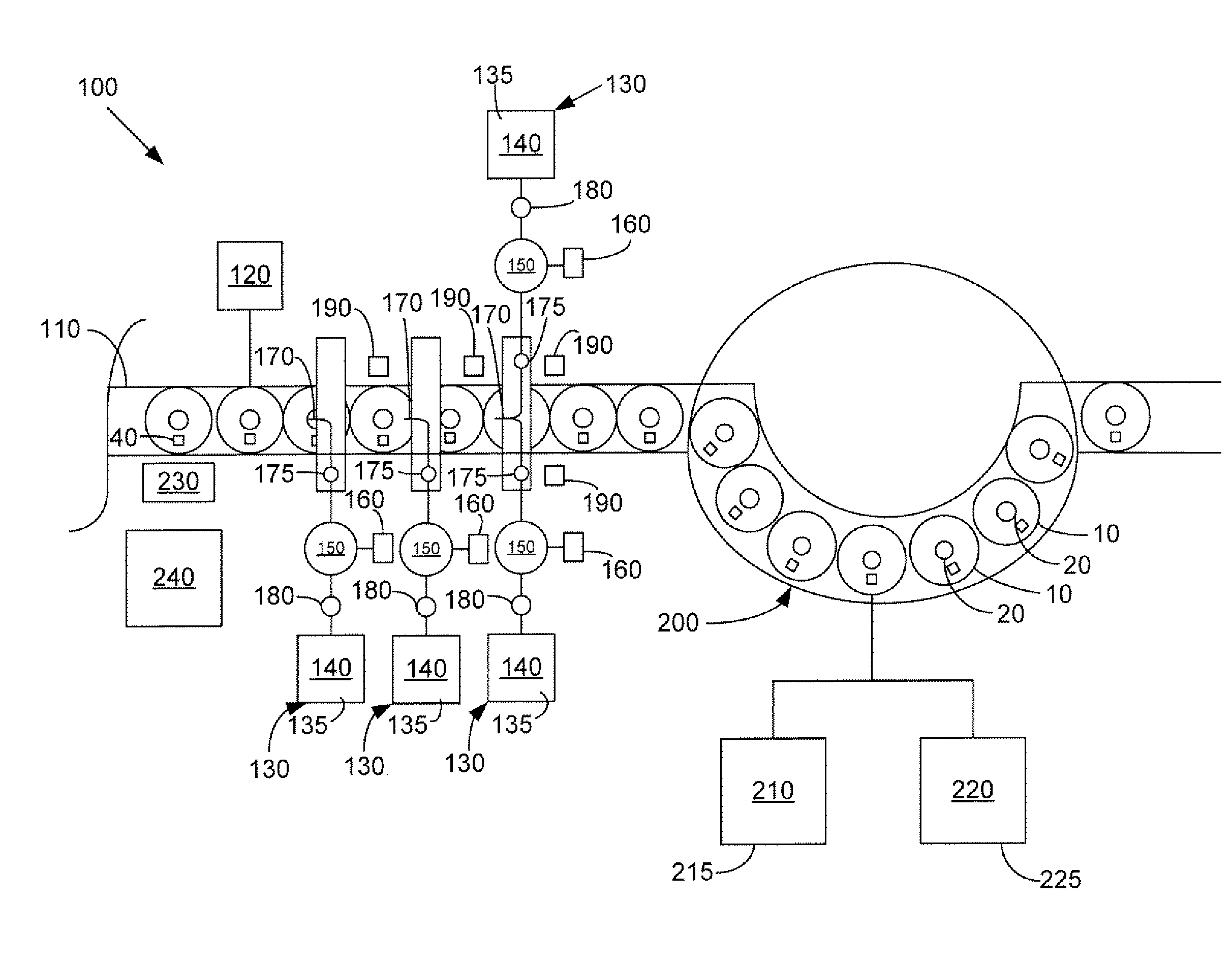

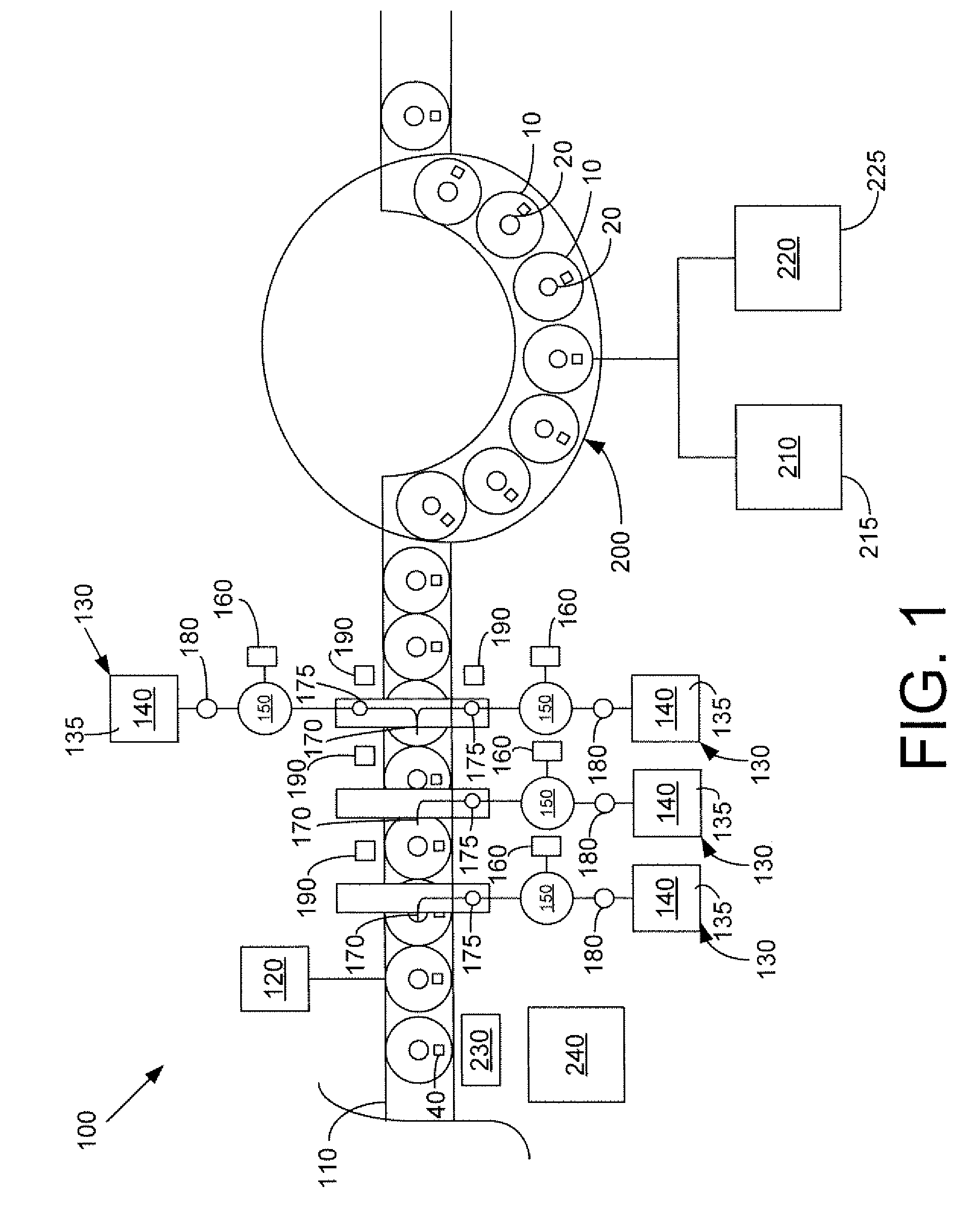

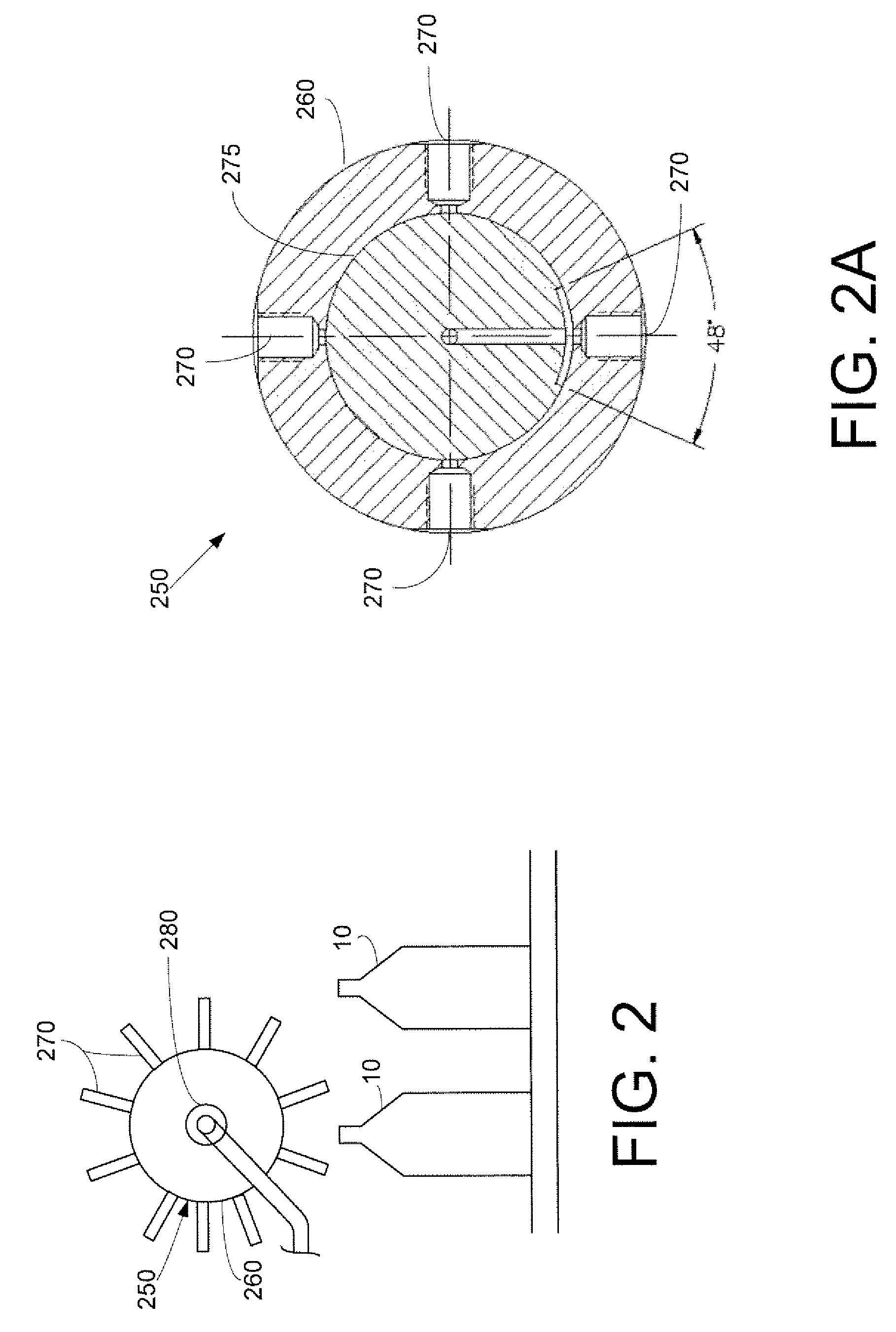

Multiple stream filling system

InactiveUS8479784B2Liquid fillingSafety device in filling machineryEngineeringMechanical engineering

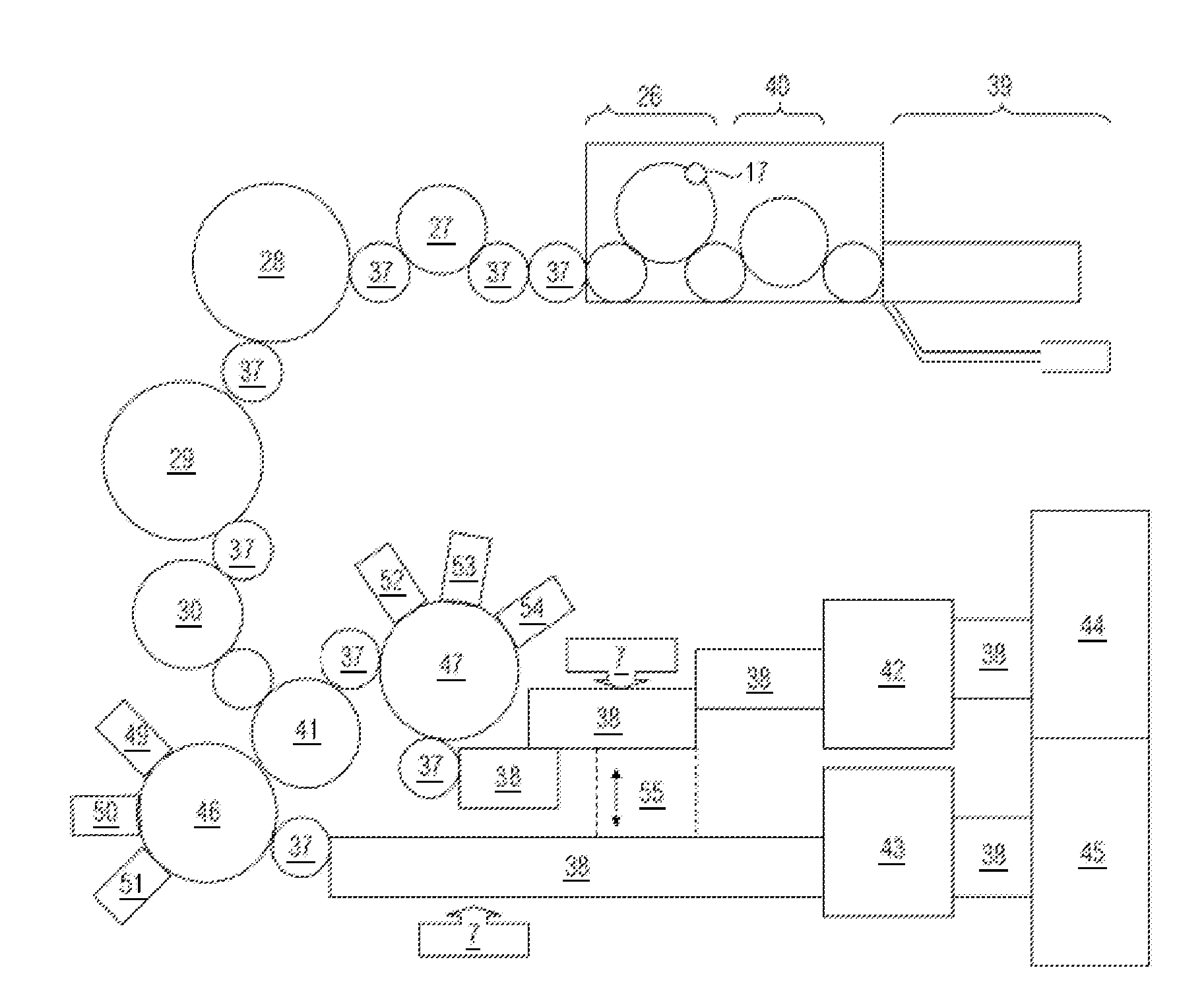

A filling line for filling a number of containers. The filing line may include a continuous conveyor, one or more micro-ingredient dosers positioned about the continuous conveyor, and one or more macro-ingredient stations positioned along the continuous conveyor.

Owner:THE COCA-COLA CO

Container volume control unit at upstream of filling level control unit

ActiveCN103562122ALarge capacityQuick and easy to run comparisonsSafety device in filling machineryLiquid materialEngineeringMechanical engineering

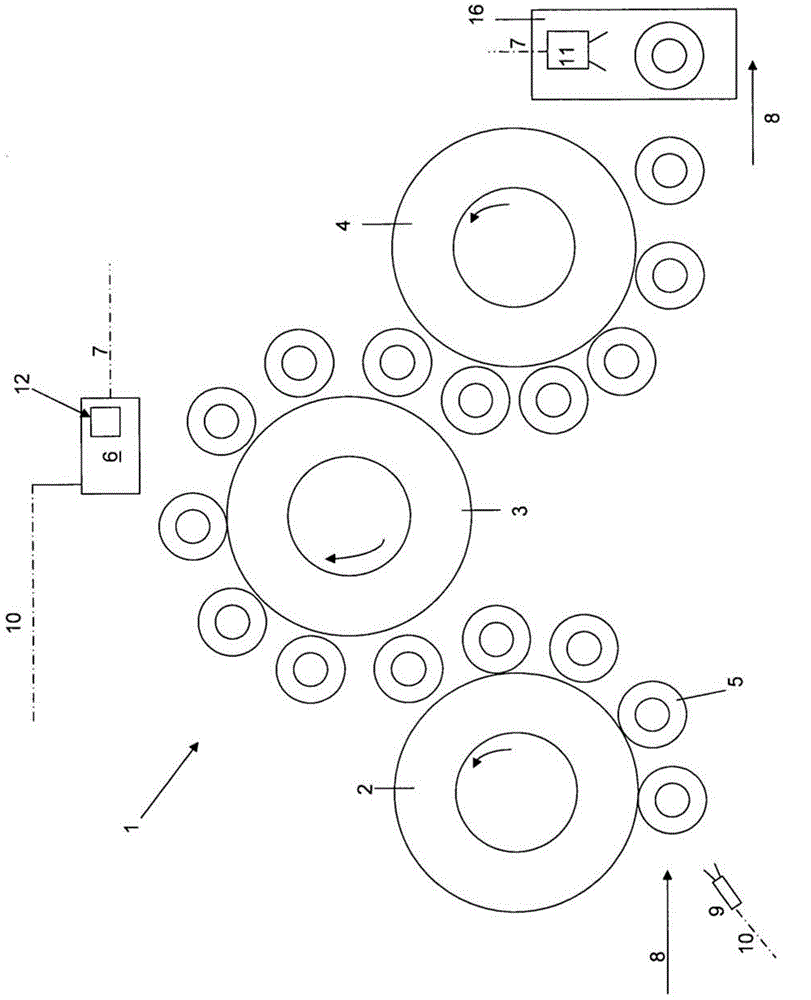

The invention relates to a container handling device, in particular a filling machine (1) for filling containers (5), wherein the filling machine (1) is connected downstream of a filling level control unit. Advantageously, at least one container detection element (9) is provided, which is disposed separately from the filling level control unit, upstream thereof, wherein both the filling level control unit and the at least one container detection element (9) guide respective inspection data of the containers (5) inspected independently of one another to a control and regulating device (6), wherein the at least one container detection element (9) detects and forwards at least one partial contour of the relevant container (5) as inspection data. The invention also relates to an inspection and filling process of the filling machine (1).

Owner:KHS GMBH

Method and apparatus for handling receptacles

The present disclosure is directed to an apparatus for handling at least one receptacle to be filled with a pourable product. The apparatus includes a conveying unit configured to advance the at least one receptacle along a path; a filling unit configured to fill the at least one receptacle with the pourable product as the at least one receptacle is advanced along the path; a labeling unit configured to apply at least one label onto the at least one receptacle during advancement of the at least one receptacle along the path; a labeling detection unit configured to detect correctness of the application of the at least one label on the at least one receptacle based on at least one predetermined criterion; and an electronic control unit configured to cooperate with the labeling detection unit to control the operation of the filling unit based on the correctness of the labeling of the at least one receptacle.

Owner:SIDEL PARTICIPATIONS SAS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com